Crane general Presentation.ppt

- Количество слайдов: 49

Cranes and Rigging www. sarens. com

Cranes and Rigging www. sarens. com

Session Objectives Understand the crane and its operations Choose the correct sling or rigging hardware Inspect rigging hardware Rig a load correctly www. sarens. com

Session Objectives Understand the crane and its operations Choose the correct sling or rigging hardware Inspect rigging hardware Rig a load correctly www. sarens. com

Introduction about Crane A crane is a type of machine, generally equipped with a hoist, wire ropes or chains, and sheaves, that can be used both to lift and lower materials and to move them horizontally. It uses one or more simple machines to create mechanical advantage and thus move loads beyond the normal capability of a man. Cranes are commonly employed in the transport industry for the loading and unloading of freight, in the construction industry for the movement of materials and in the manufacturing industry for the assembling of heavy equipment& erection of heavy equipment. www. sarens. com

Introduction about Crane A crane is a type of machine, generally equipped with a hoist, wire ropes or chains, and sheaves, that can be used both to lift and lower materials and to move them horizontally. It uses one or more simple machines to create mechanical advantage and thus move loads beyond the normal capability of a man. Cranes are commonly employed in the transport industry for the loading and unloading of freight, in the construction industry for the movement of materials and in the manufacturing industry for the assembling of heavy equipment& erection of heavy equipment. www. sarens. com

