e9e3f77b2fc6eb466b181a4ea72ac1c9.ppt

- Количество слайдов: 57

Controlled Atmosphere and Modified Atmosphere Storage Dr. Ron Porat Dept. of Postharvest Science of Fresh Produce ARO, The Volcani Center, Bet Dagan, Israel

Controlled Atmosphere and Modified Atmosphere Storage Dr. Ron Porat Dept. of Postharvest Science of Fresh Produce ARO, The Volcani Center, Bet Dagan, Israel

Normal room air contains 21% O 2 and 0. 03% CO 2. However, it was found that low oxygen and high carbon dioxide levels slow ripening, reduce the development of some peel disorders and inhibit pathogen growth.

Normal room air contains 21% O 2 and 0. 03% CO 2. However, it was found that low oxygen and high carbon dioxide levels slow ripening, reduce the development of some peel disorders and inhibit pathogen growth.

The terms controlled atmosphere (CA) and modified atmosphere (MA) imply using an atmospheric compositions that is different from air, but they differ in the degree of their control of the gases concentrations. Control atmosphere (CA) – generally refers to decreased O 2 and increased CO 2 concentrations, by a precise control of the gas composition. Modified atmosphere (MA) – is used when the control of the storage atmosphere is not closely controlled, such as in plastic film packaging.

The terms controlled atmosphere (CA) and modified atmosphere (MA) imply using an atmospheric compositions that is different from air, but they differ in the degree of their control of the gases concentrations. Control atmosphere (CA) – generally refers to decreased O 2 and increased CO 2 concentrations, by a precise control of the gas composition. Modified atmosphere (MA) – is used when the control of the storage atmosphere is not closely controlled, such as in plastic film packaging.

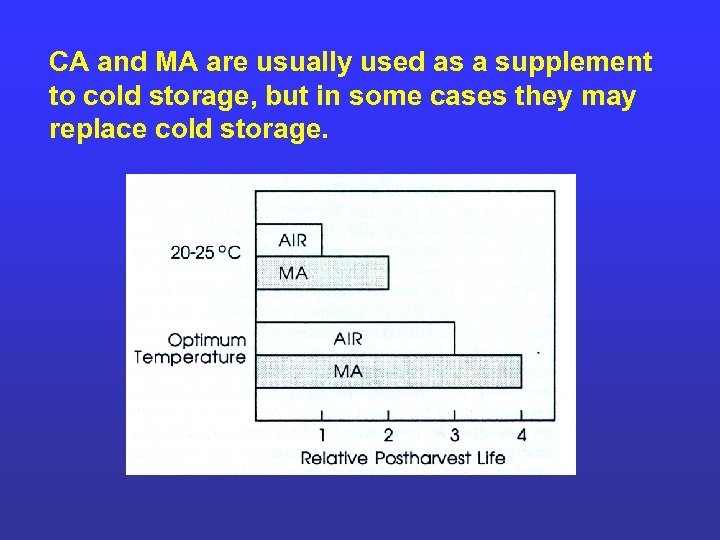

CA and MA are usually used as a supplement to cold storage, but in some cases they may replace cold storage.

CA and MA are usually used as a supplement to cold storage, but in some cases they may replace cold storage.

Potential benefits of CA: 1) Retardation of ripening and senescence. 2) 2) Inhibits ethylene effects. 3) 3) Reduction of certain physiological disorders. 4) 4) Inhibition of pathogen growth. 5) 5) May be used for insect control.

Potential benefits of CA: 1) Retardation of ripening and senescence. 2) 2) Inhibits ethylene effects. 3) 3) Reduction of certain physiological disorders. 4) 4) Inhibition of pathogen growth. 5) 5) May be used for insect control.

Potential harmful effects of CA: 1) May cause irregular ripening after storage. 2) 2) May cause certain physiological disorders. 3) 3) May enhance anaerobic respiration and development of off-flavors. 4) 4) May cause susceptibility to decay.

Potential harmful effects of CA: 1) May cause irregular ripening after storage. 2) 2) May cause certain physiological disorders. 3) 3) May enhance anaerobic respiration and development of off-flavors. 4) 4) May cause susceptibility to decay.

Fruits and vegetables differ in their tolerance to low O 2 and to high CO 2 concentrations. Extreme oxygen and carbon dioxide concentrations (above the limits for each cultivar) may cause physiological and pathological deterioration, interrupt with normal ripening and enhance anaerobic respiration and development of offflavors.

Fruits and vegetables differ in their tolerance to low O 2 and to high CO 2 concentrations. Extreme oxygen and carbon dioxide concentrations (above the limits for each cultivar) may cause physiological and pathological deterioration, interrupt with normal ripening and enhance anaerobic respiration and development of offflavors.

