a632a475593ebc17970989967436f320.ppt

- Количество слайдов: 23

CONTROLS & INSTRUMENTATION FOR 660 MW SUPERCRITICAL UNIT @ Tiroda 1/16/2012 1

CONTROLS & INSTRUMENTATION FOR 660 MW SUPERCRITICAL UNIT @ Tiroda 1/16/2012 1

Road Map Ø Instrumentation at Tiroda Power Plant Ø Feedwater Control Ø Automation technologies Ø IT Integration

Road Map Ø Instrumentation at Tiroda Power Plant Ø Feedwater Control Ø Automation technologies Ø IT Integration

INSTRUMENTATION @ TIRODA

INSTRUMENTATION @ TIRODA

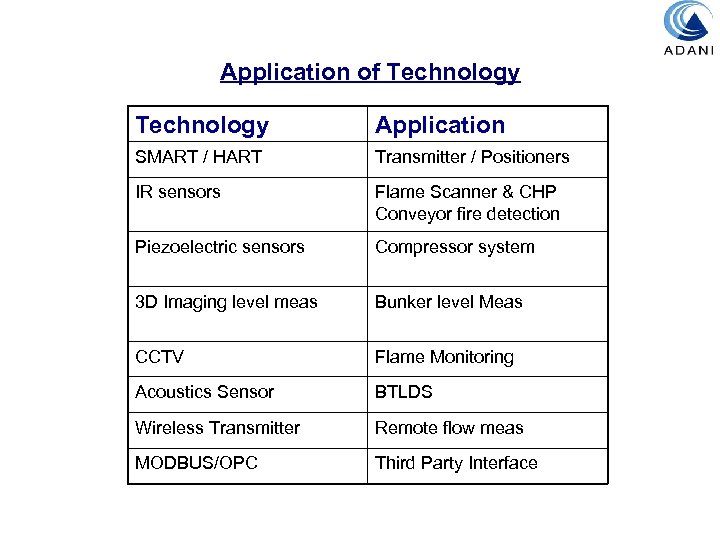

Application of Technology Application SMART / HART Transmitter / Positioners IR sensors Flame Scanner & CHP Conveyor fire detection Piezoelectric sensors Compressor system 3 D Imaging level meas Bunker level Meas CCTV Flame Monitoring Acoustics Sensor BTLDS Wireless Transmitter Remote flow meas MODBUS/OPC Third Party Interface

Application of Technology Application SMART / HART Transmitter / Positioners IR sensors Flame Scanner & CHP Conveyor fire detection Piezoelectric sensors Compressor system 3 D Imaging level meas Bunker level Meas CCTV Flame Monitoring Acoustics Sensor BTLDS Wireless Transmitter Remote flow meas MODBUS/OPC Third Party Interface

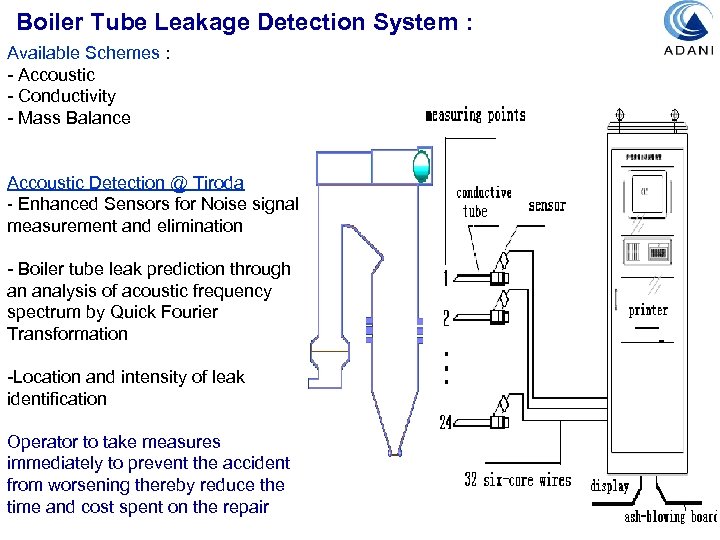

Boiler Tube Leakage Detection System : Available Schemes : - Accoustic - Conductivity - Mass Balance Accoustic Detection @ Tiroda - Enhanced Sensors for Noise signal measurement and elimination - Boiler tube leak prediction through an analysis of acoustic frequency spectrum by Quick Fourier Transformation -Location and intensity of leak identification Operator to take measures immediately to prevent the accident from worsening thereby reduce the time and cost spent on the repair