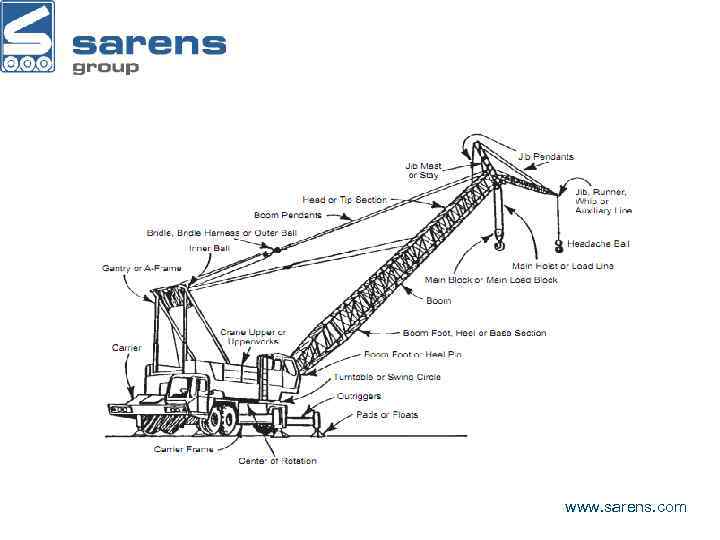

www. sarens. com

www. sarens. com

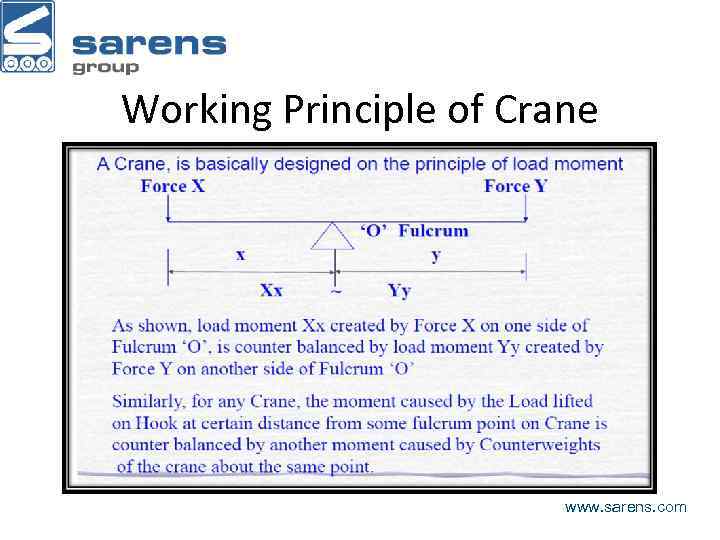

Working Principle of Crane www. sarens. com

Working Principle of Crane www. sarens. com

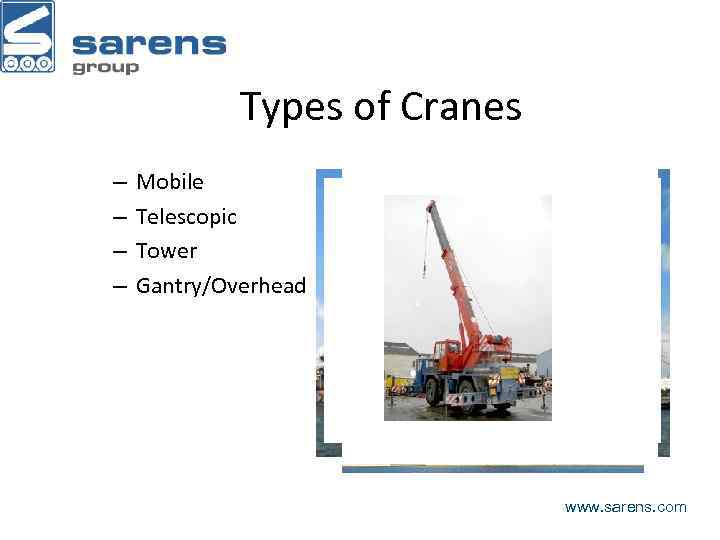

Types of Cranes – – Mobile Telescopic Tower Gantry/Overhead www. sarens. com

Types of Cranes – – Mobile Telescopic Tower Gantry/Overhead www. sarens. com

Crane Standards – – – ANSI/ASME ANSI B 30. 2. 0, Overhead and Gantry Cranes ANSI B 30. 3, Hammerhead Tower Cranes ANSI B 30. 4, Portal, Tower, and Pillar Cranes ANSI B 30. 5 Crawler, Locomotive, and Truck Cranes ANSI B 30. 6, Derricks ANSI B 30. 9, Slings ANSI B 30. 10, Hooks ANSI B 30. 19, Cableways ANSI B 30. 20, Below-the-Hook Lifting Devices ANSI B 56. 6, Rough Terrain Forklift Trucks www. sarens. com

Crane Standards – – – ANSI/ASME ANSI B 30. 2. 0, Overhead and Gantry Cranes ANSI B 30. 3, Hammerhead Tower Cranes ANSI B 30. 4, Portal, Tower, and Pillar Cranes ANSI B 30. 5 Crawler, Locomotive, and Truck Cranes ANSI B 30. 6, Derricks ANSI B 30. 9, Slings ANSI B 30. 10, Hooks ANSI B 30. 19, Cableways ANSI B 30. 20, Below-the-Hook Lifting Devices ANSI B 56. 6, Rough Terrain Forklift Trucks www. sarens. com

Lifting Tackles Lifting tackles are used to connect load to the crane. The most commonly used lifting tackles are…. • Slings • Shackles • Lifting Beam / Spreader Beam www. sarens. com

Lifting Tackles Lifting tackles are used to connect load to the crane. The most commonly used lifting tackles are…. • Slings • Shackles • Lifting Beam / Spreader Beam www. sarens. com

Sling Selection • Rated capacity • Material composition • Size, design, and configuration • Condition • Tags www. sarens. com

Sling Selection • Rated capacity • Material composition • Size, design, and configuration • Condition • Tags www. sarens. com

Chain Slings – Strong – Fit shape of load – Tolerate high temperatures – Damaged by shocks – Watch for damage www. sarens. com

Chain Slings – Strong – Fit shape of load – Tolerate high temperatures – Damaged by shocks – Watch for damage www. sarens. com

Wire Rope Slings – Composed of strands of wire rope – May have fiber core – Can experience cracking or kinking www. sarens. com

Wire Rope Slings – Composed of strands of wire rope – May have fiber core – Can experience cracking or kinking www. sarens. com