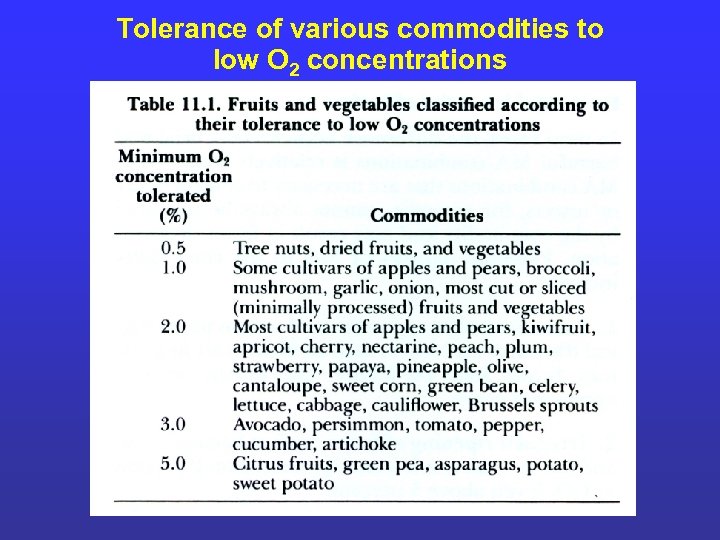

Tolerance of various commodities to low O 2 concentrations

Tolerance of various commodities to low O 2 concentrations

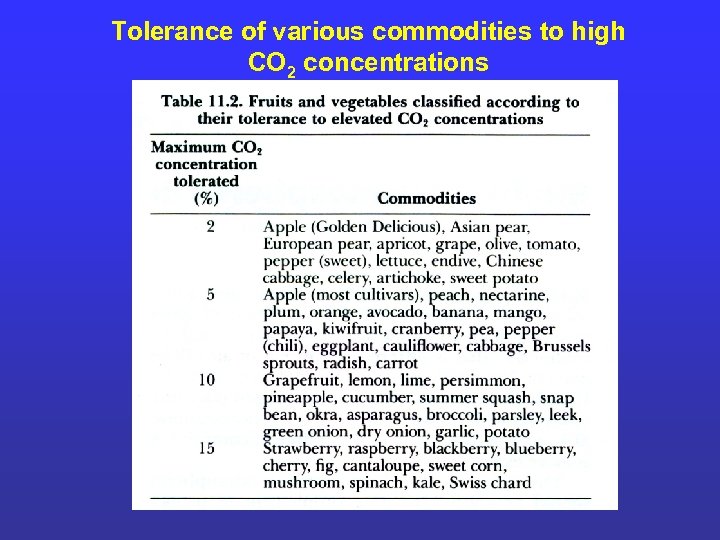

Tolerance of various commodities to high CO 2 concentrations

Tolerance of various commodities to high CO 2 concentrations

Fruits and vegetables can be grouped according to their storage potential under optimum temperature, RH and CA conditions as followed: Up to 1 year – apple and pear Up to 6 months – kiwi, persimmon, pomegranate Up to 3 months – avocado, banana, cherry, grape, mango, nectarine, peach, plum Up to 1 month – apricot, fig, papaya, pineapple, strawberry

Fruits and vegetables can be grouped according to their storage potential under optimum temperature, RH and CA conditions as followed: Up to 1 year – apple and pear Up to 6 months – kiwi, persimmon, pomegranate Up to 3 months – avocado, banana, cherry, grape, mango, nectarine, peach, plum Up to 1 month – apricot, fig, papaya, pineapple, strawberry

CA or MA may be applied to improve the storage potential of either short- or long-lasting commodities.

CA or MA may be applied to improve the storage potential of either short- or long-lasting commodities.

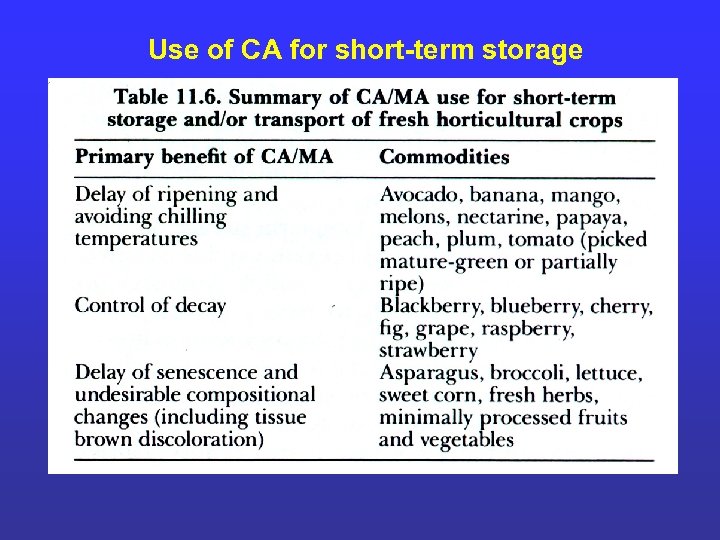

Use of CA for short-term storage

Use of CA for short-term storage

Transportation of strawberries in CO 2 – enriched atmosphere – Trans. Fresh (Tectroll) technology

Transportation of strawberries in CO 2 – enriched atmosphere – Trans. Fresh (Tectroll) technology

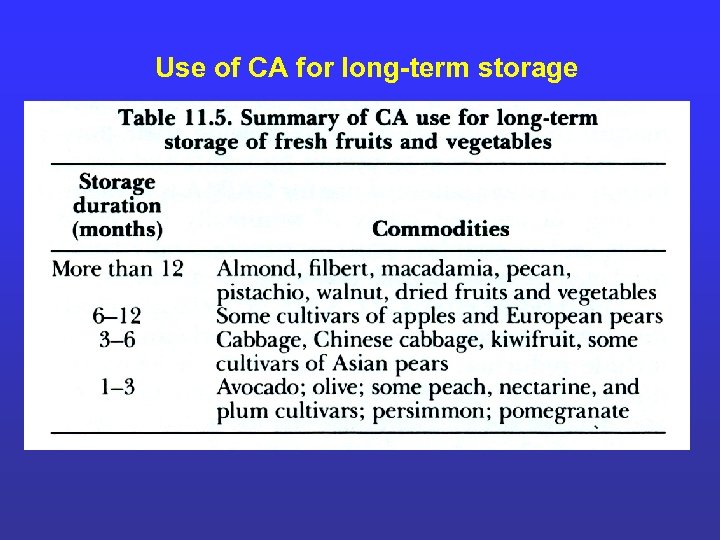

Use of CA for long-term storage

Use of CA for long-term storage

CA recommendations A CD-ROM entitled: “CA Recommendations (2001)” was published by the University of California, Postharvest Technology Center. The CD-ROM can be ordered through website access at http: //postharvest. ucdavis. edu.

CA recommendations A CD-ROM entitled: “CA Recommendations (2001)” was published by the University of California, Postharvest Technology Center. The CD-ROM can be ordered through website access at http: //postharvest. ucdavis. edu.

