CONTACT INFORMATION for Course Leaders:

CONTACT INFORMATION for Course Leaders:

Seminar Contents

Seminar Contents

Part 1

Part 1

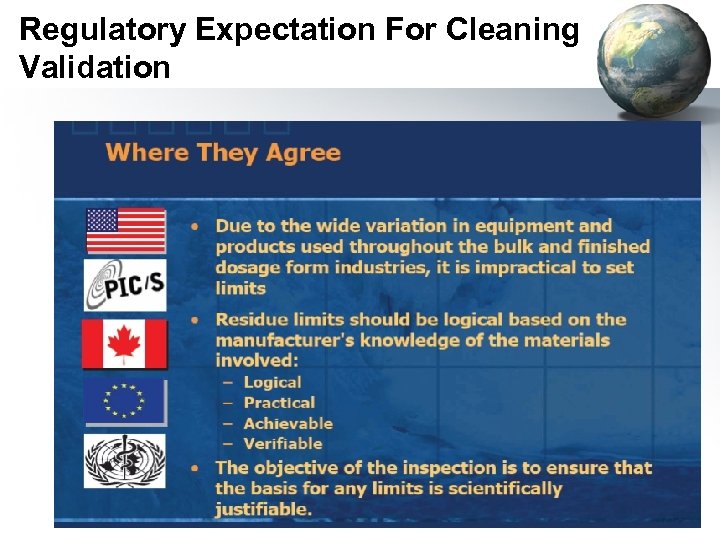

Regulatory Expectation For Cleaning Validation

Regulatory Expectation For Cleaning Validation

Possible types of limits

Possible types of limits

Visual inspection

Visual inspection

Chemical analytical limits

Chemical analytical limits

Possible uses of “limit”

Possible uses of “limit”

Other basis for limit

Other basis for limit

Safety factors

Safety factors

Limit depends on. . .

Limit depends on. . .

