474d874e18e1c72287a85936ac4290ad.ppt

- Количество слайдов: 32

Correlation and Error Localization Analytical versus Experimental Dynamics of a Large Structural Assembly Thesis presentation, Herman Marquart, 2013 Correlation and Error Localization 1/31

Correlation and Error Localization Analytical versus Experimental Dynamics of a Large Structural Assembly Thesis presentation, Herman Marquart, 2013 Correlation and Error Localization 1/31

Content • • Introduction Theory Methodology Results Discussion Conclusion Recommendations Correlation and Error Localization 2/31

Content • • Introduction Theory Methodology Results Discussion Conclusion Recommendations Correlation and Error Localization 2/31

Department at ASML Mechanical Analysis • Structural Dynamics • Component • Well defined modeling process • Largely automated in software • Assembly • Less defined modeling process • Requires more subjective interferences Correlation and Error Localization 3/31

Department at ASML Mechanical Analysis • Structural Dynamics • Component • Well defined modeling process • Largely automated in software • Assembly • Less defined modeling process • Requires more subjective interferences Correlation and Error Localization 3/31

Assignment from ASML Formulated as… “Improve the correlation (process) of analytical and experimental structural assembly models” • Procedure • First understand the current process • Determine typical properties of a structural assembly • Determine applicability of correlation tools • Determine typical errors made during modeling • Define specific research problem • Propose methodology Correlation and Error Localization 4/31

Assignment from ASML Formulated as… “Improve the correlation (process) of analytical and experimental structural assembly models” • Procedure • First understand the current process • Determine typical properties of a structural assembly • Determine applicability of correlation tools • Determine typical errors made during modeling • Define specific research problem • Propose methodology Correlation and Error Localization 4/31

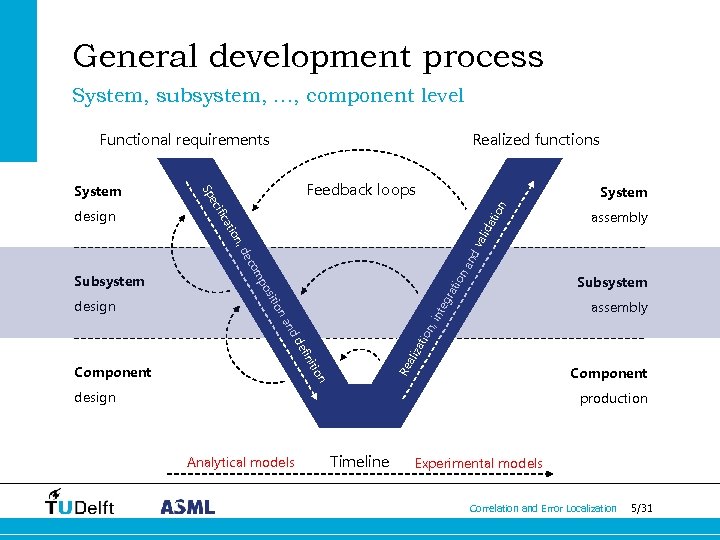

General development process System, subsystem, …, component level Functional requirements System ion dv ali da ti t ica on if ec design Feedback loops Sp System Realized functions Subsystem Component Re itio ali fin zat de ion nd , in na Component assembly teg itio rat s po ion om design an ec , d Subsystem assembly n design production Analytical models Timeline Experimental models Correlation and Error Localization 5/31

General development process System, subsystem, …, component level Functional requirements System ion dv ali da ti t ica on if ec design Feedback loops Sp System Realized functions Subsystem Component Re itio ali fin zat de ion nd , in na Component assembly teg itio rat s po ion om design an ec , d Subsystem assembly n design production Analytical models Timeline Experimental models Correlation and Error Localization 5/31

