37b547c4615335d37edfaed25e03bd5a.ppt

- Количество слайдов: 18

Cooling of the electronics box E. Lavrik, A. Lymanets, H. -R. Schmidt Universität Tübingen 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 1

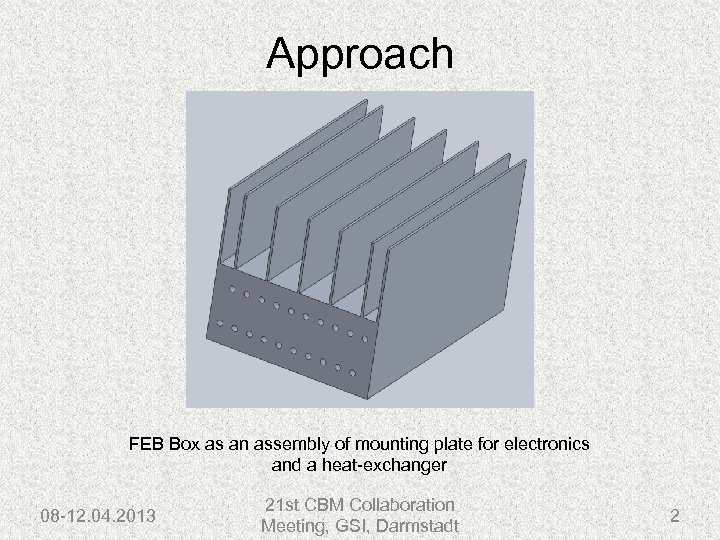

Approach FEB Box as an assembly of mounting plate for electronics and a heat-exchanger 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 2

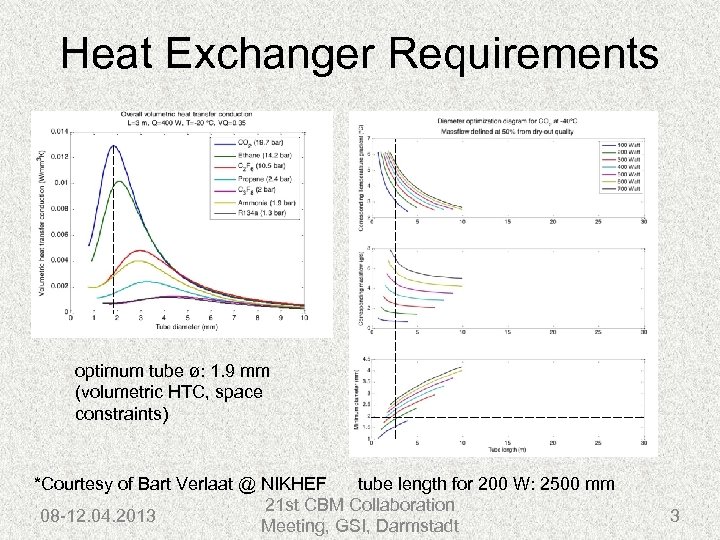

Heat Exchanger Requirements optimum tube ø: 1. 9 mm (volumetric HTC, space constraints) *Courtesy of Bart Verlaat @ NIKHEF tube length for 200 W: 2500 mm 21 st CBM Collaboration 08 -12. 04. 2013 Meeting, GSI, Darmstadt 3

