856c5f8a475e5a0b668a103627268d07.ppt

- Количество слайдов: 24

CONTAC Real Time Operational Perfomance and Variability Supervision Diego Arenas CONTAC INGENIEROS OPERATIONAL INTELLIGENCE TECHNOLOGIES Empowering your PI Rt. PM infrastructure

CONTAC Why real time KPI´s? Cost Quality Efficiency Reliability Same for Steel, Pulp&paper, Petrochem, Utilities, etc. Process operations are complex systems, where perfomance goals are evaluated using different business KPI´s criteria. Business KPI time-frames ranges from long term “operational management control loops”, such as mine planing-mine operation, to short term, such as concentrator recovery control vs. short term program. Despite the KPI time frame, most of the business KPI are rooted to the operation, it can be said that business KPI are built in real time.

CONTAC The value fishbone, . . . how the business KPI´s are built Quality Efficiency Cost Reliability Business KPI´s are “built” in real time. Gains and losses happen in real time A process bottleneck (leading to quality, throughput losses): a conveyor, or a pump or a control valve working at its maximum capacity or speed for an extended period of time A cascaded (and $$$$ amplified) variability: cyclone feed density variability that leads to a size variability that leads to a flotation recovery variability. Quality losses (plus: energy, operational time, consumables, etc. ): because of an inefficient operation of its regulatory system.

CONTAC What we know about the process behavior? • Large number of process variables • Complex cause-effect relationships • Different (time based) Operation Modes: drift, noise, start-up, set point changes, disturbances, etc. • Large data bases for Real Time and Historical information about process variables and equipment vital signs. The Need: an automated system capable to online analize thousands of process variable data and generate context based meaningful information • How to determine early alerts if the process or machine is deviating from a pattern or moving to a new one, being an “on quality pattern”, a “throughput pattern”, a “malfunction pattern”, etc. ? • How to determine the “most influencing” factors that drives the evolution of a certain process variable or equipment vital sign KPI?

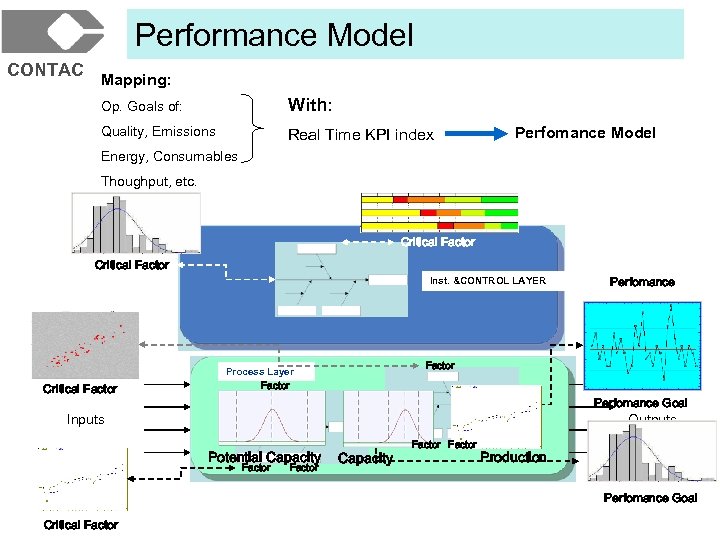

Performance Model CONTAC Mapping: Op. Goals of: With: Quality, Emissions Real Time KPI index Perfomance Model Energy, Consumables Thoughput, etc. Critical Factor Inst. &CONTROL LAYER Critical Factor Perfomance Factor Process Layer Factor Perfomance Goal Inputs Outputs Potential Capacity Factor Production Perfomance Goal Critical Factor

