Optimization_Vienna.ppt

- Количество слайдов: 18

Coupling STAR-CCM+ with Optimization Software IOSO by the example of axial 8 -stages jet engine compressor. Folomeev V. , (Sarov Engineering Center) Iakunin A. , (JSC Klimov) STAR Global Conference 2014, March 17 -19, Vienna 1

Objectives q q To create the procedure for coupling CFD code STARCCM+ with optimization software IOSO To improve the law of turning guide vanes for the first tree stages of axial compressor. STAR Global Conference 2014, March 17 -19, Vienna 2

Main steps q q q Create axial 8 -stages compressor CFD model Develop the optimization task IOSO supports only windows platform when clusters usually operate on Linux, thus we need do develop the procedure for net connection STAR Global Conference 2014, March 17 -19, Vienna 3

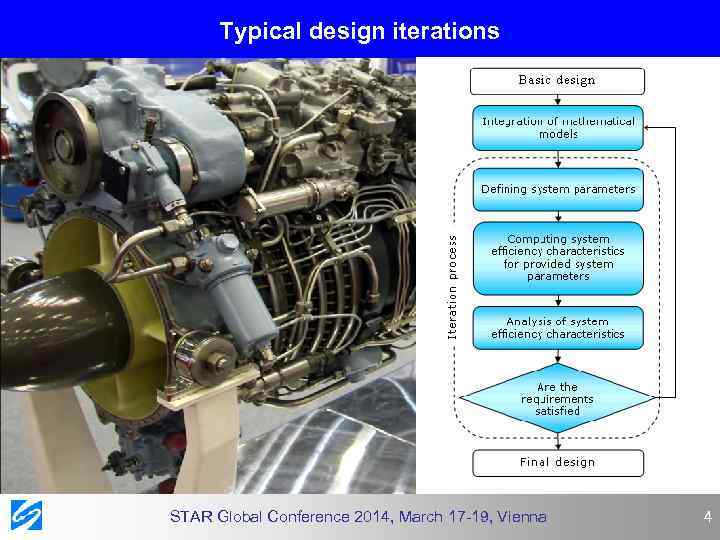

Typical design iterations STAR Global Conference 2014, March 17 -19, Vienna 4