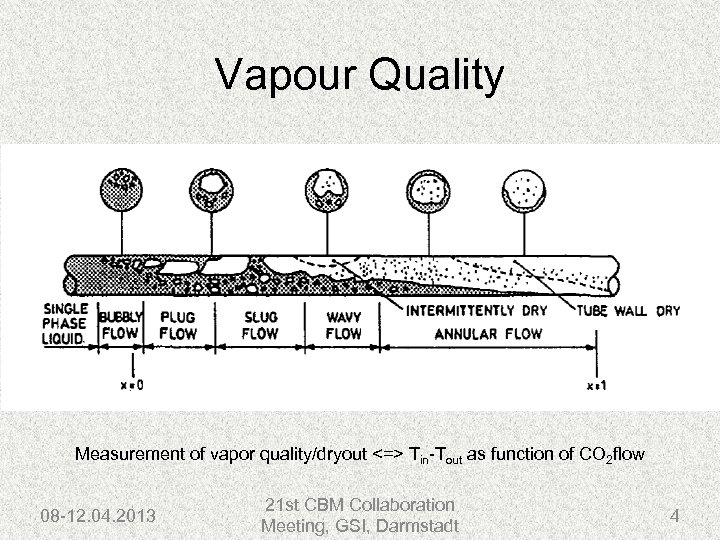

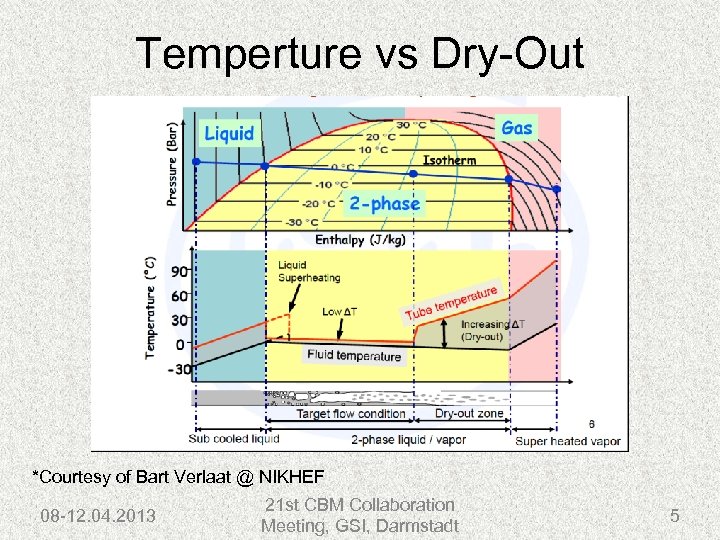

Vapour Quality Measurement of vapor quality/dryout <=> Tin-Tout as function of CO 2 flow 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 4

Temperture vs Dry-Out *Courtesy of Bart Verlaat @ NIKHEF 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 5

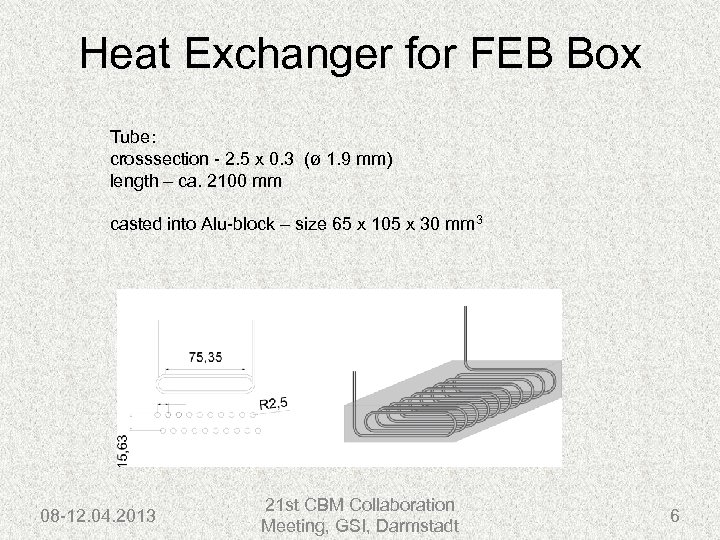

Heat Exchanger for FEB Box Tube: crosssection - 2. 5 x 0. 3 (ø 1. 9 mm) length – ca. 2100 mm casted into Alu-block – size 65 x 105 x 30 mm 3 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 6

