d0a061754a245b4f2077a5dd98a22b34.ppt

- Количество слайдов: 38

Considerations for Implementing Maintenance Line Operations Safety Assessments (M-LOSA) August 2014 (v 6)

Considerations for Implementing Maintenance Line Operations Safety Assessments (M-LOSA) August 2014 (v 6)

Agenda Q Who is involved? Q What is LOSA? Q Why LOSA? Q Status Report and LOSA Products Q Steps to Implement LOSA Q Questions/Discussion? 2

Agenda Q Who is involved? Q What is LOSA? Q Why LOSA? Q Status Report and LOSA Products Q Steps to Implement LOSA Q Questions/Discussion? 2

What is LOSA? 3

What is LOSA? 3

LOSA is…. ¡ Line Operations Safety Assessment FOQA ASAP SMS ASRS LOSA CASS 4

LOSA is…. ¡ Line Operations Safety Assessment FOQA ASAP SMS ASRS LOSA CASS 4

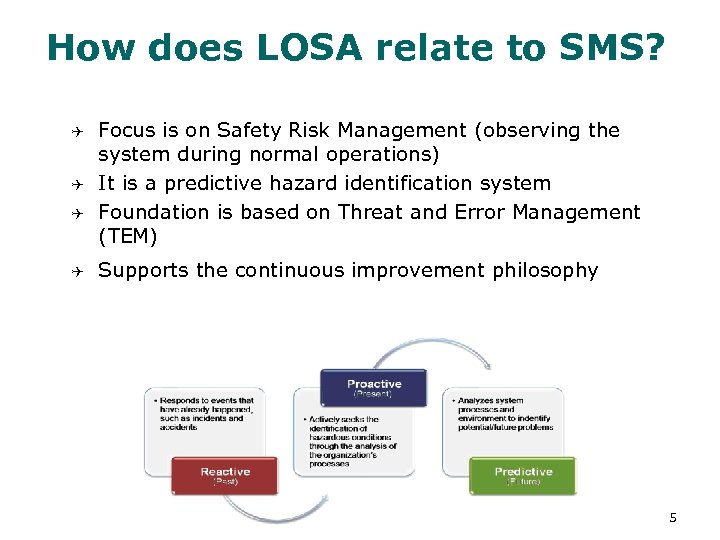

How does LOSA relate to SMS? Q Q Focus is on Safety Risk Management (observing the system during normal operations) It is a predictive hazard identification system Foundation is based on Threat and Error Management (TEM) Supports the continuous improvement philosophy 5

How does LOSA relate to SMS? Q Q Focus is on Safety Risk Management (observing the system during normal operations) It is a predictive hazard identification system Foundation is based on Threat and Error Management (TEM) Supports the continuous improvement philosophy 5

Reactive Hazard Identification Q Q Investigation of accidents and incidents. Boeing Maintenance Error Decision Aid (MEDA) for line maintenance and heavy maintenance. Boeing MEDA Workshops for back shop maintenance. Boeing Ramp Error Decision Aid (REDA) 6

Reactive Hazard Identification Q Q Investigation of accidents and incidents. Boeing Maintenance Error Decision Aid (MEDA) for line maintenance and heavy maintenance. Boeing MEDA Workshops for back shop maintenance. Boeing Ramp Error Decision Aid (REDA) 6

Proactive Hazard Identification Q Mandatory and voluntary reporting systems, safety assessment, and surveys Q Quality Assurance Audits Q Internal hazard reporting systems Q Safety surveys 7

Proactive Hazard Identification Q Mandatory and voluntary reporting systems, safety assessment, and surveys Q Quality Assurance Audits Q Internal hazard reporting systems Q Safety surveys 7

Predictive Hazard Identification Q Confidential reporting systems, flight data analysis, and normal operations monitoring. Q Digital Flight Data Recorder (DFDR) Analysis Q Line Operations Safety Assessment (LOSA) Q Flight Q Maintenance Q Ramp 8

