b1f41995d8073d38ddc5ebdcefb4c22d.ppt

- Количество слайдов: 30

Corporation Overview

Corporation Overview

Corporate Data Company name SEIKO EPSON CORPORATION Chairman Seiji Hanaoka President Minoru Usui Head Office Suwa, Nagano Founded 1942 Paid in capital 53, 204 million Consolidated sales 985. 3 billion *($10. 590 billion)** Operating income 18. 2 billion* ($ 195 million)** No. of group companies 106 (Japan: 26, overseas: 80)*** No. of employees Head Office 77, 936 (consolidated)*** * Results for fiscal year ended March 31, 2010 ** U. S. dollar amounts are included solely for the convenience of readers. The rate of ¥ 93. 04 = U. S. $1 at March 31, 2010, has been used for the purpose of this presentation ***As of March 31, 2010

Corporate Data Company name SEIKO EPSON CORPORATION Chairman Seiji Hanaoka President Minoru Usui Head Office Suwa, Nagano Founded 1942 Paid in capital 53, 204 million Consolidated sales 985. 3 billion *($10. 590 billion)** Operating income 18. 2 billion* ($ 195 million)** No. of group companies 106 (Japan: 26, overseas: 80)*** No. of employees Head Office 77, 936 (consolidated)*** * Results for fiscal year ended March 31, 2010 ** U. S. dollar amounts are included solely for the convenience of readers. The rate of ¥ 93. 04 = U. S. $1 at March 31, 2010, has been used for the purpose of this presentation ***As of March 31, 2010

![Epson Overview Consolidated Total Sales (FYE 3/09): ¥ 985. 3 Bn [$10. 59 billion] Epson Overview Consolidated Total Sales (FYE 3/09): ¥ 985. 3 Bn [$10. 59 billion]](https://present5.com/presentation/b1f41995d8073d38ddc5ebdcefb4c22d/image-3.jpg) Epson Overview Consolidated Total Sales (FYE 3/09): ¥ 985. 3 Bn [$10. 59 billion] Information-Related Equipment Imaging and Visual Information Products Instruments Electronic Devices PCs Semi. Quartz Displays Devices conducto rs Notes 1. Segment sales exclude intersegment sales 2. % of sales for each product categories in each business segment include sales that occurred between the product categories, within the business segments 3. U. S. dollar amounts are included solely for the convenience of readers. The rate of ¥ 93. 04 = U. S. $1 at March 31, 2010, has been used for the purpose of this presentation. Precision Products Watch, Optical, FA Products

Epson Overview Consolidated Total Sales (FYE 3/09): ¥ 985. 3 Bn [$10. 59 billion] Information-Related Equipment Imaging and Visual Information Products Instruments Electronic Devices PCs Semi. Quartz Displays Devices conducto rs Notes 1. Segment sales exclude intersegment sales 2. % of sales for each product categories in each business segment include sales that occurred between the product categories, within the business segments 3. U. S. dollar amounts are included solely for the convenience of readers. The rate of ¥ 93. 04 = U. S. $1 at March 31, 2010, has been used for the purpose of this presentation. Precision Products Watch, Optical, FA Products

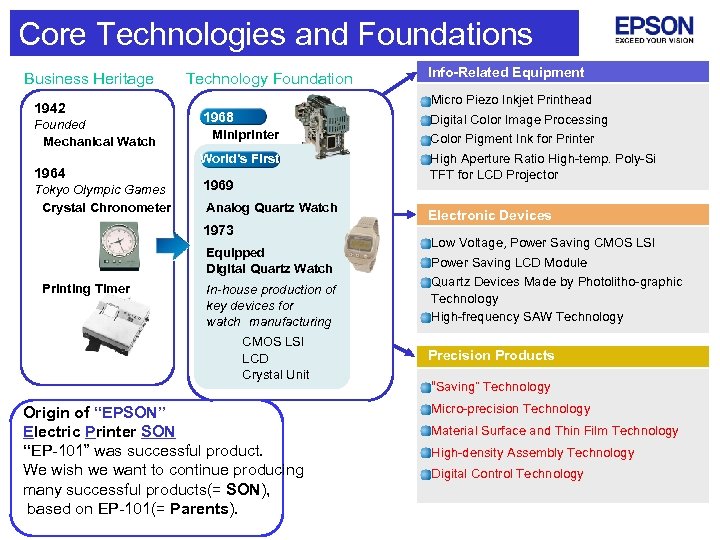

Core Technologies and Foundations Business Heritage 1942 Founded Mechanical Watch 1964 Technology Foundation 1968 Miniprinter World’s First Tokyo Olympic Games Crystal Chronometer 1969 1973 Analog Quartz Watch Equipped Digital Quartz Watch Printing Timer In-house production of key devices for watch manufacturing CMOS LSI LCD Crystal Unit Origin of “EPSON” Electric Printer SON “EP-101” was successful product. We wish we want to continue producing many successful products(= SON), based on EP-101(= Parents). Info-Related Equipment Micro Piezo Inkjet Printhead Digital Color Image Processing Color Pigment Ink for Printer High Aperture Ratio High-temp. Poly-Si TFT for LCD Projector Electronic Devices Low Voltage, Power Saving CMOS LSI Power Saving LCD Module Quartz Devices Made by Photolitho-graphic Technology High-frequency SAW Technology Precision Products “Saving” Technology Micro-precision Technology Material Surface and Thin Film Technology High-density Assembly Technology Digital Control Technology

Core Technologies and Foundations Business Heritage 1942 Founded Mechanical Watch 1964 Technology Foundation 1968 Miniprinter World’s First Tokyo Olympic Games Crystal Chronometer 1969 1973 Analog Quartz Watch Equipped Digital Quartz Watch Printing Timer In-house production of key devices for watch manufacturing CMOS LSI LCD Crystal Unit Origin of “EPSON” Electric Printer SON “EP-101” was successful product. We wish we want to continue producing many successful products(= SON), based on EP-101(= Parents). Info-Related Equipment Micro Piezo Inkjet Printhead Digital Color Image Processing Color Pigment Ink for Printer High Aperture Ratio High-temp. Poly-Si TFT for LCD Projector Electronic Devices Low Voltage, Power Saving CMOS LSI Power Saving LCD Module Quartz Devices Made by Photolitho-graphic Technology High-frequency SAW Technology Precision Products “Saving” Technology Micro-precision Technology Material Surface and Thin Film Technology High-density Assembly Technology Digital Control Technology