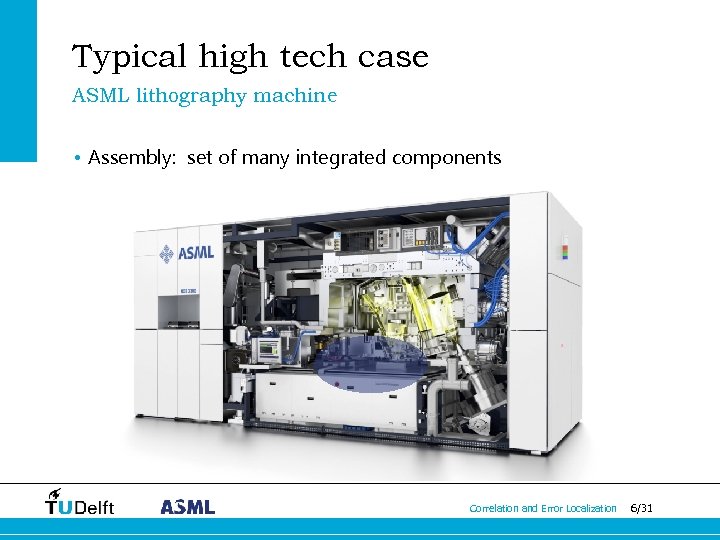

Typical high tech case ASML lithography machine • Assembly: set of many integrated components Correlation and Error Localization 6/31

Typical high tech case ASML lithography machine • Assembly: set of many integrated components Correlation and Error Localization 6/31

Typical high tech case Positioning module • Typical properties of such an assembly • Complex base structure (master structure) • Thin walled box structure • Many thin ribs and spacers • Many holes • Many components attached (slave structures) • Several large components • Many small components • Cables, wires, pipes, channels, … Correlation and Error Localization 7/31

Typical high tech case Positioning module • Typical properties of such an assembly • Complex base structure (master structure) • Thin walled box structure • Many thin ribs and spacers • Many holes • Many components attached (slave structures) • Several large components • Many small components • Cables, wires, pipes, channels, … Correlation and Error Localization 7/31

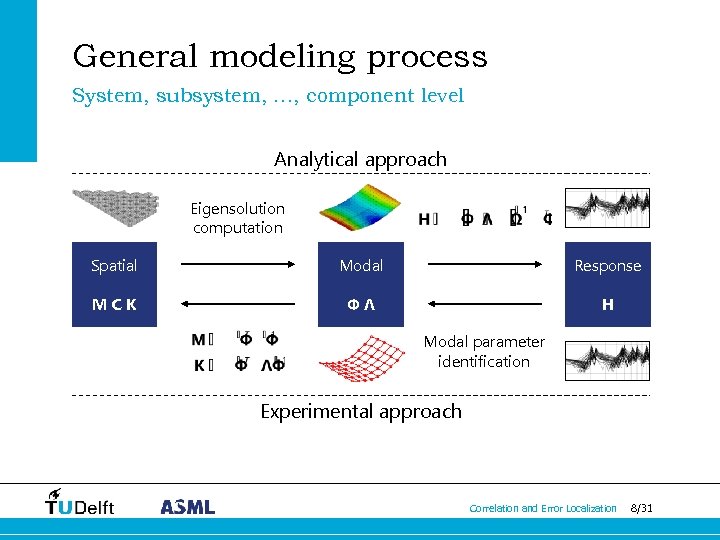

General modeling process System, subsystem, …, component level Analytical approach Eigensolution computation Spatial Modal Response MCK ΦΛ H Modal parameter identification Experimental approach Correlation and Error Localization 8/31

General modeling process System, subsystem, …, component level Analytical approach Eigensolution computation Spatial Modal Response MCK ΦΛ H Modal parameter identification Experimental approach Correlation and Error Localization 8/31

Analytical approach Assembly • Substructure assembly into components • • Natural approach Enables parallel engineering Possibly more attention to details More flexible to local modifications • Reduce each substructure • Approximation • Speeds up computation of eigensolutions • Easy reuse and exchange of components • Assemble reduced substructures Correlation and Error Localization 9/31

