e835509e4b22701629c85906dfa433eb.ppt

- Количество слайдов: 24

Cost Drivers Learning Event, 2 nd November 2005 Oct 2005 EMC Nov 05 Seminar

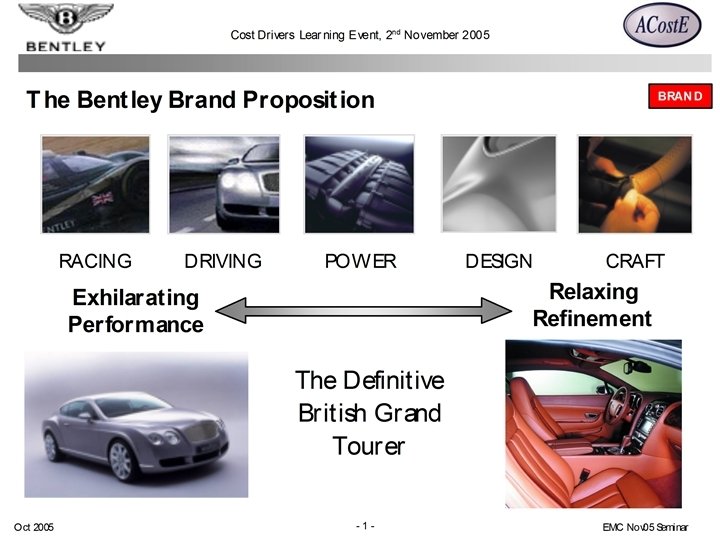

Cost Drivers Learning Event, 2 nd November 2005 Oct 2005 EMC Nov 05 Seminar

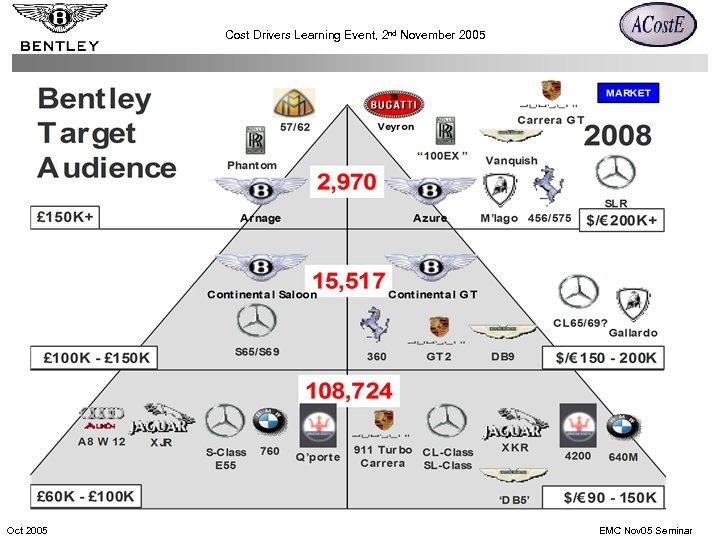

Cost Drivers Learning Event, 2 nd November 2005 Oct 2005 EMC Nov 05 Seminar

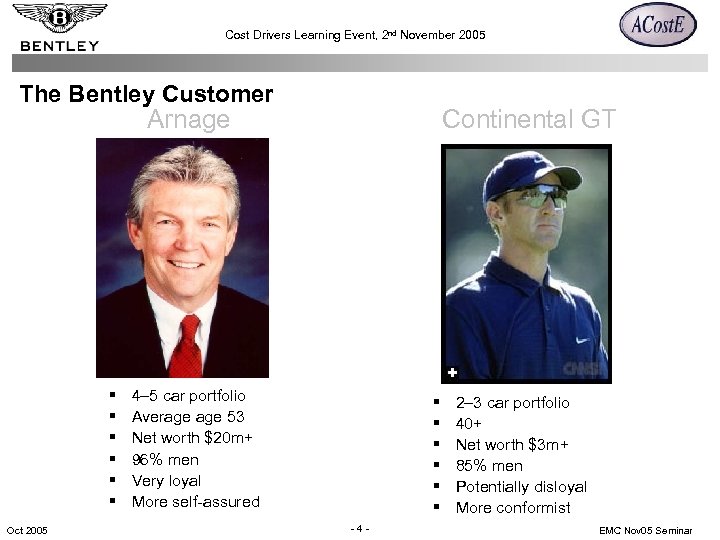

Cost Drivers Learning Event, 2 nd November 2005 The Bentley Customer Arnage § § § Oct 2005 Continental GT 4– 5 car portfolio Average 53 Net worth $20 m+ 96% men Very loyal More self-assured § § § -4 - 2– 3 car portfolio 40+ Net worth $3 m+ 85% men Potentially disloyal More conformist EMC Nov 05 Seminar

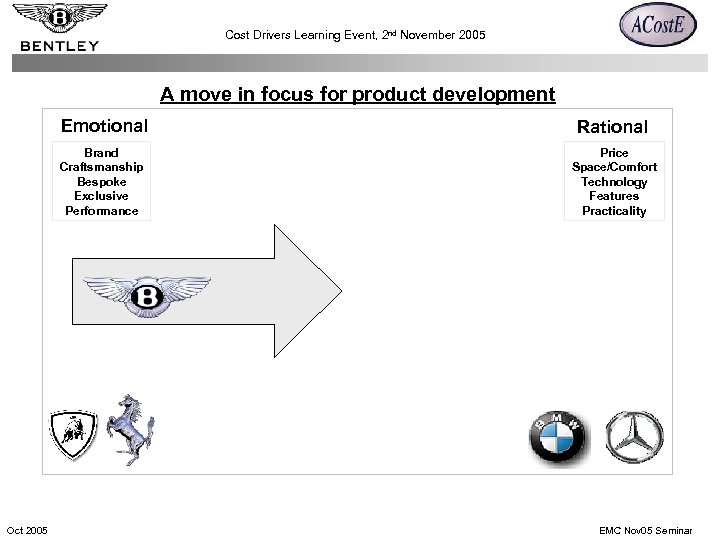

Cost Drivers Learning Event, 2 nd November 2005 A move in focus for product development Emotional Brand Craftsmanship Bespoke Exclusive Performance Oct 2005 Rational Price Space/Comfort Technology Features Practicality EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 BRAND Sacred Cows § § § § § Crewe design, engineering, manufacture Maintenance of pinnacle positioning within HLS Reinforcement of ‘British Grand Tourer’ proposition Road Presence Quality of (natural) materials Constrained supply 8 cylinders minimum Capacity to personalise Premium Price Point: 10%+over main target competitor § High torque – peak torque at low revs Oct 2005 -6 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 PRODUCT EMERGENCE PROCESS (PEP) • Process for delivery of new product to the customer, from concept to finished product • Owned by Product Management with cross functional representatives working together through regular meetings • Gateways are in place for specific decision points, only when the tasks are completed do you go through the ‘gate’ to the next stage. • Teams are identified by areas of the vehicle (modules) and further divided into Simultaneous Engineering Teams (SET) each represented by Product Engineering, Manufacturing Engineering, Marketing, Finance, Purchase. Oct 2005 -7 - EMC Nov 05 Seminar

