f005fd603ecdcd66e573977673ff845f.ppt

- Количество слайдов: 16

Copyright @2009, Novomet

BOOSTER PUMPING SYSTEM Copyright @2009, Novomet

Application: Pressure increase in the pipeline with operating capacity up to 25 000 BPD from 60 -160 kg/cm to max 300 kg/cm 2 Copyright @2009, Novomet

Agenda: 1. Pit version of booster pumping system 2. Horizontal booster pumping system 3. Benefits of horizontal booster pumping system 4. Features of horizontal booster pumping system 5. Penetrator, motor, seal features 6. Case study: first horizontal booster pumping system NR 2000 at Surgutneftegas

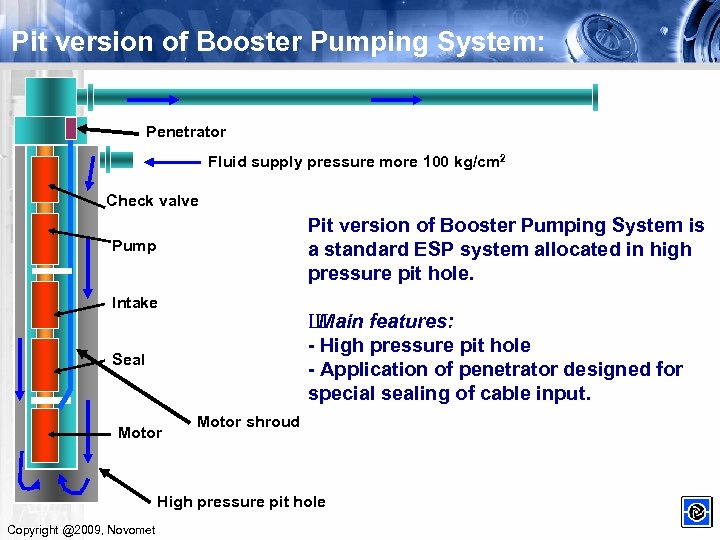

Pit version of Booster Pumping System: Penetrator Fluid supply pressure more 100 kg/cm 2 Check valve Pit version of Booster Pumping System is a standard ESP system allocated in high pressure pit hole. Pump Intake Ш Main features: - High pressure pit hole - Application of penetrator designed for special sealing of cable input. Seal Motor shroud High pressure pit hole Copyright @2009, Novomet

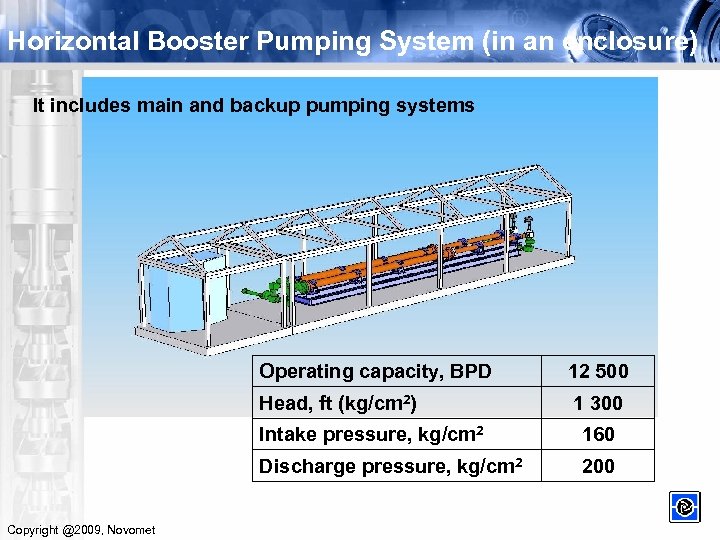

Horizontal Booster Pumping System (in an enclosure) It includes main and backup pumping systems Operating capacity, BPD 12 500 Head, ft (kg/cm 2) 1 300 Intake pressure, kg/cm 2 Discharge pressure, kg/cm 2 Copyright @2009, Novomet 160 200

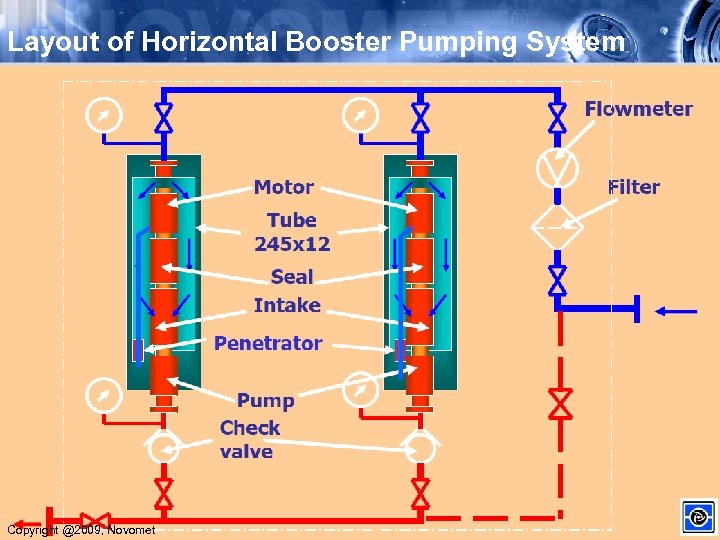

Layout of Horizontal Booster Pumping System Copyright @2009, Novomet

Benefits of Horizontal Booster pumping system 1. Easy in delivery due to modular construction 2. Easy installation, repair and maintenance 3. Maximum level of technical process monitoring 4. Reduction of down time due to backup equipment availability Copyright @2009, Novomet

