ec39f6c56c067e9cea27275a3ea4e999.ppt

- Количество слайдов: 27

CORPORATE PRESENTATION

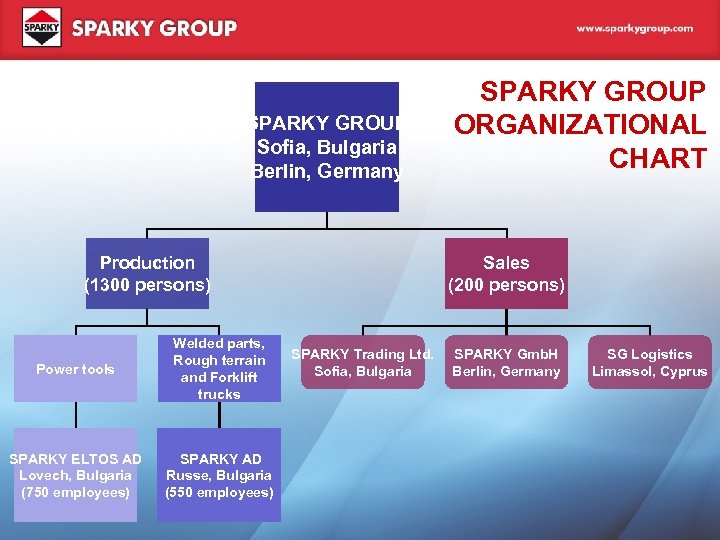

SPARKY GROUP Sofia, Bulgaria Berlin, Germany Sales (200 persons) Production (1300 persons) Power tools Welded parts, Rough terrain and Forklift trucks SPARKY ELTOS AD Lovech, Bulgaria (750 employees) SPARKY AD Russe, Bulgaria (550 employees) SPARKY GROUP ORGANIZATIONAL CHART SPARKY Trading Ltd. Sofia, Bulgaria SPARKY Gmb. H Berlin, Germany SG Logistics Limassol, Cyprus

THE FACTORIES SPARKY ELTOS AD manufacturing plant in Lovech, Bulgaria for production of power tools SPARKY AD Russe manufacturing plant in Russe, Bulgaria for production of welded parts, agricultural machines, backhoe loaders and rough terrain trucks

PRODUCTION SPARKY ELTOS AD R&D Engineering Plastic injection Manufacture of electric motors Manufacture of mechanical parts Metal heat treatment Manufacture of moulds and tooling Foundry for Al and Mg alloys Assembly Painting shop SPARKY AD RUSSE R&D Engineering Foundry for steel and cast iron Welding Metal heat treatment Forging Painting shop Assembly Control equipment

WHO ARE WE The brand name SPARKY The Markets EU countries, Eastern Europe, Middle East, Russia and CIS The Team Highly educated, well-trained staff with long experience in industrial production Continuous training and professional education

WHO ARE WE The Management Experience Crisis management End-user oriented corporate communication The Production Continuous expansion of the product ranges Constant renovation Investment in new technologies Environmental awareness

WHAT WE DO Production of professional power tools – SPARKY branded and in cooperation with other established producers of power tools Production of private label power tools Production of components for other companies (outsourcing) Assembly work for established producers of power tools and other products

WHAT WE DO Production of forgings, castings, welded and machined parts on a subcontracting basis for leading European and world manufacturers Production of forklift trucks and backhoe loaders for the East European and Russian markets Original Equipment Manufacturer (OEM) assembly