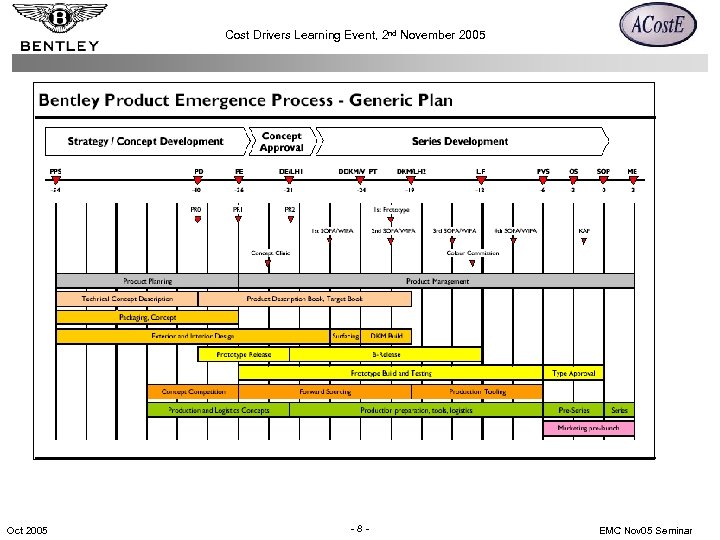

Cost Drivers Learning Event, 2 nd November 2005 Oct 2005 -8 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 COST MANAGEMENT PROCESS Oct 2005 -9 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 DELIVER PROGRAMME PROFITABILITY This is the responsibility of everybody on the project. The Project Team, Module members & SE Teams are key in ensuring delivery and taking corrective action where necessary ROLES • Co-ordination of Financial Information for the project is the responsibility of Finance. • Marketing supply information with respect to the Markets and pricing. • Product Management and Marketing provide a “Whole Life Plan” • Engineering, Purchasing, Quality, Finance and Manufacturing Engineering populate the Simultaneous Working Teams and Modules; buy-in and delivery to targets must be achieved at this level. The philosophy is “Our Target” & we’ll examine why this is required. Oct 2005 - 10 - EMC Nov 05 Seminar

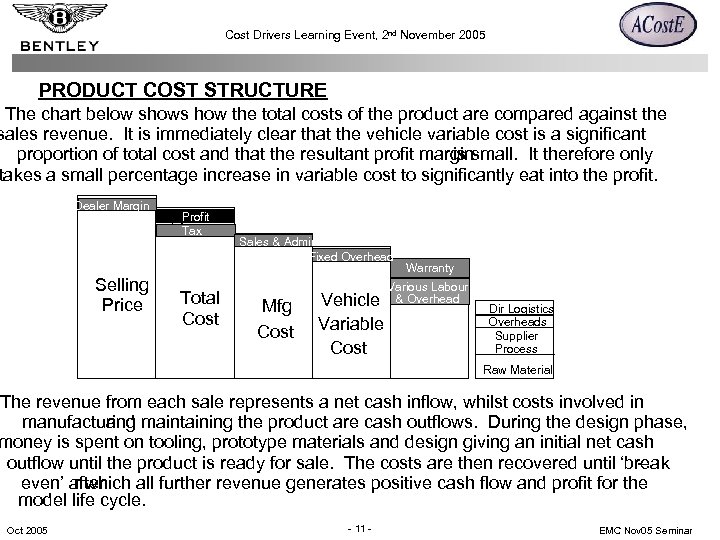

Cost Drivers Learning Event, 2 nd November 2005 PRODUCT COST STRUCTURE The chart below shows how the total costs of the product are compared against the sales revenue. It is immediately clear that the vehicle variable cost is a significant proportion of total cost and that the resultant profit marginsmall. It therefore only is takes a small percentage increase in variable cost to significantly eat into the profit. Dealer Margin Profit Tax Selling Price Total Cost Sales & Admin Fixed Overhead Mfg Cost Vehicle Variable Cost Warranty Various Labour & Overhead Material Cost Dir Logistics Overheads Supplier Process Raw Material The revenue from each sale represents a net cash inflow, whilst costs involved in manufacturing maintaining the product are cash outflows. During the design phase, and money is spent on tooling, prototype materials and design giving an initial net cash outflow until the product is ready for sale. The costs are then recovered until ‘break even’ after r which all further revenue generates positive cash flow and profit for the model life cycle. Oct 2005 - 11 - EMC Nov 05 Seminar