Predictive Hazard Identification Q Confidential reporting systems, flight data analysis, and normal operations monitoring. Q Digital Flight Data Recorder (DFDR) Analysis Q Line Operations Safety Assessment (LOSA) Q Flight Q Maintenance Q Ramp 8

Intent of LOSA Observations Q Observe day-to-day work behaviors during normal operations Q Discover procedural and systemic threats and errors Q Reduce injuries & equipment/aircraft damage Q Generate baseline data, implement new changes, and generate follow-up data to assess effectiveness 9

Intent of LOSA Observations Q Observe day-to-day work behaviors during normal operations Q Discover procedural and systemic threats and errors Q Reduce injuries & equipment/aircraft damage Q Generate baseline data, implement new changes, and generate follow-up data to assess effectiveness 9

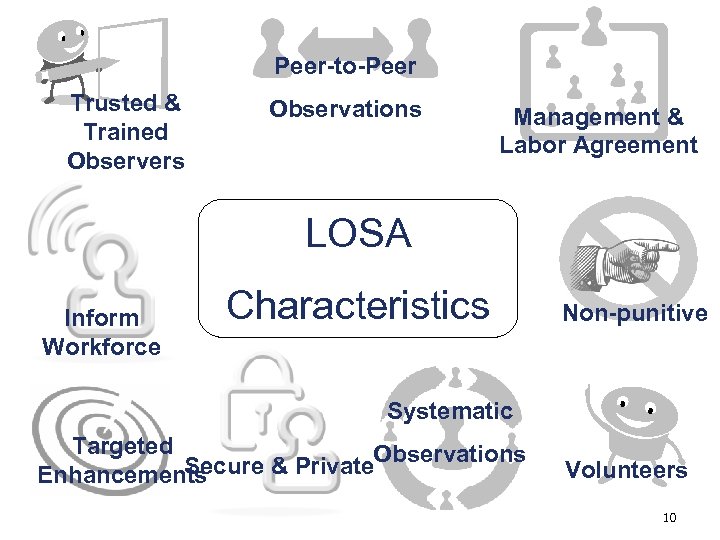

Peer-to-Peer Trusted & Trained Observers Observations Management & Labor Agreement LOSA Inform Workforce Characteristics Non-punitive Systematic Targeted Secure & Private. Observations Enhancements Volunteers 10

Peer-to-Peer Trusted & Trained Observers Observations Management & Labor Agreement LOSA Inform Workforce Characteristics Non-punitive Systematic Targeted Secure & Private. Observations Enhancements Volunteers 10

Why LOSA? QSafety Issues QCost Issues 11

Why LOSA? QSafety Issues QCost Issues 11

Why LOSA – Safety Issues Maintenance-Related Accidents Q Maintenance system failures, due to errors and/or violations, can affect safety of flight: 1. Primary Cause of an accident. Accident is due to the maintenance/inspection failure. Accident is not in any way due to flight crew action. 2. Contributing Factor to an accident. Accident chain begins with a maintenance/inspection failure that is incorrectly handled by the flight crew, ultimately ending up as an accident (Primary Cause is pilot error). 12

Why LOSA – Safety Issues Maintenance-Related Accidents Q Maintenance system failures, due to errors and/or violations, can affect safety of flight: 1. Primary Cause of an accident. Accident is due to the maintenance/inspection failure. Accident is not in any way due to flight crew action. 2. Contributing Factor to an accident. Accident chain begins with a maintenance/inspection failure that is incorrectly handled by the flight crew, ultimately ending up as an accident (Primary Cause is pilot error). 12