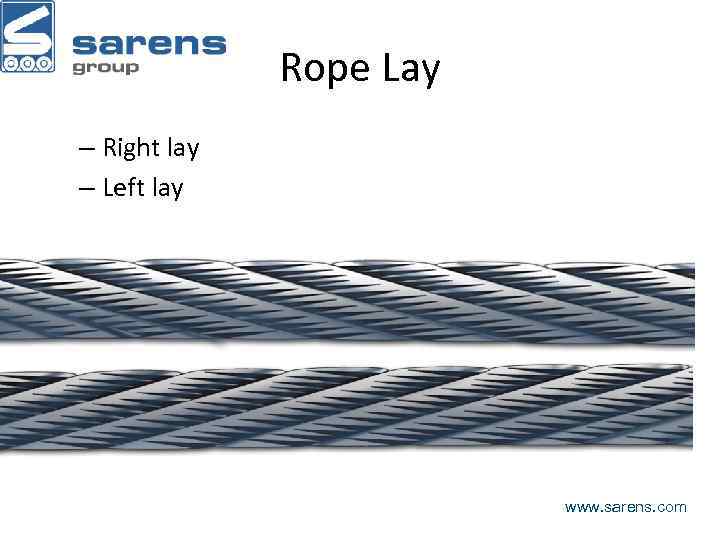

Rope Lay – Right lay – Left lay www. sarens. com

Rope Lay – Right lay – Left lay www. sarens. com

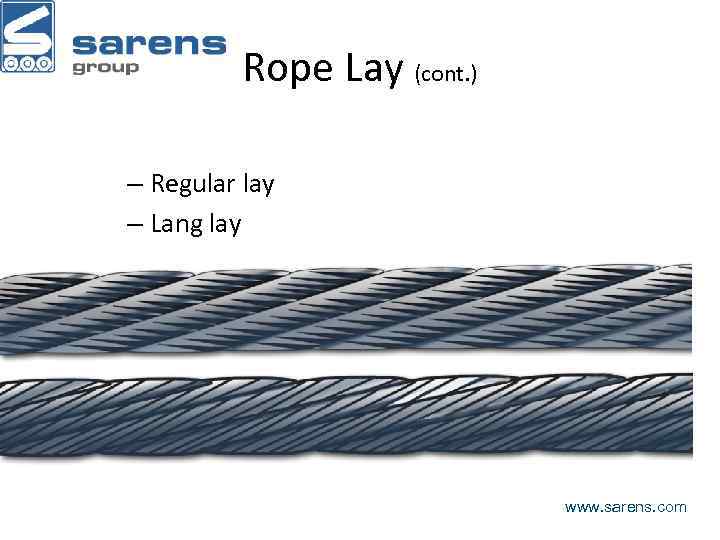

Rope Lay (cont. ) – Regular lay – Lang lay www. sarens. com

Rope Lay (cont. ) – Regular lay – Lang lay www. sarens. com

Wire Rope Sling Selection – Strength – Flexibility – Durability www. sarens. com

Wire Rope Sling Selection – Strength – Flexibility – Durability www. sarens. com

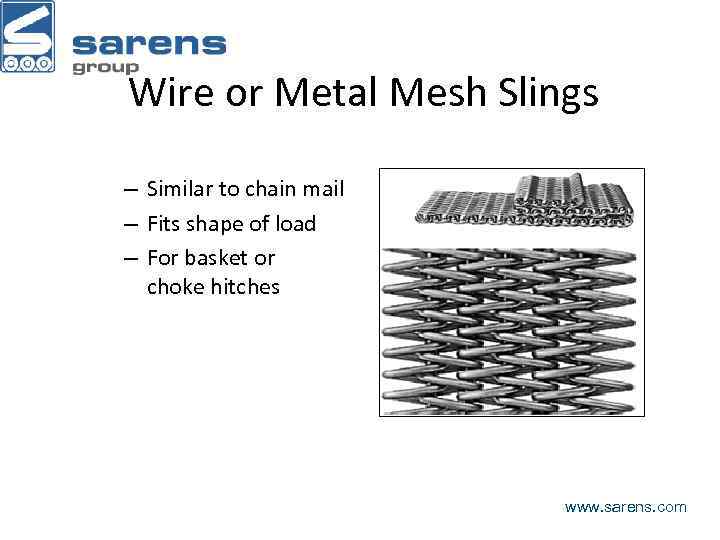

Wire or Metal Mesh Slings – Similar to chain mail – Fits shape of load – For basket or choke hitches www. sarens. com

Wire or Metal Mesh Slings – Similar to chain mail – Fits shape of load – For basket or choke hitches www. sarens. com

Fiber Rope Slings • For lighter loads • Protect surface of load • Susceptible to deterioration • Stretch when wet • Must be inspected thoroughly www. sarens. com

Fiber Rope Slings • For lighter loads • Protect surface of load • Susceptible to deterioration • Stretch when wet • Must be inspected thoroughly www. sarens. com

Synthetic Web Slings – Nylon, Dacron, or polyester – Contour to fit the load – Durable and resistant to degradation www. sarens. com

Synthetic Web Slings – Nylon, Dacron, or polyester – Contour to fit the load – Durable and resistant to degradation www. sarens. com