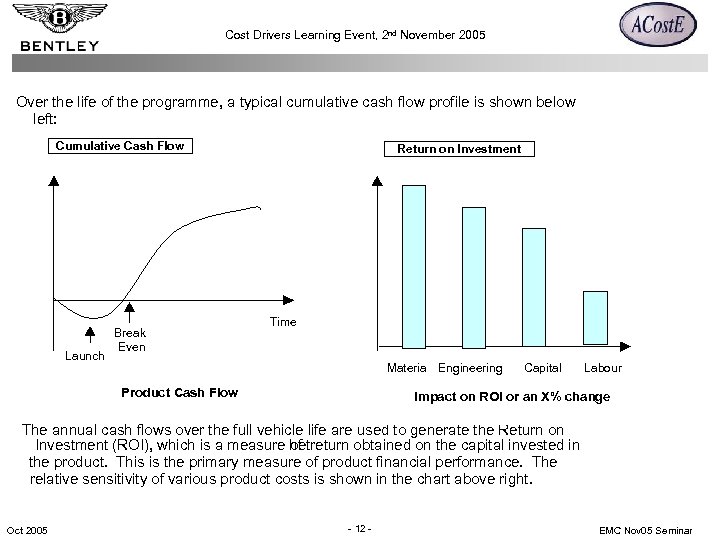

Cost Drivers Learning Event, 2 nd November 2005 Over the life of the programme, a typical cumulative cash flow profile is shown below left: Cumulative Cash Flow Launch Break Even Return on Investment Time Material Engineering Product Cash Flow Capital Labour Impact on ROI or an X% change The annual cash flows over the full vehicle life are used to generate the Return on Investment (ROI), which is a measure hetreturn obtained on the capital invested in of the product. This is the primary measure of product financial performance. The relative sensitivity of various product costs is shown in the chart above right. Oct 2005 - 12 - EMC Nov 05 Seminar

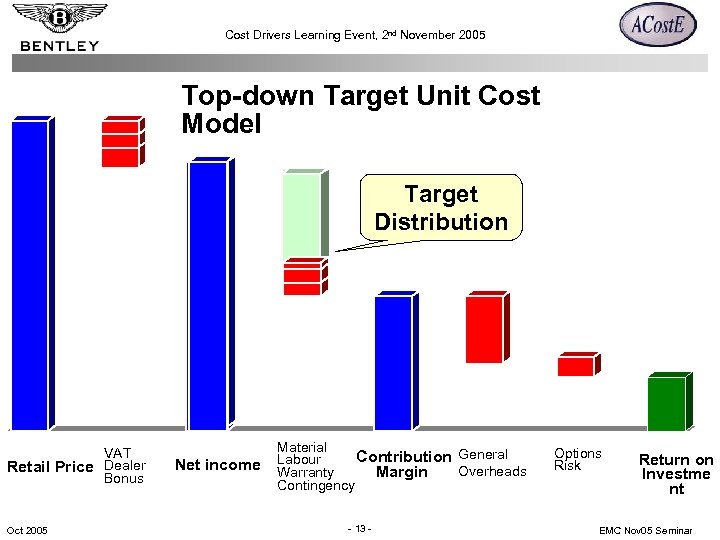

Cost Drivers Learning Event, 2 nd November 2005 Top-down Target Unit Cost Model Target Distribution VAT Retail Price Dealer Bonus Oct 2005 Net income Material Contribution General Labour Overheads Margin Warranty Contingency - 13 - Options Risk Return on Investme nt EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 Stage 1: Develop Product Concept The product concept and programme content defined in the is and Project Target Book, targets will be defined for all the main financial parameters that affect the Return on Investment (ROI). Stage 2: Develop Vehicle Cost Targets From the PD approval stage the vehicle unit cost target and targets for engineering and investmecost are fixed for the life of the nt programme. Oct 2005 - 14 - EMC Nov 05 Seminar

