0983fbbf955575e4833de95e9b2fc68b.ppt

- Количество слайдов: 14

CONTENTS • DESIGN PROBLEM • INTRODUCTION • FLOW CHART OF DESIGN • NECESSARY RELATIONS • PROPOSED DESIGN • CONCLUSIONS • BIBLIOGRAPHY 1

DESIGN PROBLEM Design a shell and tube heat exchanger for heating 370 tons/hr of crude oil (sp gr. of 0. 826 at 15 C and normal boiling point 241 C) from 65 C to 90 C using kerosene (sp. gr. 0. 81 at 15 C and normal boiling point of 193. 5 C) available at a temperature of 150 C. Choose the flow rate of kerosene so that it does not vaporize 2

INTRODUCTION • Most versatile type of heat exchangers • Applications - Process industries, Conventional and nuclear power stations • Provide relatively large ratios of heat transfer area to volume 3

DESIGN FLOWCHART 4

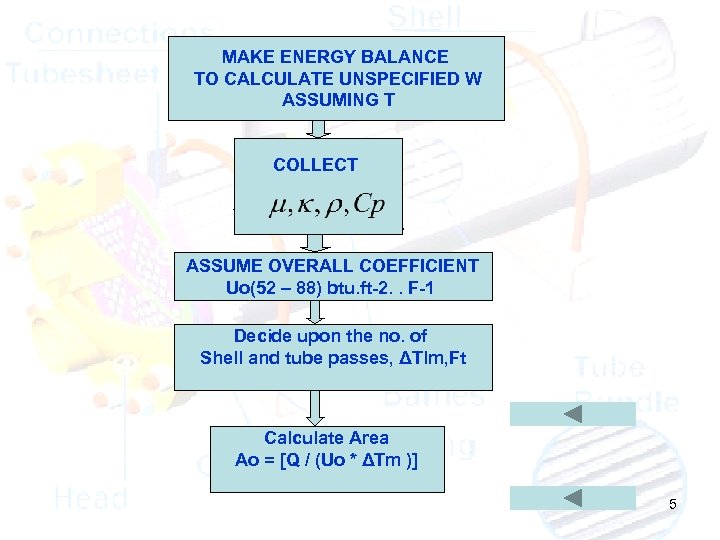

MAKE ENERGY BALANCE TO CALCULATE UNSPECIFIED W ASSUMING T COLLECT ASSUME OVERALL COEFFICIENT Uo(52 – 88) btu. ft-2. . F-1 Decide upon the no. of Shell and tube passes, ΔTlm, Ft Calculate Area Ao = [Q / (Uo * ΔTm )] 5

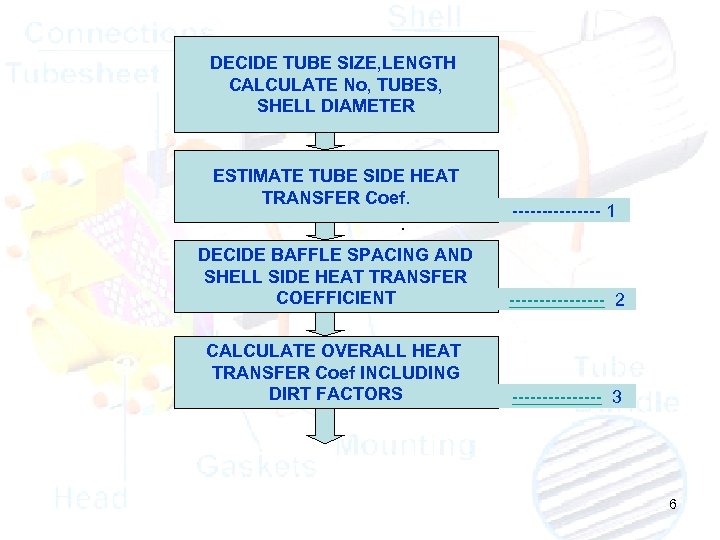

DECIDE TUBE SIZE, LENGTH CALCULATE No, TUBES, SHELL DIAMETER ESTIMATE TUBE SIDE HEAT TRANSFER Coef. -------- 1 DECIDE BAFFLE SPACING AND SHELL SIDE HEAT TRANSFER COEFFICIENT -------- 2 CALCULATE OVERALL HEAT TRANSFER Coef INCLUDING DIRT FACTORS -------- 3 6

