82eee7022fb9838a5e3c0c356a4af831.ppt

- Количество слайдов: 23

CPI's New Printed Electronics Line-bringing interactivity to print Neil Porter October 31 st 2012 © CPI 2012. All rights reserved.

Centre for Process Innovation (CPI) • UK-based technology innovation centre • CPI’s Printable Electronics Centre focuses on design, development and prototyping for the emerging printable electronics industry

BPIF Labels Technical Seminar Aim • To demonstrate that any label converter using commercially available equipment can be part of the Integrated Smart Systems supply chain through printing of conductive inks in a standard pressroom

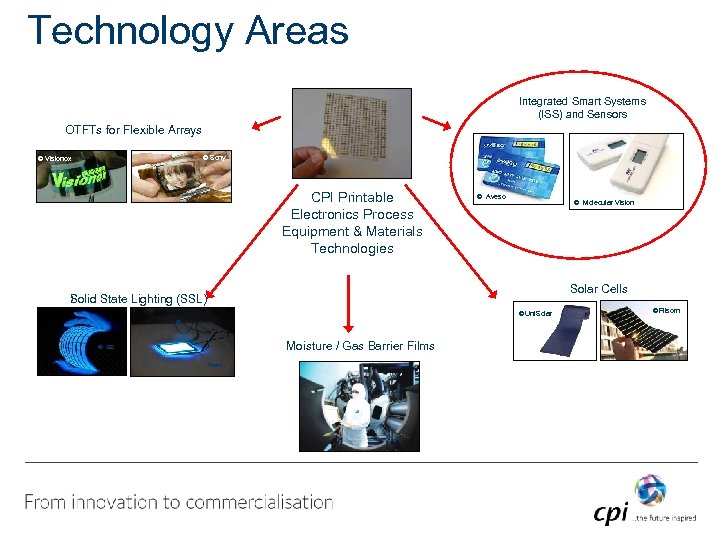

Technology Areas Integrated Smart Systems (ISS) and Sensors OTFTs for Flexible Arrays© Sony © Visionox CPI Printable Electronics Process Equipment & Materials Technologies ) Solid © Aveso © Molecular Vision Solar Cells State Lighting (SSL) © Uni. Solar © Thorn Moisture / Gas Barrier Films © GE Thorn © Flisom

Integrated Smart Systems (ISS) • Integrated Smart Systems are functional items produced by the integration of electronic components with circuits prepared by traditional printing processes +

Printed Electronic Devices ISS technology

Market Areas • Food/drink, tobacco, cosmetics, music, software & FMCG packaging • Pharmaceutical/healthcare applications • Publishing • Advertising • POS/POP • Lightweight, robust inexpensive wiring looms • Automotive, Aviation, architectural & military • Within consumer products & industrial goods • Brand protection & anti-counterfeit

ISS Equipment Criteria • Print industry recognised equipment and processes • Non clean room location • Versatile enough to support wide range of applications • Cost effective to run for development work but also capable of small scale production runs • Sufficiently instrumented to provide process feedback • Ability to offer an upgrade path to support the ISS technology roadmap

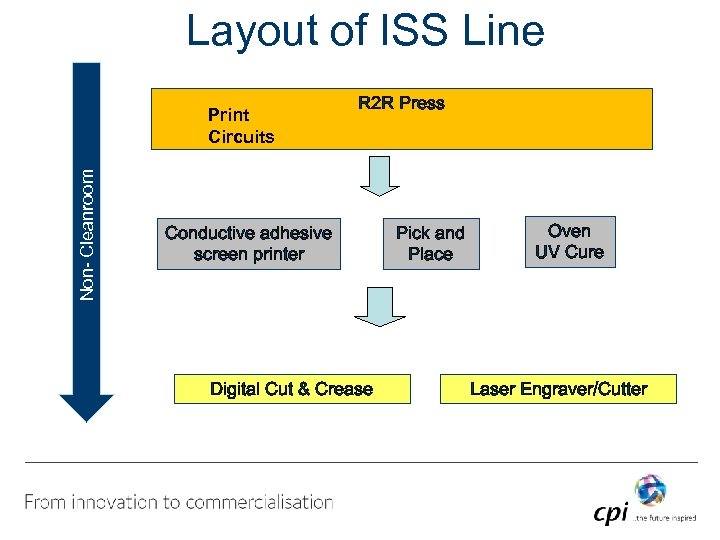

Layout of ISS Line Non- Cleanroom Print Circuits R 2 R Press Conductive adhesive screen printer Digital Cut & Crease Pick and Place Oven UV Cure Laser Engraver/Cutter