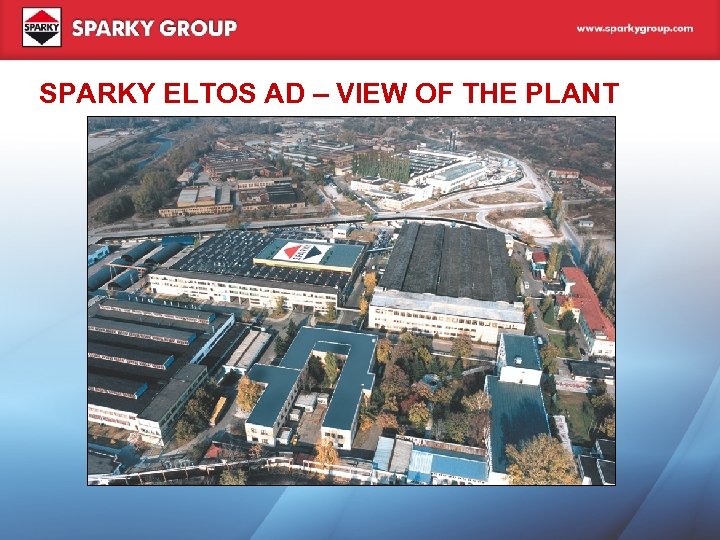

SPARKY ELTOS AD – VIEW OF THE PLANT

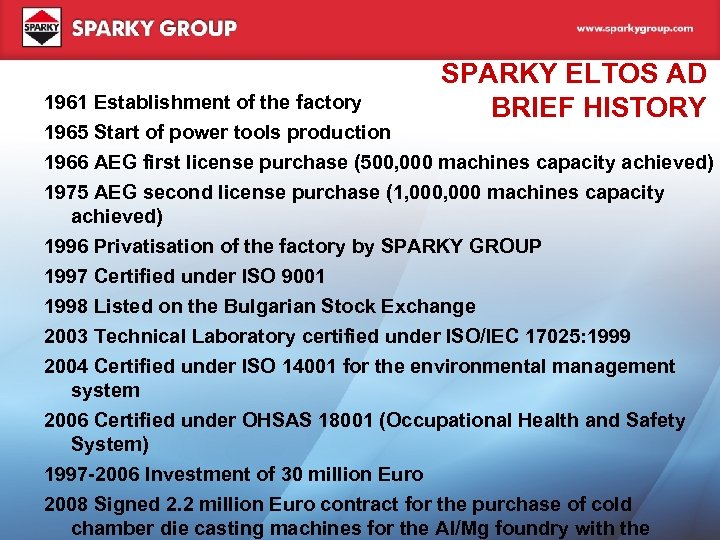

1961 Establishment of the factory 1965 Start of power tools production SPARKY ELTOS AD BRIEF HISTORY 1966 AEG first license purchase (500, 000 machines capacity achieved) 1975 AEG second license purchase (1, 000 machines capacity achieved) 1996 Privatisation of the factory by SPARKY GROUP 1997 Certified under ISO 9001 1998 Listed on the Bulgarian Stock Exchange 2003 Technical Laboratory certified under ISO/IEC 17025: 1999 2004 Certified under ISO 14001 for the environmental management system 2006 Certified under OHSAS 18001 (Occupational Health and Safety System) 1997 -2006 Investment of 30 million Euro 2008 Signed 2. 2 million Euro contract for the purchase of cold chamber die casting machines for the Al/Mg foundry with the

SPARKY ELTOS AD ACHIEVMENTS The biggest employer in the region One of the top selling power tools brands in Bulgaria and well known in Russia and CIS The product range includes more than 150 models and modifications

Certified production processes PRODUCTION 1997 ISO 9001 certification-certificate guarantees the quality of the manufacturing process and of the products. Products are certified by TÜV Rheinland conform the standards GS DIN CE. The components and the materials are supplied by: Albis, Ina, BASF, SKF, FAG, Thyssen, Shall, Marquardt, Capax, Pirelli, LFA, Röhm, Schunk, and other well reputed manufacturers 2004 ISO 14001 certification (established and applied environmental management system for development, production and maintenance of power tools and accessories) 2006 OHSAS 18001: 1999 certification (Occupational Health and Safety System ) -certificate is developed in response to urgent customer demand for a recognisable occupational health and safety management system standard. The emphasis is placed on practices being pro-active and preventive, by the identification of hazards and the evaluation and control of work related risks The Technical Laboratory is certified by the DUTCH ACCREDITATION COUNCIL Rv. A and complies with the accreditation criteria for test laboratories as laid down in ISO/IEC 17025: 1999