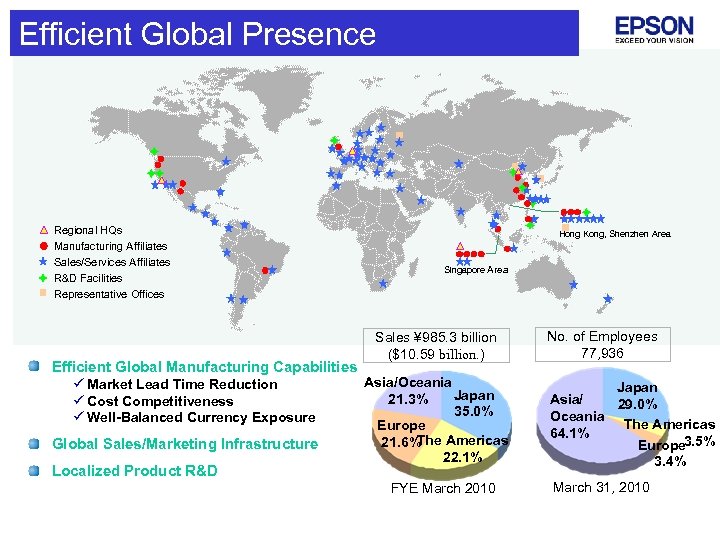

Efficient Global Presence Regional HQs Manufacturing Affiliates Sales/Services Affiliates R&D Facilities Representative Offices Hong Kong, Shenzhen Area Singapore Area Sales ¥ 985. 3 billion ($10. 59 billion. ) Efficient Global Manufacturing Capabilities Asia/Oceania ü Market Lead Time Reduction Japan 21. 3% ü Cost Competitiveness 35. 0% ü Well-Balanced Currency Exposure Europe Global Sales/Marketing Infrastructure Localized Product R&D The Americas 21. 6% 22. 1% FYE March 2010 No. of Employees 77, 936 Japan Asia/ 29. 0% Oceania The Americas 64. 1% Europe 3. 5% 3. 4% March 31, 2010

Efficient Global Presence Regional HQs Manufacturing Affiliates Sales/Services Affiliates R&D Facilities Representative Offices Hong Kong, Shenzhen Area Singapore Area Sales ¥ 985. 3 billion ($10. 59 billion. ) Efficient Global Manufacturing Capabilities Asia/Oceania ü Market Lead Time Reduction Japan 21. 3% ü Cost Competitiveness 35. 0% ü Well-Balanced Currency Exposure Europe Global Sales/Marketing Infrastructure Localized Product R&D The Americas 21. 6% 22. 1% FYE March 2010 No. of Employees 77, 936 Japan Asia/ 29. 0% Oceania The Americas 64. 1% Europe 3. 5% 3. 4% March 31, 2010

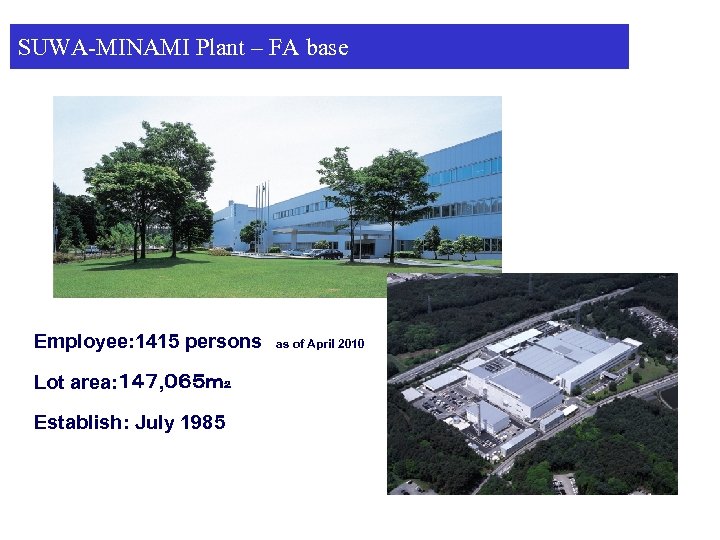

SUWA-MINAMI Plant – FA base Employee: 1415 persons as of April 2010 Lot area: 147, 065m2 Establish: July 1985

SUWA-MINAMI Plant – FA base Employee: 1415 persons as of April 2010 Lot area: 147, 065m2 Establish: July 1985

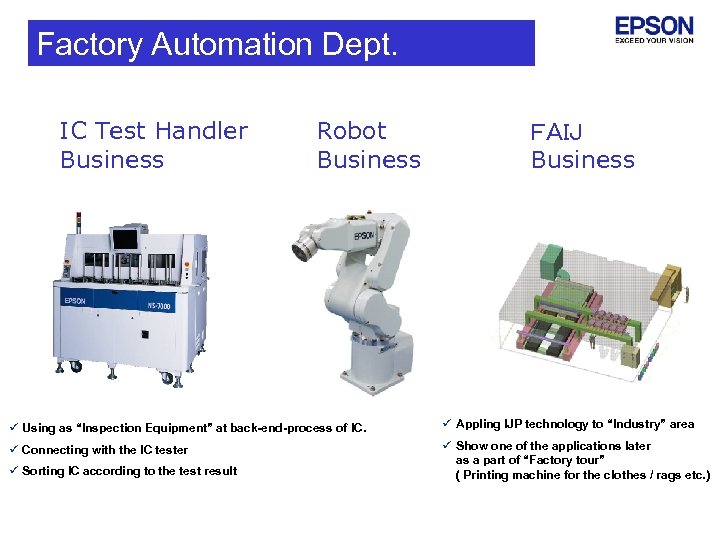

Factory Automation Dept. IC Test Handler Business Robot Business FAIJ Business ü Using as “Inspection Equipment” at back-end-process of IC. ü Appling IJP technology to “Industry” area ü Connecting with the IC tester ü Show one of the applications later as a part of “Factory tour” ( Printing machine for the clothes / rags etc. ) ü Sorting IC according to the test result

Factory Automation Dept. IC Test Handler Business Robot Business FAIJ Business ü Using as “Inspection Equipment” at back-end-process of IC. ü Appling IJP technology to “Industry” area ü Connecting with the IC tester ü Show one of the applications later as a part of “Factory tour” ( Printing machine for the clothes / rags etc. ) ü Sorting IC according to the test result