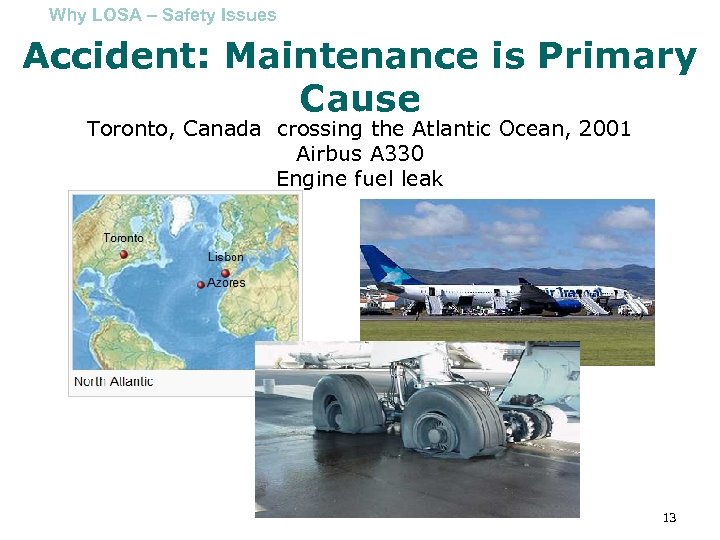

Why LOSA – Safety Issues Accident: Maintenance is Primary Cause Toronto, Canada crossing the Atlantic Ocean, 2001 Airbus A 330 Engine fuel leak 13

Why LOSA – Safety Issues Accident: Maintenance is Primary Cause Toronto, Canada crossing the Atlantic Ocean, 2001 Airbus A 330 Engine fuel leak 13

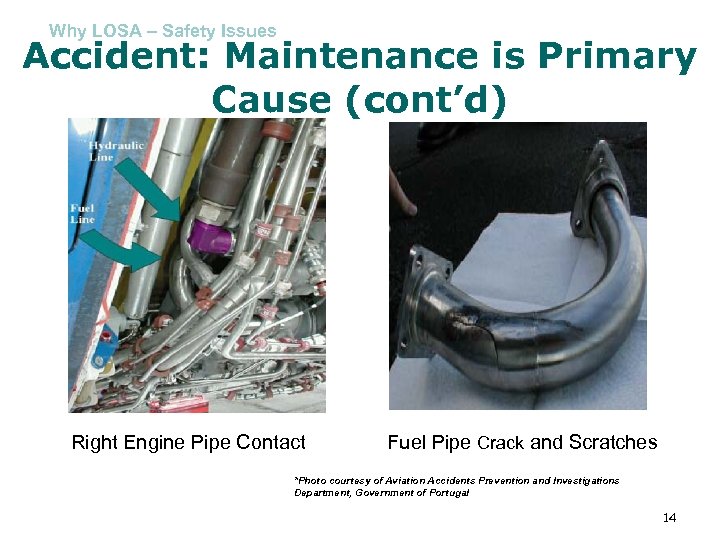

Why LOSA – Safety Issues Accident: Maintenance is Primary Cause (cont’d) Right Engine Pipe Contact Fuel Pipe Crack and Scratches *Photo courtesy of Aviation Accidents Prevention and Investigations Department, Government of Portugal 14

Why LOSA – Safety Issues Accident: Maintenance is Primary Cause (cont’d) Right Engine Pipe Contact Fuel Pipe Crack and Scratches *Photo courtesy of Aviation Accidents Prevention and Investigations Department, Government of Portugal 14