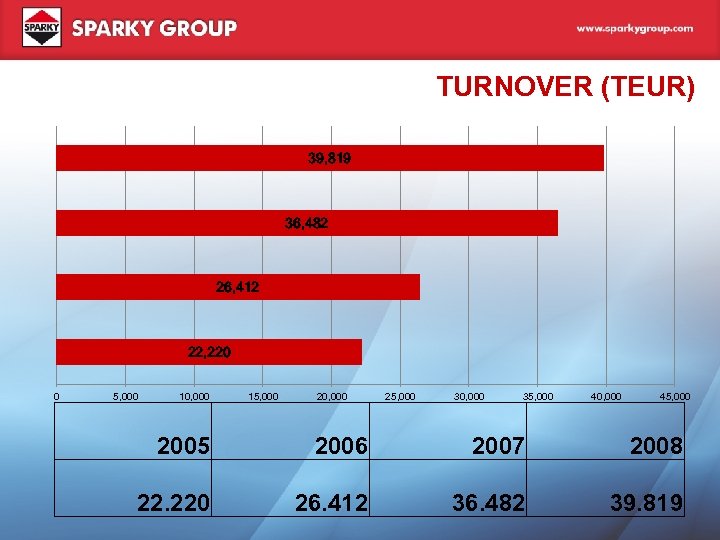

TURNOVER (TEUR) 39, 819 36, 482 26, 412 22, 220 0 5, 000 10, 000 15, 000 20, 000 25, 000 30, 000 35, 000 40, 000 45, 000 2005 2006 2007 2008 22. 220 26. 412 36. 482 39. 819

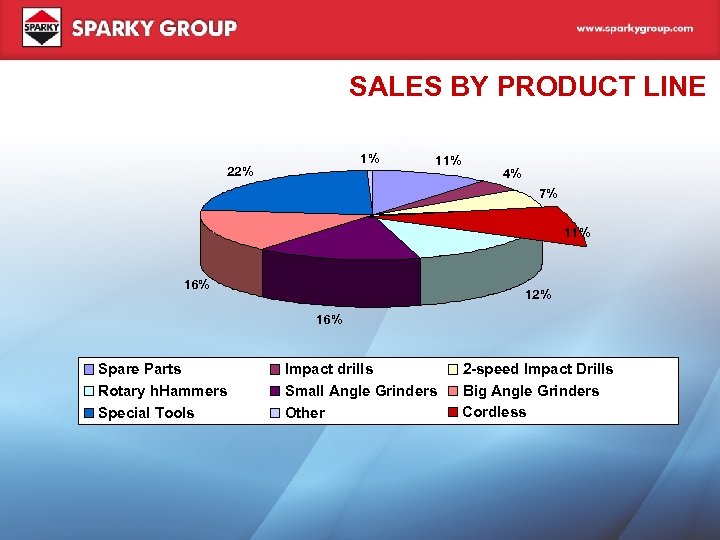

SALES BY PRODUCT LINE 1% 22% 11% 4% 7% 11% 16% 12% 16% Spare Parts Rotary h. Hammers Special Tools Impact drills Small Angle Grinders Other 2 -speed Impact Drills Big Angle Grinders Cordless