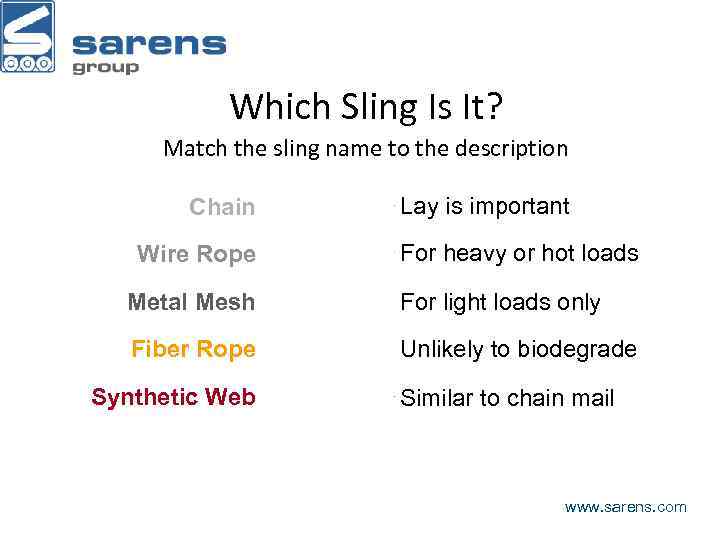

Which Sling Is It? Match the sling name to the description Chain Wire Rope Lay is important For heavy or hot loads Metal Mesh For light loads only Fiber Rope Unlikely to biodegrade Synthetic Web Similar to chain mail www. sarens. com

Which Sling Is It? Match the sling name to the description Chain Wire Rope Lay is important For heavy or hot loads Metal Mesh For light loads only Fiber Rope Unlikely to biodegrade Synthetic Web Similar to chain mail www. sarens. com

Sling Inspection Check for: Excessive wear Distortion or stretching Corrosion Heat stress Chemical damage www. sarens. com

Sling Inspection Check for: Excessive wear Distortion or stretching Corrosion Heat stress Chemical damage www. sarens. com

Chain Sling Inspection • Check inside ends and outside edges • Excessive stretching is unsafe • Watch for binding www. sarens. com

Chain Sling Inspection • Check inside ends and outside edges • Excessive stretching is unsafe • Watch for binding www. sarens. com

Wire Rope Sling Inspection • • Cracking and pitting Kinking Deformation Rust Heat stress Broken wires Damaged fittings www. sarens. com

Wire Rope Sling Inspection • • Cracking and pitting Kinking Deformation Rust Heat stress Broken wires Damaged fittings www. sarens. com

Fiber Rope Sling Inspection • Dry, discolored fibers • Powder or dust from internal wear • Fibers that come apart www. sarens. com

Fiber Rope Sling Inspection • Dry, discolored fibers • Powder or dust from internal wear • Fibers that come apart www. sarens. com

Synthetic Web Sling Inspection • Holes, snags, tears • Broken or worn stitching • Heat stress and burns www. sarens. com

Synthetic Web Sling Inspection • Holes, snags, tears • Broken or worn stitching • Heat stress and burns www. sarens. com

Sling Maintenance – – Keep it clean Repair may be possible Lubricate wire rope slings Store safely www. sarens. com

Sling Maintenance – – Keep it clean Repair may be possible Lubricate wire rope slings Store safely www. sarens. com

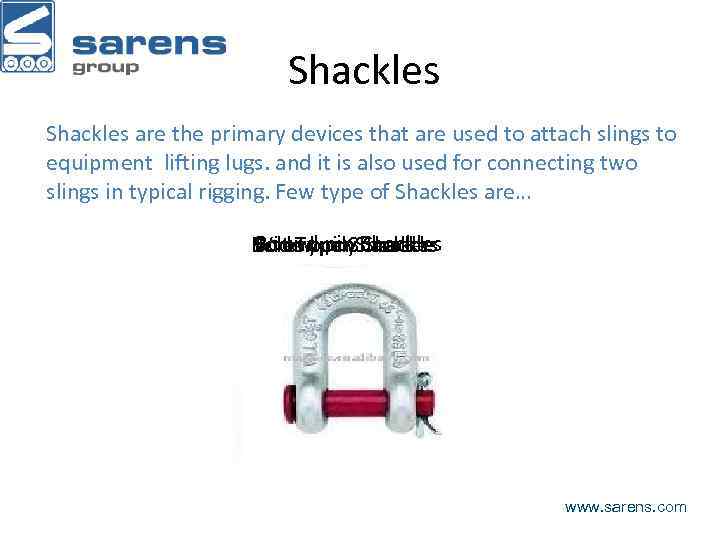

Shackles are the primary devices that are used to attach slings to equipment lifting lugs. and it is also used for connecting two slings in typical rigging. Few type of Shackles are… Round pin Shackles Bolt Type Shackle Wide body Shackle Screw pin Shackles www. sarens. com