EPSON ROBOT

EPSON ROBOT

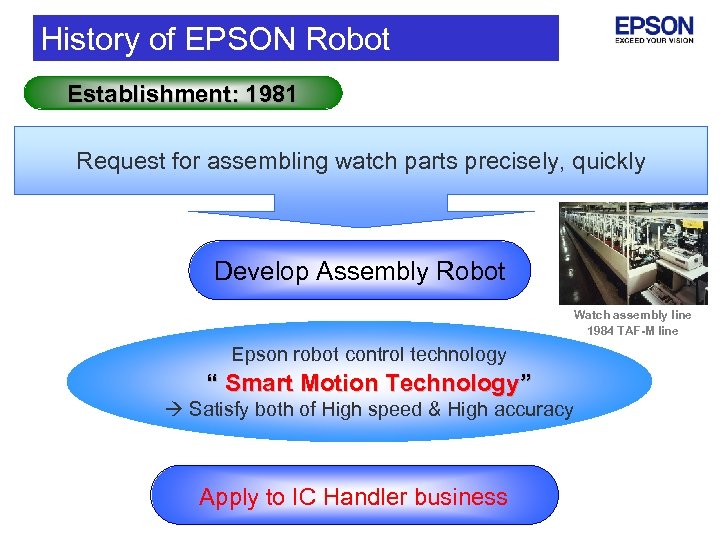

History of EPSON Robot Establishment: 1981 Request for assembling watch parts precisely, quickly Develop Assembly Robot Watch assembly line 1984 TAF-M line Epson robot control technology “ Smart Motion Technology” Satisfy both of High speed & High accuracy Apply to IC Handler business

History of EPSON Robot Establishment: 1981 Request for assembling watch parts precisely, quickly Develop Assembly Robot Watch assembly line 1984 TAF-M line Epson robot control technology “ Smart Motion Technology” Satisfy both of High speed & High accuracy Apply to IC Handler business

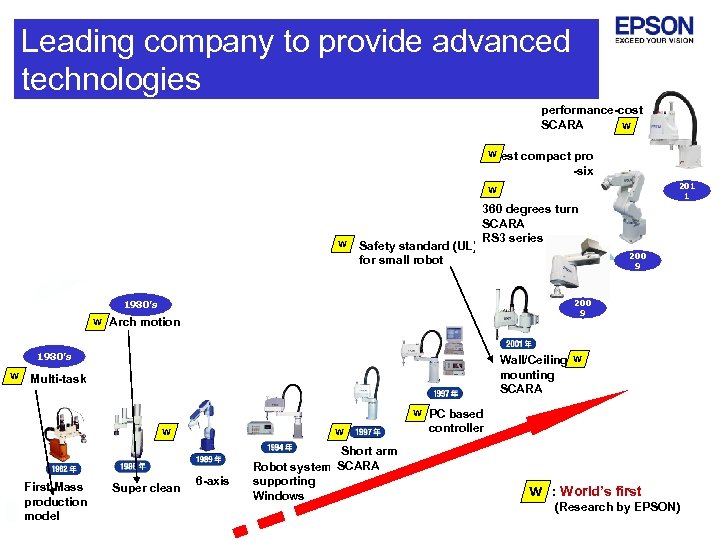

Leading company to provide advanced technologies performance-cost SCARA W W Fatest compact pro -six 201 1 W W Safety standard (UL) for small robot 360 degrees turn SCARA RS 3 series 200 9 1980’s W Arch motion 1980’s W Wall/Ceiling mounting SCARA Multi-task W W First Mass production model Super clean W 6 -axis Short arm Robot system SCARA supporting Windows W PC based controller W : World’s first (Research by EPSON)

Leading company to provide advanced technologies performance-cost SCARA W W Fatest compact pro -six 201 1 W W Safety standard (UL) for small robot 360 degrees turn SCARA RS 3 series 200 9 1980’s W Arch motion 1980’s W Wall/Ceiling mounting SCARA Multi-task W W First Mass production model Super clean W 6 -axis Short arm Robot system SCARA supporting Windows W PC based controller W : World’s first (Research by EPSON)

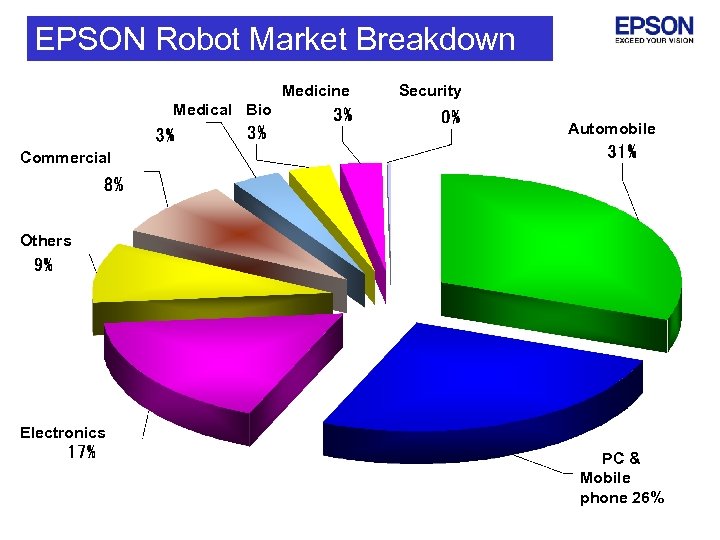

EPSON Robot Market Breakdown Medicine Security Medical Bio Automobile Commercial Others Electronics PC & Mobile phone 26%

EPSON Robot Market Breakdown Medicine Security Medical Bio Automobile Commercial Others Electronics PC & Mobile phone 26%