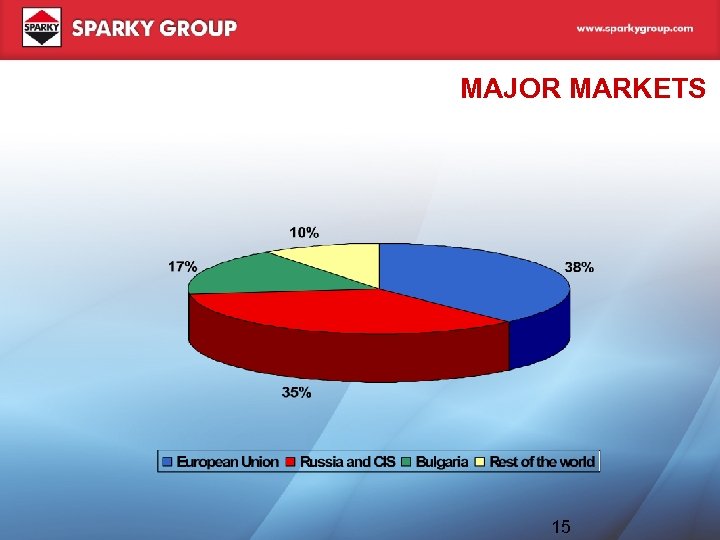

MAJOR MARKETS 15

POWER TOOLS PRODUCTION LINE

PRODUCTION OF COMPONENTS FOR RECOGNIZED MANUFACTURERS

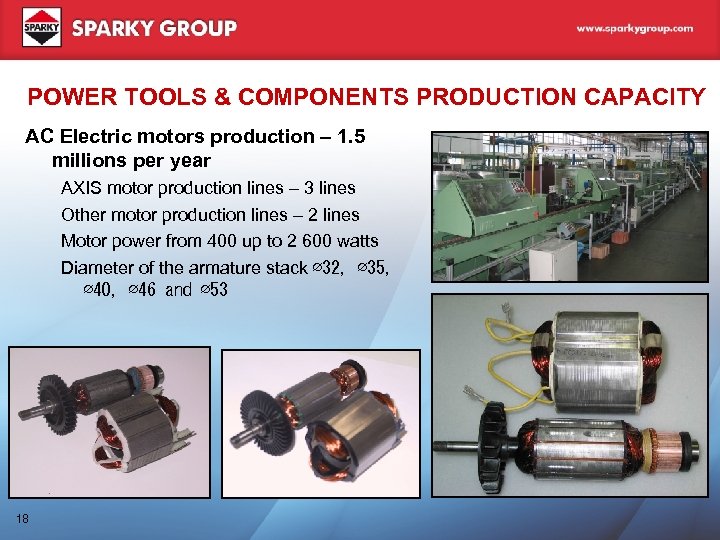

POWER TOOLS & COMPONENTS PRODUCTION CAPACITY AC Electric motors production – 1. 5 millions per year AXIS motor production lines – 3 lines Other motor production lines – 2 lines Motor power from 400 up to 2 600 watts Diameter of the armature stack ∅32, ∅35, ∅40, ∅46 and ∅53 18

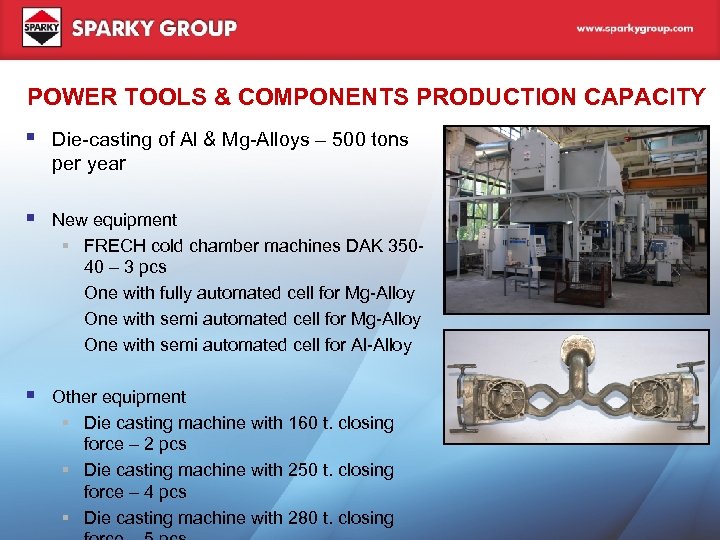

POWER TOOLS & COMPONENTS PRODUCTION CAPACITY Die-casting of Al & Mg-Alloys – 500 tons per year New equipment FRECH cold chamber machines DAK 35040 – 3 pcs One with fully automated cell for Mg-Alloy One with semi automated cell for Al-Alloy Other equipment Die casting machine with 160 t. closing force – 2 pcs Die casting machine with 250 t. closing force – 4 pcs Die casting machine with 280 t. closing