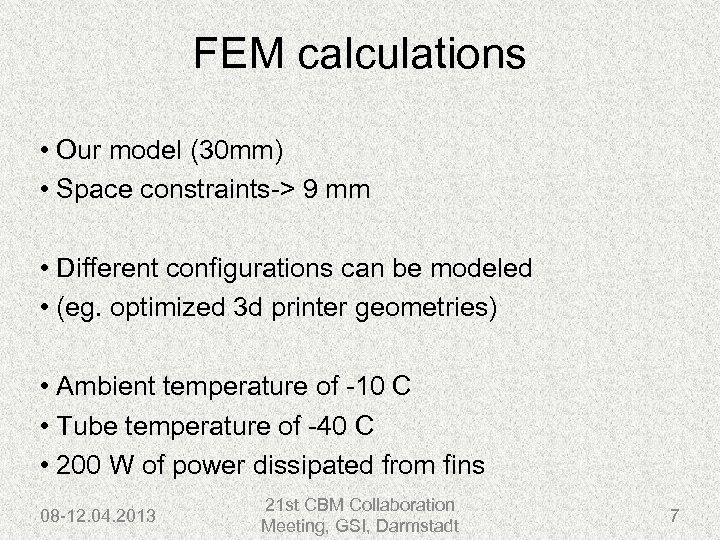

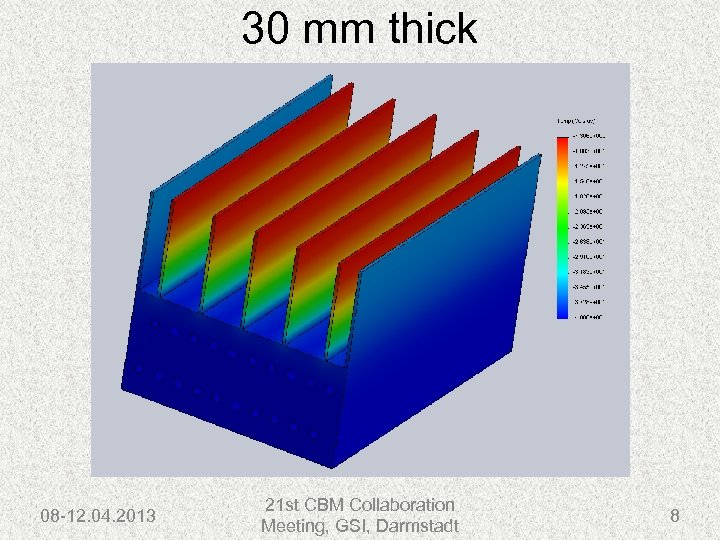

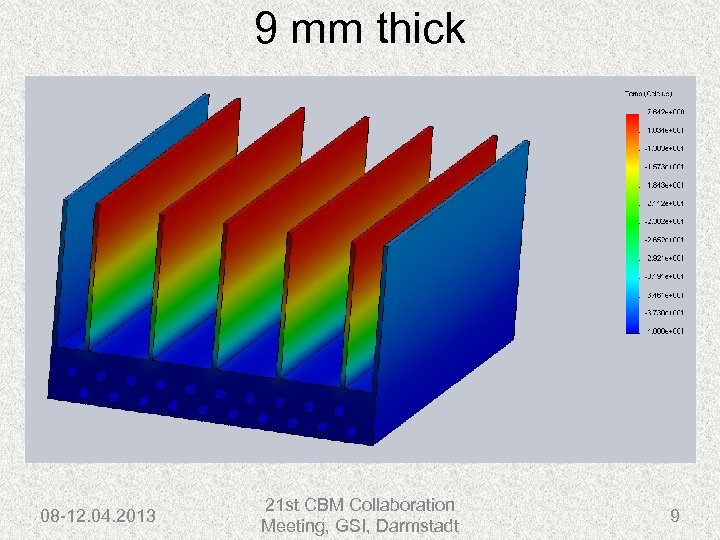

FEM calculations • Our model (30 mm) • Space constraints-> 9 mm • Different configurations can be modeled • (eg. optimized 3 d printer geometries) • Ambient temperature of -10 C • Tube temperature of -40 C • 200 W of power dissipated from fins 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 7

30 mm thick 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 8

9 mm thick 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 9

Experimental Verification • Check the temperature distribution on box • 16 Pt 100 sensors distributed in box • Freezer -10 C • Verify calculations • Result may differ from ideal simulations 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 10

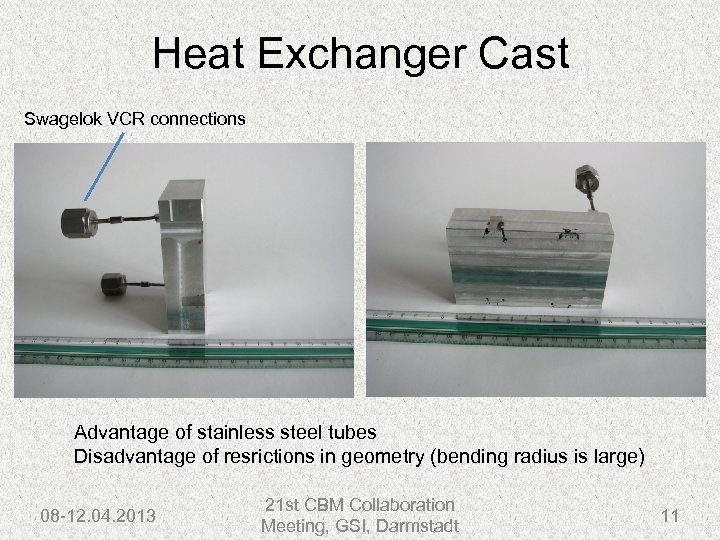

Heat Exchanger Cast Swagelok VCR connections Advantage of stainless steel tubes Disadvantage of resrictions in geometry (bending radius is large) 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 11

