452d30d3884886c2b818c8fb1fb9b04c.ppt

- Количество слайдов: 32

CORPORATE QUALITY MANAGEMENT 1

CORPORATE QUALITY MANAGEMENT 1

1. Quality System 1. 2. 3. 4. Guidance and Support to all ITI Units for Implementation / Surveillance / Re-certification of • ISO 9001 Quality Management System (QMS) • ISO 14001 Environmental Management System (EMS) Quality related Mo. U targets Quality related Issues Quality Policy and Quality Manual 2

1. Quality System 1. 2. 3. 4. Guidance and Support to all ITI Units for Implementation / Surveillance / Re-certification of • ISO 9001 Quality Management System (QMS) • ISO 14001 Environmental Management System (EMS) Quality related Mo. U targets Quality related Issues Quality Policy and Quality Manual 2

2. Components, VDC, VRC, Standards and Reliability 1. Qualification Approval and Standardization of Electronic Components, 2. Qualification Approval and Standardization of Electromechanical and Mechanical Components, PCBs & Raw Materials 3. Vendor Development and Vendor Rating 4. Corporate Standards 5. Reliability Engineering Laboratory 6. Component Testing Laboratory 3

2. Components, VDC, VRC, Standards and Reliability 1. Qualification Approval and Standardization of Electronic Components, 2. Qualification Approval and Standardization of Electromechanical and Mechanical Components, PCBs & Raw Materials 3. Vendor Development and Vendor Rating 4. Corporate Standards 5. Reliability Engineering Laboratory 6. Component Testing Laboratory 3

Corporate QA Organisation Chart 4

Corporate QA Organisation Chart 4

Quality System …. details -1 1. Corporate QA played a key role in bringing up the Plants to meet the ISO 9000 requirements through training, document preparation, auditing and other activities and enabled the Units to get ISO 9000 Certification with out engaging any external consultants. Trained and experienced Manpower of Corporate QA was well utilised for this purpose. 2. Providing training to Plant Personnel whenever the ISO 9001 standard is revised to enable Plants to align with the new requirements. 5

Quality System …. details -1 1. Corporate QA played a key role in bringing up the Plants to meet the ISO 9000 requirements through training, document preparation, auditing and other activities and enabled the Units to get ISO 9000 Certification with out engaging any external consultants. Trained and experienced Manpower of Corporate QA was well utilised for this purpose. 2. Providing training to Plant Personnel whenever the ISO 9001 standard is revised to enable Plants to align with the new requirements. 5

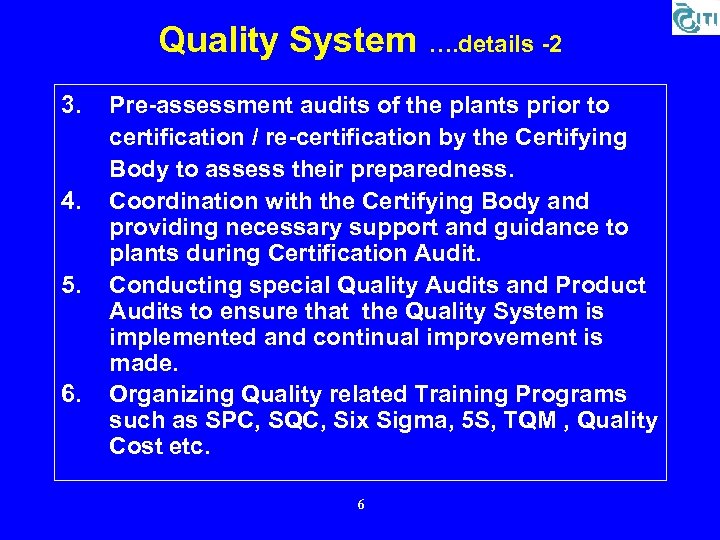

Quality System …. details -2 3. 4. 5. 6. Pre-assessment audits of the plants prior to certification / re-certification by the Certifying Body to assess their preparedness. Coordination with the Certifying Body and providing necessary support and guidance to plants during Certification Audit. Conducting special Quality Audits and Product Audits to ensure that the Quality System is implemented and continual improvement is made. Organizing Quality related Training Programs such as SPC, SQC, Six Sigma, 5 S, TQM , Quality Cost etc. 6

Quality System …. details -2 3. 4. 5. 6. Pre-assessment audits of the plants prior to certification / re-certification by the Certifying Body to assess their preparedness. Coordination with the Certifying Body and providing necessary support and guidance to plants during Certification Audit. Conducting special Quality Audits and Product Audits to ensure that the Quality System is implemented and continual improvement is made. Organizing Quality related Training Programs such as SPC, SQC, Six Sigma, 5 S, TQM , Quality Cost etc. 6

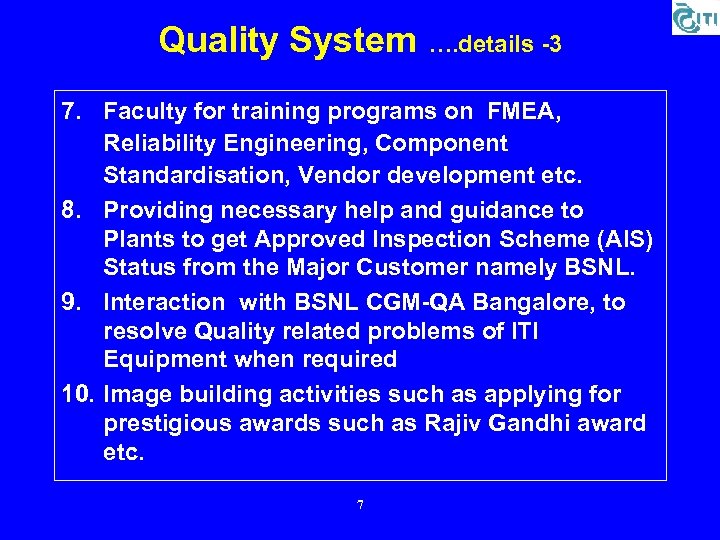

Quality System …. details -3 7. Faculty for training programs on FMEA, Reliability Engineering, Component Standardisation, Vendor development etc. 8. Providing necessary help and guidance to Plants to get Approved Inspection Scheme (AIS) Status from the Major Customer namely BSNL. 9. Interaction with BSNL CGM-QA Bangalore, to resolve Quality related problems of ITI Equipment when required 10. Image building activities such as applying for prestigious awards such as Rajiv Gandhi award etc. 7

Quality System …. details -3 7. Faculty for training programs on FMEA, Reliability Engineering, Component Standardisation, Vendor development etc. 8. Providing necessary help and guidance to Plants to get Approved Inspection Scheme (AIS) Status from the Major Customer namely BSNL. 9. Interaction with BSNL CGM-QA Bangalore, to resolve Quality related problems of ITI Equipment when required 10. Image building activities such as applying for prestigious awards such as Rajiv Gandhi award etc. 7