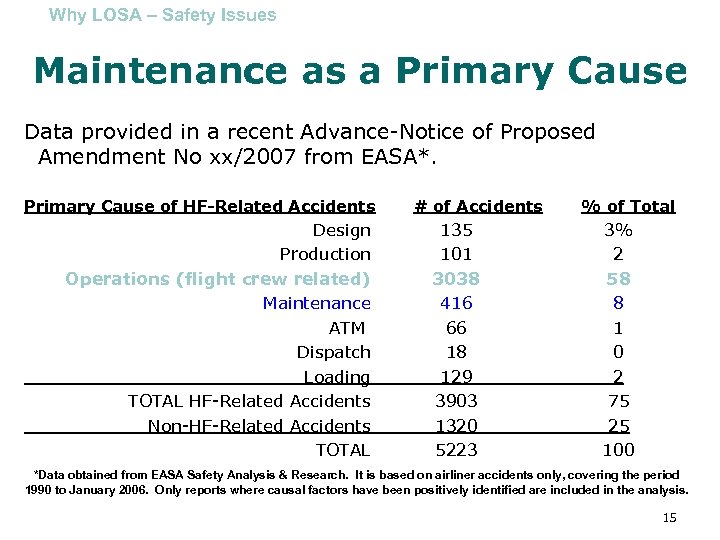

Why LOSA – Safety Issues Maintenance as a Primary Cause Data provided in a recent Advance-Notice of Proposed Amendment No xx/2007 from EASA*. Primary Cause of HF-Related Accidents Design Production Operations (flight crew related) Maintenance ATM Dispatch Loading TOTAL HF-Related Accidents Non-HF-Related Accidents TOTAL # of Accidents 135 101 3038 416 66 18 129 3903 1320 5223 % of Total 3% 2 58 8 1 0 2 75 25 100 *Data obtained from EASA Safety Analysis & Research. It is based on airliner accidents only, covering the period 1990 to January 2006. Only reports where causal factors have been positively identified are included in the analysis. 15

Why LOSA – Safety Issues Maintenance as a Primary Cause Data provided in a recent Advance-Notice of Proposed Amendment No xx/2007 from EASA*. Primary Cause of HF-Related Accidents Design Production Operations (flight crew related) Maintenance ATM Dispatch Loading TOTAL HF-Related Accidents Non-HF-Related Accidents TOTAL # of Accidents 135 101 3038 416 66 18 129 3903 1320 5223 % of Total 3% 2 58 8 1 0 2 75 25 100 *Data obtained from EASA Safety Analysis & Research. It is based on airliner accidents only, covering the period 1990 to January 2006. Only reports where causal factors have been positively identified are included in the analysis. 15

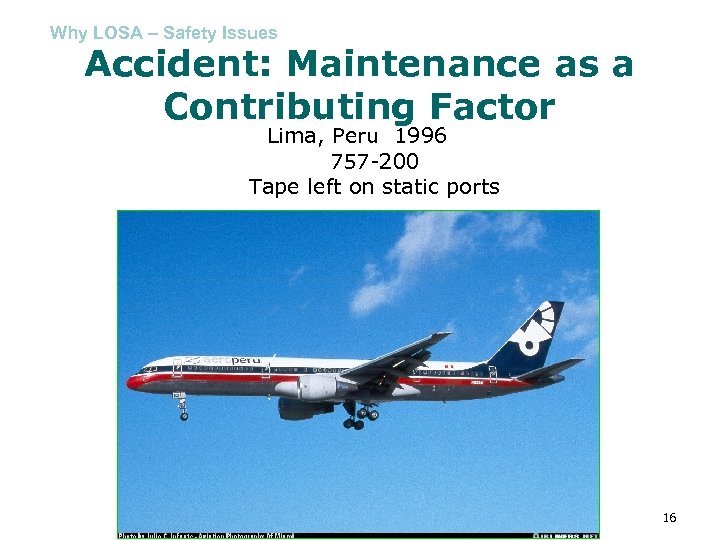

Why LOSA – Safety Issues Accident: Maintenance as a Contributing Factor Lima, Peru 1996 757 -200 Tape left on static ports 16

Why LOSA – Safety Issues Accident: Maintenance as a Contributing Factor Lima, Peru 1996 757 -200 Tape left on static ports 16