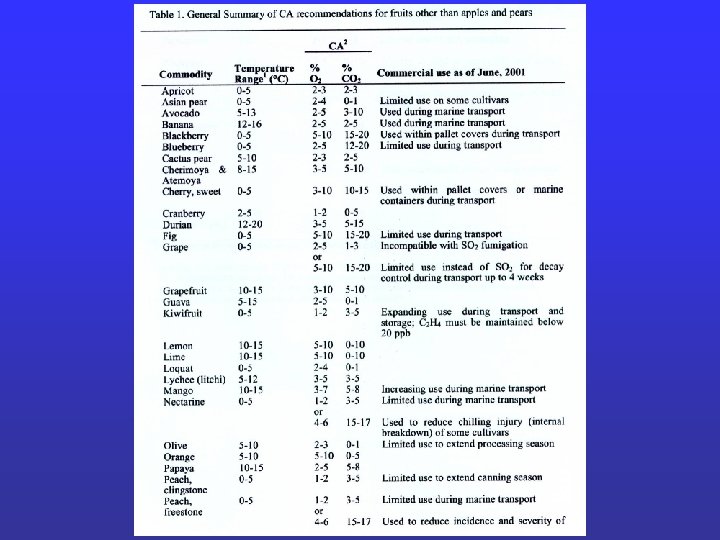

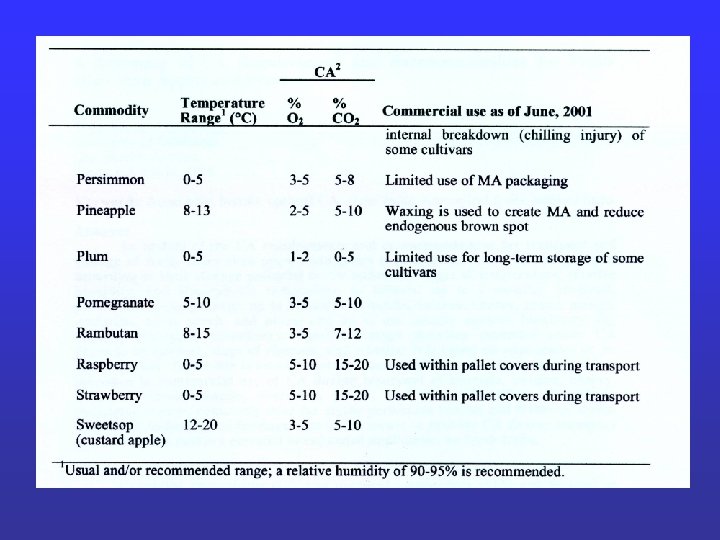

Acta Hortic. (2003) 600: 737 -740 The above recent publication from the 8 th Int. CA Conference (2002) provides a list of the optimal CA conditions for 35 selected horticultural commodities.

Acta Hortic. (2003) 600: 737 -740 The above recent publication from the 8 th Int. CA Conference (2002) provides a list of the optimal CA conditions for 35 selected horticultural commodities.

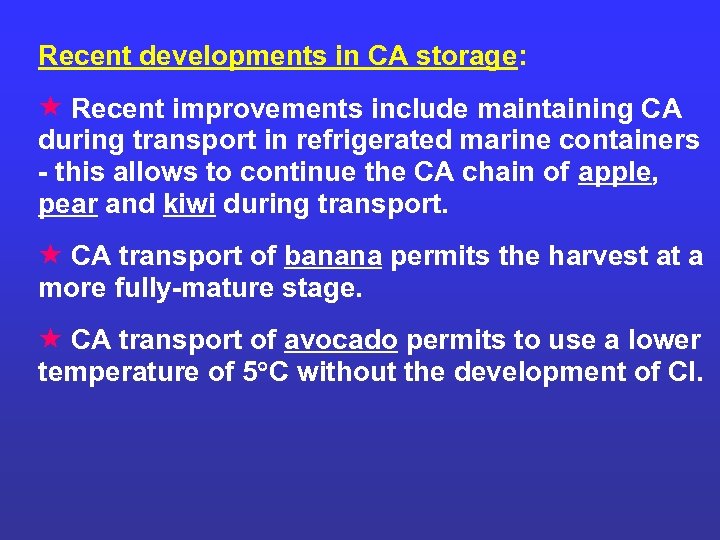

Recent developments in CA storage: Recent improvements include maintaining CA during transport in refrigerated marine containers - this allows to continue the CA chain of apple, pear and kiwi during transport. CA transport of banana permits the harvest at a more fully-mature stage. CA transport of avocado permits to use a lower temperature of 5 C without the development of CI.

Recent developments in CA storage: Recent improvements include maintaining CA during transport in refrigerated marine containers - this allows to continue the CA chain of apple, pear and kiwi during transport. CA transport of banana permits the harvest at a more fully-mature stage. CA transport of avocado permits to use a lower temperature of 5 C without the development of CI.

In addition to CA, there is also a continuing increase in the use of plastic films and MAP. The greatest use of MAP is for fresh-cut products (to maintain 2 -5% O 2 and 8 -12% CO 2). It is possible to improve gas control in MAP by adding absorbers of ethylene, carbon dioxide and oxygen.

In addition to CA, there is also a continuing increase in the use of plastic films and MAP. The greatest use of MAP is for fresh-cut products (to maintain 2 -5% O 2 and 8 -12% CO 2). It is possible to improve gas control in MAP by adding absorbers of ethylene, carbon dioxide and oxygen.