Boiler Tube Leakage Detection System : Available Schemes : - Accoustic - Conductivity - Mass Balance Accoustic Detection @ Tiroda - Enhanced Sensors for Noise signal measurement and elimination - Boiler tube leak prediction through an analysis of acoustic frequency spectrum by Quick Fourier Transformation -Location and intensity of leak identification Operator to take measures immediately to prevent the accident from worsening thereby reduce the time and cost spent on the repair

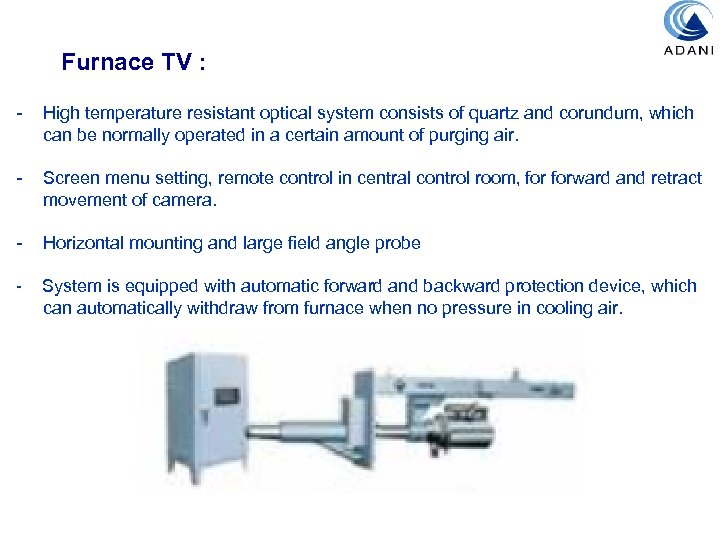

Furnace TV : - High temperature resistant optical system consists of quartz and corundum, which can be normally operated in a certain amount of purging air. - Screen menu setting, remote control in central control room, forward and retract movement of camera. - Horizontal mounting and large field angle probe - System is equipped with automatic forward and backward protection device, which can automatically withdraw from furnace when no pressure in cooling air.

Furnace TV : - High temperature resistant optical system consists of quartz and corundum, which can be normally operated in a certain amount of purging air. - Screen menu setting, remote control in central control room, forward and retract movement of camera. - Horizontal mounting and large field angle probe - System is equipped with automatic forward and backward protection device, which can automatically withdraw from furnace when no pressure in cooling air.