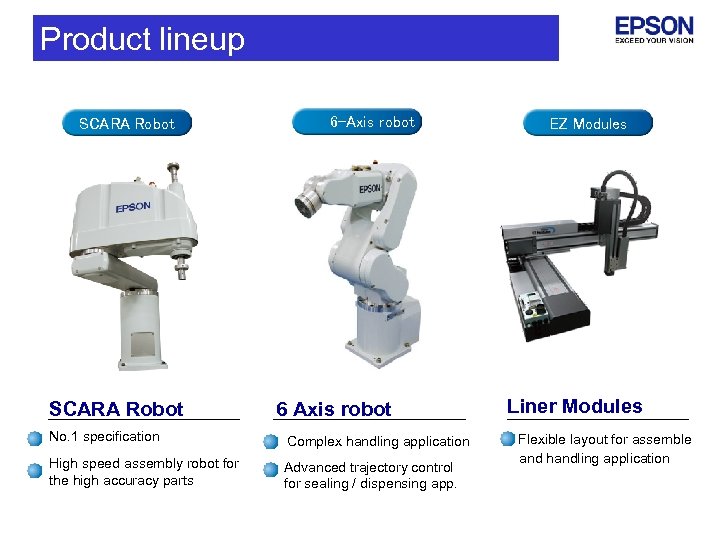

Product lineup SCARA Robot 6 -Axis robot EZ Modules SCARA Robot 6 Axis robot Liner Modules No. 1 specification High speed assembly robot for the high accuracy parts Complex handling application Flexible layout for assemble Advanced trajectory control for sealing / dispensing app. and handling application

Product lineup SCARA Robot 6 -Axis robot EZ Modules SCARA Robot 6 Axis robot Liner Modules No. 1 specification High speed assembly robot for the high accuracy parts Complex handling application Flexible layout for assemble Advanced trajectory control for sealing / dispensing app. and handling application

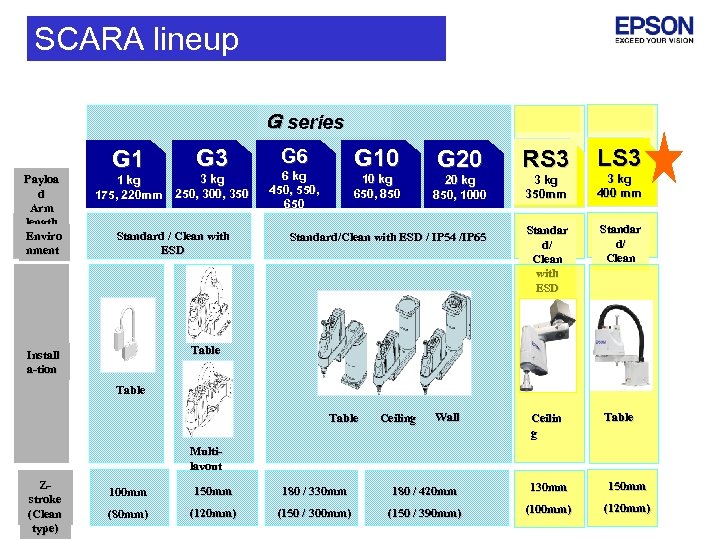

SCARA lineup G series Payloa d Arm length Enviro nment G 1 1 kg 175, 220 mm G 3 3 kg 250, 300, 350 Standard / Clean with ESD G 10 G 6 6 kg 450, 550, 650 10 kg 650, 850 G 20 20 kg 850, 1000 Standard/Clean with ESD / IP 54 /IP 65 RS 3 LS 3 3 kg 350 mm 3 kg 400 mm Standar d/ Clean with ESD Standar d/ Clean Ceilin g Table Install a-tion Table Ceiling Wall Multilayout Zstroke (Clean type) 100 mm 150 mm 180 / 330 mm 180 / 420 mm 130 mm 150 mm (80 mm) (120 mm) (150 / 300 mm) (150 / 390 mm) (100 mm) (120 mm)

SCARA lineup G series Payloa d Arm length Enviro nment G 1 1 kg 175, 220 mm G 3 3 kg 250, 300, 350 Standard / Clean with ESD G 10 G 6 6 kg 450, 550, 650 10 kg 650, 850 G 20 20 kg 850, 1000 Standard/Clean with ESD / IP 54 /IP 65 RS 3 LS 3 3 kg 350 mm 3 kg 400 mm Standar d/ Clean with ESD Standar d/ Clean Ceilin g Table Install a-tion Table Ceiling Wall Multilayout Zstroke (Clean type) 100 mm 150 mm 180 / 330 mm 180 / 420 mm 130 mm 150 mm (80 mm) (120 mm) (150 / 300 mm) (150 / 390 mm) (100 mm) (120 mm)

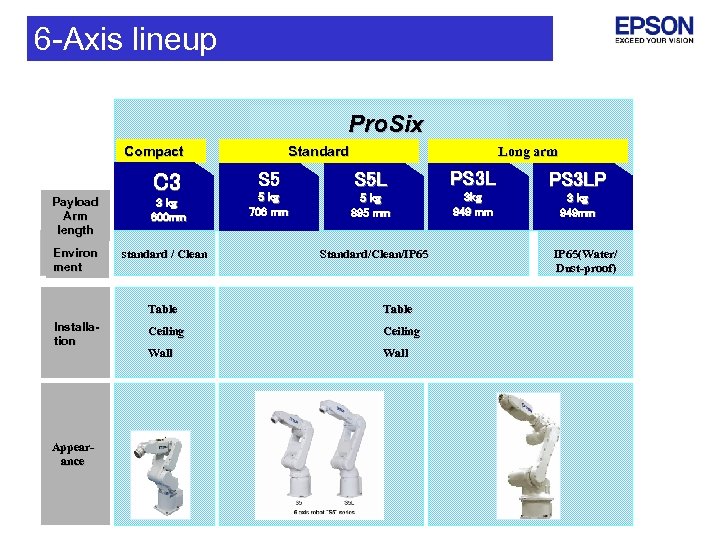

6 -Axis lineup Pro. Six Compact Payload Arm length Environ ment C 3 3 kg 600 mm standard / Clean Standard Long arm S 5 L PS 3 LP 5 kg 706 mm 5 kg 895 mm 3 kg 949 mm 3 kg 949 mm Standard/Clean/IP 65 Table Installation Appearance Table Ceiling Wall IP 65(Water/ Dust-proof)

6 -Axis lineup Pro. Six Compact Payload Arm length Environ ment C 3 3 kg 600 mm standard / Clean Standard Long arm S 5 L PS 3 LP 5 kg 706 mm 5 kg 895 mm 3 kg 949 mm 3 kg 949 mm Standard/Clean/IP 65 Table Installation Appearance Table Ceiling Wall IP 65(Water/ Dust-proof)