Analytical approach Assembly • Substructure assembly into components • • Natural approach Enables parallel engineering Possibly more attention to details More flexible to local modifications • Reduce each substructure • Approximation • Speeds up computation of eigensolutions • Easy reuse and exchange of components • Assemble reduced substructures Correlation and Error Localization 9/31

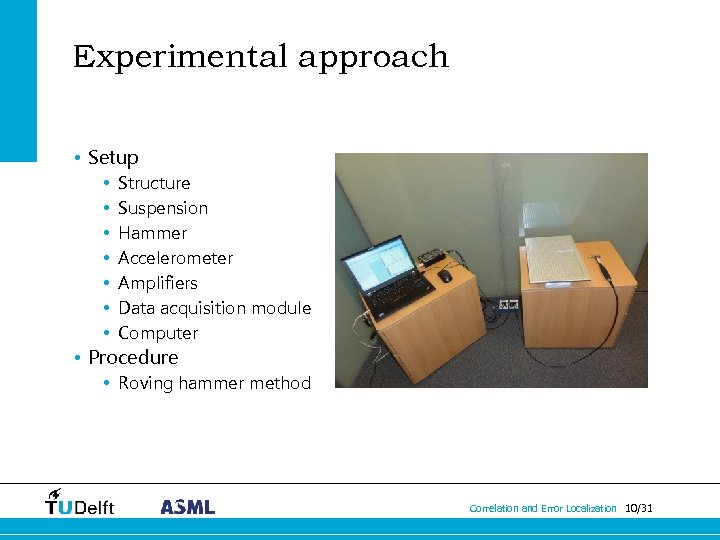

Experimental approach • Setup • • Structure Suspension Hammer Accelerometer Amplifiers Data acquisition module Computer • Procedure • Roving hammer method Correlation and Error Localization 10/31

Experimental approach • Setup • • Structure Suspension Hammer Accelerometer Amplifiers Data acquisition module Computer • Procedure • Roving hammer method Correlation and Error Localization 10/31

Theory discussion Theory versus application • Practical issues • • Many small components Lots of effort required to perform such detailed analysis Simpler models could be sufficient Limited amount of time available • Practical solutions • Omission of slave structures • Omission of structural dynamics of slave structures • Simplification of connections • However, assumptions are not always valid… Correlation and Error Localization 11/31

Theory discussion Theory versus application • Practical issues • • Many small components Lots of effort required to perform such detailed analysis Simpler models could be sufficient Limited amount of time available • Practical solutions • Omission of slave structures • Omission of structural dynamics of slave structures • Simplification of connections • However, assumptions are not always valid… Correlation and Error Localization 11/31

Research problem Formulated as… “What is the influence of a relatively lightweight resonating slave structure on the global structural dynamic behaviour of the master structure? How could you find the location of an unmeasured resonating slave structure with existing correlation tools and validation procedures, when multiple components are suspicious? ” Correlation and Error Localization 12/31

Research problem Formulated as… “What is the influence of a relatively lightweight resonating slave structure on the global structural dynamic behaviour of the master structure? How could you find the location of an unmeasured resonating slave structure with existing correlation tools and validation procedures, when multiple components are suspicious? ” Correlation and Error Localization 12/31

Methodology … influence … • Simulation • Create simplified structural assembly • Master structure • Slave structures • Multiple non-resonating • One resonating • Compare and correlate models; observe typical effects • Intended design versus realized design • Multiple positions of the resonating slave structure • Validation Correlation and Error Localization 13/31

Methodology … influence … • Simulation • Create simplified structural assembly • Master structure • Slave structures • Multiple non-resonating • One resonating • Compare and correlate models; observe typical effects • Intended design versus realized design • Multiple positions of the resonating slave structure • Validation Correlation and Error Localization 13/31