Features of Horizontal Booster Pumping system 1. Fluid gets inside high pressure horizontal pipe where motor, seal and intake are situated. 2. Easy repair and maintenance are achieved due to pump location outside the pipe. 3. Horizontal assembly of motor, seal and intake, vertical filling of oil and test running of seal and motor. 4. Penetrator is used for lead-in of power cable in high pressure pipe. 5. Supply pipeline includes filters and flowmeters to treat and measure fluid 6. Automation control of operation due to presence of various regulating valves with electric drives Copyright @2009, Novomet

Features of Horizontal Booster Pumping system 7. Microclimate system provides the most comfortable operation conditions for equipment and service personnel. 8. System hoisting gears allow to provide assembly and disassembly without outside lifting devices. 9. Switchboard ensures automated operation of booster pumping system. 10. Remote control system allows to run the station from the required distance with overall control of system units. 11. To use all technical functions of system it is required to provide technological pipelines, power cable and cables of automatic systems. Copyright @2009, Novomet

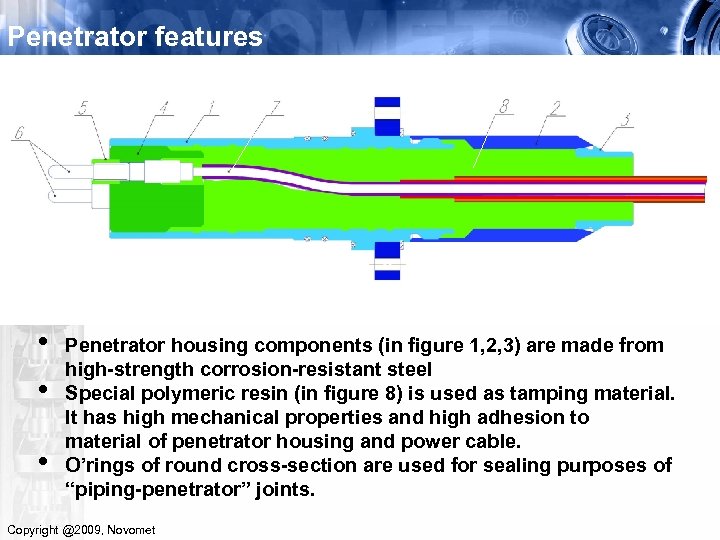

Penetrator features • • • Penetrator housing components (in figure 1, 2, 3) are made from high-strength corrosion-resistant steel Special polymeric resin (in figure 8) is used as tamping material. It has high mechanical properties and high adhesion to material of penetrator housing and power cable. O’rings of round cross-section are used for sealing purposes of “piping-penetrator” joints. Copyright @2009, Novomet

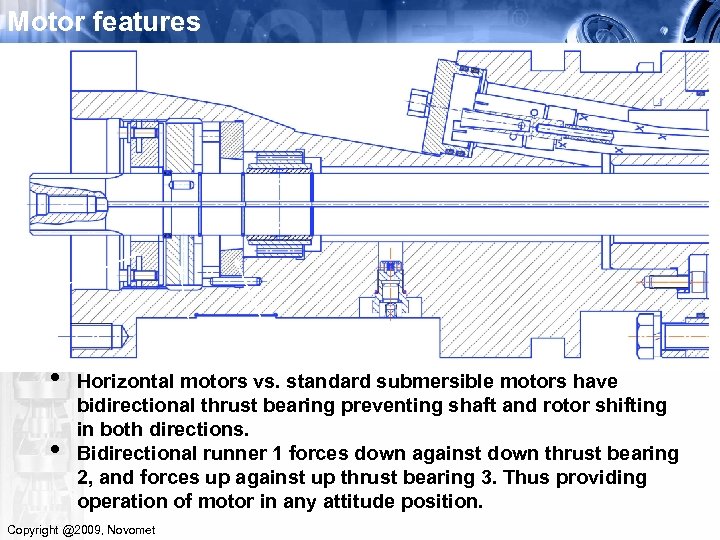

Motor features 3 1 • • 2 Horizontal motors vs. standard submersible motors have bidirectional thrust bearing preventing shaft and rotor shifting in both directions. Bidirectional runner 1 forces down against down thrust bearing 2, and forces up against up thrust bearing 3. Thus providing operation of motor in any attitude position. Copyright @2009, Novomet