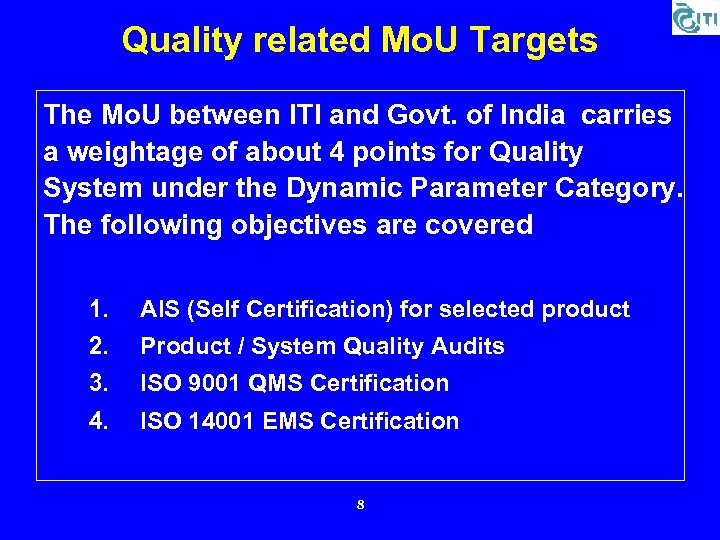

Quality related Mo. U Targets The Mo. U between ITI and Govt. of India carries a weightage of about 4 points for Quality System under the Dynamic Parameter Category. The following objectives are covered 1. AIS (Self Certification) for selected product 2. Product / System Quality Audits 3. ISO 9001 QMS Certification 4. ISO 14001 EMS Certification 8

Quality related Mo. U Targets The Mo. U between ITI and Govt. of India carries a weightage of about 4 points for Quality System under the Dynamic Parameter Category. The following objectives are covered 1. AIS (Self Certification) for selected product 2. Product / System Quality Audits 3. ISO 9001 QMS Certification 4. ISO 14001 EMS Certification 8

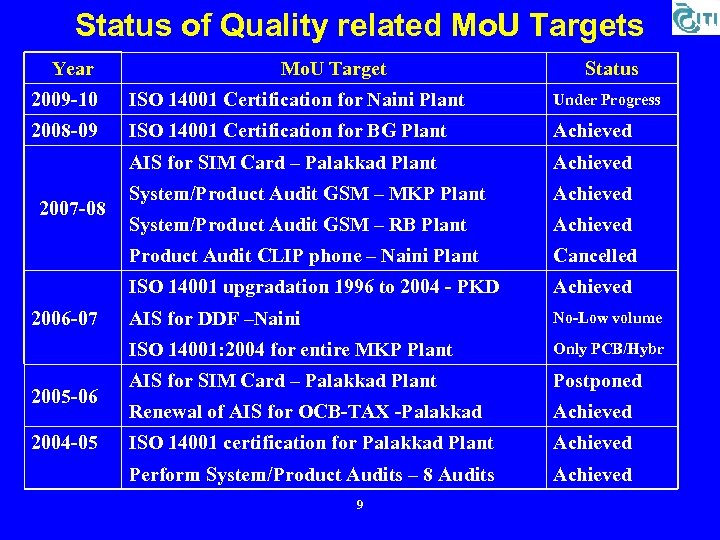

Status of Quality related Mo. U Targets Year Mo. U Target Status 2009 -10 ISO 14001 Certification for Naini Plant Under Progress 2008 -09 ISO 14001 Certification for BG Plant Achieved AIS for SIM Card – Palakkad Plant Achieved System/Product Audit GSM – MKP Plant Achieved System/Product Audit GSM – RB Plant Achieved Product Audit CLIP phone – Naini Plant Cancelled ISO 14001 upgradation 1996 to 2004 - PKD Achieved AIS for DDF –Naini No-Low volume ISO 14001: 2004 for entire MKP Plant Only PCB/Hybr AIS for SIM Card – Palakkad Plant Postponed Renewal of AIS for OCB-TAX -Palakkad Achieved ISO 14001 certification for Palakkad Plant Achieved Perform System/Product Audits – 8 Audits Achieved 2007 -08 2006 -07 2005 -06 2004 -05 9

Status of Quality related Mo. U Targets Year Mo. U Target Status 2009 -10 ISO 14001 Certification for Naini Plant Under Progress 2008 -09 ISO 14001 Certification for BG Plant Achieved AIS for SIM Card – Palakkad Plant Achieved System/Product Audit GSM – MKP Plant Achieved System/Product Audit GSM – RB Plant Achieved Product Audit CLIP phone – Naini Plant Cancelled ISO 14001 upgradation 1996 to 2004 - PKD Achieved AIS for DDF –Naini No-Low volume ISO 14001: 2004 for entire MKP Plant Only PCB/Hybr AIS for SIM Card – Palakkad Plant Postponed Renewal of AIS for OCB-TAX -Palakkad Achieved ISO 14001 certification for Palakkad Plant Achieved Perform System/Product Audits – 8 Audits Achieved 2007 -08 2006 -07 2005 -06 2004 -05 9

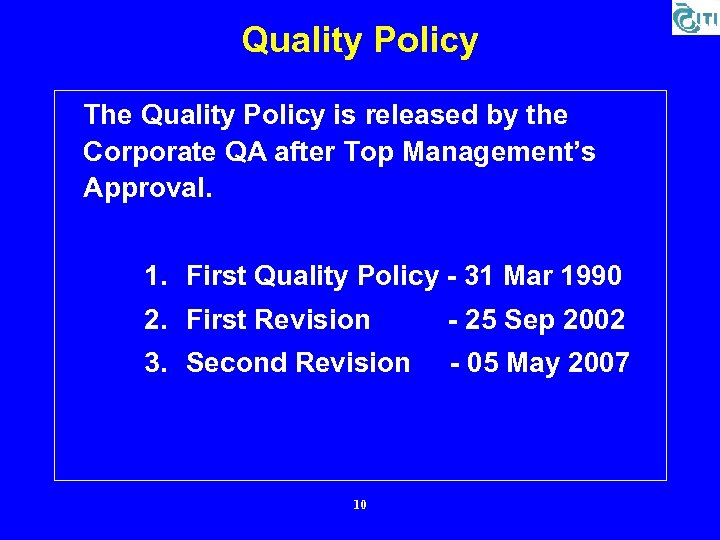

Quality Policy The Quality Policy is released by the Corporate QA after Top Management’s Approval. 1. First Quality Policy - 31 Mar 1990 2. First Revision - 25 Sep 2002 3. Second Revision - 05 May 2007 10

Quality Policy The Quality Policy is released by the Corporate QA after Top Management’s Approval. 1. First Quality Policy - 31 Mar 1990 2. First Revision - 25 Sep 2002 3. Second Revision - 05 May 2007 10