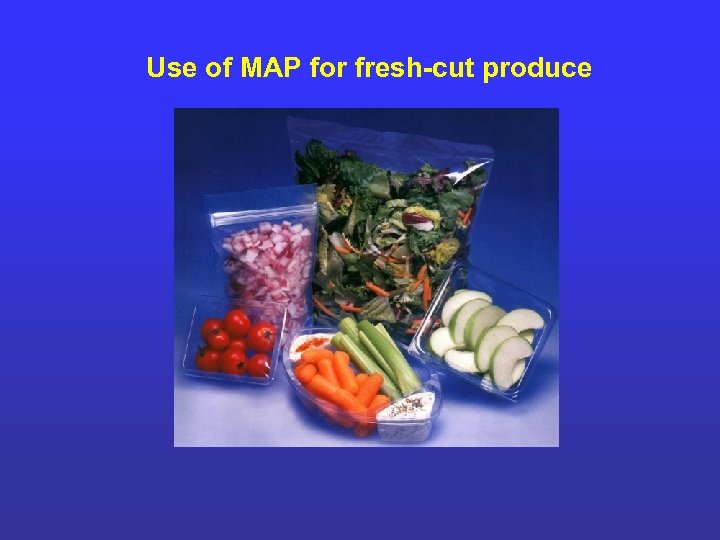

Use of MAP for fresh-cut produce

Use of MAP for fresh-cut produce

Fresh-cut lettuce in MAP

Fresh-cut lettuce in MAP

Fresh-cut fruit in MAP

Fresh-cut fruit in MAP

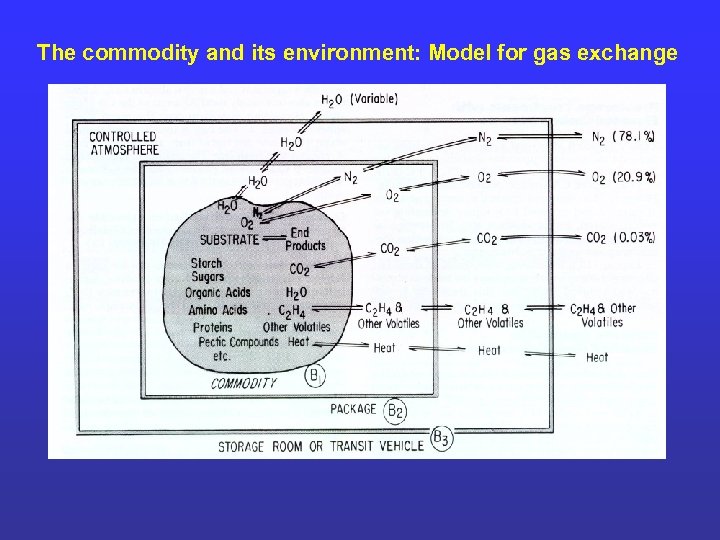

The commodity and its environment: Model for gas exchange

The commodity and its environment: Model for gas exchange

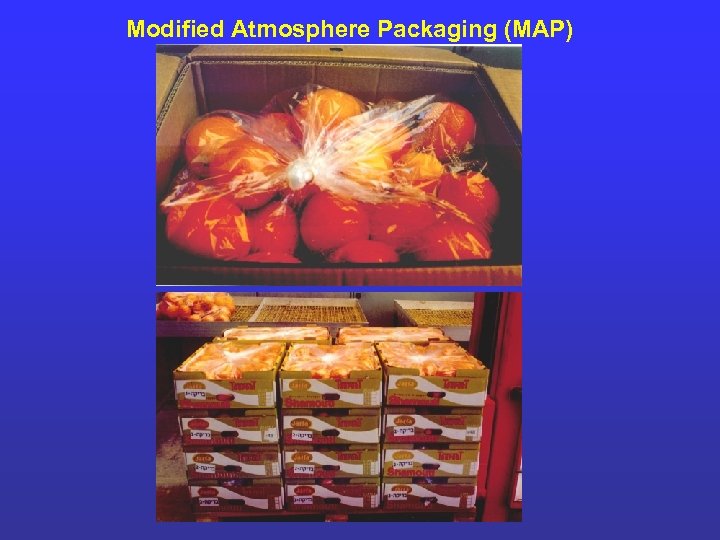

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP)