Shackles are the primary devices that are used to attach slings to equipment lifting lugs. and it is also used for connecting two slings in typical rigging. Few type of Shackles are… Round pin Shackles Bolt Type Shackle Wide body Shackle Screw pin Shackles www. sarens. com

Shackles, Clips, Eyes, and Other Hardware – Inspect with care – Never use equipment with parts malfunctioning or missing www. sarens. com

Shackles, Clips, Eyes, and Other Hardware – Inspect with care – Never use equipment with parts malfunctioning or missing www. sarens. com

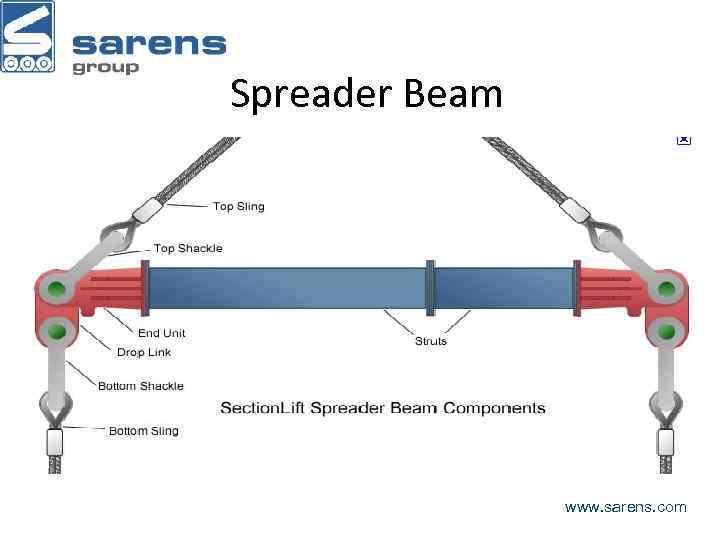

Spreader Beam A lifting beam is a solid or fabricated metal or wooden beam, suspended from a hoist/crane or from forks of a forklift, designed to provide multiple lifting points. The lifting beam enables the user to attach the load at more than one point therein securing and controlling the load's movement. Lifting beams may have fixed or swivel hooks. Some lifting beams are spreader beams. Lifting Beams are used in low headroom applications, and structurally are able to handle the load throughout the beam spread. Beams allow multiple point pick up of the load for balance or support purposes. Beams can be used from two hoists to increase lift capacity. www. sarens. com

Spreader Beam A lifting beam is a solid or fabricated metal or wooden beam, suspended from a hoist/crane or from forks of a forklift, designed to provide multiple lifting points. The lifting beam enables the user to attach the load at more than one point therein securing and controlling the load's movement. Lifting beams may have fixed or swivel hooks. Some lifting beams are spreader beams. Lifting Beams are used in low headroom applications, and structurally are able to handle the load throughout the beam spread. Beams allow multiple point pick up of the load for balance or support purposes. Beams can be used from two hoists to increase lift capacity. www. sarens. com

Hooks – A safety latch is essential – Bent hooks must be retired www. sarens. com

Hooks – A safety latch is essential – Bent hooks must be retired www. sarens. com

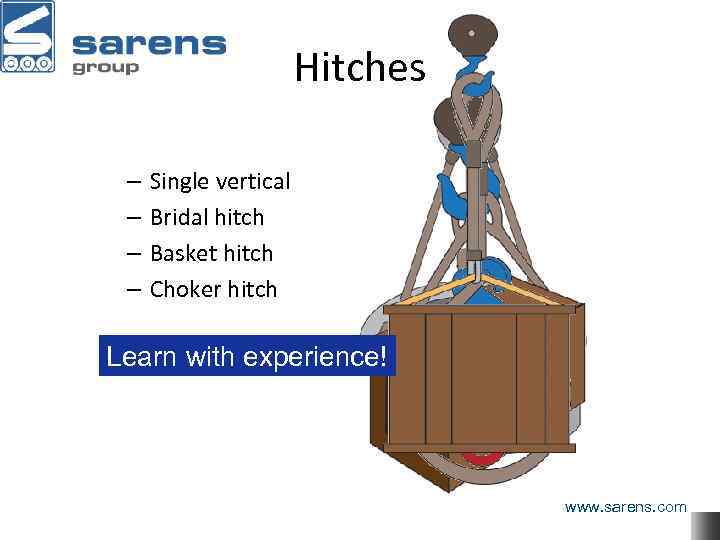

Hitches – – Single vertical Bridal hitch Basket hitch Choker hitch Learn with experience! www. sarens. com

Hitches – – Single vertical Bridal hitch Basket hitch Choker hitch Learn with experience! www. sarens. com