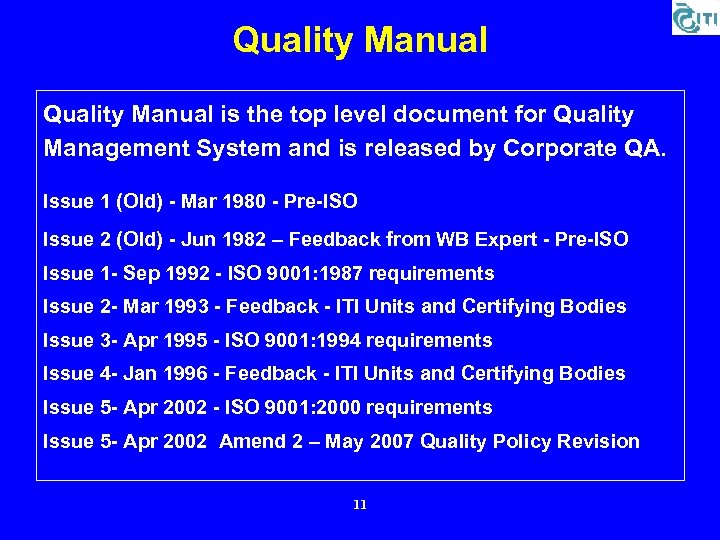

Quality Manual is the top level document for Quality Management System and is released by Corporate QA. Issue 1 (Old) - Mar 1980 - Pre-ISO Issue 2 (Old) - Jun 1982 – Feedback from WB Expert - Pre-ISO Issue 1 - Sep 1992 - ISO 9001: 1987 requirements Issue 2 - Mar 1993 - Feedback - ITI Units and Certifying Bodies Issue 3 - Apr 1995 - ISO 9001: 1994 requirements Issue 4 - Jan 1996 - Feedback - ITI Units and Certifying Bodies Issue 5 - Apr 2002 - ISO 9001: 2000 requirements Issue 5 - Apr 2002 Amend 2 – May 2007 Quality Policy Revision 11

Quality Manual is the top level document for Quality Management System and is released by Corporate QA. Issue 1 (Old) - Mar 1980 - Pre-ISO Issue 2 (Old) - Jun 1982 – Feedback from WB Expert - Pre-ISO Issue 1 - Sep 1992 - ISO 9001: 1987 requirements Issue 2 - Mar 1993 - Feedback - ITI Units and Certifying Bodies Issue 3 - Apr 1995 - ISO 9001: 1994 requirements Issue 4 - Jan 1996 - Feedback - ITI Units and Certifying Bodies Issue 5 - Apr 2002 - ISO 9001: 2000 requirements Issue 5 - Apr 2002 Amend 2 – May 2007 Quality Policy Revision 11

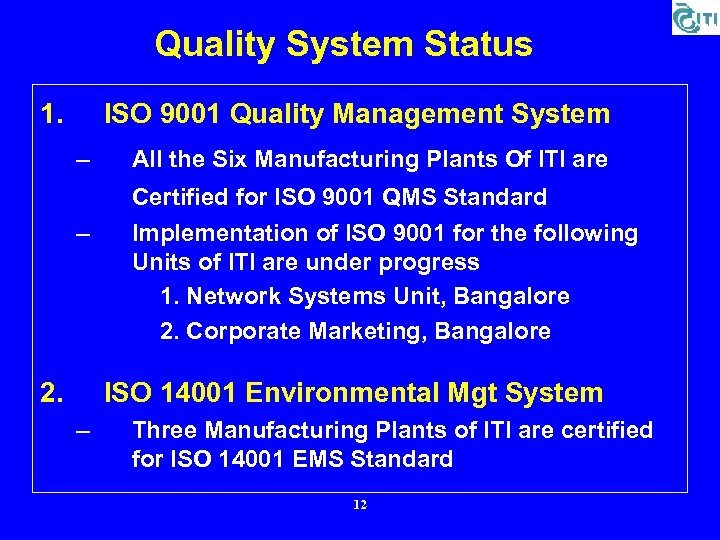

Quality System Status 1. ISO 9001 Quality Management System – All the Six Manufacturing Plants Of ITI are Certified for ISO 9001 QMS Standard – 2. Implementation of ISO 9001 for the following Units of ITI are under progress 1. Network Systems Unit, Bangalore 2. Corporate Marketing, Bangalore ISO 14001 Environmental Mgt System – Three Manufacturing Plants of ITI are certified for ISO 14001 EMS Standard 12

Quality System Status 1. ISO 9001 Quality Management System – All the Six Manufacturing Plants Of ITI are Certified for ISO 9001 QMS Standard – 2. Implementation of ISO 9001 for the following Units of ITI are under progress 1. Network Systems Unit, Bangalore 2. Corporate Marketing, Bangalore ISO 14001 Environmental Mgt System – Three Manufacturing Plants of ITI are certified for ISO 14001 EMS Standard 12

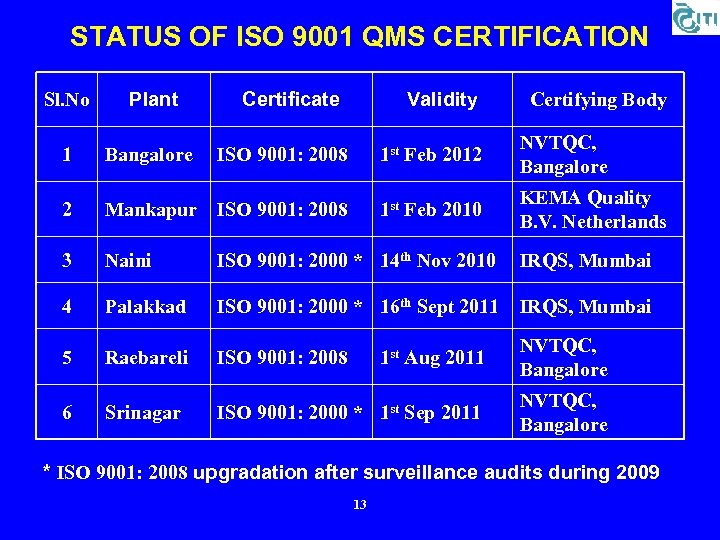

STATUS OF ISO 9001 QMS CERTIFICATION Sl. No Plant Certificate Validity 1 Bangalore ISO 9001: 2008 1 st Feb 2012 NVTQC, Bangalore 2 Mankapur ISO 9001: 2008 1 st Feb 2010 KEMA Quality B. V. Netherlands 3 Naini ISO 9001: 2000 * 14 th Nov 2010 IRQS, Mumbai 4 Palakkad ISO 9001: 2000 * 16 th Sept 2011 IRQS, Mumbai 5 Raebareli ISO 9001: 2008 1 st Aug 2011 NVTQC, Bangalore 6 Srinagar ISO 9001: 2000 * 1 st Sep 2011 NVTQC, Bangalore Certifying Body * ISO 9001: 2008 upgradation after surveillance audits during 2009 13