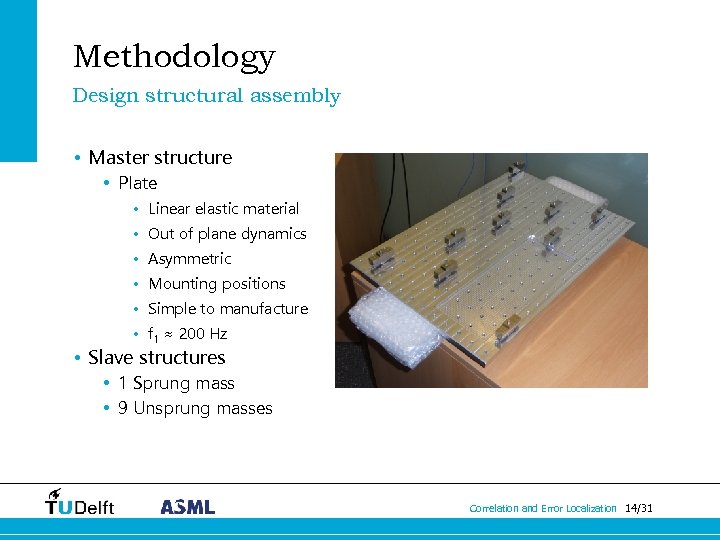

Methodology Design structural assembly • Master structure • Plate • Linear elastic material • Out of plane dynamics • Asymmetric • Mounting positions • Simple to manufacture • f 1 ≈ 200 Hz • Slave structures • 1 Sprung mass • 9 Unsprung masses Correlation and Error Localization 14/31

Methodology Design structural assembly • Master structure • Plate • Linear elastic material • Out of plane dynamics • Asymmetric • Mounting positions • Simple to manufacture • f 1 ≈ 200 Hz • Slave structures • 1 Sprung mass • 9 Unsprung masses Correlation and Error Localization 14/31

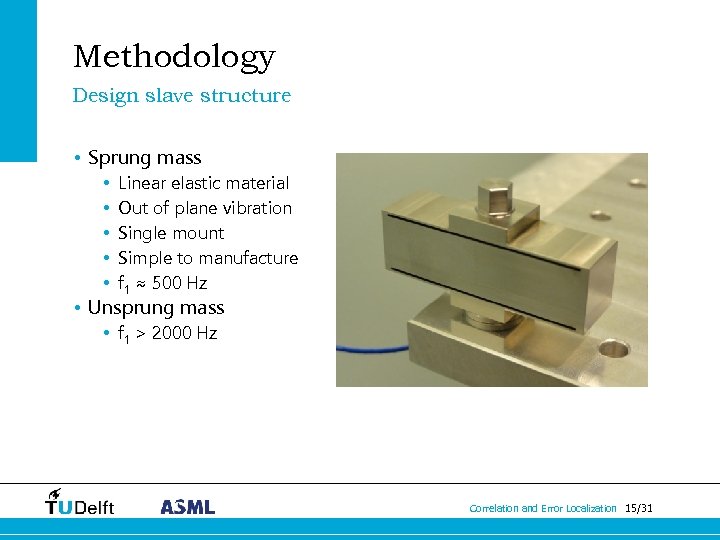

Methodology Design slave structure • Sprung mass • • • Linear elastic material Out of plane vibration Single mount Simple to manufacture f 1 ≈ 500 Hz • Unsprung mass • f 1 > 2000 Hz Correlation and Error Localization 15/31

Methodology Design slave structure • Sprung mass • • • Linear elastic material Out of plane vibration Single mount Simple to manufacture f 1 ≈ 500 Hz • Unsprung mass • f 1 > 2000 Hz Correlation and Error Localization 15/31

![Results … influence … • Compare and Correlate • Frequencies [Hz] Realized design Intended Results … influence … • Compare and Correlate • Frequencies [Hz] Realized design Intended](https://present5.com/presentation/474d874e18e1c72287a85936ac4290ad/image-16.jpg) Results … influence … • Compare and Correlate • Frequencies [Hz] Realized design Intended design 1 sprung mass + 9 unsprung masses 10 unsprung masses Correlation and Error Localization 16/31