Why LOSA? QSafety Issues QCost Issues 17

Why LOSA? QSafety Issues QCost Issues 17

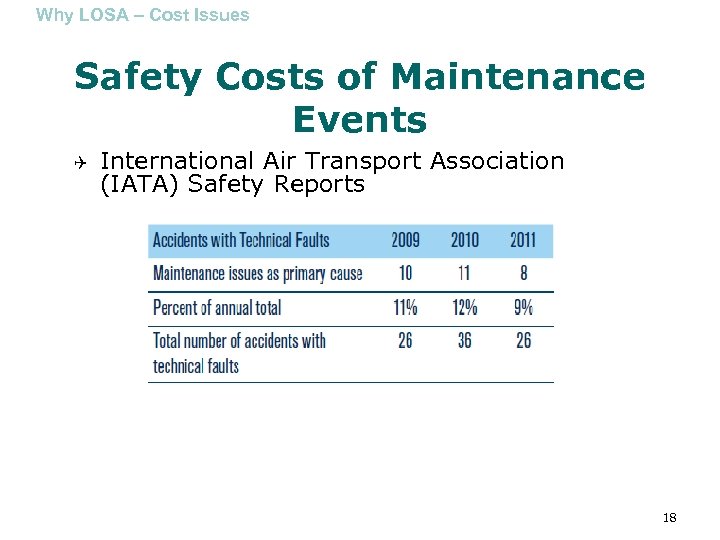

Why LOSA – Cost Issues Safety Costs of Maintenance Events Q International Air Transport Association (IATA) Safety Reports 18

Why LOSA – Cost Issues Safety Costs of Maintenance Events Q International Air Transport Association (IATA) Safety Reports 18

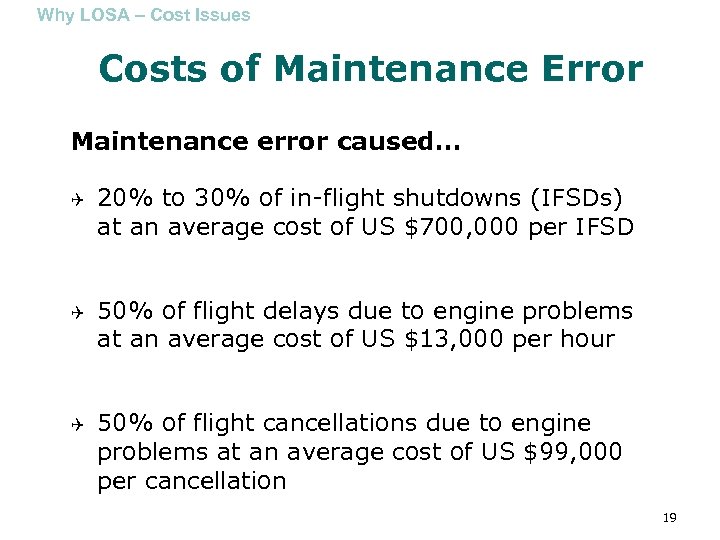

Why LOSA – Cost Issues Costs of Maintenance Error Maintenance error caused… Q 20% to 30% of in-flight shutdowns (IFSDs) at an average cost of US $700, 000 per IFSD Q 50% of flight delays due to engine problems at an average cost of US $13, 000 per hour Q 50% of flight cancellations due to engine problems at an average cost of US $99, 000 per cancellation 19

Why LOSA – Cost Issues Costs of Maintenance Error Maintenance error caused… Q 20% to 30% of in-flight shutdowns (IFSDs) at an average cost of US $700, 000 per IFSD Q 50% of flight delays due to engine problems at an average cost of US $13, 000 per hour Q 50% of flight cancellations due to engine problems at an average cost of US $99, 000 per cancellation 19