STATUS OF ISO 9001 QMS CERTIFICATION Sl. No Plant Certificate Validity 1 Bangalore ISO 9001: 2008 1 st Feb 2012 NVTQC, Bangalore 2 Mankapur ISO 9001: 2008 1 st Feb 2010 KEMA Quality B. V. Netherlands 3 Naini ISO 9001: 2000 * 14 th Nov 2010 IRQS, Mumbai 4 Palakkad ISO 9001: 2000 * 16 th Sept 2011 IRQS, Mumbai 5 Raebareli ISO 9001: 2008 1 st Aug 2011 NVTQC, Bangalore 6 Srinagar ISO 9001: 2000 * 1 st Sep 2011 NVTQC, Bangalore Certifying Body * ISO 9001: 2008 upgradation after surveillance audits during 2009 13

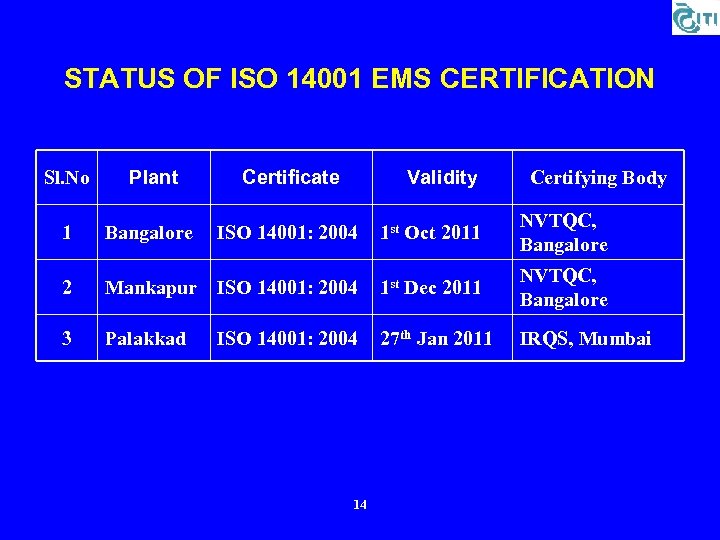

STATUS OF ISO 14001 EMS CERTIFICATION Sl. No Plant Certificate Validity 1 Bangalore ISO 14001: 2004 1 st Oct 2011 NVTQC, Bangalore 2 Mankapur ISO 14001: 2004 1 st Dec 2011 NVTQC, Bangalore 3 Palakkad ISO 14001: 2004 27 th Jan 2011 IRQS, Mumbai 14 Certifying Body

STATUS OF ISO 14001 EMS CERTIFICATION Sl. No Plant Certificate Validity 1 Bangalore ISO 14001: 2004 1 st Oct 2011 NVTQC, Bangalore 2 Mankapur ISO 14001: 2004 1 st Dec 2011 NVTQC, Bangalore 3 Palakkad ISO 14001: 2004 27 th Jan 2011 IRQS, Mumbai 14 Certifying Body

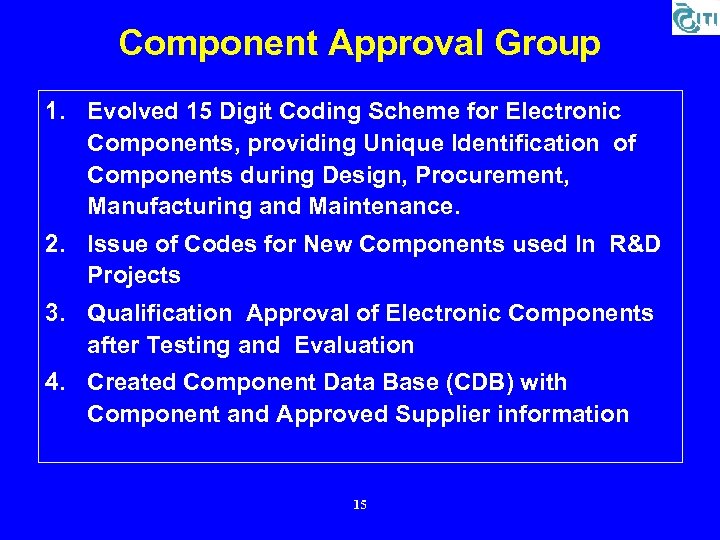

Component Approval Group 1. Evolved 15 Digit Coding Scheme for Electronic Components, providing Unique Identification of Components during Design, Procurement, Manufacturing and Maintenance. 2. Issue of Codes for New Components used In R&D Projects 3. Qualification Approval of Electronic Components after Testing and Evaluation 4. Created Component Data Base (CDB) with Component and Approved Supplier information 15

Component Approval Group 1. Evolved 15 Digit Coding Scheme for Electronic Components, providing Unique Identification of Components during Design, Procurement, Manufacturing and Maintenance. 2. Issue of Codes for New Components used In R&D Projects 3. Qualification Approval of Electronic Components after Testing and Evaluation 4. Created Component Data Base (CDB) with Component and Approved Supplier information 15

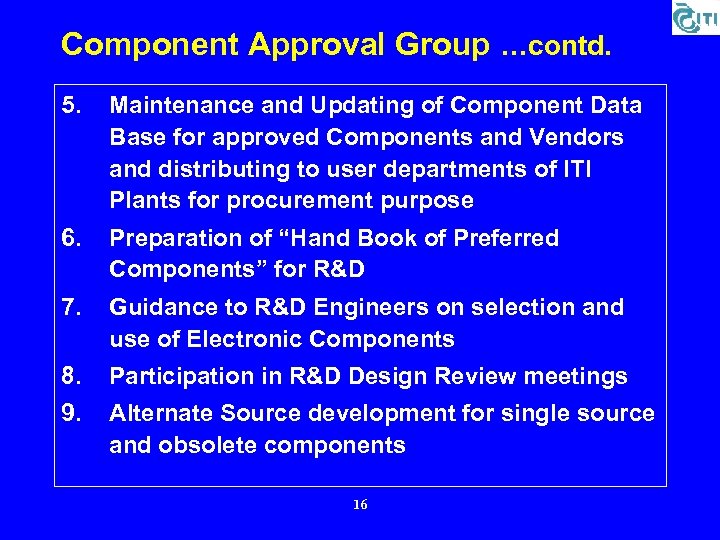

Component Approval Group …contd. 5. Maintenance and Updating of Component Data Base for approved Components and Vendors and distributing to user departments of ITI Plants for procurement purpose 6. Preparation of “Hand Book of Preferred Components” for R&D 7. Guidance to R&D Engineers on selection and use of Electronic Components 8. Participation in R&D Design Review meetings 9. Alternate Source development for single source and obsolete components 16

Component Approval Group …contd. 5. Maintenance and Updating of Component Data Base for approved Components and Vendors and distributing to user departments of ITI Plants for procurement purpose 6. Preparation of “Hand Book of Preferred Components” for R&D 7. Guidance to R&D Engineers on selection and use of Electronic Components 8. Participation in R&D Design Review meetings 9. Alternate Source development for single source and obsolete components 16