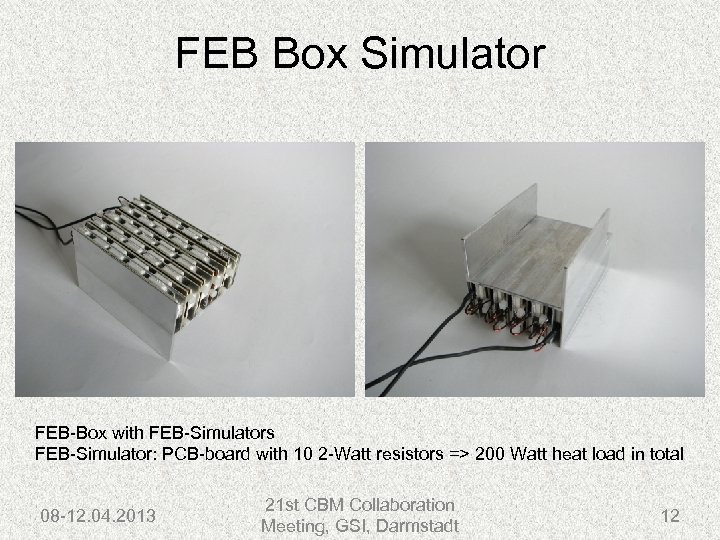

FEB Box Simulator FEB-Box with FEB-Simulators FEB-Simulator: PCB-board with 10 2 -Watt resistors => 200 Watt heat load in total 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 12

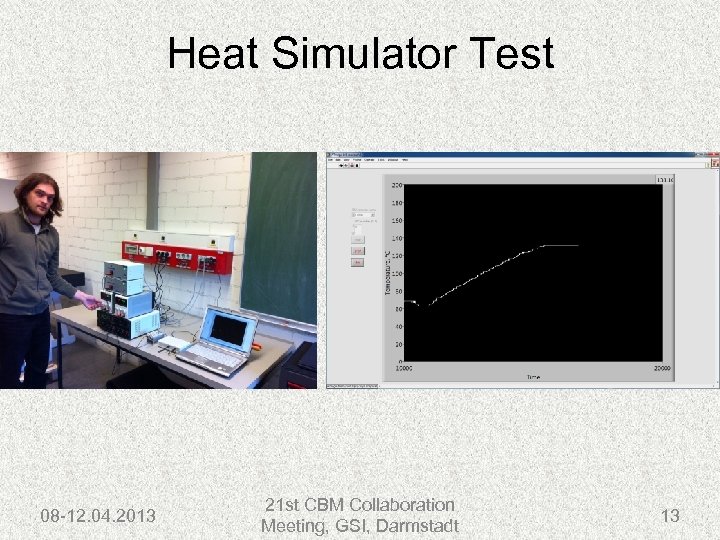

Heat Simulator Test 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 13

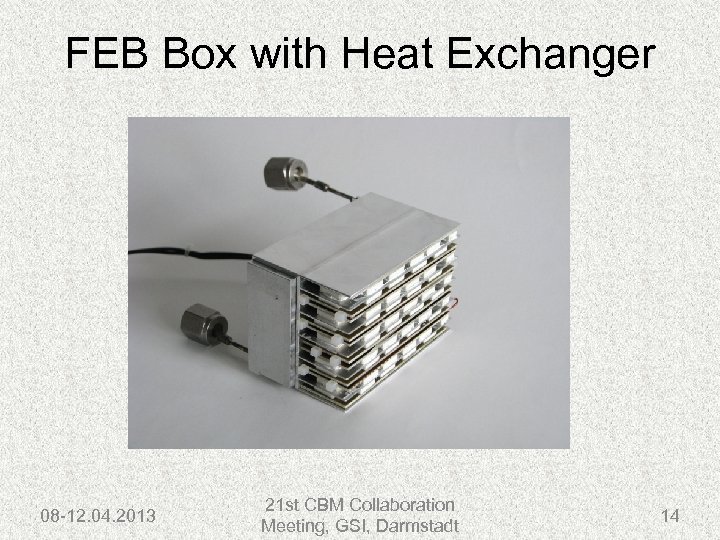

FEB Box with Heat Exchanger 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 14