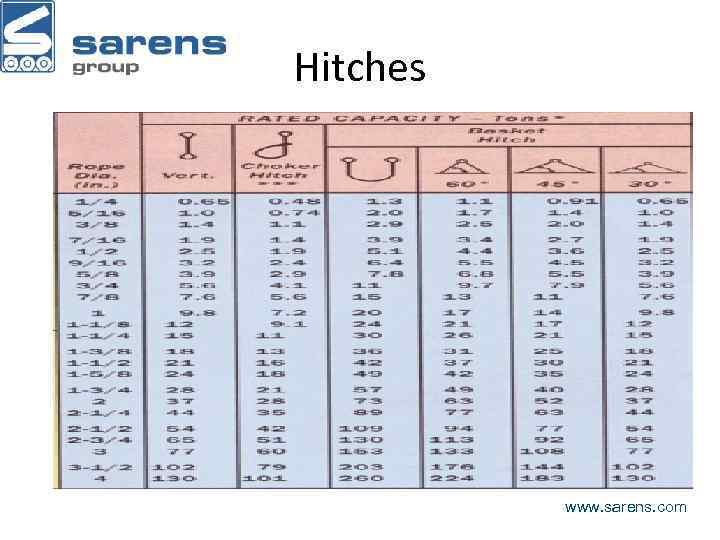

Hitches www. sarens. com

Hitches www. sarens. com

Rigging Procedure www. sarens. com

Rigging Procedure www. sarens. com

Essential Data • • Weight of Load Rated Capacity Boom Height/Length/Angle Load Chart and Lift Radius www. sarens. com

Essential Data • • Weight of Load Rated Capacity Boom Height/Length/Angle Load Chart and Lift Radius www. sarens. com

Important factors before lifting with crane Working Load limit proof or test load is the load applied to a Safe Workingload-A(WLL): In most cases, the Safe Working Load Payload weight: The weight of the item to be lifted or hauled. Proof or test Load (SWL): The working load limit is the maximum load that an item of lifting equipment is designed to will be the same as the WLL. The exceptions are where the Payload weight includes the actual item weight, plus the weight Lifting Device or Rigging Equipment for the purpose of proof raise, lower or suspend. particular conditions of use require a reduction to a lower of attachments, saddles, temporary supports, etc. testing. It should appear on the test certificate. safe working load. Examples would be severe environmental conditions such as very low temperatures, inaccuracy of weight, likelihood of shock loading www. sarens. com

Important factors before lifting with crane Working Load limit proof or test load is the load applied to a Safe Workingload-A(WLL): In most cases, the Safe Working Load Payload weight: The weight of the item to be lifted or hauled. Proof or test Load (SWL): The working load limit is the maximum load that an item of lifting equipment is designed to will be the same as the WLL. The exceptions are where the Payload weight includes the actual item weight, plus the weight Lifting Device or Rigging Equipment for the purpose of proof raise, lower or suspend. particular conditions of use require a reduction to a lower of attachments, saddles, temporary supports, etc. testing. It should appear on the test certificate. safe working load. Examples would be severe environmental conditions such as very low temperatures, inaccuracy of weight, likelihood of shock loading www. sarens. com

Load Chart Load chart provides the capacity of crane at various boom length, radius, boom angle and various configuration. www. sarens. com

Load Chart Load chart provides the capacity of crane at various boom length, radius, boom angle and various configuration. www. sarens. com