Results … influence … • Compare and Correlate • Frequencies [Hz] Realized design Intended design 1 sprung mass + 9 unsprung masses 10 unsprung masses Correlation and Error Localization 16/31

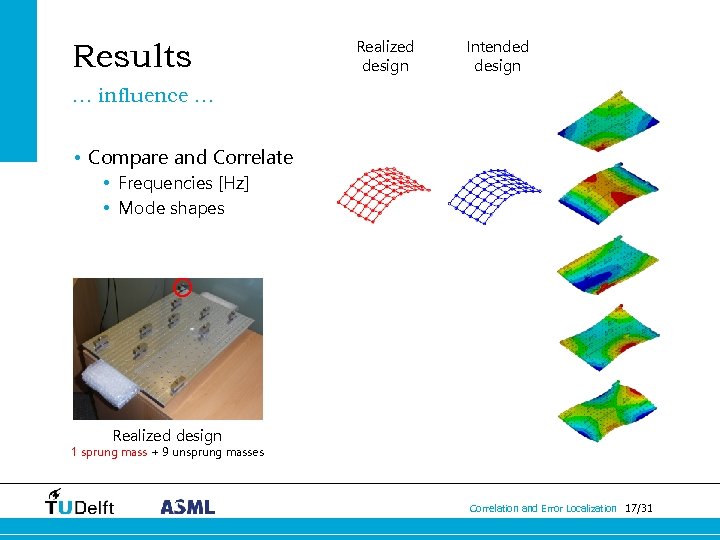

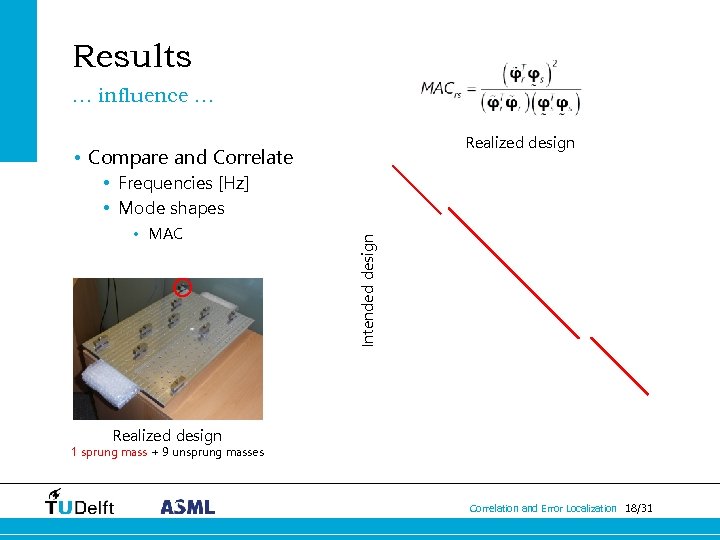

Results Realized design Intended design … influence … • Compare and Correlate • Frequencies [Hz] • Mode shapes Realized design 1 sprung mass + 9 unsprung masses Correlation and Error Localization 17/31

Results Realized design Intended design … influence … • Compare and Correlate • Frequencies [Hz] • Mode shapes Realized design 1 sprung mass + 9 unsprung masses Correlation and Error Localization 17/31

Results … influence … Intended design Realized design • Compare and Correlate • MAC Intended design • Frequencies [Hz] • Mode shapes Realized design 1 sprung mass + 9 unsprung masses Correlation and Error Localization 18/31

Results … influence … Intended design Realized design • Compare and Correlate • MAC Intended design • Frequencies [Hz] • Mode shapes Realized design 1 sprung mass + 9 unsprung masses Correlation and Error Localization 18/31