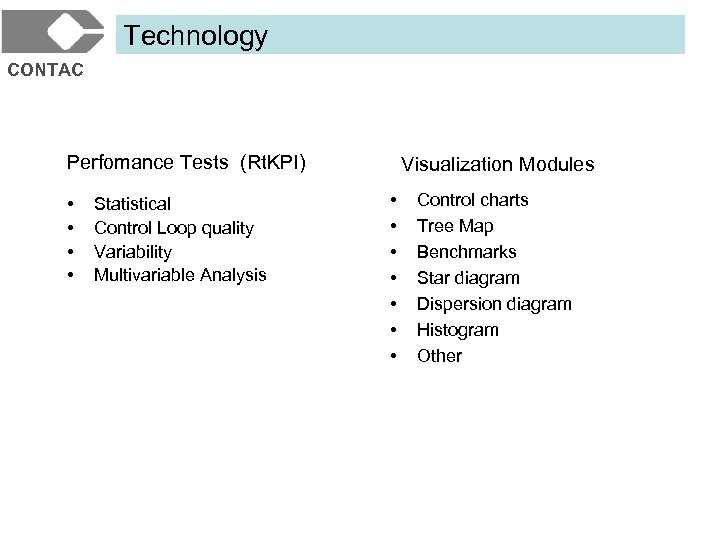

Technology CONTAC Perfomance Tests (Rt. KPI) • • Statistical Control Loop quality Variability Multivariable Analysis Visualization Modules • • Control charts Tree Map Benchmarks Star diagram Dispersion diagram Histogram Other

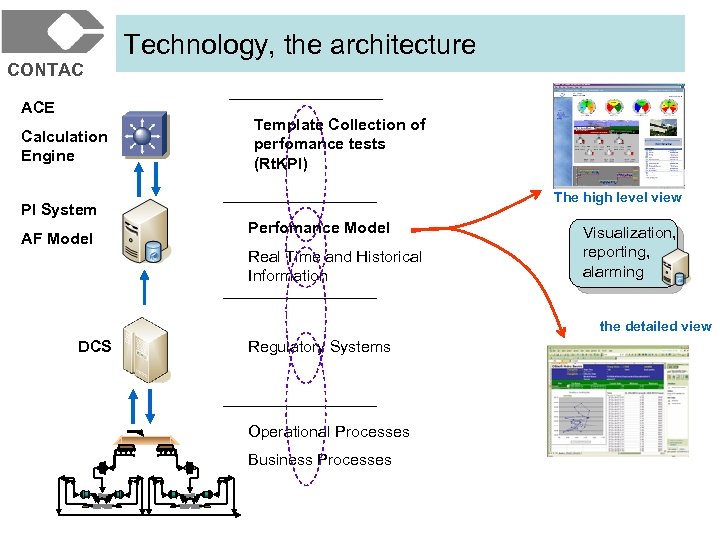

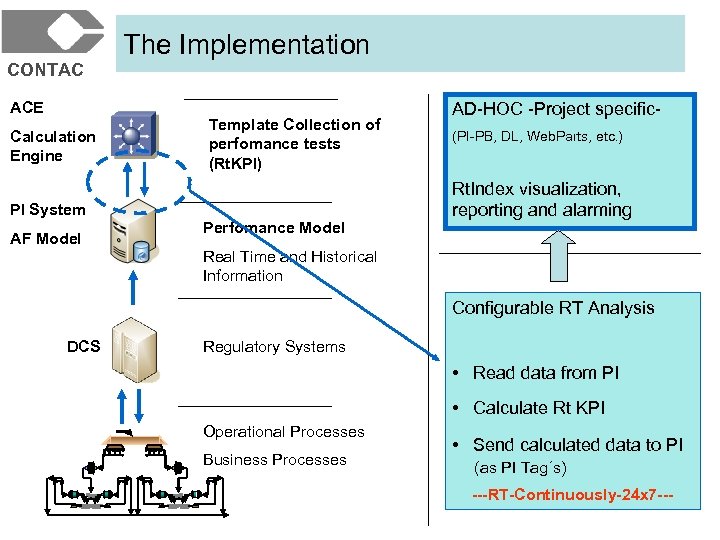

CONTAC ACE Calculation Engine Technology, the architecture Template Collection of perfomance tests (Rt. KPI) The high level view PI System AF Model Perfomance Model Real Time and Historical Information Visualization, reporting, alarming the detailed view DCS Regulatory Systems Operational Processes Business Processes