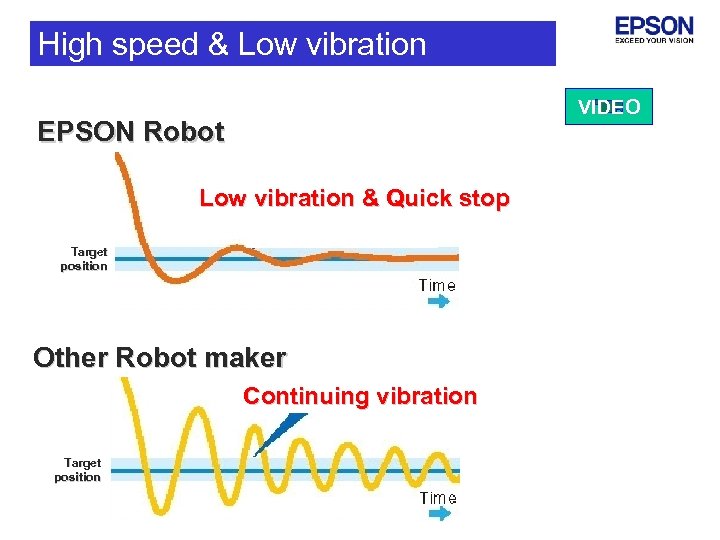

High speed & Low vibration VIDEO EPSON Robot Low vibration & Quick stop Target position Other Robot maker Continuing vibration Target position

High speed & Low vibration VIDEO EPSON Robot Low vibration & Quick stop Target position Other Robot maker Continuing vibration Target position

![High Speed SCARA VIDEO Cycle time [sec] EPSON is the fastest SCARA Faster Faste High Speed SCARA VIDEO Cycle time [sec] EPSON is the fastest SCARA Faster Faste](https://present5.com/presentation/b1f41995d8073d38ddc5ebdcefb4c22d/image-16.jpg) High Speed SCARA VIDEO Cycle time [sec] EPSON is the fastest SCARA Faster Faste Other makers Slower Cycle time is at 1 kg payload, 25 mm. X 300 mm. X 25 mm motion

High Speed SCARA VIDEO Cycle time [sec] EPSON is the fastest SCARA Faster Faste Other makers Slower Cycle time is at 1 kg payload, 25 mm. X 300 mm. X 25 mm motion

![High Speed 6 -axis (Compact class) VIDEO Cycle time [sec] 0. 37 sec Fastest High Speed 6 -axis (Compact class) VIDEO Cycle time [sec] 0. 37 sec Fastest](https://present5.com/presentation/b1f41995d8073d38ddc5ebdcefb4c22d/image-17.jpg) High Speed 6 -axis (Compact class) VIDEO Cycle time [sec] 0. 37 sec Fastest compact 6 -axis Faster Faste 0. 4 0. 5 Other makers Slower ü Repeatability:± 0. 02 mm Fast & Precision

High Speed 6 -axis (Compact class) VIDEO Cycle time [sec] 0. 37 sec Fastest compact 6 -axis Faster Faste 0. 4 0. 5 Other makers Slower ü Repeatability:± 0. 02 mm Fast & Precision

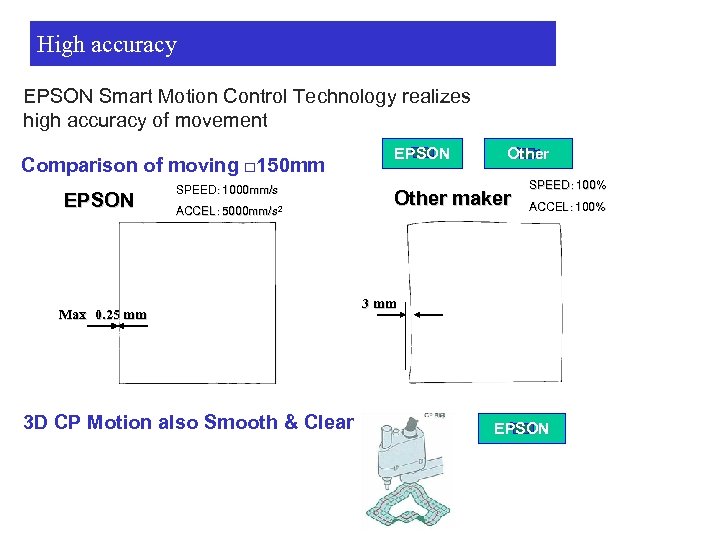

High accuracy EPSON Smart Motion Control Technology realizes high accuracy of movement Comparison of moving □ 150 mm EPSON SPEED: 1000 mm/s SPEED: ACCEL: 5000 mm/s 2 ACCEL: Max 0. 25 mm Max 3 D CP Motion also Smooth & Clear EPSON Other maker SPEED: 100% SPEED: ACCEL: 100% ACCEL: 3 mm EPSON

High accuracy EPSON Smart Motion Control Technology realizes high accuracy of movement Comparison of moving □ 150 mm EPSON SPEED: 1000 mm/s SPEED: ACCEL: 5000 mm/s 2 ACCEL: Max 0. 25 mm Max 3 D CP Motion also Smooth & Clear EPSON Other maker SPEED: 100% SPEED: ACCEL: 100% ACCEL: 3 mm EPSON

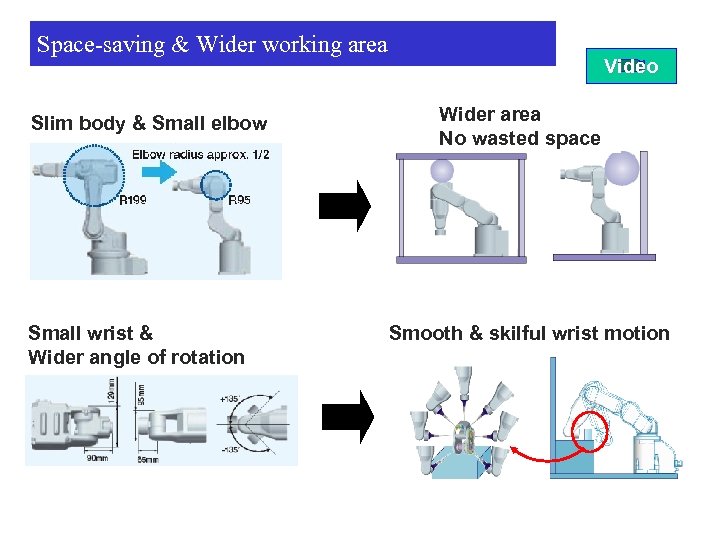

Space-saving & Wider working area Slim body & Small elbow Small wrist & Wider angle of rotation Video Wider area No wasted space Smooth & skilful wrist motion