Commercial MAP of banana fruit

Commercial MAP of banana fruit

Banana – individual bags

Banana – individual bags

Commercial MAP of kiwi

Commercial MAP of kiwi

Commercial MAP of broccoli

Commercial MAP of broccoli

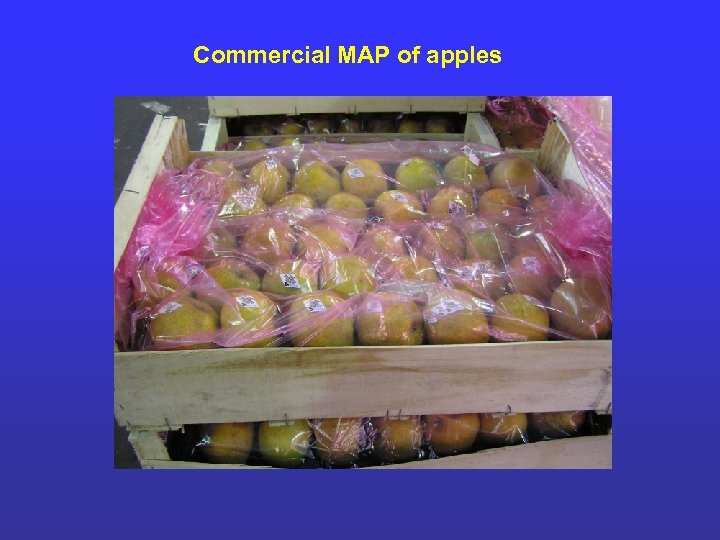

Commercial MAP of apples

Commercial MAP of apples

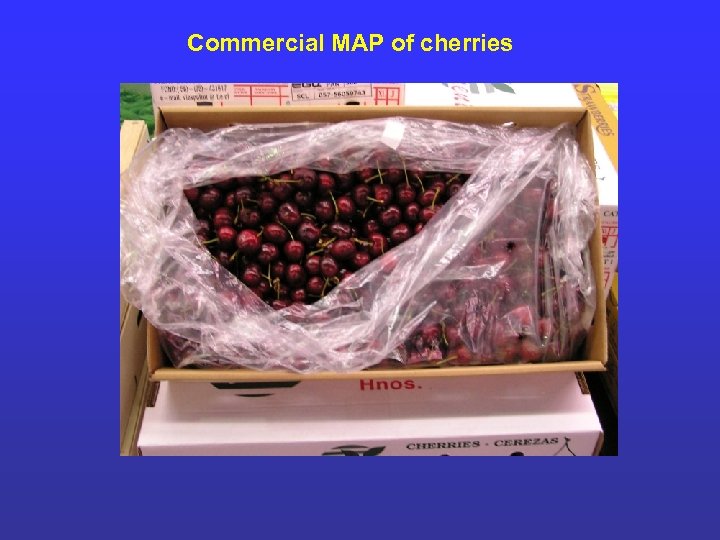

Commercial MAP of cherries

Commercial MAP of cherries

Commercial MAP of grapes

Commercial MAP of grapes

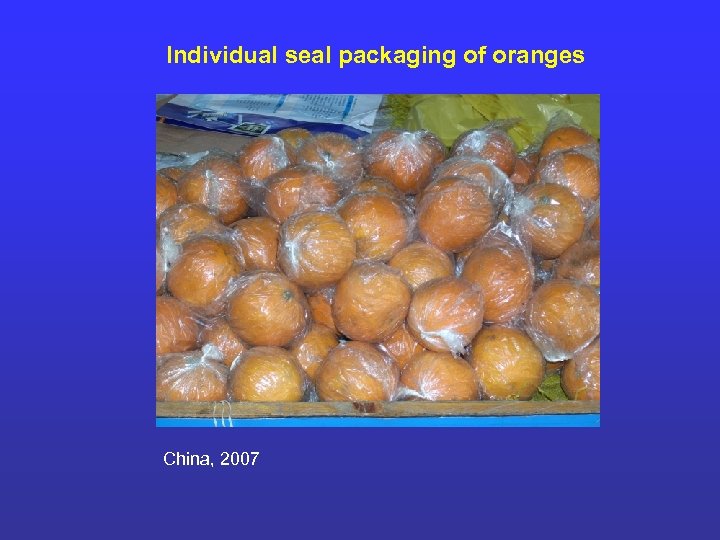

Individual seal packaging of oranges China, 2007

Individual seal packaging of oranges China, 2007

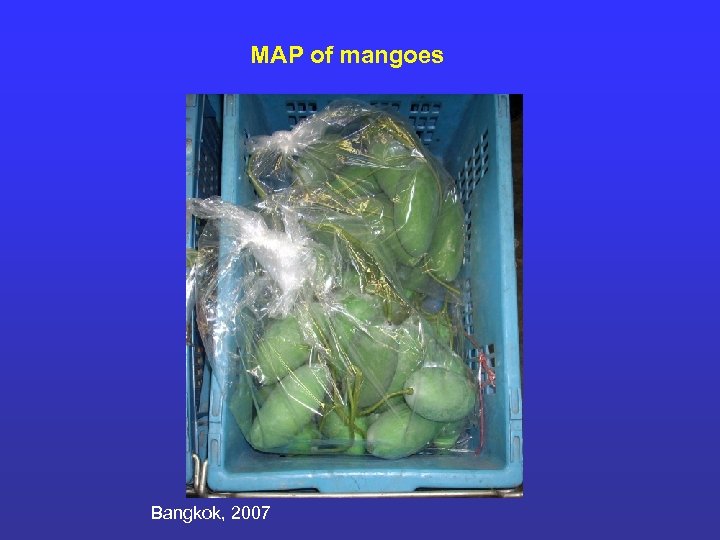

MAP of mangoes Bangkok, 2007

MAP of mangoes Bangkok, 2007

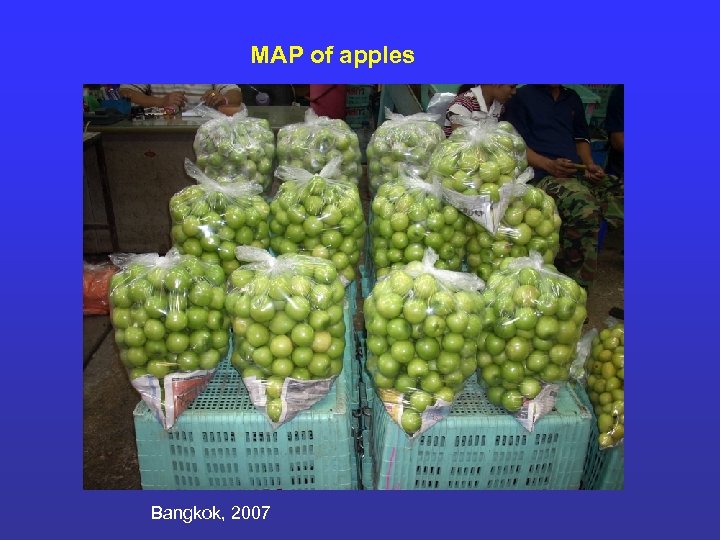

MAP of apples Bangkok, 2007

MAP of apples Bangkok, 2007

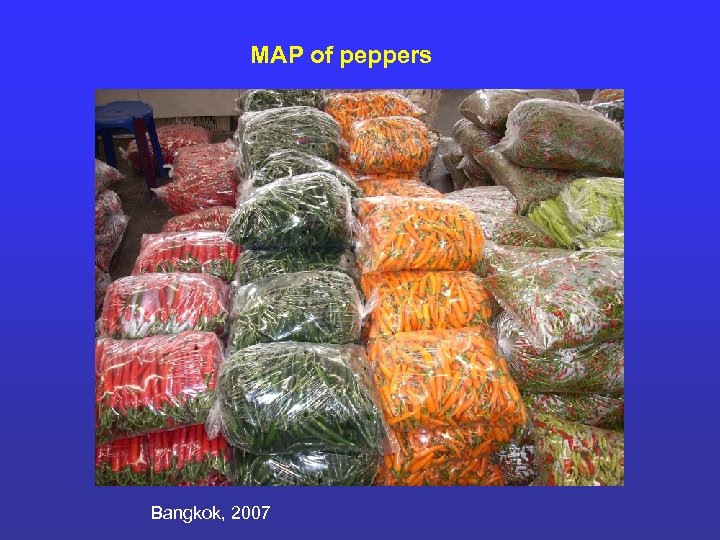

MAP of peppers Bangkok, 2007

MAP of peppers Bangkok, 2007

Pallet of Mango fruit covered with PE

Pallet of Mango fruit covered with PE

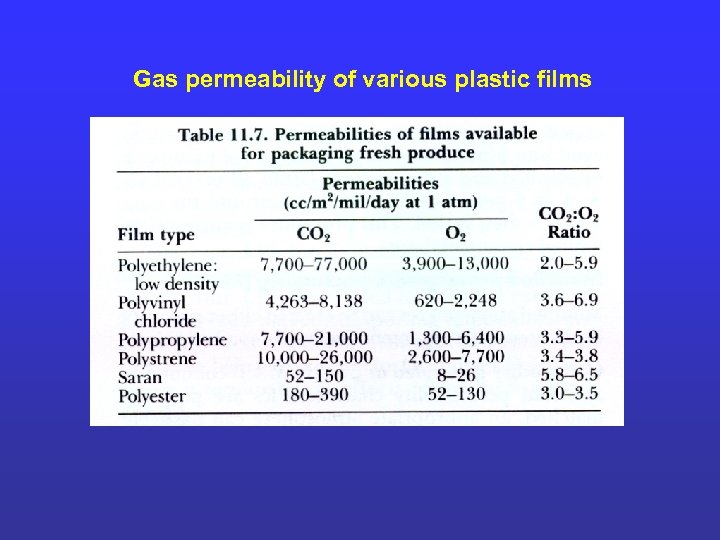

Gas permeability of various plastic films

Gas permeability of various plastic films

Perforated bags Bangkok, 2007

Perforated bags Bangkok, 2007