Component Approval Group …contd… 2 10. Identification of equivalent ITI Codes for Components used in To. T Projects to utilise surplus inventory and avoid production bottlenecks. 11. Interaction with CACT, BSNL QA, Bangalore for approval of components after testing the components at ITI labs. (Bangalore / Naini). 12. Participation in LCSO (Electronic Components Standardization Organization) and BIS panel / committee meetings for Defence and non. Defence Component Standardization 17

Component Approval Group …contd… 2 10. Identification of equivalent ITI Codes for Components used in To. T Projects to utilise surplus inventory and avoid production bottlenecks. 11. Interaction with CACT, BSNL QA, Bangalore for approval of components after testing the components at ITI labs. (Bangalore / Naini). 12. Participation in LCSO (Electronic Components Standardization Organization) and BIS panel / committee meetings for Defence and non. Defence Component Standardization 17

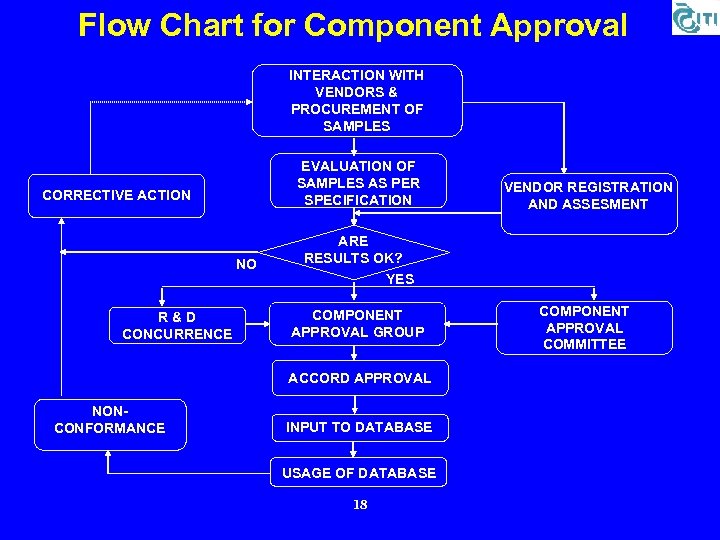

Flow Chart for Component Approval INTERACTION WITH VENDORS & PROCUREMENT OF SAMPLES EVALUATION OF SAMPLES AS PER SPECIFICATION CORRECTIVE ACTION NO R&D CONCURRENCE ARE RESULTS OK? YES COMPONENT APPROVAL GROUP ACCORD APPROVAL NONCONFORMANCE VENDOR REGISTRATION AND ASSESMENT INPUT TO DATABASE USAGE OF DATABASE 18 COMPONENT APPROVAL COMMITTEE

Flow Chart for Component Approval INTERACTION WITH VENDORS & PROCUREMENT OF SAMPLES EVALUATION OF SAMPLES AS PER SPECIFICATION CORRECTIVE ACTION NO R&D CONCURRENCE ARE RESULTS OK? YES COMPONENT APPROVAL GROUP ACCORD APPROVAL NONCONFORMANCE VENDOR REGISTRATION AND ASSESMENT INPUT TO DATABASE USAGE OF DATABASE 18 COMPONENT APPROVAL COMMITTEE

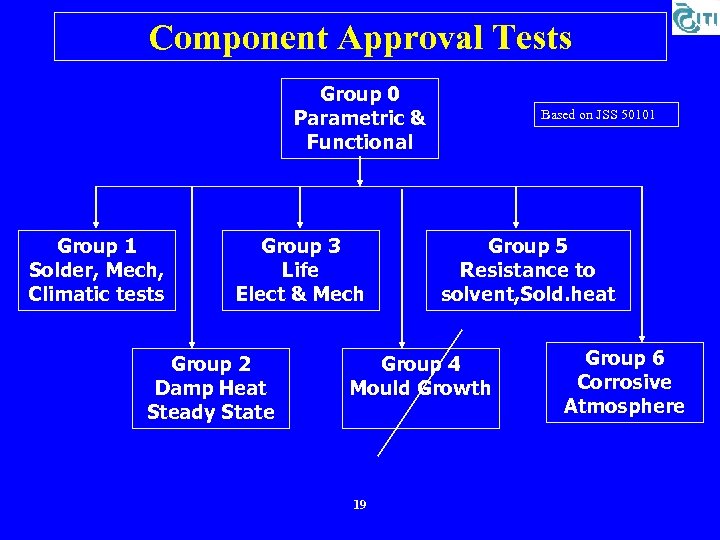

Component Approval Tests Group 0 Parametric & Functional Group 1 Solder, Mech, Climatic tests Group 3 Life Elect & Mech Group 2 Damp Heat Steady State Based on JSS 50101 Group 5 Resistance to solvent, Sold. heat Group 4 Mould Growth 19 Group 6 Corrosive Atmosphere

Component Approval Tests Group 0 Parametric & Functional Group 1 Solder, Mech, Climatic tests Group 3 Life Elect & Mech Group 2 Damp Heat Steady State Based on JSS 50101 Group 5 Resistance to solvent, Sold. heat Group 4 Mould Growth 19 Group 6 Corrosive Atmosphere

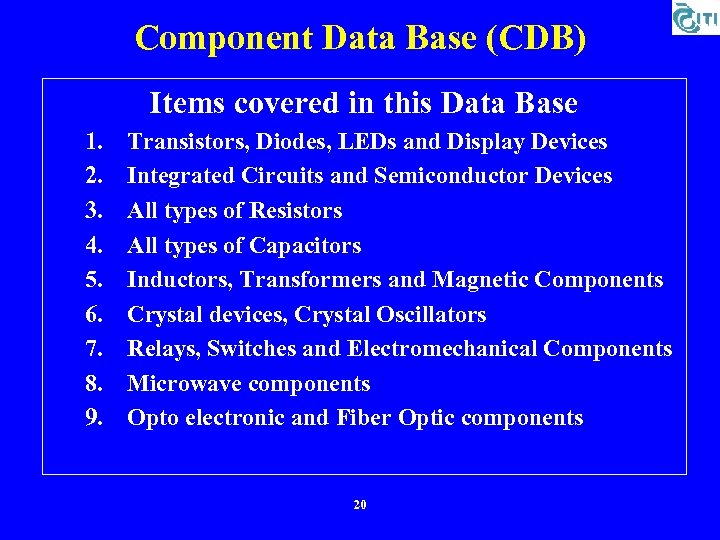

Component Data Base (CDB) Items covered in this Data Base 1. 2. 3. 4. 5. 6. 7. 8. 9. Transistors, Diodes, LEDs and Display Devices Integrated Circuits and Semiconductor Devices All types of Resistors All types of Capacitors Inductors, Transformers and Magnetic Components Crystal devices, Crystal Oscillators Relays, Switches and Electromechanical Components Microwave components Opto electronic and Fiber Optic components 20