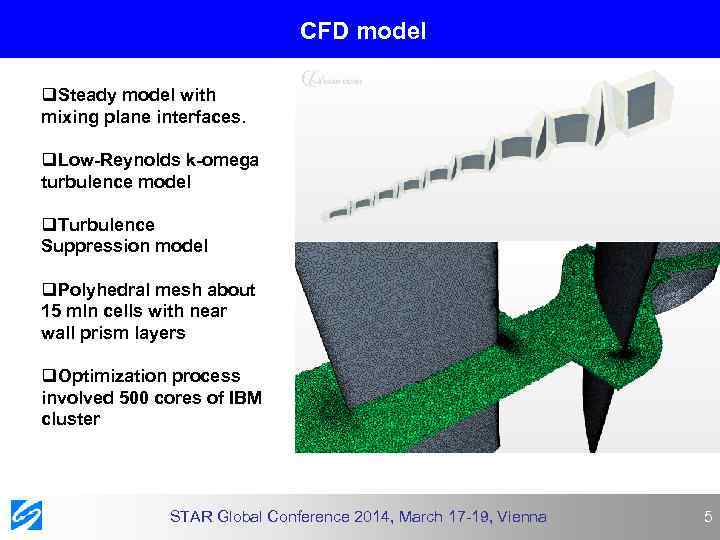

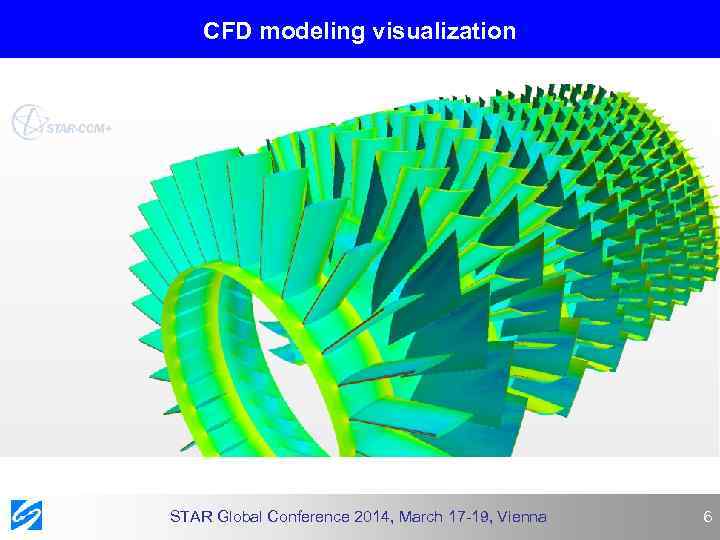

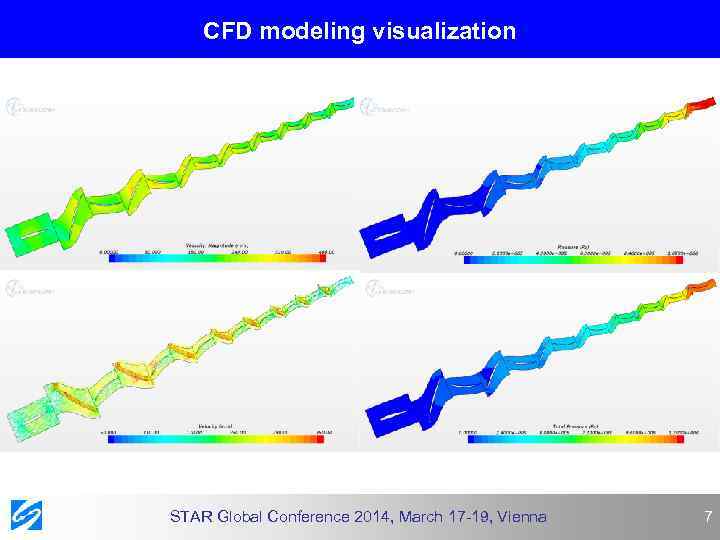

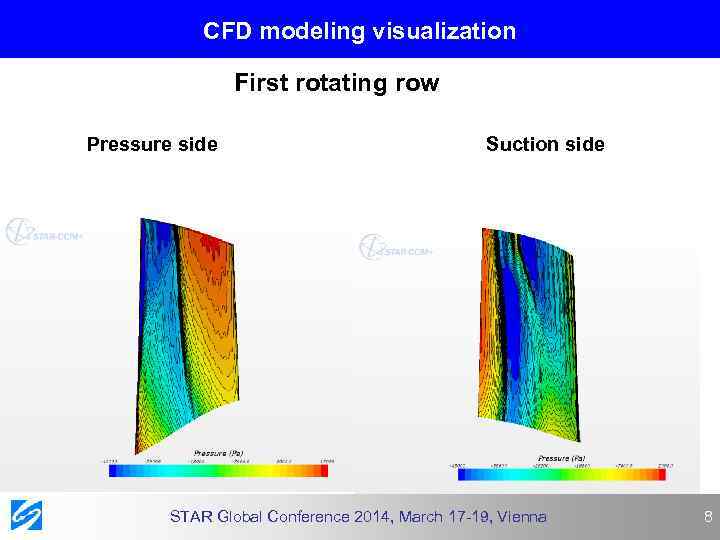

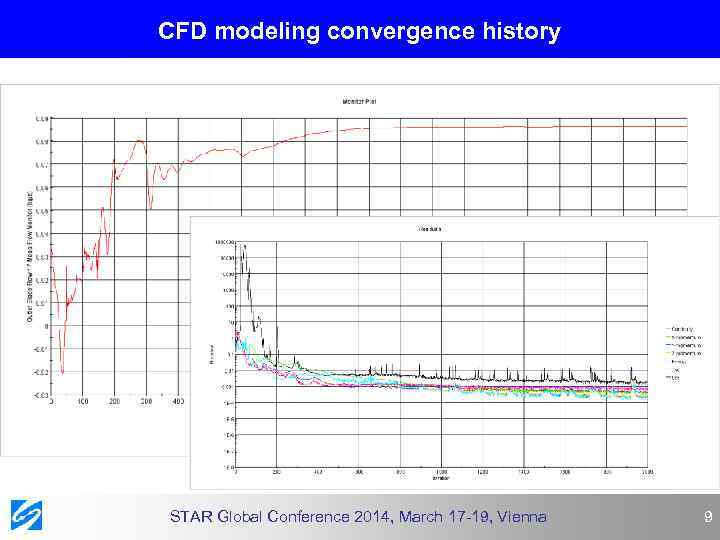

CFD model q. Steady model with mixing plane interfaces. q. Low-Reynolds k-omega turbulence model q. Turbulence Suppression model q. Polyhedral mesh about 15 mln cells with near wall prism layers q. Optimization process involved 500 cores of IBM cluster STAR Global Conference 2014, March 17 -19, Vienna 5

CFD modeling visualization STAR Global Conference 2014, March 17 -19, Vienna 6

CFD modeling visualization STAR Global Conference 2014, March 17 -19, Vienna 7

CFD modeling visualization First rotating row Pressure side Suction side STAR Global Conference 2014, March 17 -19, Vienna 8

CFD modeling convergence history STAR Global Conference 2014, March 17 -19, Vienna 9