Part 2 Setting Limits for Use in Cleaning Validation – Case Study

Part 2 Setting Limits for Use in Cleaning Validation – Case Study

Does not depend on…

Does not depend on…

But we aren’t just worried about product residues

But we aren’t just worried about product residues

Setting the non-product related limits

Setting the non-product related limits

Setting the non-product related limits

Setting the non-product related limits

The Centrifuge

The Centrifuge

Centrifuge Example

Centrifuge Example

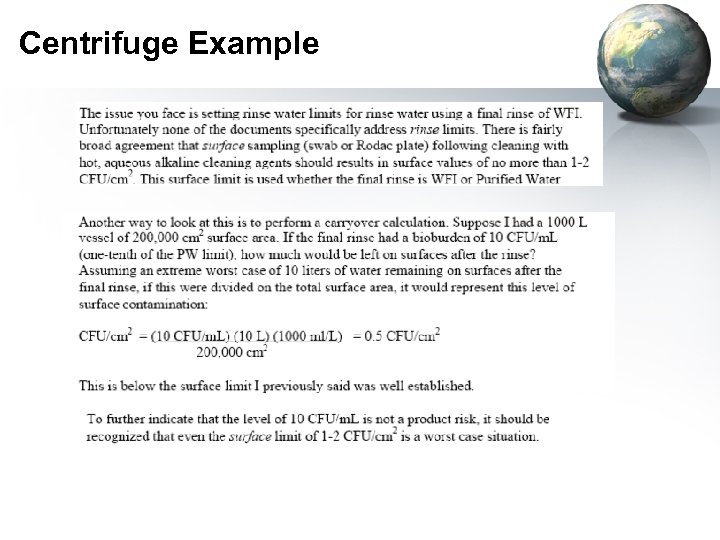

Centrifuge Example

Centrifuge Example

Centrifuge Example

Centrifuge Example

Centrifuge Example

Centrifuge Example

What about TOC? Is <500 ppb realistic

What about TOC? Is <500 ppb realistic

TOC

TOC

Endotoxin

Endotoxin

Conductivity

Conductivity

Product Specific Residues

Product Specific Residues

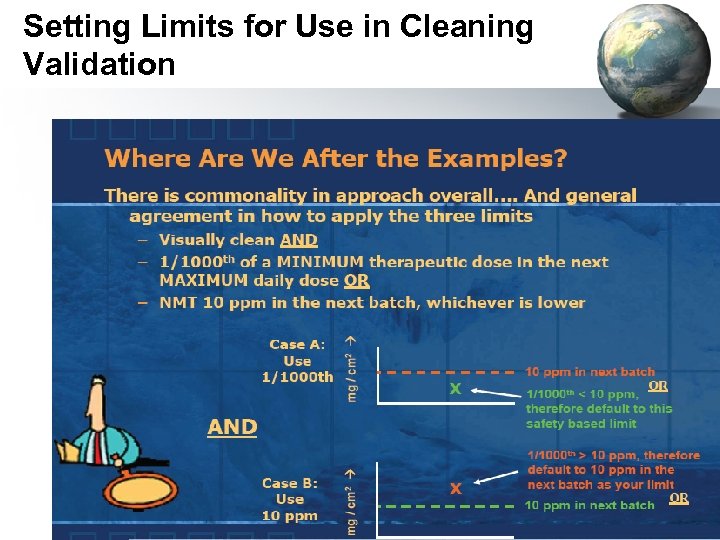