Space-saving & Wider working area Slim body & Small elbow Small wrist & Wider angle of rotation Video Wider area No wasted space Smooth & skilful wrist motion

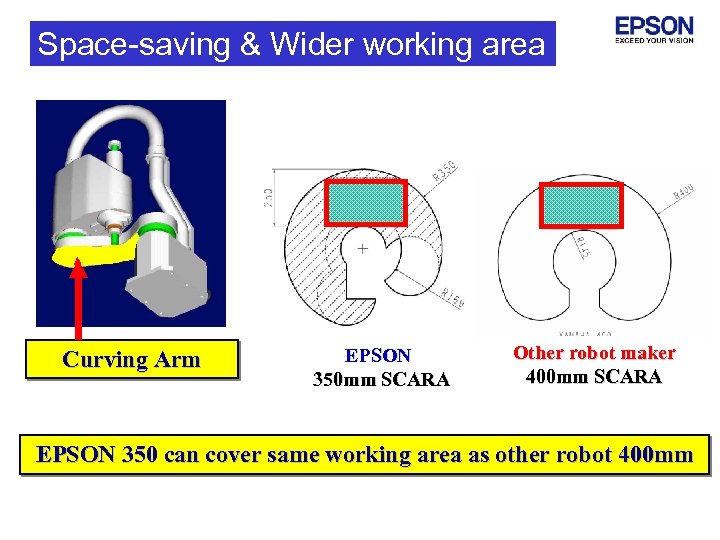

Space-saving & Wider working area B 5 Curving Arm EPSON 350 mm SCARA B 5 Other robot maker 400 mm SCARA EPSON 350 can cover same working area as other robot 400 mm

Space-saving & Wider working area B 5 Curving Arm EPSON 350 mm SCARA B 5 Other robot maker 400 mm SCARA EPSON 350 can cover same working area as other robot 400 mm

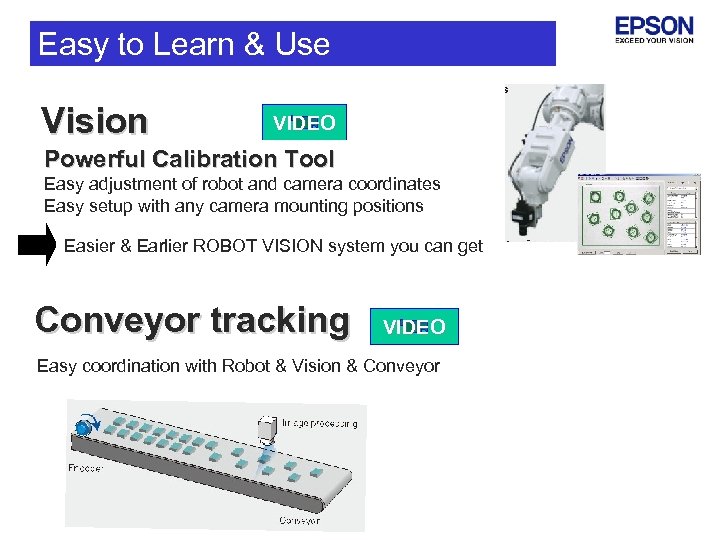

Easy to Learn & Use Vision VIDEO Powerful Calibration Tool Easy adjustment of robot and camera coordinates Easy setup with any camera mounting positions Easier & Earlier ROBOT VISION system you can get Conveyor tracking VIDEO Easy coordination with Robot & Vision & Conveyor

Easy to Learn & Use Vision VIDEO Powerful Calibration Tool Easy adjustment of robot and camera coordinates Easy setup with any camera mounting positions Easier & Earlier ROBOT VISION system you can get Conveyor tracking VIDEO Easy coordination with Robot & Vision & Conveyor

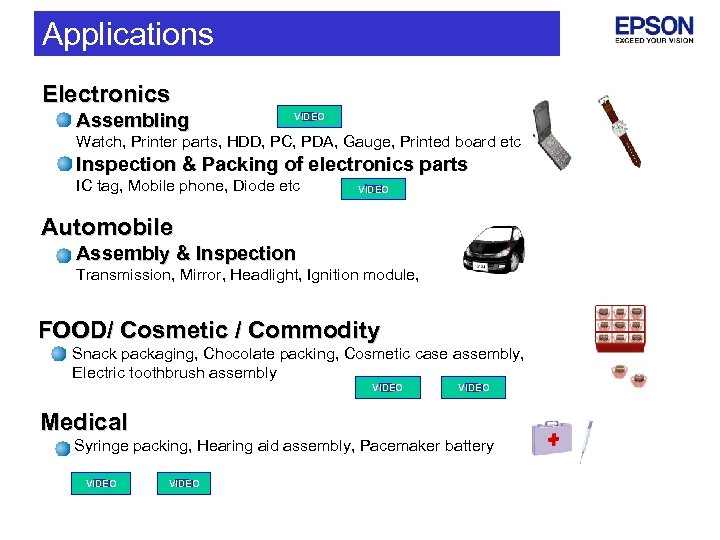

Applications Electronics Assembling VIDEO Watch, Printer parts, HDD, PC, PDA, Gauge, Printed board etc Inspection & Packing of electronics parts IC tag, Mobile phone, Diode etc VIDEO Automobile Assembly & Inspection Transmission, Mirror, Headlight, Ignition module, FOOD/ Cosmetic / Commodity Snack packaging, Chocolate packing, Cosmetic case assembly, Electric toothbrush assembly VIDEO Medical Syringe packing, Hearing aid assembly, Pacemaker battery VIDEO

Applications Electronics Assembling VIDEO Watch, Printer parts, HDD, PC, PDA, Gauge, Printed board etc Inspection & Packing of electronics parts IC tag, Mobile phone, Diode etc VIDEO Automobile Assembly & Inspection Transmission, Mirror, Headlight, Ignition module, FOOD/ Cosmetic / Commodity Snack packaging, Chocolate packing, Cosmetic case assembly, Electric toothbrush assembly VIDEO Medical Syringe packing, Hearing aid assembly, Pacemaker battery VIDEO