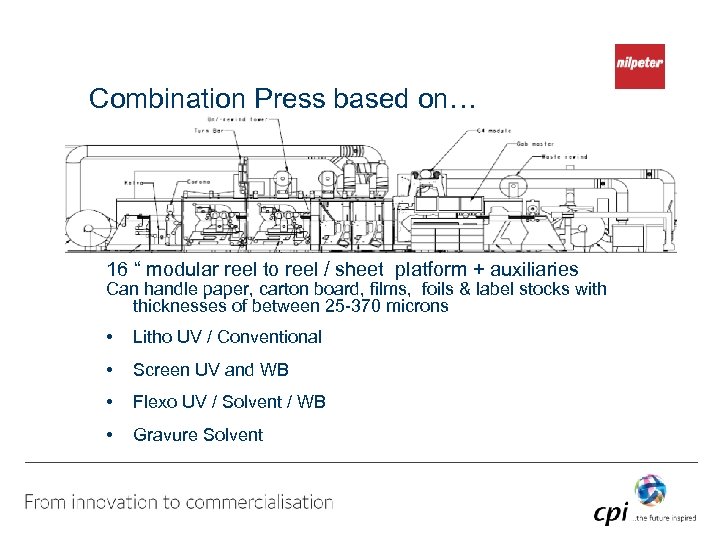

Combination Press based on… 16 “ modular reel to reel / sheet platform + auxiliaries Can handle paper, carton board, films, foils & label stocks with thicknesses of between 25 -370 microns • Litho UV / Conventional • Screen UV and WB • Flexo UV / Solvent / WB • Gravure Solvent

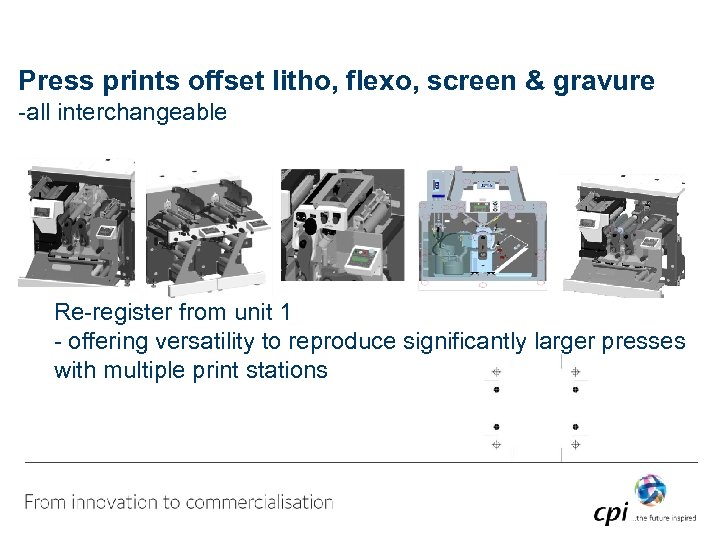

Press prints offset litho, flexo, screen & gravure -all interchangeable Re-register from unit 1 - offering versatility to reproduce significantly larger presses with multiple print stations

Ancillary On-Press Processes De-Lam Re-lam Cold Foil UV Lamination Die cutting & sheeting

ISS line Print graphics (Nilpeter) Print conductive circuits / devices. Inks available for Flexo, Screen, Gravure, Litho Add components and integrate into packaging to create interactive products / smart packaging. (Offline / online equipment)