Component Data Base (CDB) Items covered in this Data Base 1. 2. 3. 4. 5. 6. 7. 8. 9. Transistors, Diodes, LEDs and Display Devices Integrated Circuits and Semiconductor Devices All types of Resistors All types of Capacitors Inductors, Transformers and Magnetic Components Crystal devices, Crystal Oscillators Relays, Switches and Electromechanical Components Microwave components Opto electronic and Fiber Optic components 20

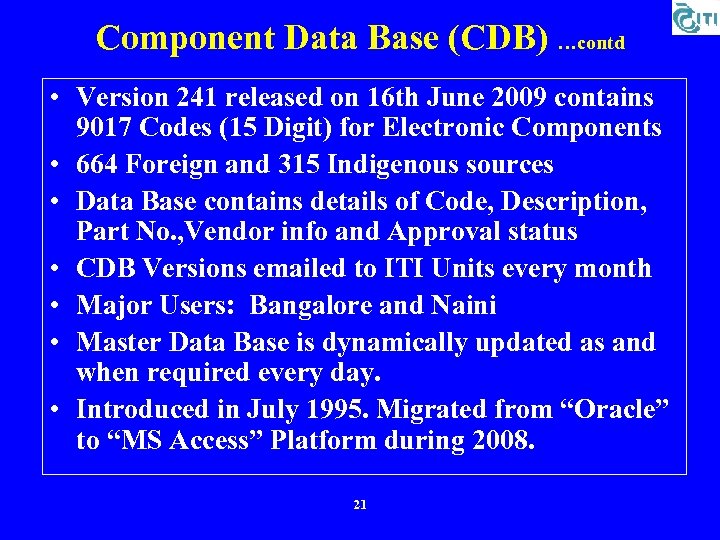

Component Data Base (CDB) …contd • Version 241 released on 16 th June 2009 contains 9017 Codes (15 Digit) for Electronic Components • 664 Foreign and 315 Indigenous sources • Data Base contains details of Code, Description, Part No. , Vendor info and Approval status • CDB Versions emailed to ITI Units every month • Major Users: Bangalore and Naini • Master Data Base is dynamically updated as and when required every day. • Introduced in July 1995. Migrated from “Oracle” to “MS Access” Platform during 2008. 21

Component Data Base (CDB) …contd • Version 241 released on 16 th June 2009 contains 9017 Codes (15 Digit) for Electronic Components • 664 Foreign and 315 Indigenous sources • Data Base contains details of Code, Description, Part No. , Vendor info and Approval status • CDB Versions emailed to ITI Units every month • Major Users: Bangalore and Naini • Master Data Base is dynamically updated as and when required every day. • Introduced in July 1995. Migrated from “Oracle” to “MS Access” Platform during 2008. 21

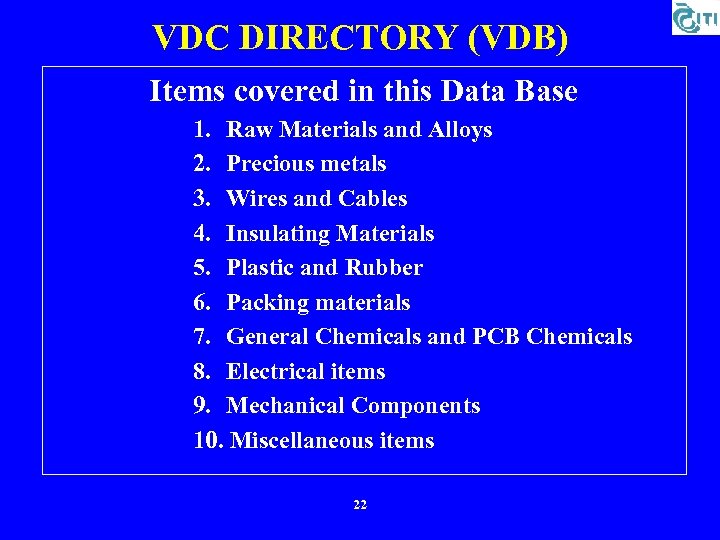

VDC DIRECTORY (VDB) Items covered in this Data Base 1. Raw Materials and Alloys 2. Precious metals 3. Wires and Cables 4. Insulating Materials 5. Plastic and Rubber 6. Packing materials 7. General Chemicals and PCB Chemicals 8. Electrical items 9. Mechanical Components 10. Miscellaneous items 22

VDC DIRECTORY (VDB) Items covered in this Data Base 1. Raw Materials and Alloys 2. Precious metals 3. Wires and Cables 4. Insulating Materials 5. Plastic and Rubber 6. Packing materials 7. General Chemicals and PCB Chemicals 8. Electrical items 9. Mechanical Components 10. Miscellaneous items 22

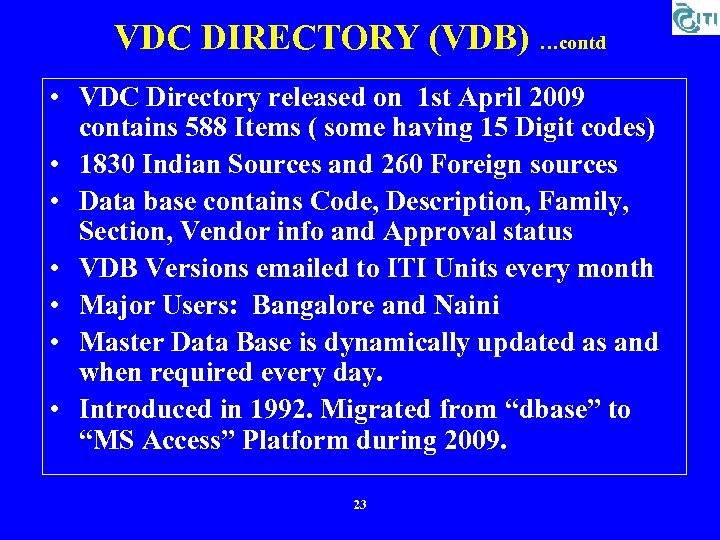

VDC DIRECTORY (VDB) …contd • VDC Directory released on 1 st April 2009 contains 588 Items ( some having 15 Digit codes) • 1830 Indian Sources and 260 Foreign sources • Data base contains Code, Description, Family, Section, Vendor info and Approval status • VDB Versions emailed to ITI Units every month • Major Users: Bangalore and Naini • Master Data Base is dynamically updated as and when required every day. • Introduced in 1992. Migrated from “dbase” to “MS Access” Platform during 2009. 23

VDC DIRECTORY (VDB) …contd • VDC Directory released on 1 st April 2009 contains 588 Items ( some having 15 Digit codes) • 1830 Indian Sources and 260 Foreign sources • Data base contains Code, Description, Family, Section, Vendor info and Approval status • VDB Versions emailed to ITI Units every month • Major Users: Bangalore and Naini • Master Data Base is dynamically updated as and when required every day. • Introduced in 1992. Migrated from “dbase” to “MS Access” Platform during 2009. 23