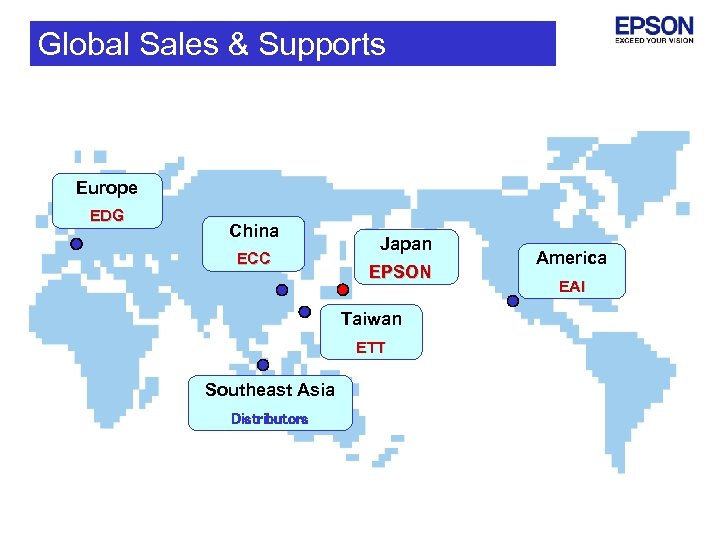

Global Sales & Supports Europe EDG China ECC Japan EPSON Taiwan ETT Southeast Asia Distributors America EAI

Global Sales & Supports Europe EDG China ECC Japan EPSON Taiwan ETT Southeast Asia Distributors America EAI

LS 3 introduction

LS 3 introduction

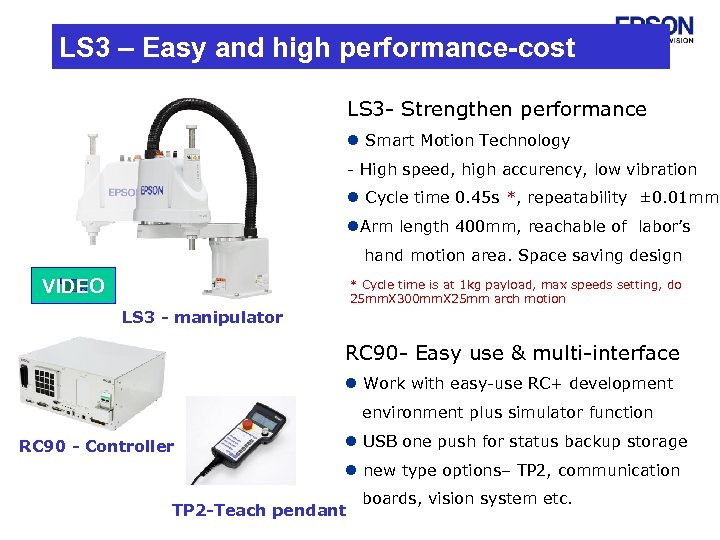

LS 3 – Easy and high performance-cost LS 3 - Strengthen performance l Smart Motion Technology - High speed, high accurency, low vibration l Cycle time 0. 45 s *, repeatability ± 0. 01 mm l. Arm length 400 mm, reachable of labor’s hand motion area. Space saving design VIDEO * Cycle time is at 1 kg payload, max speeds setting, do 25 mm. X 300 mm. X 25 mm arch motion LS 3 - manipulator RC 90 - Easy use & multi-interface l Work with easy-use RC+ development environment plus simulator function RC 90 - Controller l USB one push for status backup storage l new type options– TP 2, communication TP 2 -Teach pendant boards, vision system etc.

LS 3 – Easy and high performance-cost LS 3 - Strengthen performance l Smart Motion Technology - High speed, high accurency, low vibration l Cycle time 0. 45 s *, repeatability ± 0. 01 mm l. Arm length 400 mm, reachable of labor’s hand motion area. Space saving design VIDEO * Cycle time is at 1 kg payload, max speeds setting, do 25 mm. X 300 mm. X 25 mm arch motion LS 3 - manipulator RC 90 - Easy use & multi-interface l Work with easy-use RC+ development environment plus simulator function RC 90 - Controller l USB one push for status backup storage l new type options– TP 2, communication TP 2 -Teach pendant boards, vision system etc.