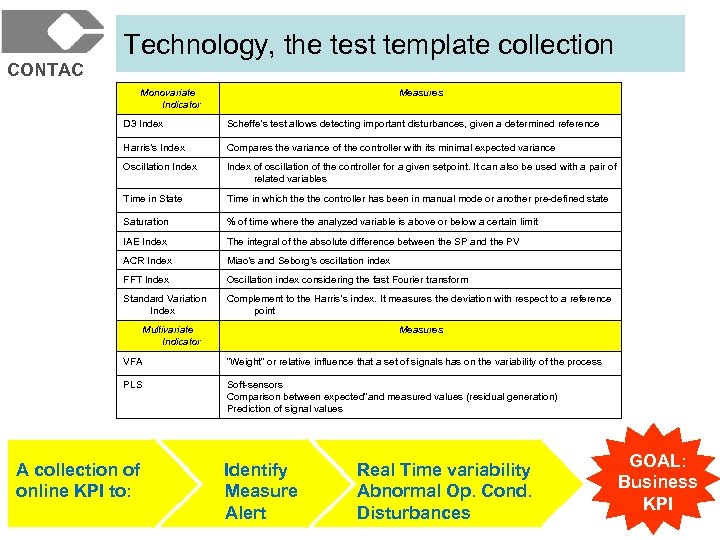

CONTAC Technology, the test template collection Monovariate Indicator Measures D 3 Index Scheffe’s test allows detecting important disturbances, given a determined reference Harris’s Index Compares the variance of the controller with its minimal expected variance Oscillation Index of oscillation of the controller for a given setpoint. It can also be used with a pair of related variables Time in State Time in which the controller has been in manual mode or another pre-defined state Saturation % of time where the analyzed variable is above or below a certain limit IAE Index The integral of the absolute difference between the SP and the PV ACR Index Miao’s and Seborg’s oscillation index FFT Index Oscillation index considering the fast Fourier transform Standard Variation Index Complement to the Harris’s index. It measures the deviation with respect to a reference point Multivariate Indicator Measures VFA “Weight” or relative influence that a set of signals has on the variability of the process PLS Soft-sensors Comparison between expected”and measured values (residual generation) Prediction of signal values A collection of online KPI to: Identify Measure Alert Real Time variability Abnormal Op. Cond. Disturbances GOAL: Business KPI

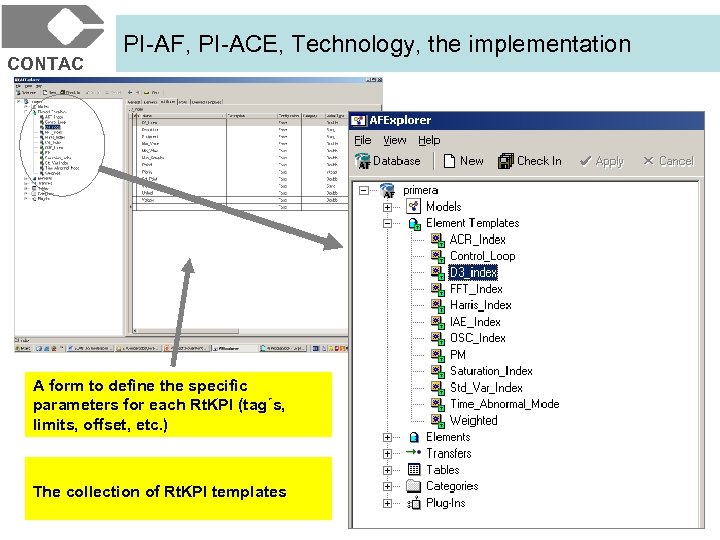

CONTAC PI-AF, PI-ACE, Technology, the implementation A form to define the specific parameters for each Rt. KPI (tag´s, limits, offset, etc. ) The collection of Rt. KPI templates