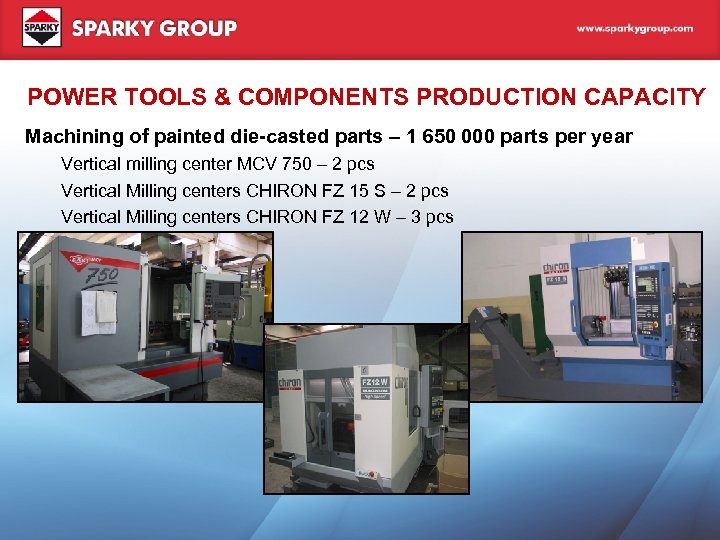

POWER TOOLS & COMPONENTS PRODUCTION CAPACITY Machining of painted die-casted parts – 1 650 000 parts per year Vertical milling center MCV 750 – 2 pcs Vertical Milling centers CHIRON FZ 15 S – 2 pcs Vertical Milling centers CHIRON FZ 12 W – 3 pcs

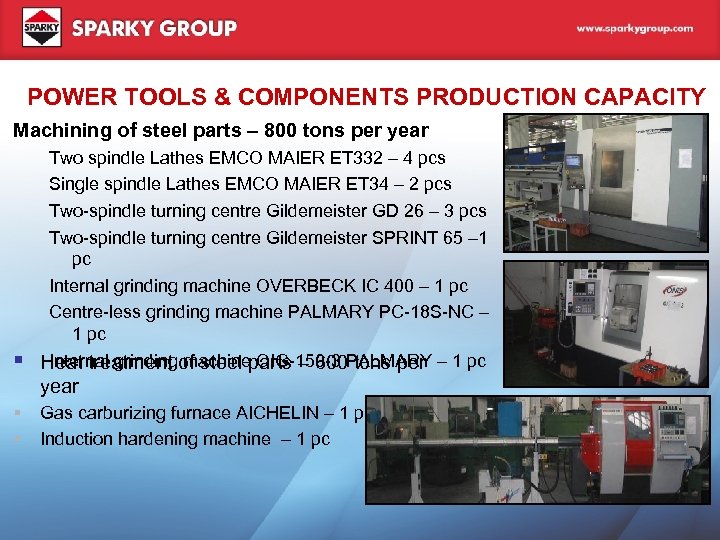

POWER TOOLS & COMPONENTS PRODUCTION CAPACITY Machining of steel parts – 800 tons per year Two spindle Lathes EMCO MAIER ЕТ 332 – 4 pcs Single spindle Lathes EMCO MAIER ЕТ 34 – 2 pcs Two-spindle turning centre Gildemeister GD 26 – 3 pcs Two-spindle turning centre Gildemeister SPRINT 65 – 1 pc Internal grinding machine OVERBECK IC 400 – 1 pc Centre-less grinding machine PALMARY PC-18 S-NC – 1 pc Internal grinding machine OIG-150 -3 tons per Heat treatment of steel parts – 600 PALMARY – 1 pc year Gas carburizing furnace AICHELIN – 1 pc Induction hardening machine – 1 pc