FEEDWATER CONTROL The key differentiator between subcritical and supercritical…

FEEDWATER CONTROL The key differentiator between subcritical and supercritical…

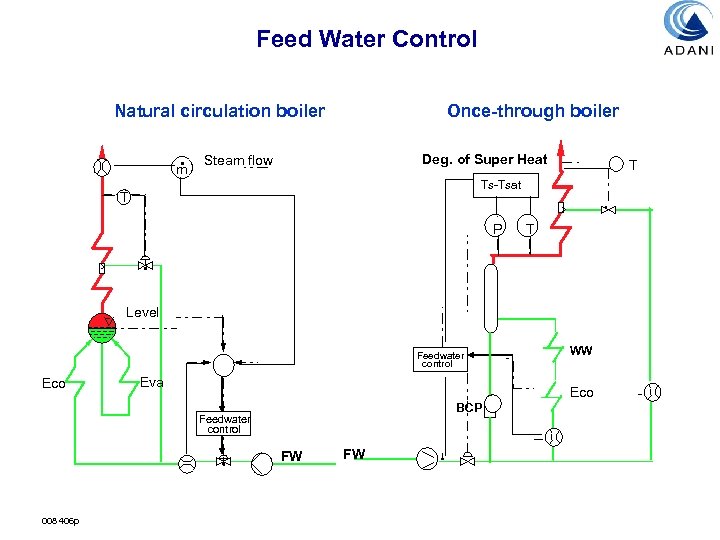

Feed Water Control Natural circulation boiler • m Once-through boiler Deg. of Super Heat Steam flow T Ts-Tsat T P T Level Feedwater control Eco Eva Eco BCP Feedwater control FW 008 406 p WW FW

Feed Water Control Natural circulation boiler • m Once-through boiler Deg. of Super Heat Steam flow T Ts-Tsat T P T Level Feedwater control Eco Eva Eco BCP Feedwater control FW 008 406 p WW FW

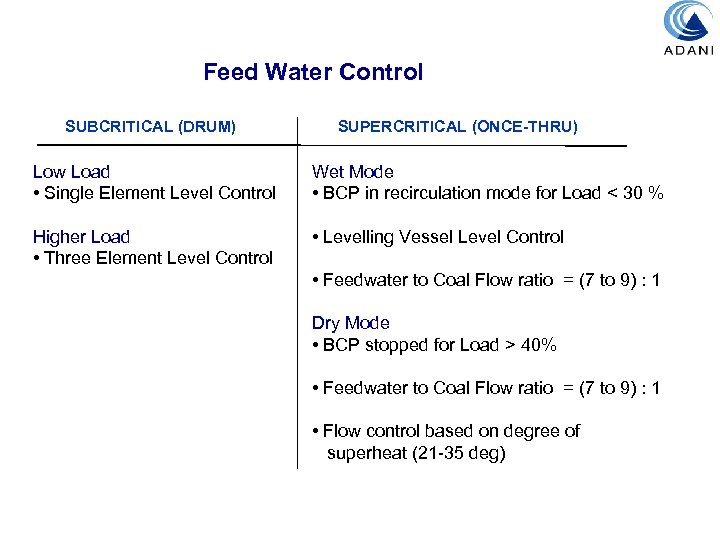

Feed Water Control SUBCRITICAL (DRUM) SUPERCRITICAL (ONCE-THRU) Low Load • Single Element Level Control Wet Mode • BCP in recirculation mode for Load < 30 % Higher Load • Three Element Level Control • Levelling Vessel Level Control • Feedwater to Coal Flow ratio = (7 to 9) : 1 Dry Mode • BCP stopped for Load > 40% • Feedwater to Coal Flow ratio = (7 to 9) : 1 • Flow control based on degree of superheat (21 -35 deg)

Feed Water Control SUBCRITICAL (DRUM) SUPERCRITICAL (ONCE-THRU) Low Load • Single Element Level Control Wet Mode • BCP in recirculation mode for Load < 30 % Higher Load • Three Element Level Control • Levelling Vessel Level Control • Feedwater to Coal Flow ratio = (7 to 9) : 1 Dry Mode • BCP stopped for Load > 40% • Feedwater to Coal Flow ratio = (7 to 9) : 1 • Flow control based on degree of superheat (21 -35 deg)