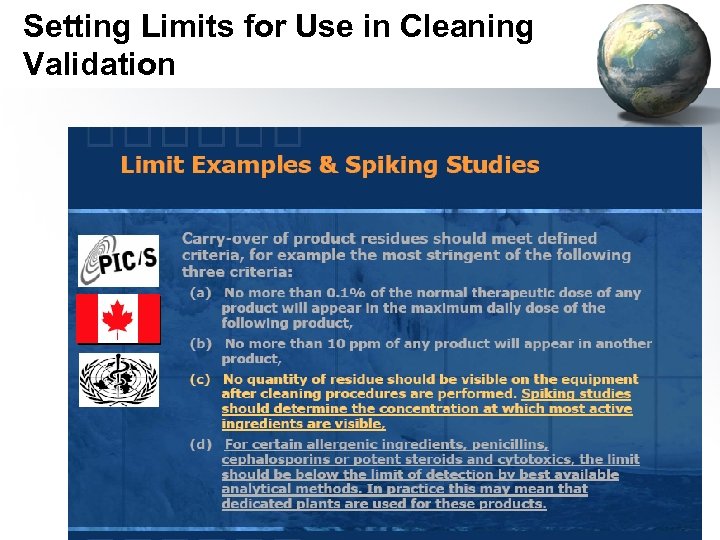

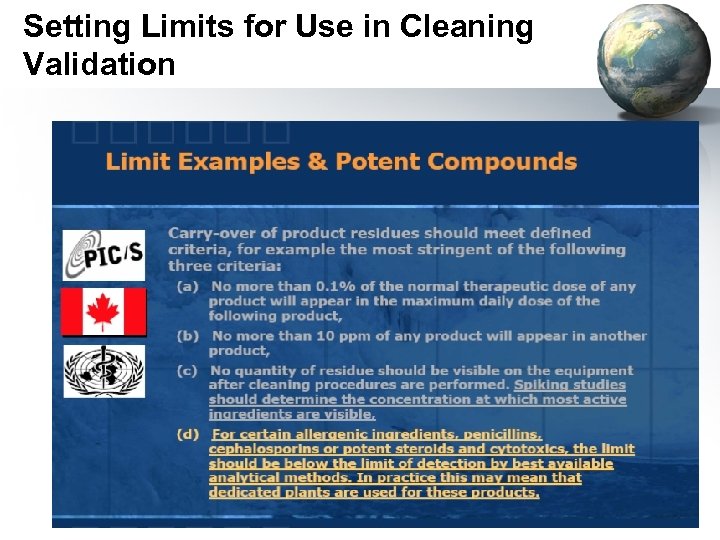

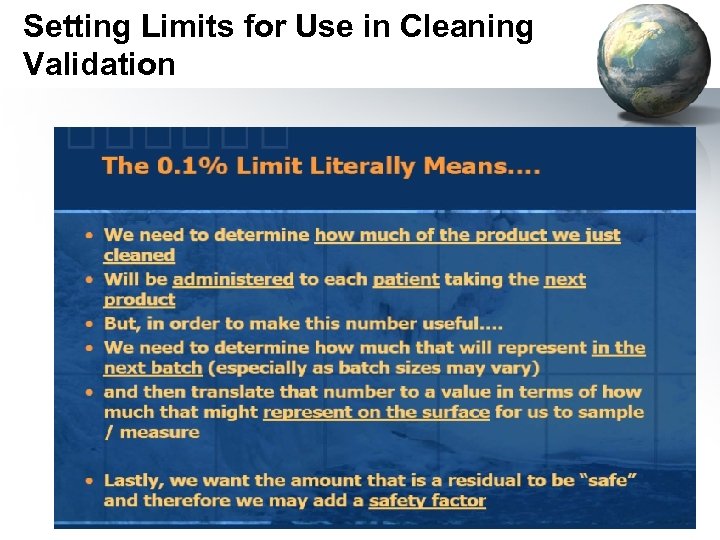

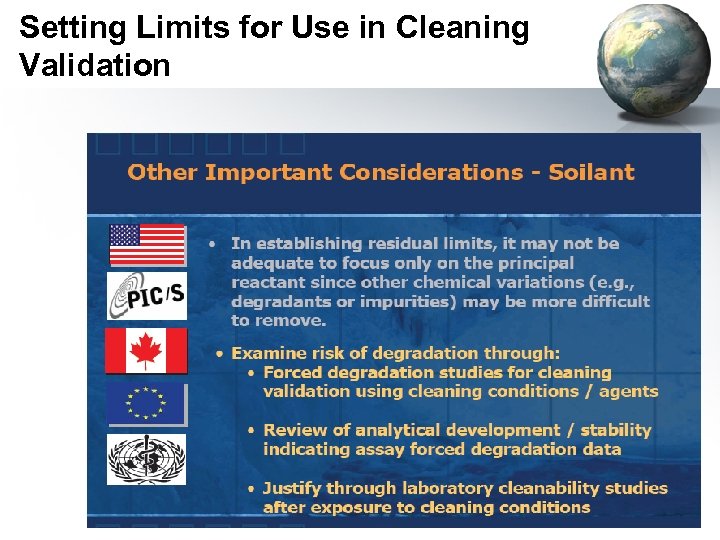

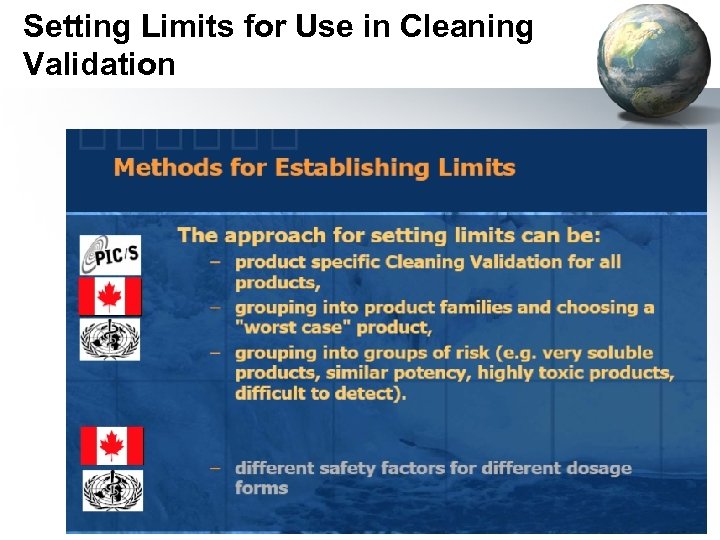

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

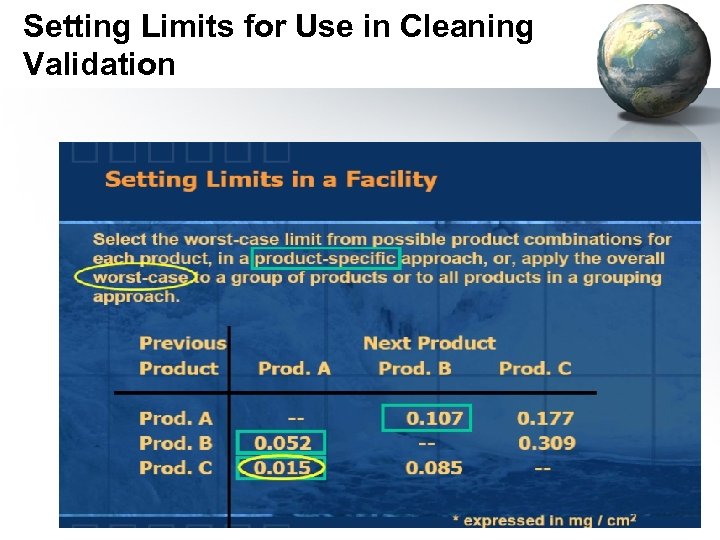

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

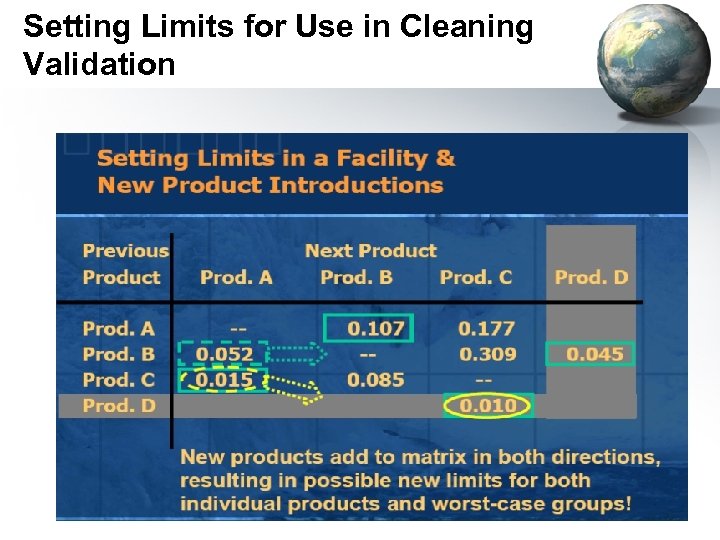

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

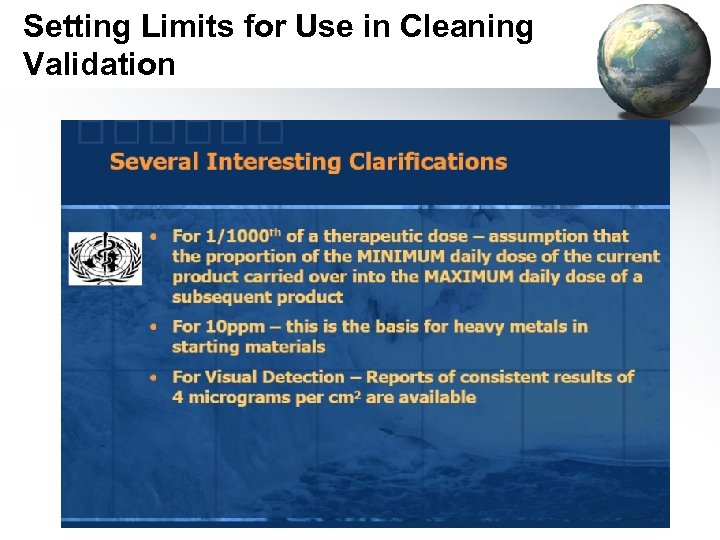

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Setting Limits for Use in Cleaning Validation

Part 3 Development Acceptance Criteria

Part 3 Development Acceptance Criteria

Cleaning Selection Process

Cleaning Selection Process

Cleaning Cycle Development Steps

Cleaning Cycle Development Steps

Cleaning Cycle Development Strategy (Step by Step)

Cleaning Cycle Development Strategy (Step by Step)