POWER TOOLS & COMPONENTS PRODUCTION CAPACITY Injection moulding of plastic parts – 550 tons per year Injection moulding machine BILLION H 1925/300 & H 2000/320 – 3 pcs Injection moulding machine ENGEL ES 1300/275 & ENGEL ES 700/175 – 5 pcs Injection moulding machine MAFFEI 40, SP 160 C 1 & MAFFEI 80, SP 390 C 2 – 2 pcs Injection moulding machine HAITIAN HTF 86 X & HTF 160 X & HTF 250 – 5 pcs

POWER TOOLS & COMPONENTS PRODUCTION CAPACITY Powder paint shop - 2 200 000 parts per year Conveyor powder paint installation for Steel, Al and Mg-Alloy part

QUALITY ASSURANCE Measurement and control equipment MEASURING CENTRE WITH THREAD MEASUREMENT MECHANISM MICRO HARDNESS DOUBLE FLANK GEAR ROLLING TESTER INSPECTION MACHINE 3 -AXIS COORDINATE MEASUREMENT MACHINE

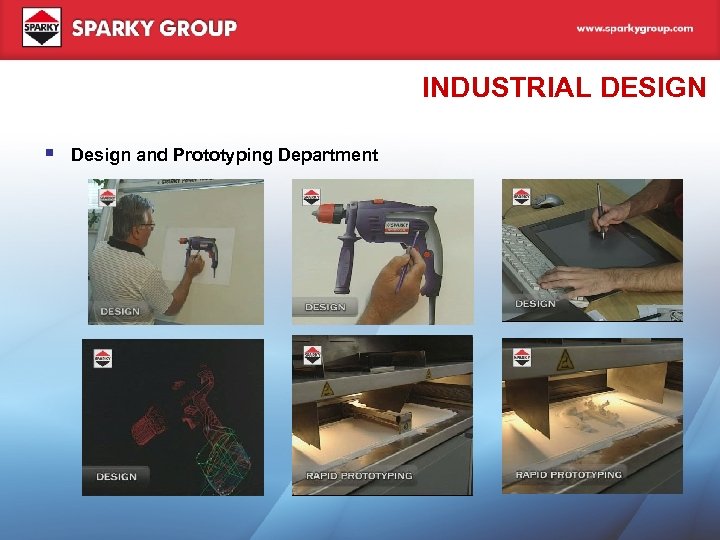

INDUSTRIAL DESIGN Design and Prototyping Department

HEAD OFFICE -BERLIN, GERMANY SPARKY Power Tools Gmb. H 20, Leipziger Strasse 10117 Berlin, Germany Tel. : +49 30 203916 -0 Fax: +49 30 203916 -66 OFFICE SOFIA, BULGARIA EXLUSIVE EXCLUSIVE REPRESENTATIVE OF SPARKY GROUP FOR FRANCE INTRADEQ 33, Avenue Du Gros Chêne, BP 70118 HERBLAY, 95613 CERGYPONTOISE CEDEX, FRANCE Tel. + 33 (0)1 30 37 47 47 Fax + 33 (0)1 30 37 52 14 e-mail: intradeq@intradeq. com SPARKY Trading Ltd. 1220 Sofia, Bulgaria 18 Parva Balgarska Armia Blvd. Tel. : + 359 (2) 9320 500 E-mail: info@sparkygroup. com Fax: + 359 (2) 9320 510 WWW. SPARKYGROUP. COM

THANK YOU AND SEE YOU SOON

ec39f6c56c067e9cea27275a3ea4e999.ppt