![Results … influence … • Compare and Correlate • MAC • FRFs Magnitude [kg-1] Results … influence … • Compare and Correlate • MAC • FRFs Magnitude [kg-1]](https://present5.com/presentation/474d874e18e1c72287a85936ac4290ad/image-19.jpg) Results … influence … • Compare and Correlate • MAC • FRFs Magnitude [kg-1] • Frequencies [Hz] • Mode shapes Realized design Frequency [Hz] Magnitude [kg-1] Intended design Realized design Frequency [Hz] 1 sprung mass + 9 unsprung masses Correlation and Error Localization 19/31

Results … influence … • Compare and Correlate • MAC • FRFs Magnitude [kg-1] • Frequencies [Hz] • Mode shapes Realized design Frequency [Hz] Magnitude [kg-1] Intended design Realized design Frequency [Hz] 1 sprung mass + 9 unsprung masses Correlation and Error Localization 19/31

Research problem Formulated as… “What is the influence of a relatively lightweight resonating slave structure on the global structural dynamic behaviour of the master structure? How could you find the location of an unmeasured resonating slave structure with existing correlation tools and validation procedures, when multiple components are suspicious? ” Correlation and Error Localization 20/31

Research problem Formulated as… “What is the influence of a relatively lightweight resonating slave structure on the global structural dynamic behaviour of the master structure? How could you find the location of an unmeasured resonating slave structure with existing correlation tools and validation procedures, when multiple components are suspicious? ” Correlation and Error Localization 20/31

Methodology … localization… • Systematically correct intended design • Known (approximately) • Additional resonance frequency • Slave structure mass • Connection stiffness • Unknown • Location • Define objective functions to quantify model correlation • Localize the resonating slave structure with objective function Correlation and Error Localization 21/31

Methodology … localization… • Systematically correct intended design • Known (approximately) • Additional resonance frequency • Slave structure mass • Connection stiffness • Unknown • Location • Define objective functions to quantify model correlation • Localize the resonating slave structure with objective function Correlation and Error Localization 21/31

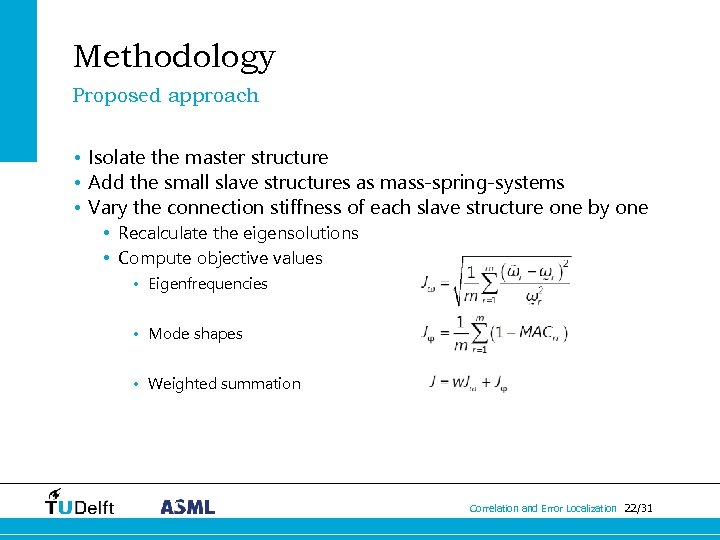

Methodology Proposed approach • Isolate the master structure • Add the small slave structures as mass-spring-systems • Vary the connection stiffness of each slave structure one by one • Recalculate the eigensolutions • Compute objective values • Eigenfrequencies • Mode shapes • Weighted summation Correlation and Error Localization 22/31

Methodology Proposed approach • Isolate the master structure • Add the small slave structures as mass-spring-systems • Vary the connection stiffness of each slave structure one by one • Recalculate the eigensolutions • Compute objective values • Eigenfrequencies • Mode shapes • Weighted summation Correlation and Error Localization 22/31