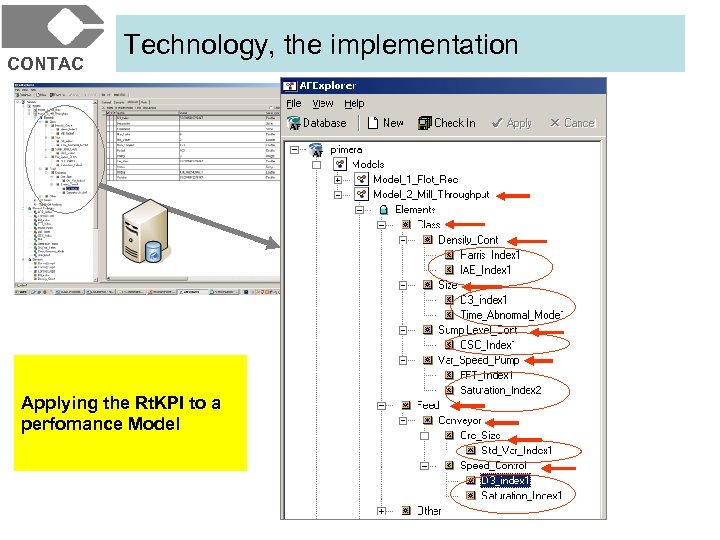

CONTAC Technology, the implementation Applying the Rt. KPI to a perfomance Model

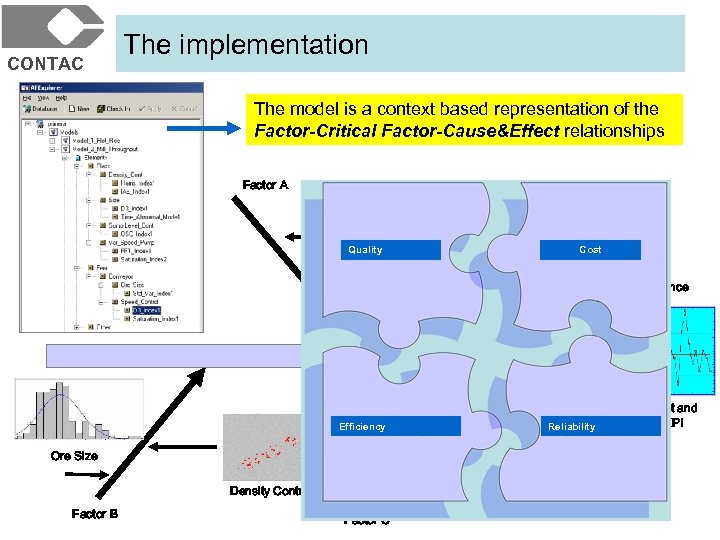

CONTAC The implementation The model is a context based representation of the Factor-Critical Factor-Cause&Effect relationships Factor A Sump Pump Quality Cost Perfomance Efficiency Reliability Ore Size Density Control Factor B Class. Harris Index Factor C Throughput and quality KPI

CONTAC The technology, summary Allows for a direct mapping between the Business KPI and its Real Time drivers. Allow for the implementation of an automatic, online perfomance supervision system, working in a 24 x 7 shift… A scalable and modular technical architecture. Plants, Lines, Processes, Equipment models can be implemented. Since the calculated index are sent back to the plant historian, the values can be trended, alarmed, shown on process diagrams, reported, e-mailed, etc.

CONTAC ACE Calculation Engine The Implementation Template Collection of perfomance tests (Rt. KPI) PI System AF Model Perfomance Model AD-HOC -Project specific(PI-PB, DL, Web. Parts, etc. ) Rt. Index visualization, reporting and alarming Real Time and Historical Information Configurable RT Analysis DCS Regulatory Systems • Read data from PI • Calculate Rt KPI Operational Processes Business Processes • Send calculated data to PI (as PI Tag´s) ---RT-Continuously-24 x 7 ---

CONTAC Implementation example Reminder: 1. Core system: KPI templates, PI-AF/ACE calculations are standard 2. Reporting and visualization are built using standard PI-Rt. PM tools 3. Nevertheless, even PB and DL are project specific, since the construction are made using PI-AF context based models, it can be reused for other applications. Again: what will be shown is a PB+DL app. , it can be modified, reused, re-done, etc. , using the RT Indexes being calculated by the standard PI-ACE/AF RT KPI templates