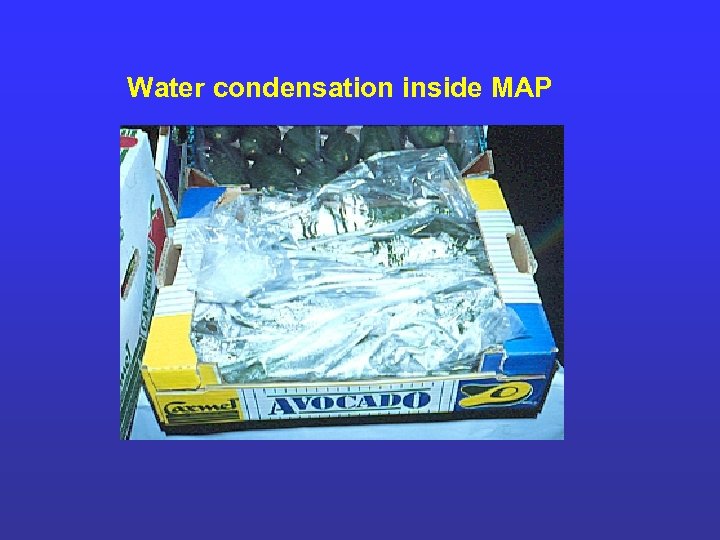

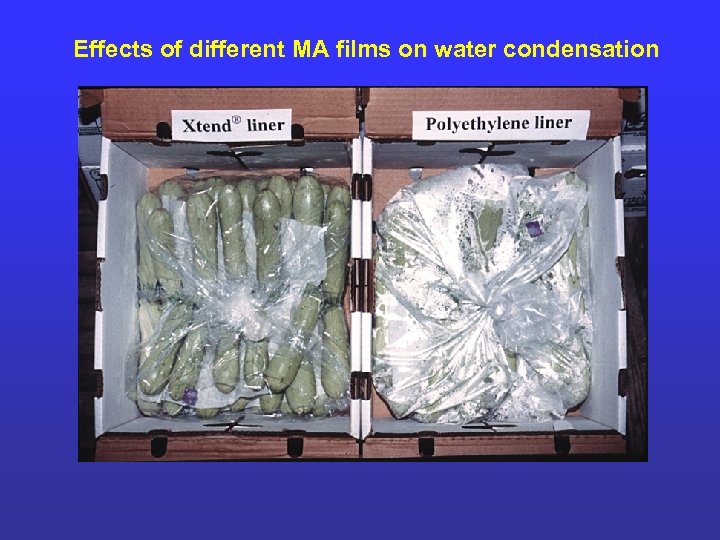

In addition to gas exchange properties, new polymeric films have been developed with various water vapor transmission rates, which allow to control the RH inside the package and to avoid problems caused by water condensation.

In addition to gas exchange properties, new polymeric films have been developed with various water vapor transmission rates, which allow to control the RH inside the package and to avoid problems caused by water condensation.

Water condensation inside MAP

Water condensation inside MAP

Effects of different MA films on water condensation

Effects of different MA films on water condensation

Effects of different MA films on water condensation

Effects of different MA films on water condensation

Water condensation and decay development Bangkok, 2007

Water condensation and decay development Bangkok, 2007

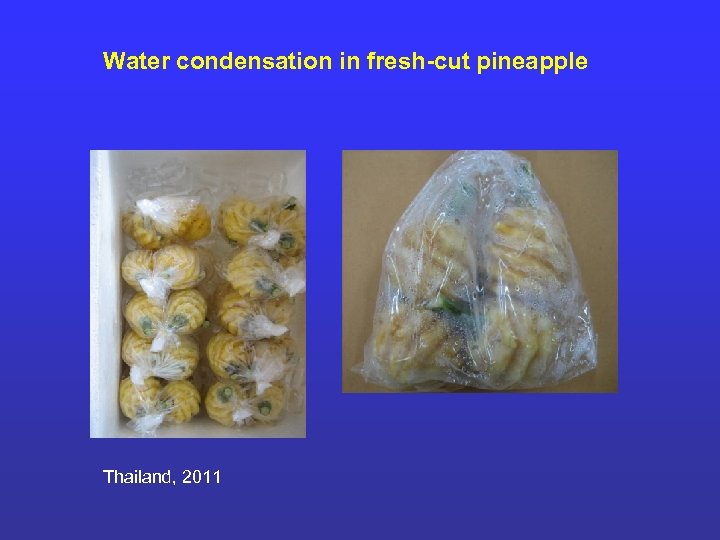

Water condensation in fresh-cut pineapple Thailand, 2011

Water condensation in fresh-cut pineapple Thailand, 2011

In commercial practice, CA is applied especially in apples and pears, whereas MA is successfully applied in a wide range of produce