Cleaning Cycle Development Strategy, Cont.

Cleaning Cycle Development Strategy, Cont.

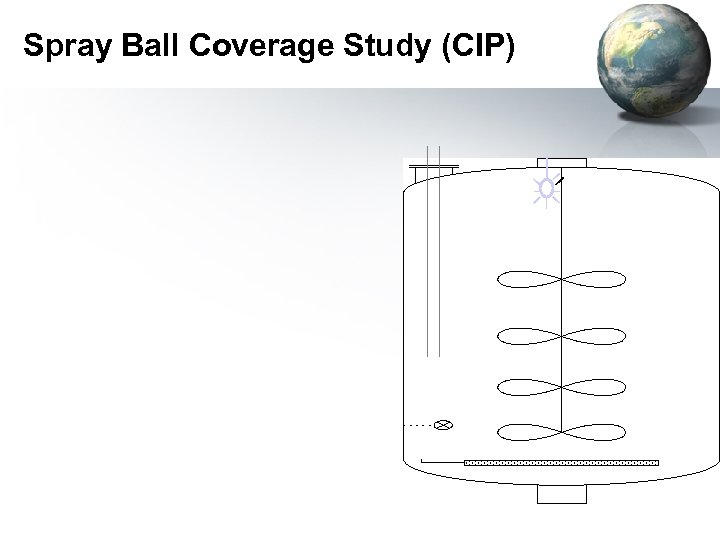

Spray Ball Coverage Study (CIP)

Spray Ball Coverage Study (CIP)

Part 4 Selection of Sample Location

Part 4 Selection of Sample Location

Worst Case Selection

Worst Case Selection

Sampling Site Selection

Sampling Site Selection

Considerations in Sampling Site Selection

Considerations in Sampling Site Selection

Part 7 Setting Acceptance Criteria and Calculating Residue Limits – Work Shop

Part 7 Setting Acceptance Criteria and Calculating Residue Limits – Work Shop

Absolute amount limit

Absolute amount limit

Limit per surface area

Limit per surface area

Analytical sample example

Analytical sample example

“Rinse” solution limits

“Rinse” solution limits

Sampling rinse example

Sampling rinse example

Summary

Summary

Things to avoid

Things to avoid