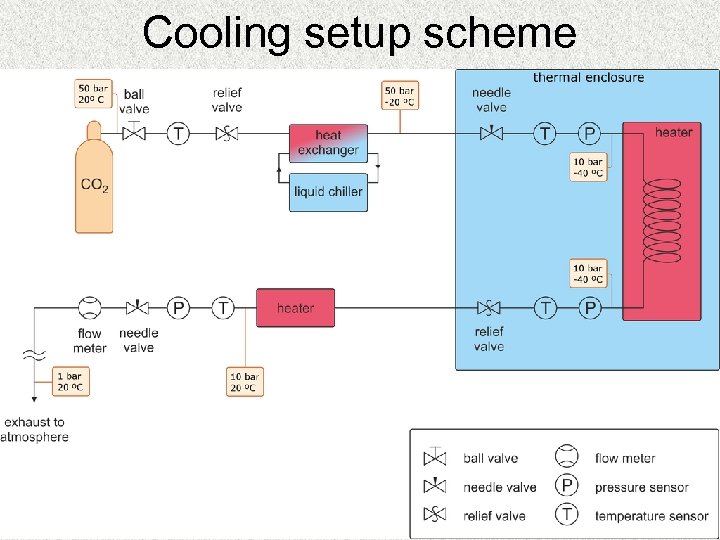

Cooling setup scheme

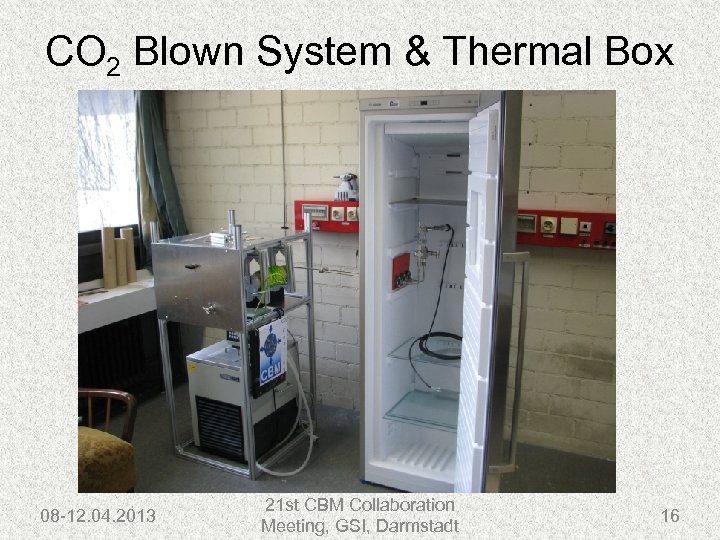

CO 2 Blown System & Thermal Box 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 16

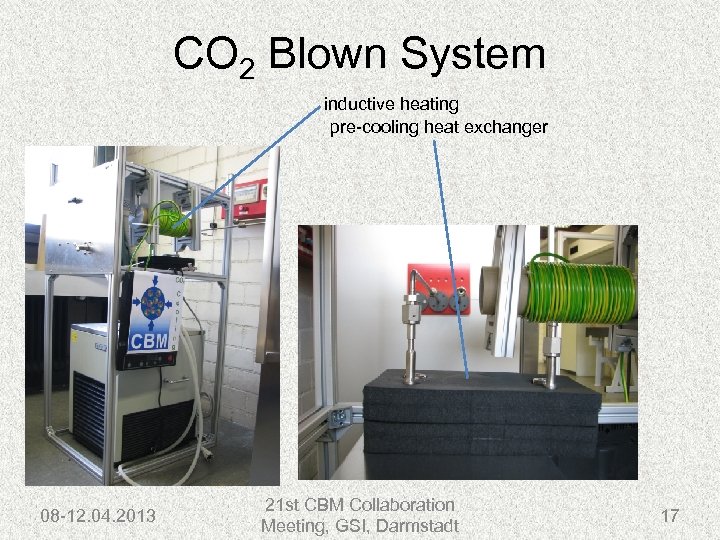

CO 2 Blown System inductive heating pre-cooling heat exchanger 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 17

Summary • Simple FEM studies are done • Will study more complex cases • Assembly of cooling setup • Control Lab. View software done. Including readout for pressure and temperature sensors, flowmeter • Try out different heat exchanger designs • First test runs to verify simulations 08 -12. 04. 2013 21 st CBM Collaboration Meeting, GSI, Darmstadt 18

37b547c4615335d37edfaed25e03bd5a.ppt