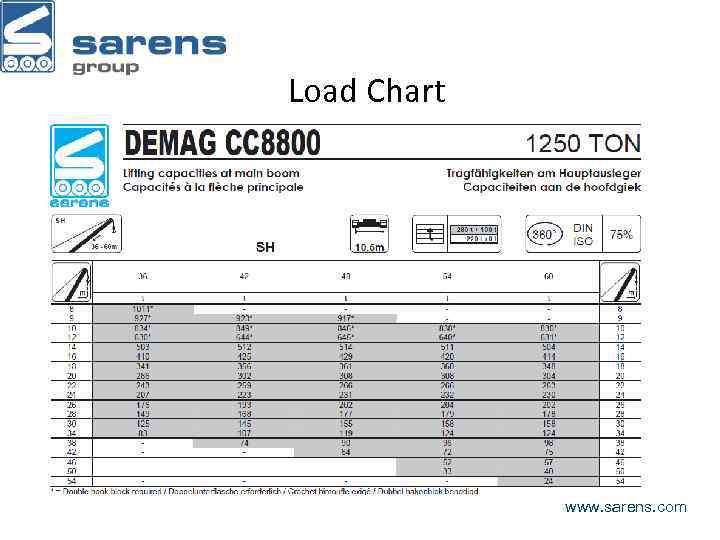

Load Chart www. sarens. com

Load Chart www. sarens. com

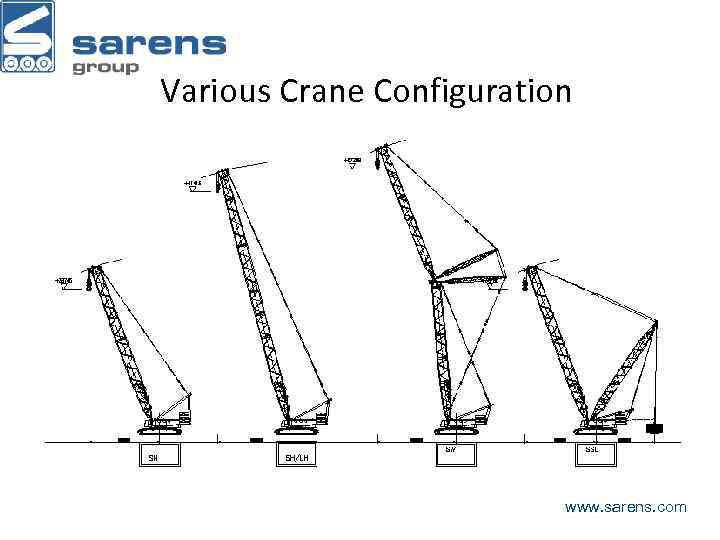

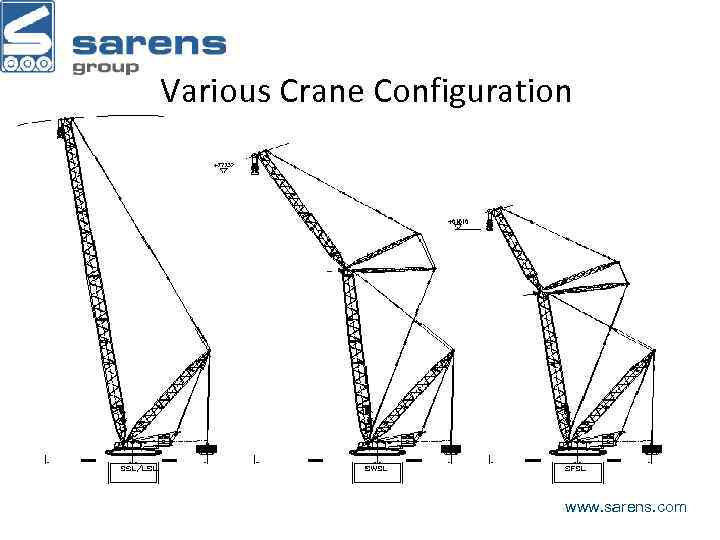

Various Crane Configuration www. sarens. com

Various Crane Configuration www. sarens. com

Various Crane Configuration www. sarens. com

Various Crane Configuration www. sarens. com

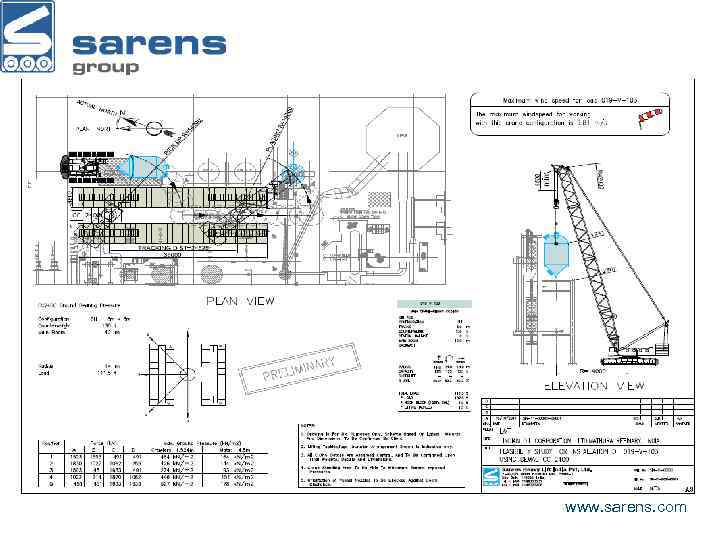

HOW TO MAKE RIGGING SCHEME INFORMATION PROVIDE BY CLIENT 1 -DIMENTIONS OF EQUIPMENT WHICH IS TO BE ERECTED. 2 -WEIGHT OF EQUIPMENT 3 -PLOT PLAN 4 -GA DRAWING OF EQUIPMENT www. sarens. com