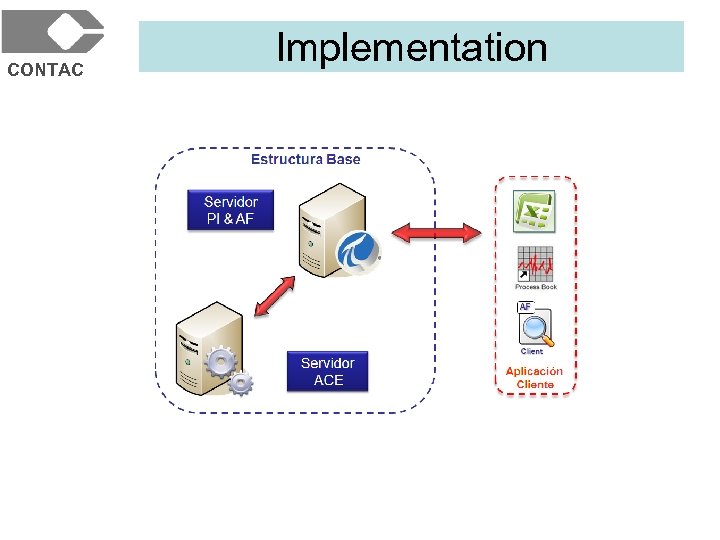

CONTAC Implementation

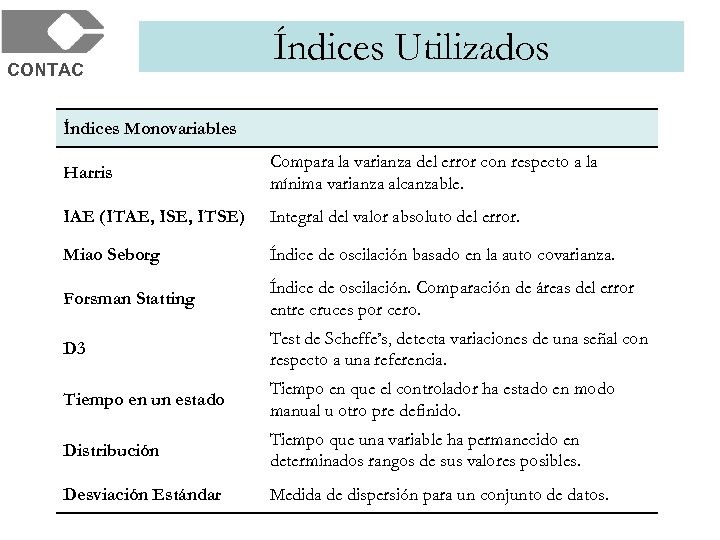

CONTAC Índices Utilizados Índices Monovariables Harris Compara la varianza del error con respecto a la mínima varianza alcanzable. IAE (ITAE, ISE, ITSE) Integral del valor absoluto del error. Miao Seborg Índice de oscilación basado en la auto covarianza. Forsman Statting Índice de oscilación. Comparación de áreas del error entre cruces por cero. D 3 Test de Scheffe’s, detecta variaciones de una señal con respecto a una referencia. Tiempo en un estado Tiempo en que el controlador ha estado en modo manual u otro pre definido. Distribución Tiempo que una variable ha permanecido en determinados rangos de sus valores posibles. Desviación Estándar Medida de dispersión para un conjunto de datos.

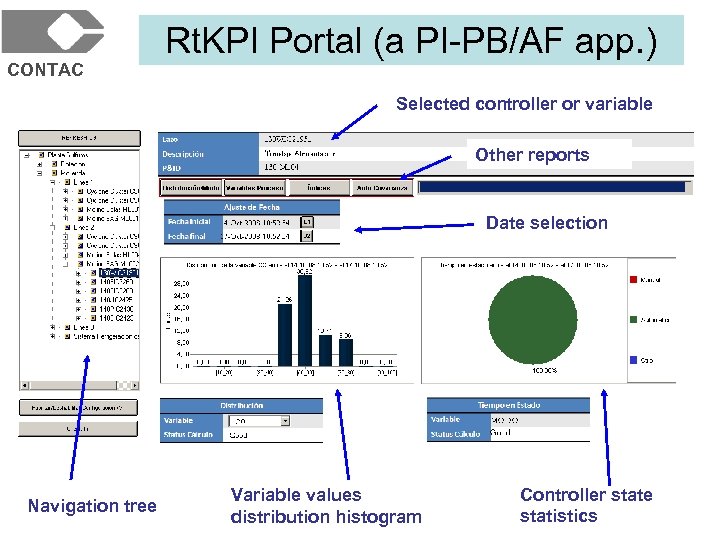

CONTAC Rt. KPI Portal (a PI-PB/AF app. ) Selected controller or variable Other reports Date selection Navigation tree Variable values distribution histogram Controller state statistics