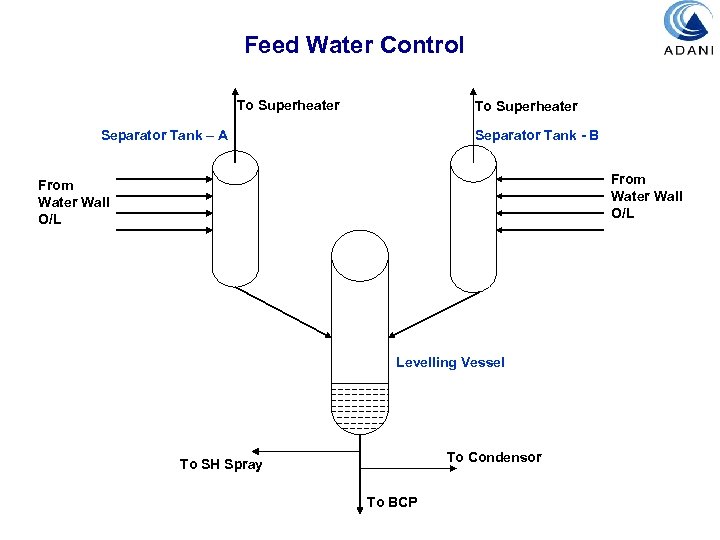

Feed Water Control To Superheater Separator Tank – A Separator Tank - B From Water Wall O/L Levelling Vessel To Condensor To SH Spray To BCP

Feed Water Control To Superheater Separator Tank – A Separator Tank - B From Water Wall O/L Levelling Vessel To Condensor To SH Spray To BCP

Feed Water Control Main objective in Super Critical Boiler FW control system is – a) To maintain Level of the Levelling Vessel at Wet Mode b) To maintain Deg. Of Superheat at Separator Outlet c) To maintain FW flow to Fuel Flow Ratio

Feed Water Control Main objective in Super Critical Boiler FW control system is – a) To maintain Level of the Levelling Vessel at Wet Mode b) To maintain Deg. Of Superheat at Separator Outlet c) To maintain FW flow to Fuel Flow Ratio

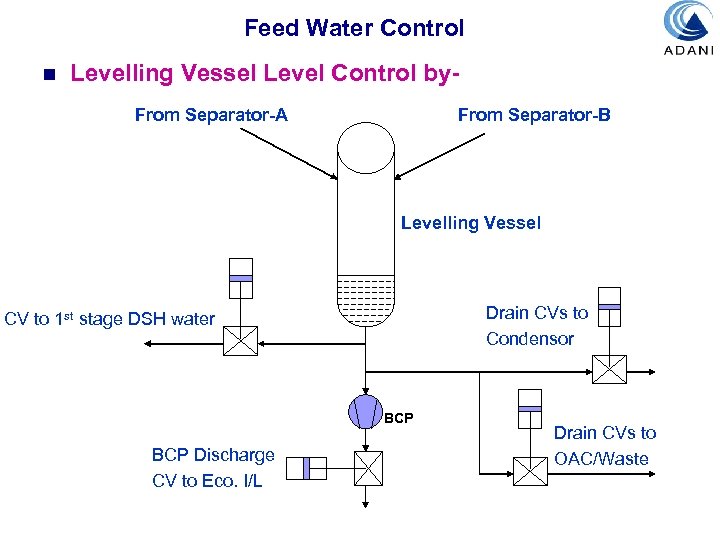

Feed Water Control n Levelling Vessel Level Control by. From Separator-A From Separator-B Levelling Vessel Drain CVs to Condensor CV to 1 st stage DSH water BCP Discharge CV to Eco. I/L Drain CVs to OAC/Waste

Feed Water Control n Levelling Vessel Level Control by. From Separator-A From Separator-B Levelling Vessel Drain CVs to Condensor CV to 1 st stage DSH water BCP Discharge CV to Eco. I/L Drain CVs to OAC/Waste

Feed Water Control Degree of Superheat is maintained in the separator outlet in the range of 21 - 35 deg. C Why Degree of Superheat ? > 35 deg C : May lead to overheating of water wall tubes. < 21 deg C : May lead to flow of wet steam to SH coils. Note : Bias for degree of superheat > 21 deg. C is in Operators control

Feed Water Control Degree of Superheat is maintained in the separator outlet in the range of 21 - 35 deg. C Why Degree of Superheat ? > 35 deg C : May lead to overheating of water wall tubes. < 21 deg C : May lead to flow of wet steam to SH coils. Note : Bias for degree of superheat > 21 deg. C is in Operators control