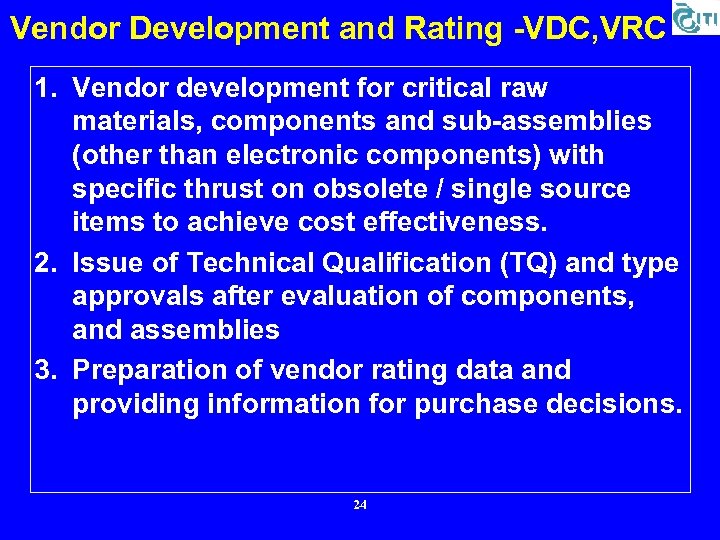

Vendor Development and Rating -VDC, VRC 1. Vendor development for critical raw materials, components and sub-assemblies (other than electronic components) with specific thrust on obsolete / single source items to achieve cost effectiveness. 2. Issue of Technical Qualification (TQ) and type approvals after evaluation of components, and assemblies 3. Preparation of vendor rating data and providing information for purchase decisions. 24

Vendor Development and Rating -VDC, VRC 1. Vendor development for critical raw materials, components and sub-assemblies (other than electronic components) with specific thrust on obsolete / single source items to achieve cost effectiveness. 2. Issue of Technical Qualification (TQ) and type approvals after evaluation of components, and assemblies 3. Preparation of vendor rating data and providing information for purchase decisions. 24

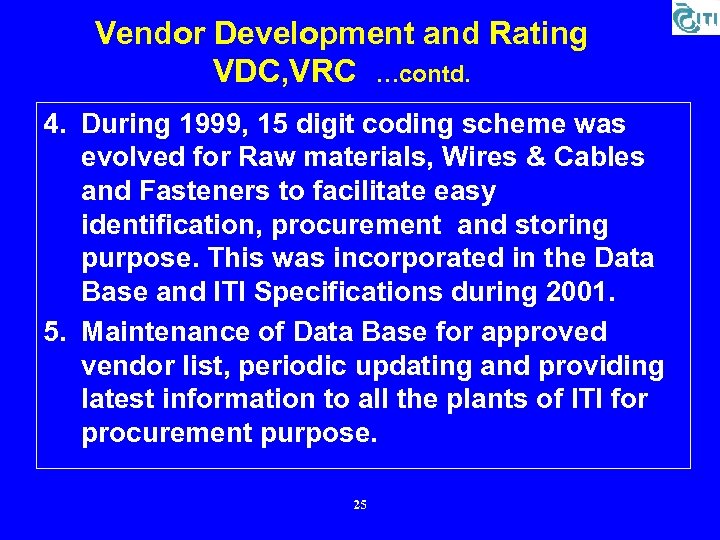

Vendor Development and Rating VDC, VRC …contd. 4. During 1999, 15 digit coding scheme was evolved for Raw materials, Wires & Cables and Fasteners to facilitate easy identification, procurement and storing purpose. This was incorporated in the Data Base and ITI Specifications during 2001. 5. Maintenance of Data Base for approved vendor list, periodic updating and providing latest information to all the plants of ITI for procurement purpose. 25

Vendor Development and Rating VDC, VRC …contd. 4. During 1999, 15 digit coding scheme was evolved for Raw materials, Wires & Cables and Fasteners to facilitate easy identification, procurement and storing purpose. This was incorporated in the Data Base and ITI Specifications during 2001. 5. Maintenance of Data Base for approved vendor list, periodic updating and providing latest information to all the plants of ITI for procurement purpose. 25

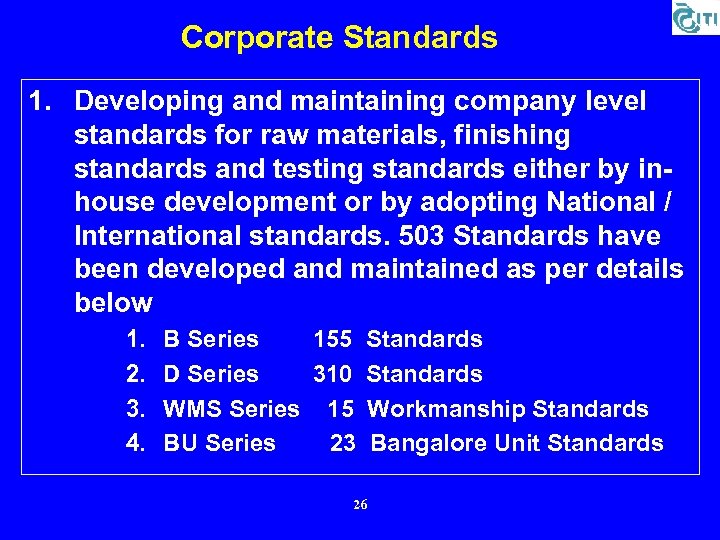

Corporate Standards 1. Developing and maintaining company level standards for raw materials, finishing standards and testing standards either by inhouse development or by adopting National / International standards. 503 Standards have been developed and maintained as per details below 1. 2. 3. 4. B Series 155 Standards D Series 310 Standards WMS Series 15 Workmanship Standards BU Series 23 Bangalore Unit Standards 26

Corporate Standards 1. Developing and maintaining company level standards for raw materials, finishing standards and testing standards either by inhouse development or by adopting National / International standards. 503 Standards have been developed and maintained as per details below 1. 2. 3. 4. B Series 155 Standards D Series 310 Standards WMS Series 15 Workmanship Standards BU Series 23 Bangalore Unit Standards 26

Corporate Standards …contd. 2. Participation with BIS ( Bureau of Indian Standards ) and contributing to formulate National standards. 3. Representation in BIS & LCSO committees 4. Liaison with BIS, LCSO, Corporate Standards of various organisations and other Standards bodies. 5. Inventory and Cost reduction through unification & variety rationalisation 6. Evolution, implementation and maintenance of uniform material codification system 27

Corporate Standards …contd. 2. Participation with BIS ( Bureau of Indian Standards ) and contributing to formulate National standards. 3. Representation in BIS & LCSO committees 4. Liaison with BIS, LCSO, Corporate Standards of various organisations and other Standards bodies. 5. Inventory and Cost reduction through unification & variety rationalisation 6. Evolution, implementation and maintenance of uniform material codification system 27