Results o w. Jω o Jφ ●J ‒R Objective value One slave structure Model variant Stiffness value Correlation and Error Localization 23/31

Results o w. Jω o Jφ ●J ‒R Objective value One slave structure Model variant Stiffness value Correlation and Error Localization 23/31

Results All slave structures 2 3 4 5 6 7 8 9 10 Objective value 1 Stiffness value Correlation and Error Localization 24/31

Results All slave structures 2 3 4 5 6 7 8 9 10 Objective value 1 Stiffness value Correlation and Error Localization 24/31

Results All slave structures 2 3 4 5 6 7 8 9 10 Objective value 1 Stiffness value Correlation and Error Localization 25/31

Results All slave structures 2 3 4 5 6 7 8 9 10 Objective value 1 Stiffness value Correlation and Error Localization 25/31

Results All slave structures 2 3 4 5 6 7 8 9 10 Objective value 1 Stiffness value Correlation and Error Localization 26/31

Results All slave structures 2 3 4 5 6 7 8 9 10 Objective value 1 Stiffness value Correlation and Error Localization 26/31

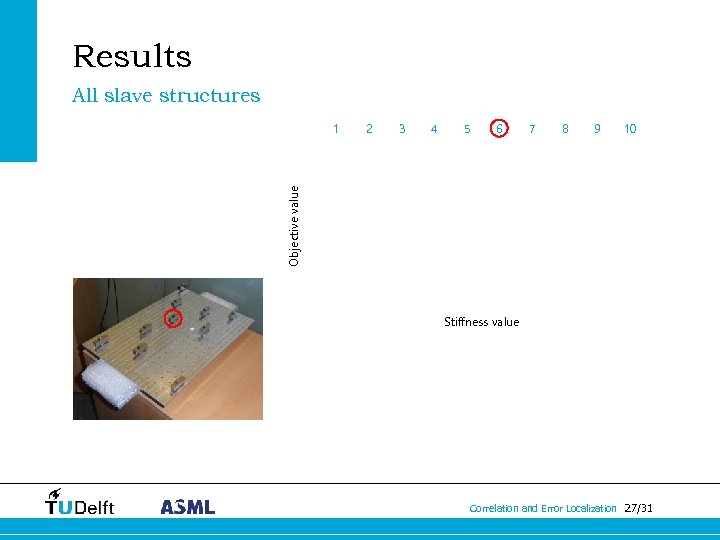

Results All slave structures 2 3 4 5 6 7 8 9 10 Objective value 1 Stiffness value Correlation and Error Localization 27/31

Results All slave structures 2 3 4 5 6 7 8 9 10 Objective value 1 Stiffness value Correlation and Error Localization 27/31

Discussion • Requirements • Validated master structure • Accurate measurements and mode shape identification • Fortunate properties • No additional measurements required • Entire process performed with ANSYS and MATLAB • Clear systematic approach Correlation and Error Localization 28/31

Discussion • Requirements • Validated master structure • Accurate measurements and mode shape identification • Fortunate properties • No additional measurements required • Entire process performed with ANSYS and MATLAB • Clear systematic approach Correlation and Error Localization 28/31

Conclusion • The proposed procedure may help localizing the resonating component, when typical structural dynamic correlations as presented, are encountered during the monitoring of the assembly process Correlation and Error Localization 29/31

Conclusion • The proposed procedure may help localizing the resonating component, when typical structural dynamic correlations as presented, are encountered during the monitoring of the assembly process Correlation and Error Localization 29/31

Recommendations • Research extension to more complex slave structures • Application to a case with multiple resonating slave structures Correlation and Error Localization 30/31

Recommendations • Research extension to more complex slave structures • Application to a case with multiple resonating slave structures Correlation and Error Localization 30/31

Questions? Correlation and Error Localization 31/31

Questions? Correlation and Error Localization 31/31

Correlation and Error Localization 32/31

Correlation and Error Localization 32/31