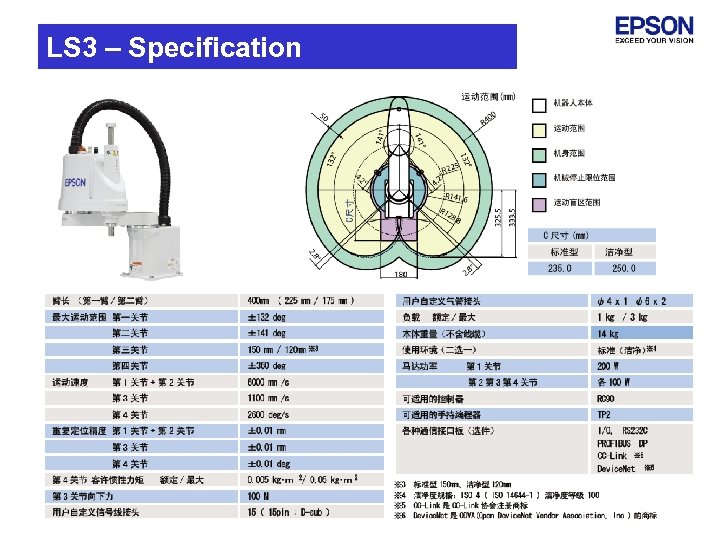

LS 3 – Specification

LS 3 – Specification

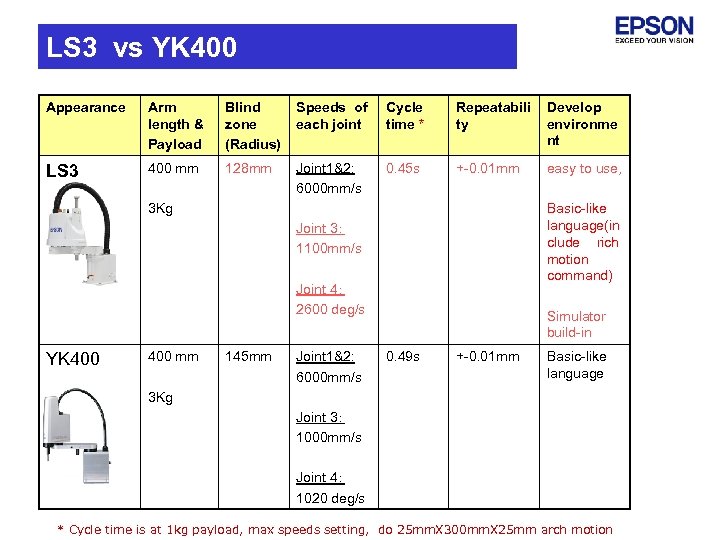

LS 3 vs YK 400 Appearance Arm length & Payload Blind zone (Radius) Speeds of each joint Cycle time * Repeatabili ty Develop environme nt LS 3 400 mm 128 mm Joint 1&2: 6000 mm/s 0. 45 s +-0. 01 mm easy to use, 3 Kg Basic-like language(in clude rich motion command) Joint 3: 1100 mm/s Joint 4: 2600 deg/s YK 400 mm 145 mm Joint 1&2: 6000 mm/s Simulator build-in 0. 49 s +-0. 01 mm Basic-like language 3 Kg Joint 3: 1000 mm/s Joint 4: 1020 deg/s * Cycle time is at 1 kg payload, max speeds setting, do 25 mm. X 300 mm. X 25 mm arch motion

LS 3 vs YK 400 Appearance Arm length & Payload Blind zone (Radius) Speeds of each joint Cycle time * Repeatabili ty Develop environme nt LS 3 400 mm 128 mm Joint 1&2: 6000 mm/s 0. 45 s +-0. 01 mm easy to use, 3 Kg Basic-like language(in clude rich motion command) Joint 3: 1100 mm/s Joint 4: 2600 deg/s YK 400 mm 145 mm Joint 1&2: 6000 mm/s Simulator build-in 0. 49 s +-0. 01 mm Basic-like language 3 Kg Joint 3: 1000 mm/s Joint 4: 1020 deg/s * Cycle time is at 1 kg payload, max speeds setting, do 25 mm. X 300 mm. X 25 mm arch motion

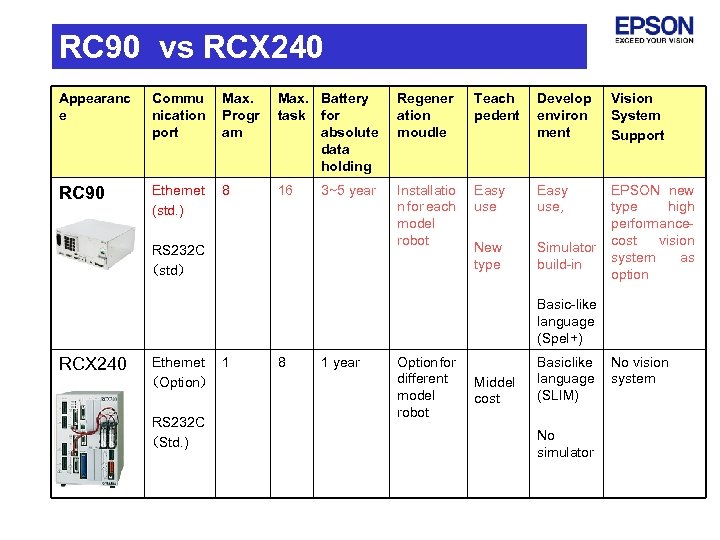

RC 90 vs RCX 240 Appearanc e Commu nication port Max. Progr am Max. Battery task for absolute data holding Regener ation moudle Teach pedent Develop environ ment Vision System Support RC 90 Ethernet (std. ) 8 16 Installatio n for each model robot Easy use, New type Simulator build-in EPSON new type high performancecost vision system as option 3~5 year RS 232 C (std) Basic-like language (Spel+) RCX 240 Ethernet (Option) RS 232 C (Std. ) 1 8 1 year Option for different model robot Middel cost Basic like language (SLIM) No simulator No vision system

RC 90 vs RCX 240 Appearanc e Commu nication port Max. Progr am Max. Battery task for absolute data holding Regener ation moudle Teach pedent Develop environ ment Vision System Support RC 90 Ethernet (std. ) 8 16 Installatio n for each model robot Easy use, New type Simulator build-in EPSON new type high performancecost vision system as option 3~5 year RS 232 C (std) Basic-like language (Spel+) RCX 240 Ethernet (Option) RS 232 C (Std. ) 1 8 1 year Option for different model robot Middel cost Basic like language (SLIM) No simulator No vision system

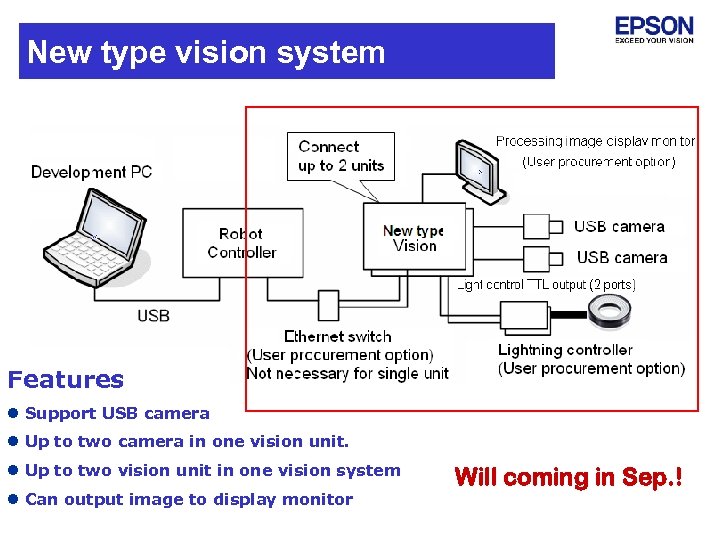

New type vision system Features l Support USB camera l Up to two camera in one vision unit. l Up to two vision unit in one vision system l Can output image to display monitor Will coming in Sep. !

New type vision system Features l Support USB camera l Up to two camera in one vision unit. l Up to two vision unit in one vision system l Can output image to display monitor Will coming in Sep. !