In commercial practice, CA is applied especially in apples and pears, whereas MA is successfully applied in a wide range of produce

The following pictures explore some applicable uses of CA and MAP storage:

The following pictures explore some applicable uses of CA and MAP storage:

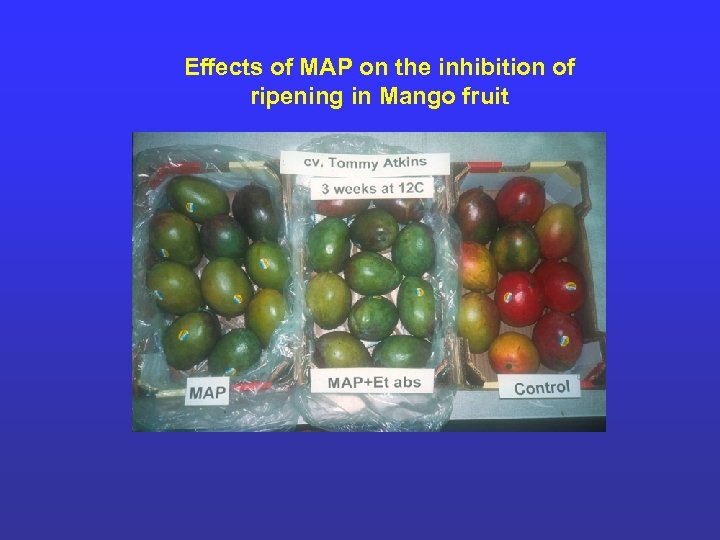

Effects of MAP on the inhibition of ripening in Mango fruit

Effects of MAP on the inhibition of ripening in Mango fruit

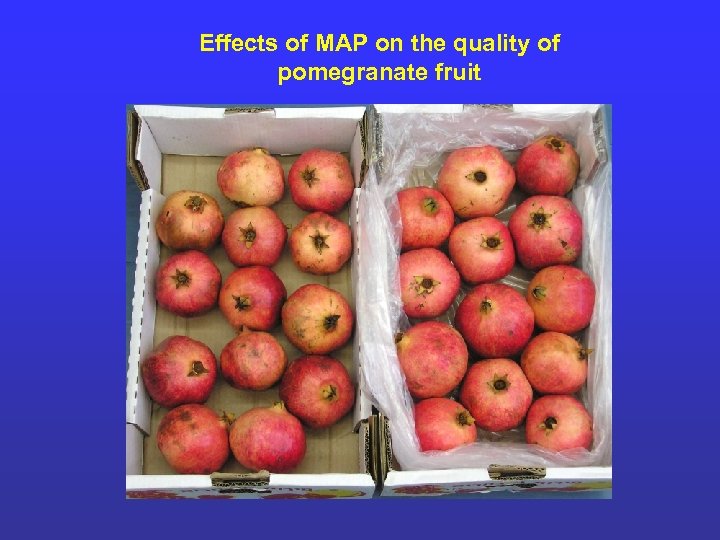

Effects of MAP on the quality of pomegranate fruit

Effects of MAP on the quality of pomegranate fruit

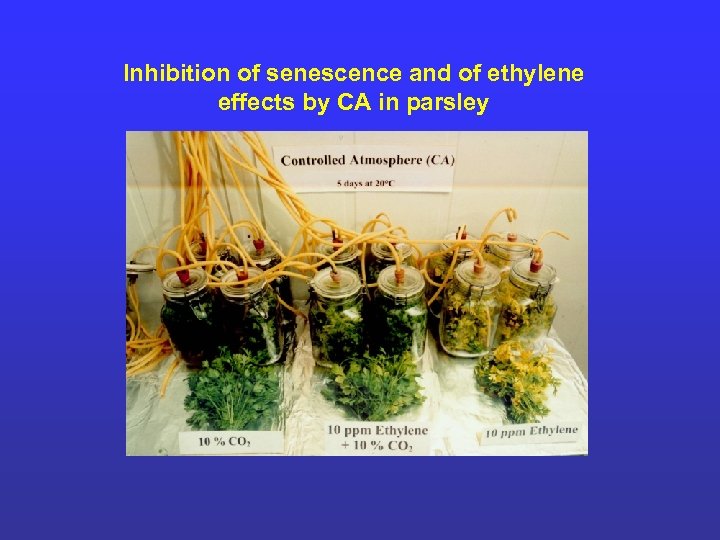

Inhibition of senescence and of ethylene effects by CA in parsley

Inhibition of senescence and of ethylene effects by CA in parsley