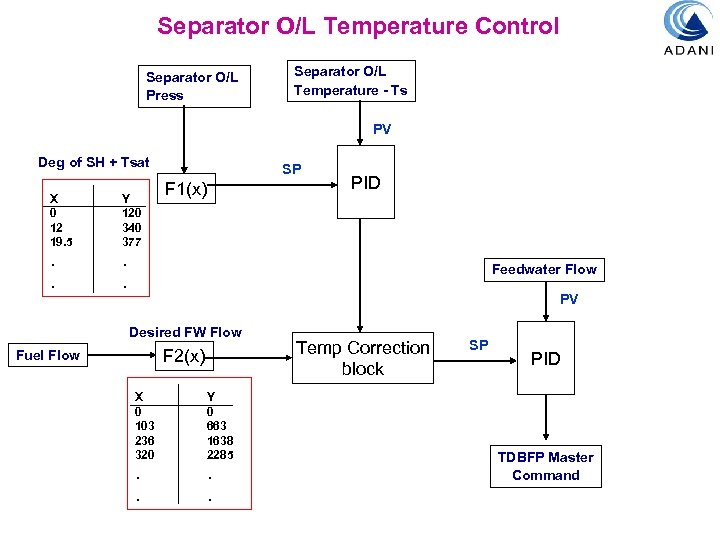

Separator O/L Temperature Control Separator O/L Press Separator O/L Temperature - Ts PV Deg of SH + Tsat X 0 12 19. 5 Y 120 340 377 . . SP F 1(x) PID . . Feedwater Flow PV Desired FW Flow F 2(x) Fuel Flow X 0 103 236 320 Y 0 663 1638 2285 . . Temp Correction block SP PID TDBFP Master Command

Separator O/L Temperature Control Separator O/L Press Separator O/L Temperature - Ts PV Deg of SH + Tsat X 0 12 19. 5 Y 120 340 377 . . SP F 1(x) PID . . Feedwater Flow PV Desired FW Flow F 2(x) Fuel Flow X 0 103 236 320 Y 0 663 1638 2285 . . Temp Correction block SP PID TDBFP Master Command

AUTOMATION TECHNOLOGIES

AUTOMATION TECHNOLOGIES

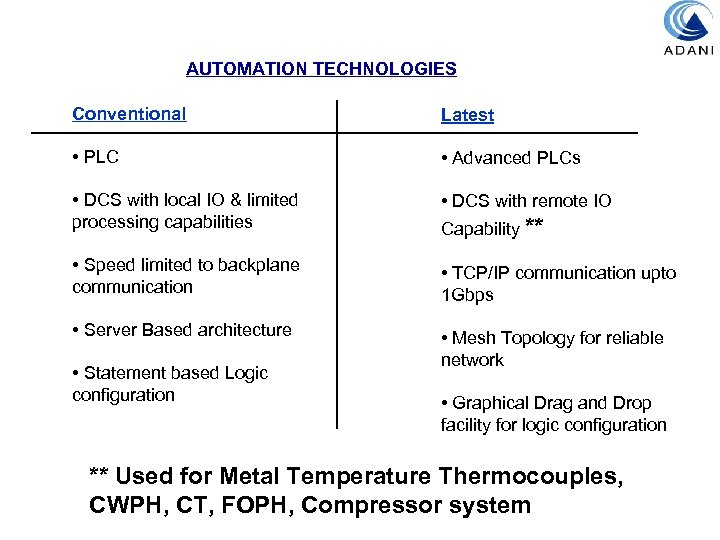

AUTOMATION TECHNOLOGIES Conventional Latest • PLC • Advanced PLCs • DCS with local IO & limited processing capabilities • DCS with remote IO Capability ** • Speed limited to backplane communication • TCP/IP communication upto 1 Gbps • Server Based architecture • Mesh Topology for reliable network • Statement based Logic configuration • Graphical Drag and Drop facility for logic configuration ** Used for Metal Temperature Thermocouples, CWPH, CT, FOPH, Compressor system