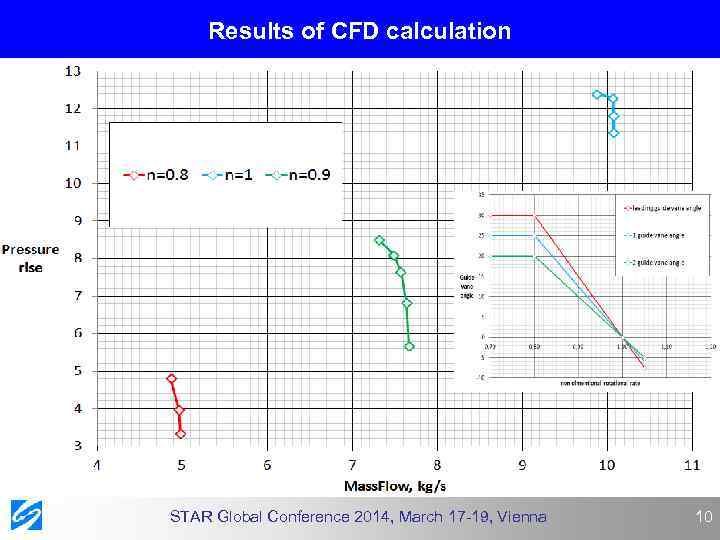

Results of CFD calculation STAR Global Conference 2014, March 17 -19, Vienna 10

Main features of the IOSO optimization technology IOSO Technology is based on the response surface technology. That is why the strategy differs significantly from the well-known approaches to optimization. The strategy has higher efficiency and provides wider range of capabilities than standard algorithms. The main advantage one can get from using the IOSO Technology is ability to solve very complex optimization tasks. IOSO Technology algorithms: Are independent of the optimization task types Have good global properties and in the majority of the cases are able to find the global optimum Have high convergence rate and allow to quickly and efficiently find the region where optimum is located Are highly robust with the respect to the computational process Allow for robust solving of stochastic optimization tasks, even if such problems have high level of noise Provide the capabilities to solve real-life optimization tasks that involve complex modern high fidelity mathematical models or engineering applications (for example, 3 D CAD, CFD or FEA software). Allow for solving robust design optimization tasks, including multidimensional single and multiobjective optimization tasks. Are very simple to use even for solving complex practical tasks of nonlinear optimization. Have full-automatic optimization algorithms which do not need to be tuned up by a user. STAR Global Conference 2014, March 17 -19, Vienna 11

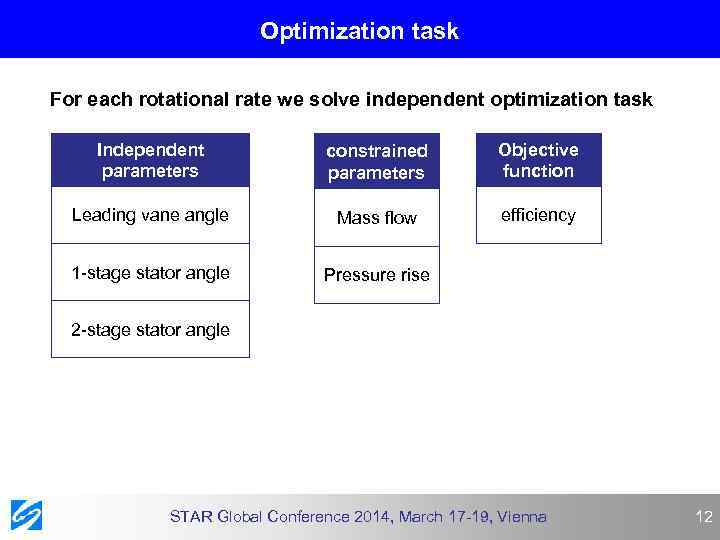

Optimization task For each rotational rate we solve independent optimization task Independent parameters constrained parameters Objective function Leading vane angle Mass flow efficiency 1 -stage stator angle Pressure rise 2 -stage stator angle STAR Global Conference 2014, March 17 -19, Vienna 12

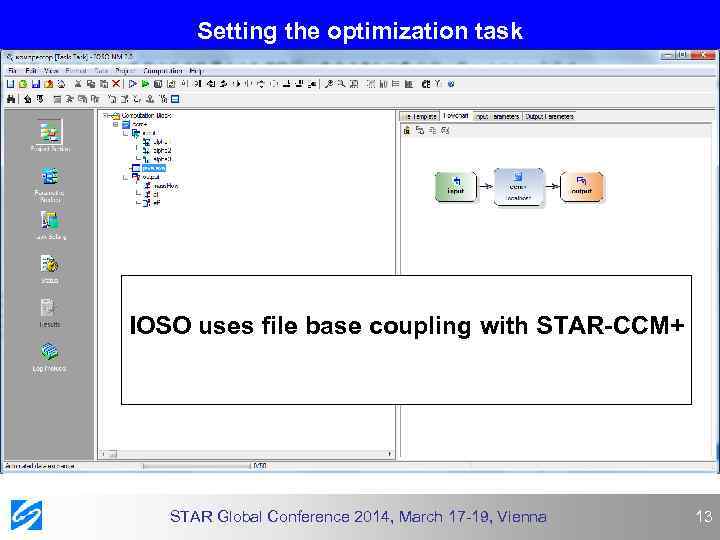

Setting the optimization task IOSO uses file base coupling with STAR-CCM+ STAR Global Conference 2014, March 17 -19, Vienna 13