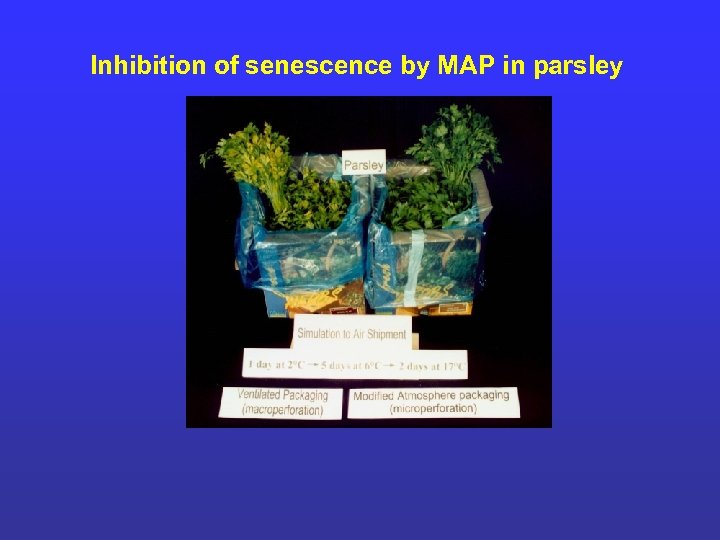

Inhibition of senescence by MAP in parsley

Inhibition of senescence by MAP in parsley

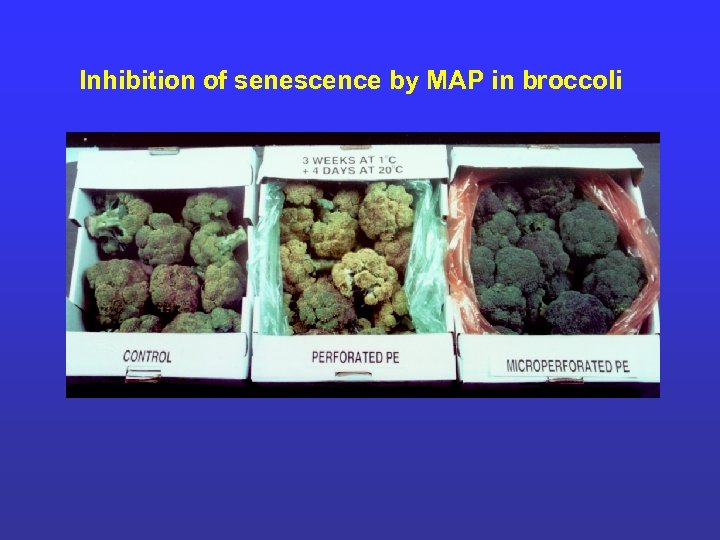

Inhibition of senescence by MAP in broccoli

Inhibition of senescence by MAP in broccoli

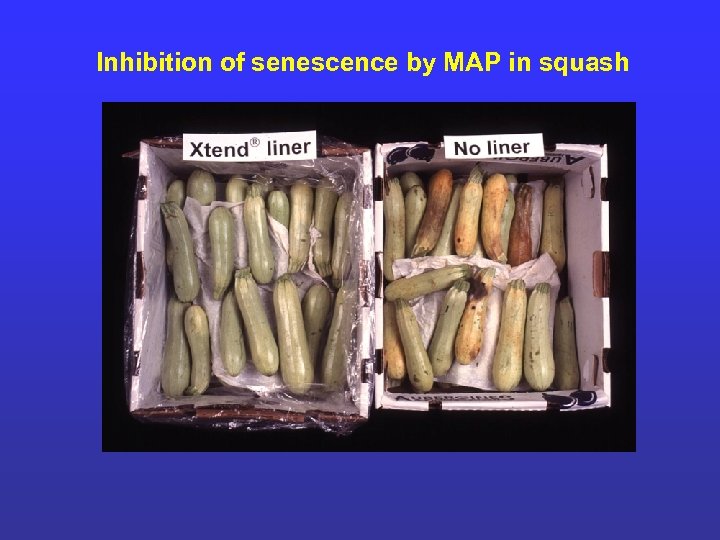

Inhibition of senescence by MAP in squash

Inhibition of senescence by MAP in squash

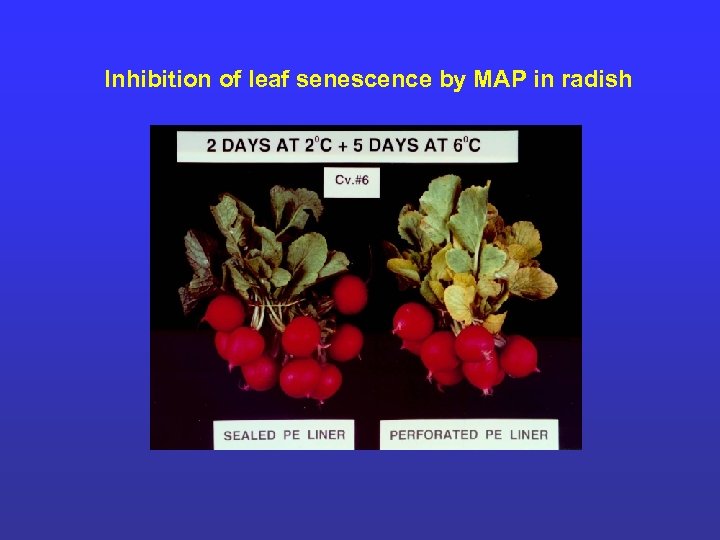

Inhibition of leaf senescence by MAP in radish

Inhibition of leaf senescence by MAP in radish

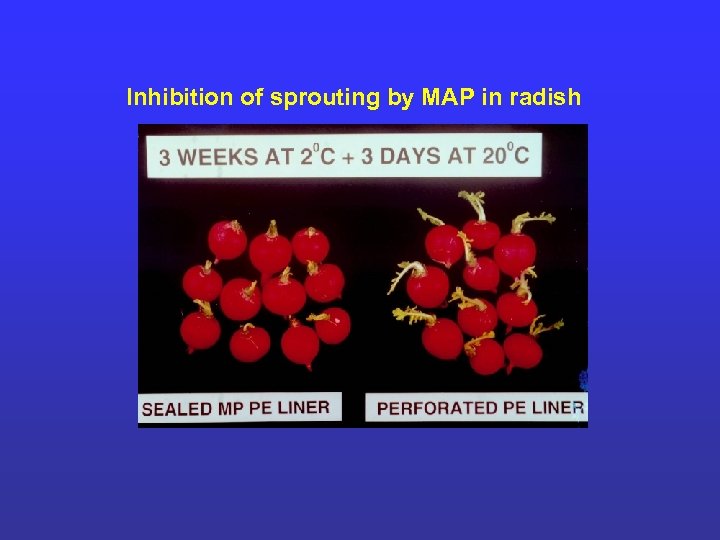

Inhibition of sprouting by MAP in radish

Inhibition of sprouting by MAP in radish

Thank you for your attention!

Thank you for your attention!