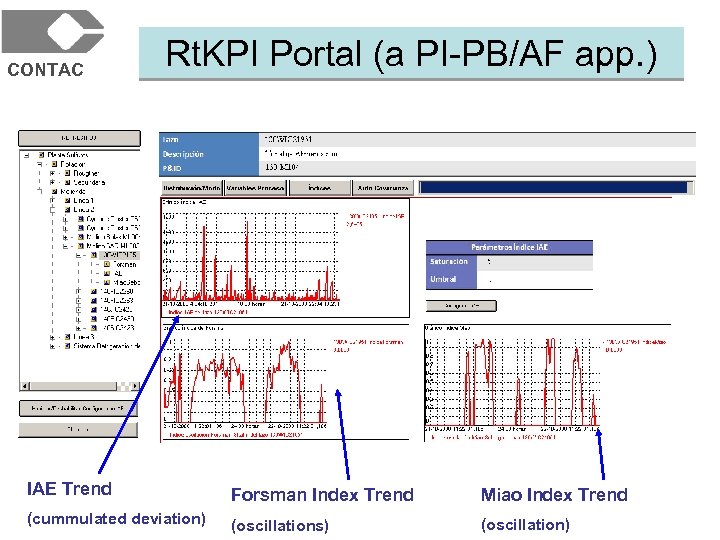

CONTAC Rt. KPI Portal (a PI-PB/AF app. ) IAE Trend Forsman Index Trend Miao Index Trend (cummulated deviation) (oscillations) (oscillation)

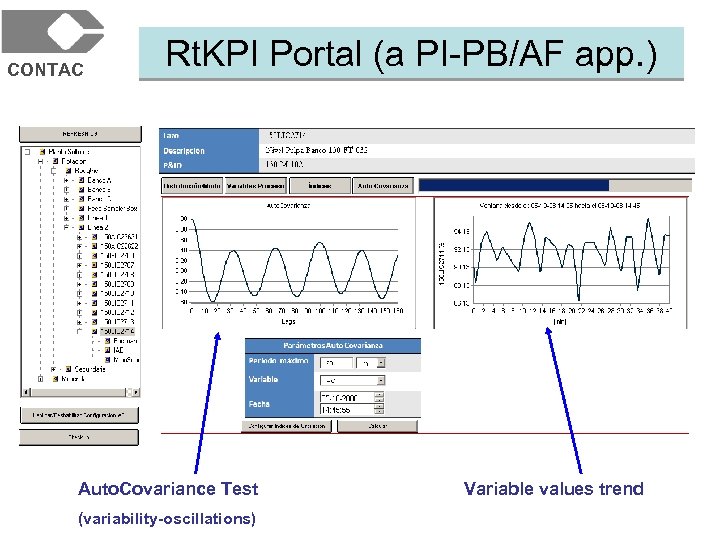

CONTAC Rt. KPI Portal (a PI-PB/AF app. ) Auto. Covariance Test (variability-oscillations) Variable values trend