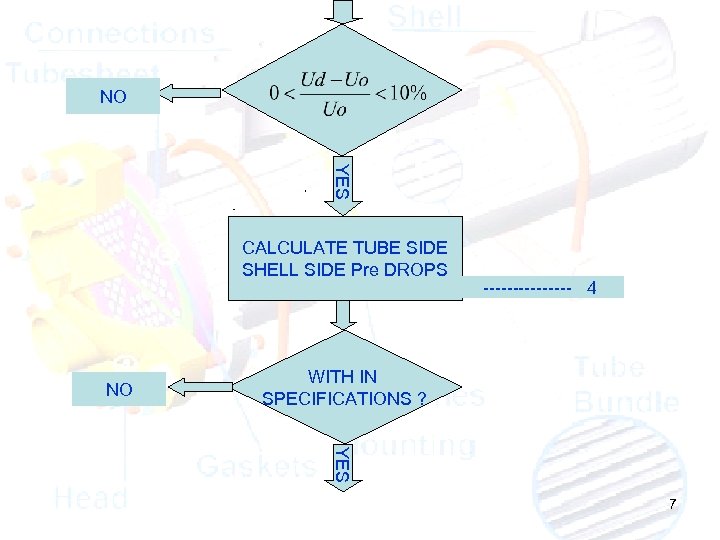

NO YES CALCULATE TUBE SIDE SHELL SIDE Pre DROPS NO -------- 4 WITH IN SPECIFICATIONS ? YES 7

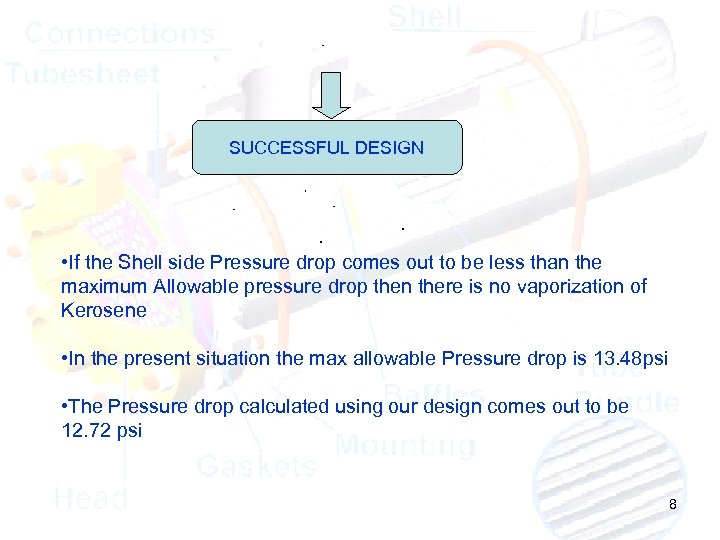

SUCCESSFUL DESIGN • If the Shell side Pressure drop comes out to be less than the maximum Allowable pressure drop then there is no vaporization of Kerosene • In the present situation the max allowable Pressure drop is 13. 48 psi • The Pressure drop calculated using our design comes out to be 12. 72 psi 8