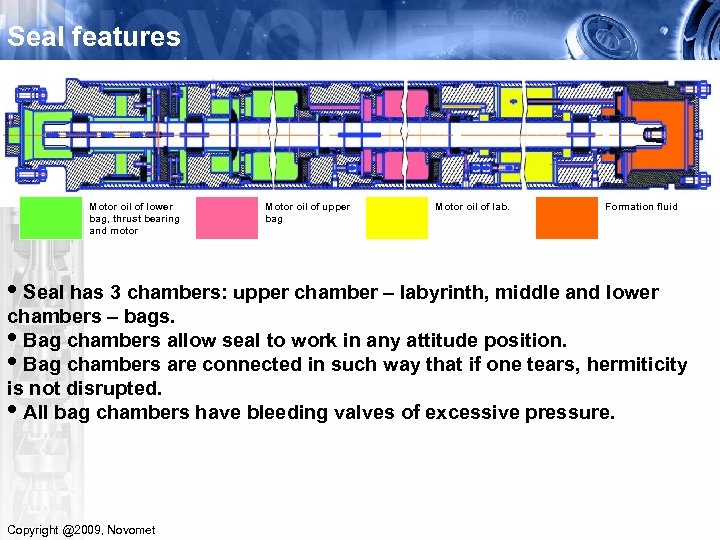

Seal features Motor oil of lower bag, thrust bearing and motor Motor oil of upper bag Motor oil of lab. Formation fluid • Seal has 3 chambers: upper chamber – labyrinth, middle and lower chambers – bags. • Bag chambers allow seal to work in any attitude position. • Bag chambers are connected in such way that if one tears, hermiticity is not disrupted. • All bag chambers have bleeding valves of excessive pressure. Copyright @2009, Novomet

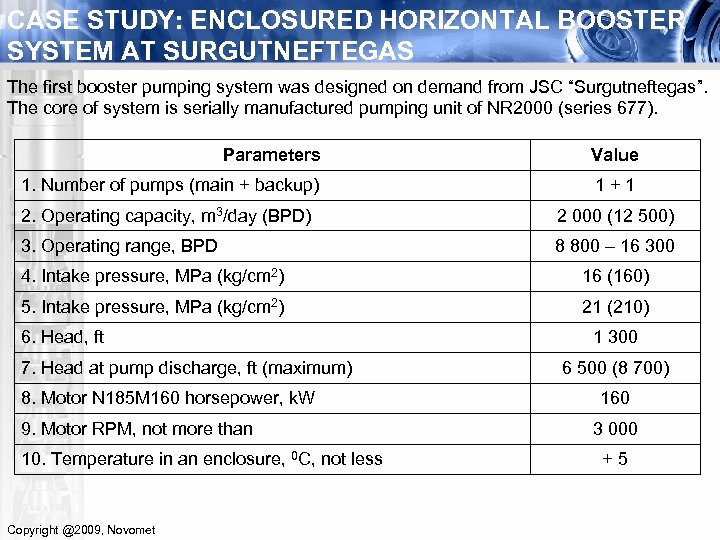

CASE STUDY: ENCLOSURED HORIZONTAL BOOSTER SYSTEM AT SURGUTNEFTEGAS The first booster pumping system was designed on demand from JSC “Surgutneftegas”. The core of system is serially manufactured pumping unit of NR 2000 (series 677). Parameters Value 1. Number of pumps (main + backup) 1+1 2. Operating capacity, m 3/day (BPD) 2 000 (12 500) 3. Operating range, BPD 8 800 – 16 300 4. Intake pressure, MPa (kg/cm 2) 16 (160) 5. Intake pressure, MPa (kg/cm 2) 21 (210) 6. Head, ft 7. Head at pump discharge, ft (maximum) 8. Motor N 185 M 160 horsepower, k. W 9. Motor RPM, not more than 10. Temperature in an enclosure, 0 C, not less Copyright @2009, Novomet 1 300 6 500 (8 700) 160 3 000 +5

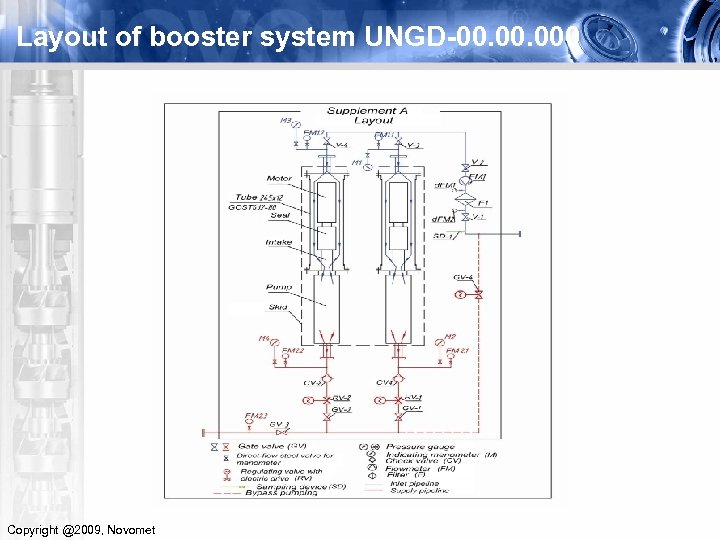

Layout of booster system UNGD-00. 000 Copyright @2009, Novomet

Thank you. Questions. Installation of B (3, 74”) series ESP Copyright @2009, Novomet

f005fd603ecdcd66e573977673ff845f.ppt