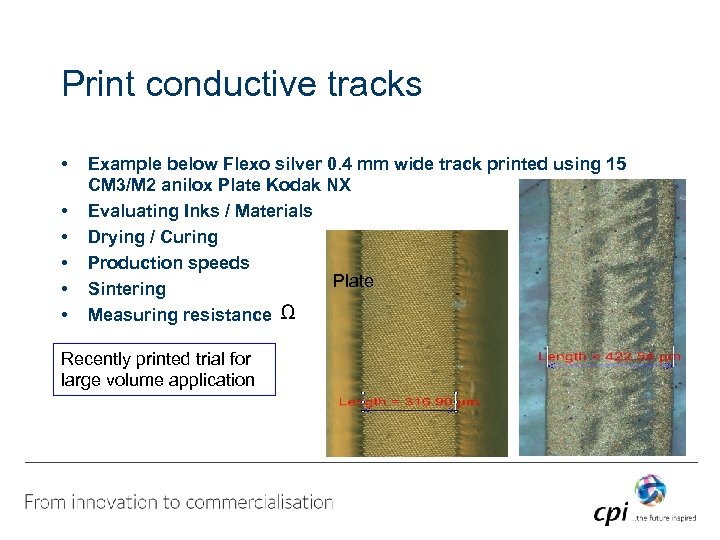

Print conductive tracks • • • Example below Flexo silver 0. 4 mm wide track printed using 15 CM 3/M 2 anilox Plate Kodak NX Evaluating Inks / Materials Drying / Curing Production speeds Plate Sintering Measuring resistance Recently printed trial for large volume application

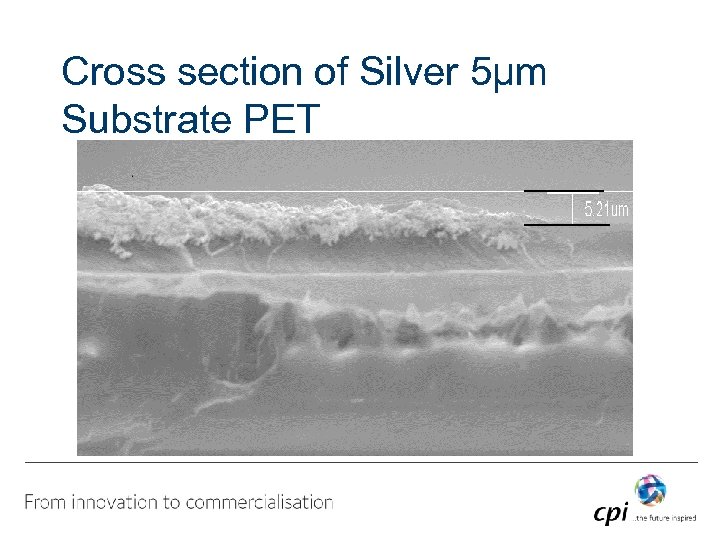

Cross section of Silver 5µm Substrate PET

Analysis Equipment at CPI • Material/ ink properties – Rheometer – Contact angle measurement • Structural properties – Optical microscopes – Scanning Electron Microscope with Elemental analysis – Atomic Force Microscope – White light interferometer

Screen Printer • DEK Screen Printer – for conductive ink & structural adhesives – print accuracy down to 10 microns

Pick and Place-component attachment • Placement and attachment of components onto conductive adhesive or tape or print • Able to position components of a range of sizes • Pick and place equipment with low to medium volume focus and high flexibility of component types • Placement accuracy of 35 microns http: //europlacer. com/en/video-iineo. html

Adhesive Curing • Cure to form electrical & structural connection between components and printed circuit/substrate • Oven - air drying adhesive systems • UV Curing - Radiation cure adhesive systems

Cut & Crease / Converting • To convert smaller quantities of print into finished products and samples • Esko digital cutting table – Cut & crease boxes – Kiss cut labels • Trotec CO 2 Laser – Fine cutting – Engraving – Ablation of circuits

Summary • CPI’s new ISS line opened in April 2012 • Equipped with commercial print, packaging and electronics equipment • Available for development, prototyping, scale up and pilot production projects

Thank you Bela Green Neil Porter Jon Helliwell ISS Programme Manager ISS Technical Print Manager Business Development Manager bela. green@uk-cpi. com neil. porter@uk-cpi. com Jon. Helliwell@uk-cpi. com 01740 625721 01740 625811

82eee7022fb9838a5e3c0c356a4af831.ppt