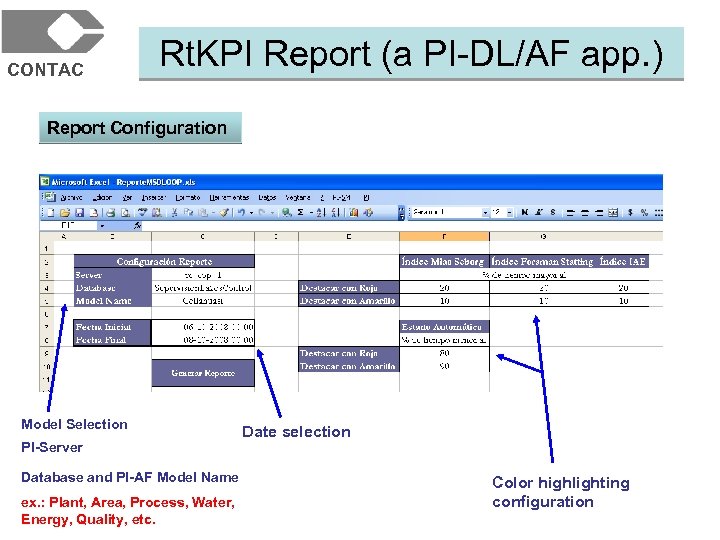

CONTAC Rt. KPI Report (a PI-DL/AF app. ) Report Configuration Model Selection PI-Server Database and PI-AF Model Name ex. : Plant, Area, Process, Water, Energy, Quality, etc. Date selection Color highlighting configuration

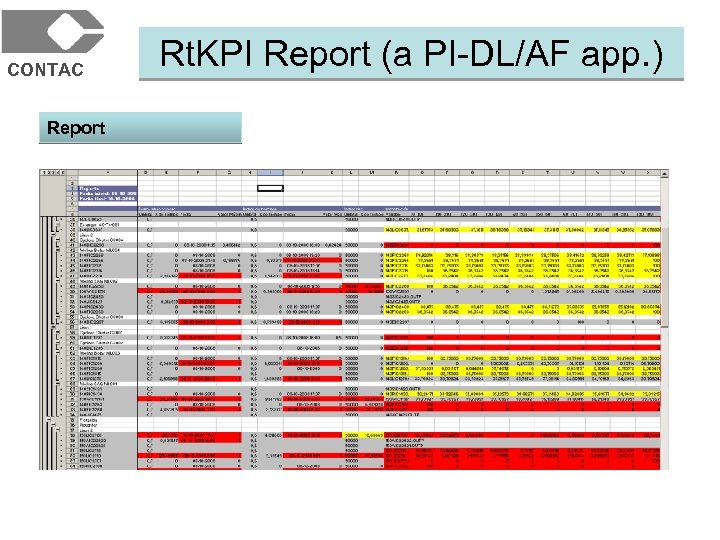

CONTAC Report Rt. KPI Report (a PI-DL/AF app. )

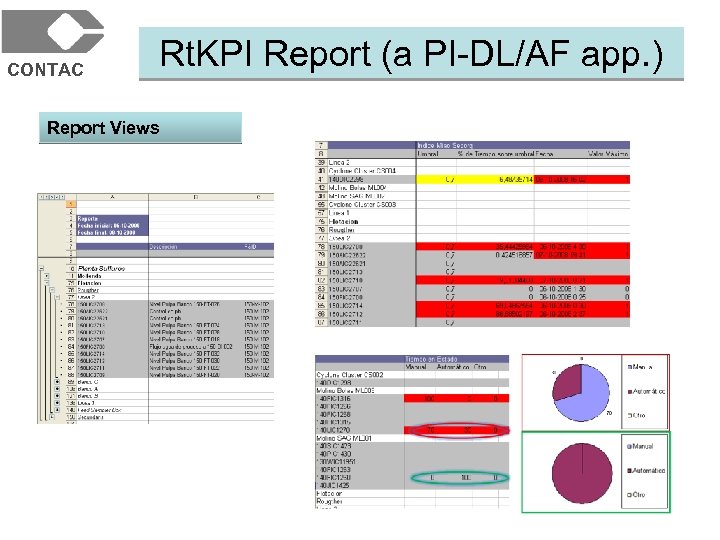

CONTAC Rt. KPI Report (a PI-DL/AF app. ) Report Views

CONTAC DEMO OPERATIONAL INTELLIGENCE TECHNOLOGIES Empowering your PI Rt. PM infrastructure

CONTAC Real Time Operational Perfomance Supervision Luis Yacher S. ; Felipe Kripper; Felipe Lineo CONTAC INGENIEROS OPERATIONAL INTELLIGENCE TECHNOLOGIES Empowering your PI Rt. PM infrastructure

856c5f8a475e5a0b668a103627268d07.ppt