HOW TO MAKE RIGGING SCHEME INFORMATION PROVIDE BY CLIENT 1 -DIMENTIONS OF EQUIPMENT WHICH IS TO BE ERECTED. 2 -WEIGHT OF EQUIPMENT 3 -PLOT PLAN 4 -GA DRAWING OF EQUIPMENT www. sarens. com

1)ERECTION WEIGHT CALCULATION Weight of equipment=x Weight of lifting hook=y* Weight of lifting tackles(slings+shackles+spreader beam)=z Total weight=x+y+z *--hook weight is taken from crane load chart. 2)ERECTION HEIGHT CALCULATION Elevation height of equipment from ground=a Height of equipment =b Sling length=c*(for horizontal lifting it is 1/3 of equipment length) Anti to block clearance=d Total height=a+b+c+d www. sarens. com

1)ERECTION WEIGHT CALCULATION Weight of equipment=x Weight of lifting hook=y* Weight of lifting tackles(slings+shackles+spreader beam)=z Total weight=x+y+z *--hook weight is taken from crane load chart. 2)ERECTION HEIGHT CALCULATION Elevation height of equipment from ground=a Height of equipment =b Sling length=c*(for horizontal lifting it is 1/3 of equipment length) Anti to block clearance=d Total height=a+b+c+d www. sarens. com

3)According to the safe working load , elevation height, and Radius(measure from plot plan), crane is selected with the help of load chart. 4)then plan view and elevation view is drawn in the rigging sheet. 5)ground bearing pressure is also calculated and chart is to be made in the rigging sheet. 6)wind speed and north direction of plant is also mention in the rigging plan sheet. www. sarens. com

3)According to the safe working load , elevation height, and Radius(measure from plot plan), crane is selected with the help of load chart. 4)then plan view and elevation view is drawn in the rigging sheet. 5)ground bearing pressure is also calculated and chart is to be made in the rigging sheet. 6)wind speed and north direction of plant is also mention in the rigging plan sheet. www. sarens. com

www. sarens. com

www. sarens. com

Preparing the Lift • Personal protective equipment (PPE) • Hook and line over load • Lines not kinked or twisted www. sarens. com © Business & Legal Reports, Inc. 0907

Preparing the Lift • Personal protective equipment (PPE) • Hook and line over load • Lines not kinked or twisted www. sarens. com © Business & Legal Reports, Inc. 0907

Preparing the Lift (cont. ) • • “Rig up the load” Hook latch closed Path clear Lift tested www. sarens. com © Business & Legal Reports, Inc. 0907

Preparing the Lift (cont. ) • • “Rig up the load” Hook latch closed Path clear Lift tested www. sarens. com © Business & Legal Reports, Inc. 0907

Rigging Hardware Data – Sling or hardware rating – Reduced angle means less capacity – Crane hardware rating www. sarens. com

Rigging Hardware Data – Sling or hardware rating – Reduced angle means less capacity – Crane hardware rating www. sarens. com

Serious Questions – – – – Sling angle Center of gravity Sharp corners Load under control Tag line Obstructions Personnel out of the way Weather www. sarens. com

Serious Questions – – – – Sling angle Center of gravity Sharp corners Load under control Tag line Obstructions Personnel out of the way Weather www. sarens. com

The “Nevers” Never • Use a twisted line • Lift by the block hook • Use unsafe equipment • Allow an unsafe lift www. sarens. com © Business & Legal Reports, Inc. 0907

The “Nevers” Never • Use a twisted line • Lift by the block hook • Use unsafe equipment • Allow an unsafe lift www. sarens. com © Business & Legal Reports, Inc. 0907

The “Nevers” (cont. ) Never • Use more than one signalman • Work under a suspended load • Turn your back on a lift www. sarens. com © Business & Legal Reports, Inc. 0907

The “Nevers” (cont. ) Never • Use more than one signalman • Work under a suspended load • Turn your back on a lift www. sarens. com © Business & Legal Reports, Inc. 0907

Key Points to Remember! Takes years of practice Is always interesting Learn all you can Be cautious; think safety Routine lifts can be deadly www. sarens. com

Key Points to Remember! Takes years of practice Is always interesting Learn all you can Be cautious; think safety Routine lifts can be deadly www. sarens. com

Key Points to Remember! Thank You. Sarens India www. sarens. com

Key Points to Remember! Thank You. Sarens India www. sarens. com