AUTOMATION TECHNOLOGIES Conventional Latest • PLC • Advanced PLCs • DCS with local IO & limited processing capabilities • DCS with remote IO Capability ** • Speed limited to backplane communication • TCP/IP communication upto 1 Gbps • Server Based architecture • Mesh Topology for reliable network • Statement based Logic configuration • Graphical Drag and Drop facility for logic configuration ** Used for Metal Temperature Thermocouples, CWPH, CT, FOPH, Compressor system

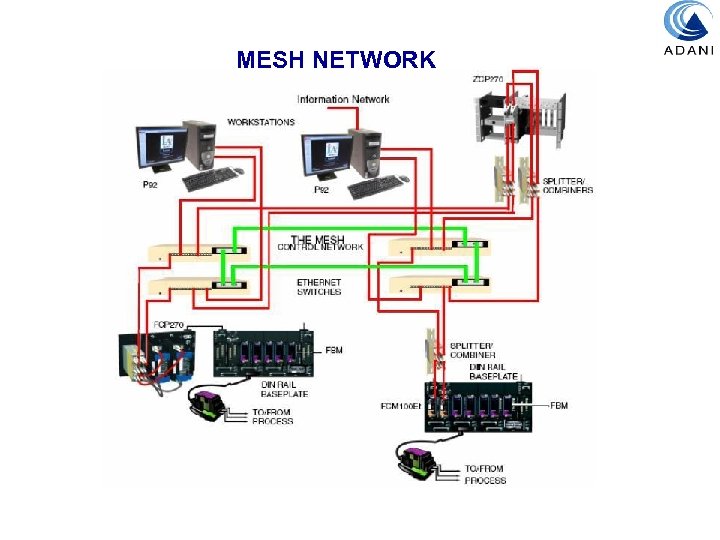

MESH NETWORK

MESH NETWORK

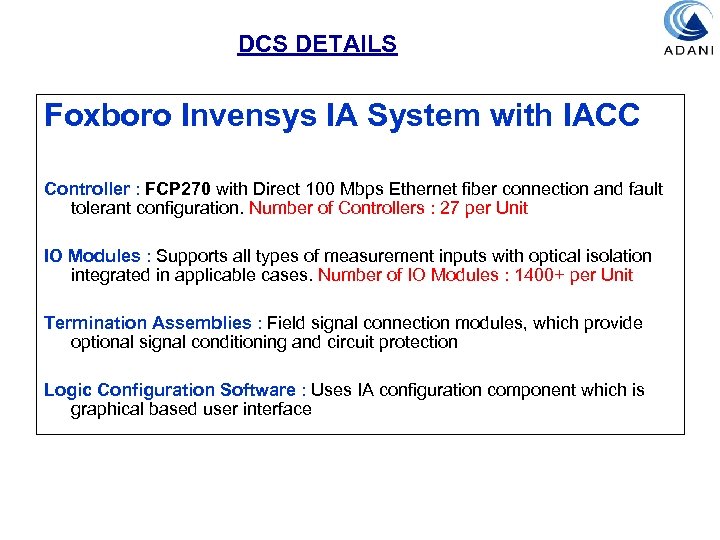

DCS DETAILS Foxboro Invensys IA System with IACC Controller : FCP 270 with Direct 100 Mbps Ethernet fiber connection and fault tolerant configuration. Number of Controllers : 27 per Unit IO Modules : Supports all types of measurement inputs with optical isolation integrated in applicable cases. Number of IO Modules : 1400+ per Unit Termination Assemblies : Field signal connection modules, which provide optional signal conditioning and circuit protection Logic Configuration Software : Uses IA configuration component which is graphical based user interface