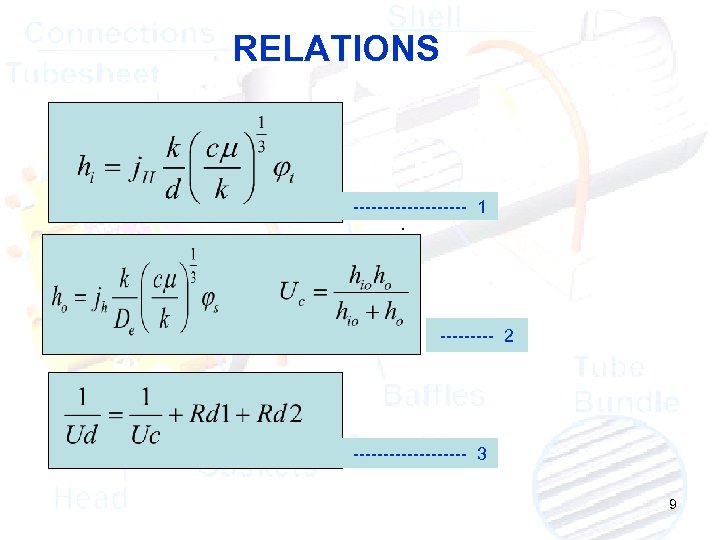

RELATIONS ---------- 1 ----- 2 ---------- 3 9

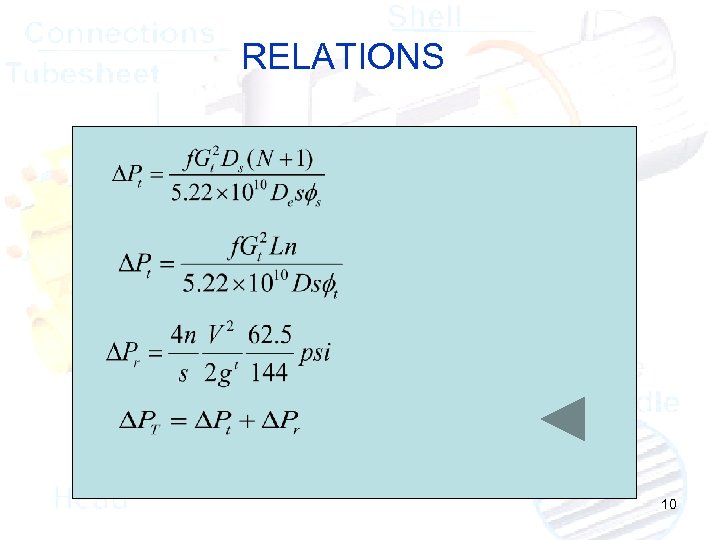

RELATIONS 10

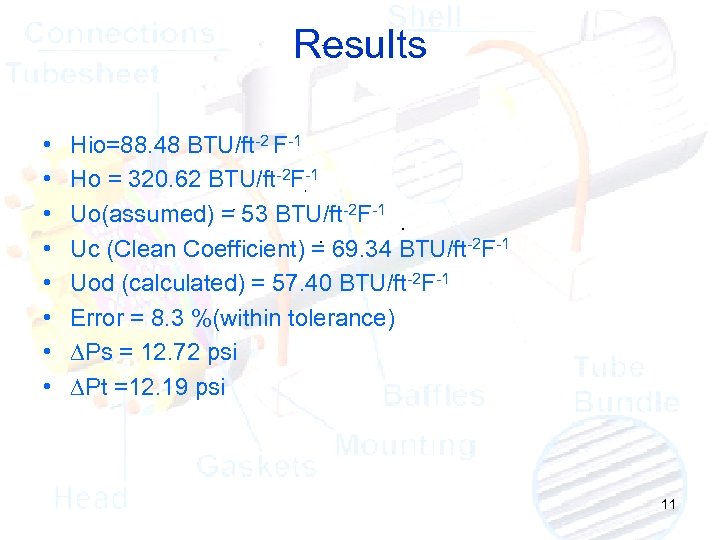

Results • • Hio=88. 48 BTU/ft-2 F-1 Ho = 320. 62 BTU/ft-2 F-1 Uo(assumed) = 53 BTU/ft-2 F-1 Uc (Clean Coefficient) = 69. 34 BTU/ft-2 F-1 Uod (calculated) = 57. 40 BTU/ft-2 F-1 Error = 8. 3 %(within tolerance) ∆Ps = 12. 72 psi ∆Pt =12. 19 psi 11

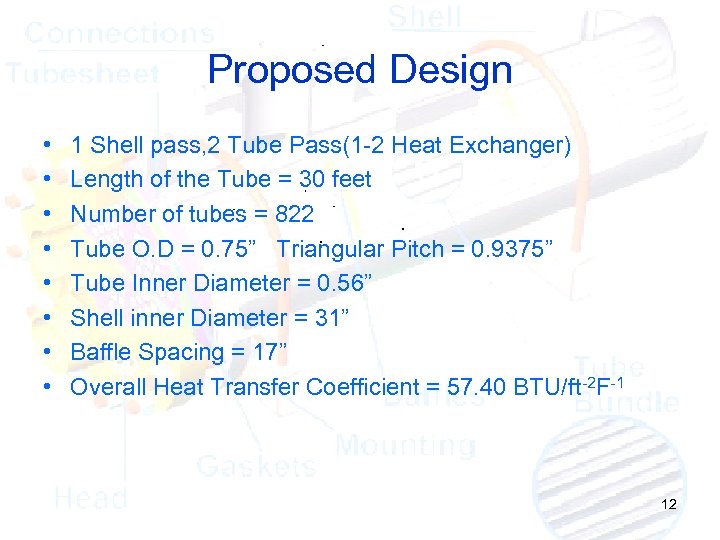

Proposed Design • • 1 Shell pass, 2 Tube Pass(1 -2 Heat Exchanger) Length of the Tube = 30 feet Number of tubes = 822 Tube O. D = 0. 75” Triangular Pitch = 0. 9375” Tube Inner Diameter = 0. 56” Shell inner Diameter = 31” Baffle Spacing = 17” Overall Heat Transfer Coefficient = 57. 40 BTU/ft-2 F-1 12

Conclusions • Pressure Drop results – less than the maximum allowable Pressure drop for this Equipment • Heat exchanger dimensions suggested – within the range used as thumb rules in Industry • Heat Transfer Area can be increased – Put more Tubes, use finned-tube Heat exchanger • Satisfactory Design was proposed 13

Bibliography • Kern, Donald Q. , “Process Heat Transfer” • Ludwig, Ernest E. , “Applied Process Design for chemical and petrochemical plants”, vol. 3, Ed. 3. • Ozisik, Nekati M. , “Heat Transfer” • Perry’s Chemical Engineers’ Handbook. (software edition) 14

0983fbbf955575e4833de95e9b2fc68b.ppt