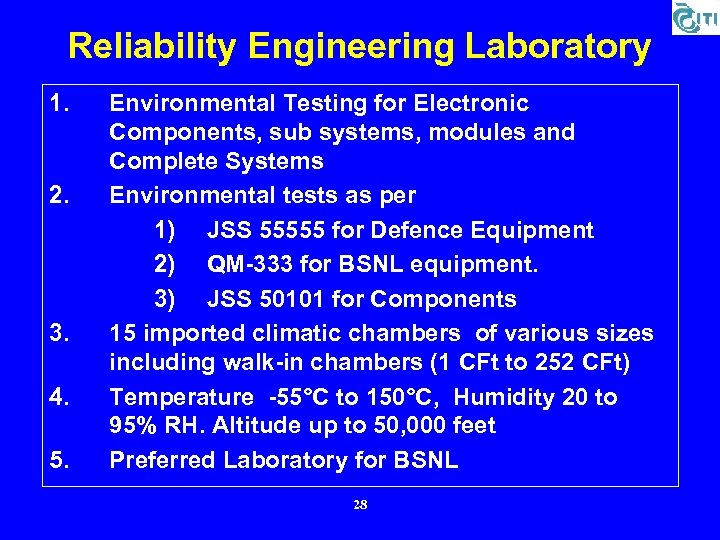

Reliability Engineering Laboratory 1. 2. 3. 4. 5. Environmental Testing for Electronic Components, sub systems, modules and Complete Systems Environmental tests as per 1) JSS 55555 for Defence Equipment 2) QM-333 for BSNL equipment. 3) JSS 50101 for Components 15 imported climatic chambers of various sizes including walk-in chambers (1 CFt to 252 CFt) Temperature -55°C to 150°C, Humidity 20 to 95% RH. Altitude up to 50, 000 feet Preferred Laboratory for BSNL 28

Reliability Engineering Laboratory 1. 2. 3. 4. 5. Environmental Testing for Electronic Components, sub systems, modules and Complete Systems Environmental tests as per 1) JSS 55555 for Defence Equipment 2) QM-333 for BSNL equipment. 3) JSS 50101 for Components 15 imported climatic chambers of various sizes including walk-in chambers (1 CFt to 252 CFt) Temperature -55°C to 150°C, Humidity 20 to 95% RH. Altitude up to 50, 000 feet Preferred Laboratory for BSNL 28

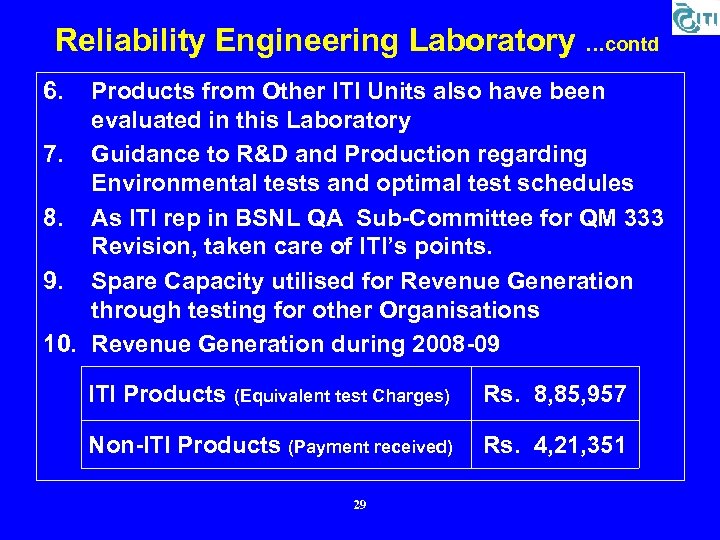

Reliability Engineering Laboratory …contd 6. Products from Other ITI Units also have been evaluated in this Laboratory 7. Guidance to R&D and Production regarding Environmental tests and optimal test schedules 8. As ITI rep in BSNL QA Sub-Committee for QM 333 Revision, taken care of ITI’s points. 9. Spare Capacity utilised for Revenue Generation through testing for other Organisations 10. Revenue Generation during 2008 -09 ITI Products (Equivalent test Charges) Rs. 8, 85, 957 Non-ITI Products (Payment received) Rs. 4, 21, 351 29

Reliability Engineering Laboratory …contd 6. Products from Other ITI Units also have been evaluated in this Laboratory 7. Guidance to R&D and Production regarding Environmental tests and optimal test schedules 8. As ITI rep in BSNL QA Sub-Committee for QM 333 Revision, taken care of ITI’s points. 9. Spare Capacity utilised for Revenue Generation through testing for other Organisations 10. Revenue Generation during 2008 -09 ITI Products (Equivalent test Charges) Rs. 8, 85, 957 Non-ITI Products (Payment received) Rs. 4, 21, 351 29

Reliability Prediction and Analysis 1. Reliability Prediction and Analysis is a contractual requirement of most of the BSNL and Defence Tenders. Railway customers are also insisting now. 2. Reliability Prediction Reports have been generated for most of the R&D products such as Microwave Systems, Line systems, Fiber Optic systems and Secrecy Equipment. 3. ASCON Phase 1 Network Availability calculations as per customer requirement. 4. More than 50 Reports have been generated from 1996 to Jan 2009 30

Reliability Prediction and Analysis 1. Reliability Prediction and Analysis is a contractual requirement of most of the BSNL and Defence Tenders. Railway customers are also insisting now. 2. Reliability Prediction Reports have been generated for most of the R&D products such as Microwave Systems, Line systems, Fiber Optic systems and Secrecy Equipment. 3. ASCON Phase 1 Network Availability calculations as per customer requirement. 4. More than 50 Reports have been generated from 1996 to Jan 2009 30

Component Testing Laboratory 1. This laboratory is equipped with a variety of test instruments, jigs and power supplies for testing and evaluation of electronic components such as resistors, capacitors, crystals, semiconductor devices, integrated circuits etc. 2. These instruments include digital LCR meter, Semiconductor Test System, Breakdown tester, Crystal test system, multi meters etc. 31

Component Testing Laboratory 1. This laboratory is equipped with a variety of test instruments, jigs and power supplies for testing and evaluation of electronic components such as resistors, capacitors, crystals, semiconductor devices, integrated circuits etc. 2. These instruments include digital LCR meter, Semiconductor Test System, Breakdown tester, Crystal test system, multi meters etc. 31

Indigenisation / Localisation activity Approval of items for Mankapur GSM-BTS Project Under localization activity for GSM-BTS Project, Evaluation Reports for 90 items comprising Connectors, Cable assembly and Cables, PCBs, Mechanical parts etc. were forwarded to ITI Mankapur Unit during the past three years. Out of this, only 70 items have been recommended by ITI for getting “Technical Qualification” (TQ) from M/s ALCATEL, France 32

Indigenisation / Localisation activity Approval of items for Mankapur GSM-BTS Project Under localization activity for GSM-BTS Project, Evaluation Reports for 90 items comprising Connectors, Cable assembly and Cables, PCBs, Mechanical parts etc. were forwarded to ITI Mankapur Unit during the past three years. Out of this, only 70 items have been recommended by ITI for getting “Technical Qualification” (TQ) from M/s ALCATEL, France 32