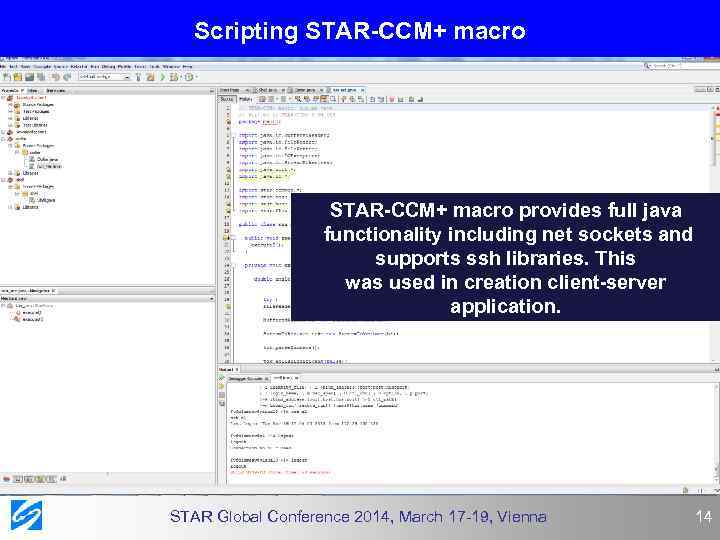

Scripting STAR-CCM+ macro provides full java functionality including net sockets and supports ssh libraries. This was used in creation client-server application. STAR Global Conference 2014, March 17 -19, Vienna 14

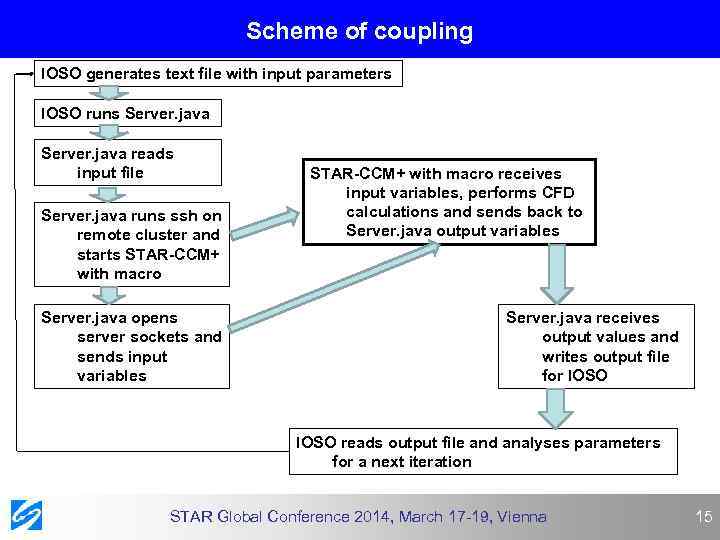

Scheme of coupling IOSO generates text file with input parameters IOSO runs Server. java reads input file Server. java runs ssh on remote cluster and starts STAR-CCM+ with macro Server. java opens server sockets and sends input variables STAR-CCM+ with macro receives input variables, performs CFD calculations and sends back to Server. java output variables Server. java receives output values and writes output file for IOSO reads output file and analyses parameters for a next iteration STAR Global Conference 2014, March 17 -19, Vienna 15

Results of optimization ü The normal rotation rate regime was examined firstly ü It was found that optimal configuration is nearly to zero for all variable angles with variation less than 0. 5 degree. This is consistent with analytical compressor design methods. ü The convergence of the optimization process was reached within 30 iterations. It approximately corresponds to 1 week of calculation on 500 cores of modern cluster solution. STAR Global Conference 2014, March 17 -19, Vienna 16

Conclusions ü The main task of this work was to develop procedure for coupling CFD code STAR-CCM+ with optimization software IOSO. This task was reached. ü Axial 8 -stages compressor served as an example for the main task. The robust CFD model of the compressor was created and tested. This model is appropriate for the automatic calculations with varying geometry parameters. ü The results of the optimization process are in agreement with other analytical methods of prediction compressor performance. It is presumed that the accuracy may be improved with complication of CFD model, for instance including harmonic balance model. STAR Global Conference 2014, March 17 -19, Vienna 17

Thank you for your attention STAR Global Conference 2014, March 17 -19, Vienna 18

Optimization_Vienna.ppt