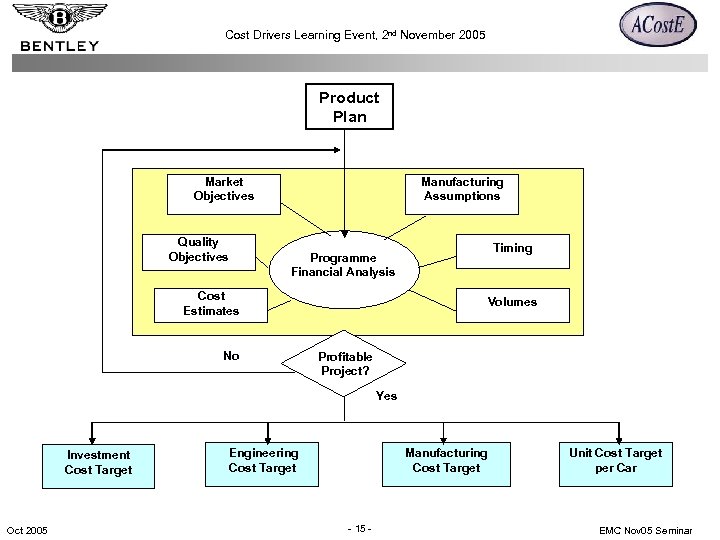

Cost Drivers Learning Event, 2 nd November 2005 Product Plan Market Objectives Quality Objectives Manufacturing Assumptions Timing Programme Financial Analysis Cost Estimates No Volumes Profitable Project? Yes Investment Cost Target Oct 2005 Engineering Cost Target Manufacturing Cost Target - 15 - Unit Cost Target per Car EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 . Oct 2005 - 16 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 Vehicle Target Powerrtrain Module Target Interior Module Target Exterior Module Target Chassis Module Target PDB Target Electrical Module Target PDB Target Assembly/Part System/Part Target Historical Costs Is target OK? Modify Proposal Benchmark Costs Brand Allowance OK OK Bottom Up Analysis Features List Oct 2005 - 17 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 Oct 2005 - 18 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 Oct 2005 - 19 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 Oct 2005 - 20 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 COST ESTIMATING SYSTEMS Oct 2005 - 21 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 NEED FOR COSTING SYSTEM §With the increasing focus on reducing product costs and particularly the supplied component costs, there was a need to have a consistent method for producing cost estimates. §We have introduced cost estimating software for the development of; –cost estimates during the design phase using parametrics –detailed cost estimates using defined processes and cost data. Oct 2005 - 22 - EMC Nov 05 Seminar

Cost Drivers Learning Event, 2 nd November 2005 BUSINESS BENEFITS §Provide cost estimates using defined processes and cost information. §Improve ‘customer’ confidence in the cost estimates produced. §Time reduction for estimates leading to improved efficiency §Product cost reduction – identify and focus on ‘cost drivers’ §Support supplier negotiations with qualified information Oct 2005 - 23 - EMC Nov 05 Seminar

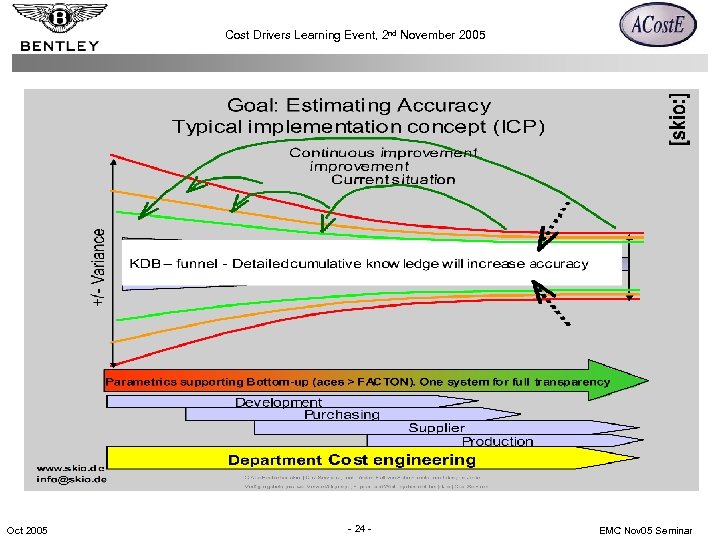

Cost Drivers Learning Event, 2 nd November 2005 Oct 2005 - 24 - EMC Nov 05 Seminar

e835509e4b22701629c85906dfa433eb.ppt