DCS DETAILS Foxboro Invensys IA System with IACC Controller : FCP 270 with Direct 100 Mbps Ethernet fiber connection and fault tolerant configuration. Number of Controllers : 27 per Unit IO Modules : Supports all types of measurement inputs with optical isolation integrated in applicable cases. Number of IO Modules : 1400+ per Unit Termination Assemblies : Field signal connection modules, which provide optional signal conditioning and circuit protection Logic Configuration Software : Uses IA configuration component which is graphical based user interface

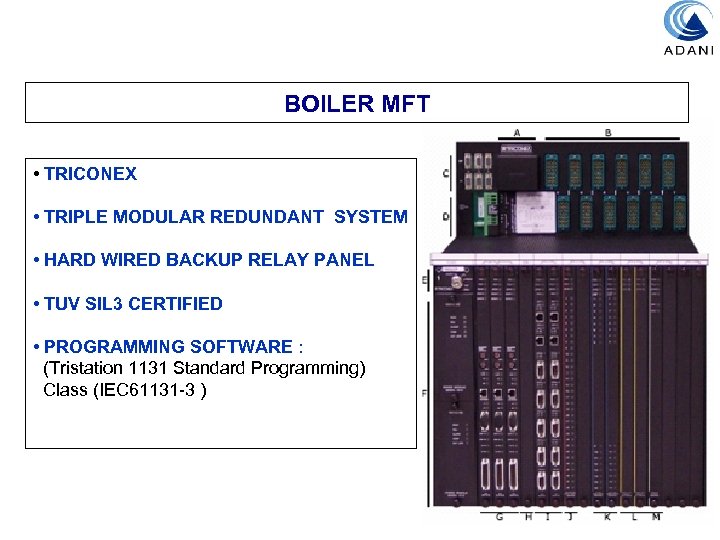

BOILER MFT • TRICONEX • TRIPLE MODULAR REDUNDANT SYSTEM • HARD WIRED BACKUP RELAY PANEL • TUV SIL 3 CERTIFIED • PROGRAMMING SOFTWARE : (Tristation 1131 Standard Programming) Class (IEC 61131 -3 )

BOILER MFT • TRICONEX • TRIPLE MODULAR REDUNDANT SYSTEM • HARD WIRED BACKUP RELAY PANEL • TUV SIL 3 CERTIFIED • PROGRAMMING SOFTWARE : (Tristation 1131 Standard Programming) Class (IEC 61131 -3 )

Benefits of Latest Technology 1. Availability of online dataa) For Operator b) For Management at Tiroda c) Corporate Office d) Other OEMs for analysis purpose of their equipments 2. Resulting in better analysis of problems by experts and quicker solutions. 3. Improved efficiency due to high speed processing of various I/Os. 4. Reduction in outages due to highly automated and reliable control system, leading to increased PLF and availability. 5. Online performance calculation of 660 MW Unit. 6. Latest technology enables predictive maintenance. 7. Reduction in Man/Megawatt Ratio.

Benefits of Latest Technology 1. Availability of online dataa) For Operator b) For Management at Tiroda c) Corporate Office d) Other OEMs for analysis purpose of their equipments 2. Resulting in better analysis of problems by experts and quicker solutions. 3. Improved efficiency due to high speed processing of various I/Os. 4. Reduction in outages due to highly automated and reliable control system, leading to increased PLF and availability. 5. Online performance calculation of 660 MW Unit. 6. Latest technology enables predictive maintenance. 7. Reduction in Man/Megawatt Ratio.

IT INTEGRATION

IT INTEGRATION

IT INTEGRATION n Management Information System ( MIS ) interface with external world and office automation system n Remote access/troubleshooting of vibration monitoring system n Integration with SAP n SMS alerts on Equipment Trip / Alarms

IT INTEGRATION n Management Information System ( MIS ) interface with external world and office automation system n Remote access/troubleshooting of vibration monitoring system n Integration with SAP n SMS alerts on Equipment Trip / Alarms

Thank You…!!

Thank You…!!