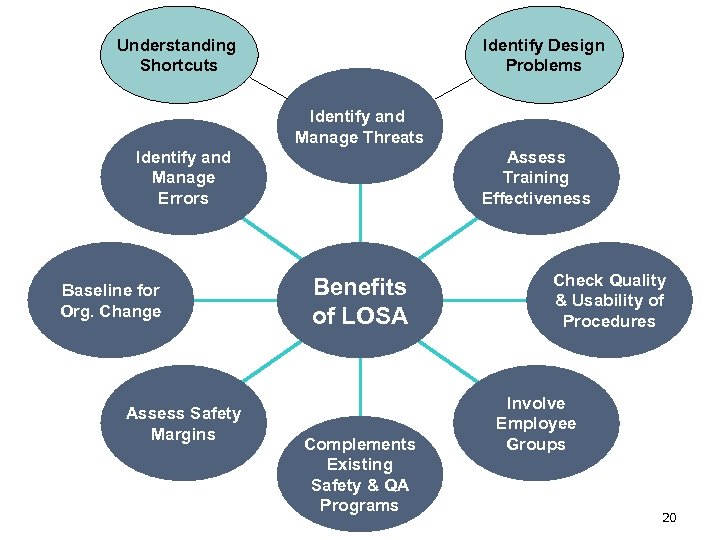

Understanding Shortcuts Identify Design Problems Identify and Manage Threats Assess Training Effectiveness Identify and Manage Errors Baseline for Org. Change Assess Safety Margins Benefits of LOSA Complements Existing Safety & QA Programs Check Quality & Usability of Procedures Involve Employee Groups 20

Understanding Shortcuts Identify Design Problems Identify and Manage Threats Assess Training Effectiveness Identify and Manage Errors Baseline for Org. Change Assess Safety Margins Benefits of LOSA Complements Existing Safety & QA Programs Check Quality & Usability of Procedures Involve Employee Groups 20

Status Report and Success Stories… 21

Status Report and Success Stories… 21

Status Report: LOSA Progress Q Support Materials are ready Available on the FAA’s Human Factors in Aviation Maintenance website: www. faa. gov/about/initiatives/maintenance_hf/losa/ Q Active users of Mx LOSA COAIR/United Q Considering LOSA and had Initial Briefing Alaska Airlines Fed. Ex Delta Air Lines UPS Garuda Airlines Jet Blue Airlines American Airlines Garuda Indonesia China Airlines EVA Airways Qantas Korean Air Etihad Airways Gulf Air 22

Status Report: LOSA Progress Q Support Materials are ready Available on the FAA’s Human Factors in Aviation Maintenance website: www. faa. gov/about/initiatives/maintenance_hf/losa/ Q Active users of Mx LOSA COAIR/United Q Considering LOSA and had Initial Briefing Alaska Airlines Fed. Ex Delta Air Lines UPS Garuda Airlines Jet Blue Airlines American Airlines Garuda Indonesia China Airlines EVA Airways Qantas Korean Air Etihad Airways Gulf Air 22

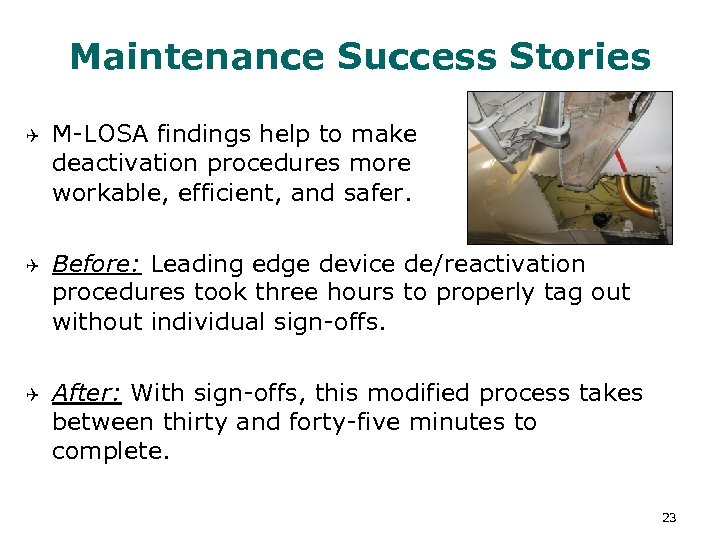

Maintenance Success Stories Q M-LOSA findings help to make deactivation procedures more workable, efficient, and safer. Q Before: Leading edge device de/reactivation procedures took three hours to properly tag out without individual sign-offs. Q After: With sign-offs, this modified process takes between thirty and forty-five minutes to complete. 23 23

Maintenance Success Stories Q M-LOSA findings help to make deactivation procedures more workable, efficient, and safer. Q Before: Leading edge device de/reactivation procedures took three hours to properly tag out without individual sign-offs. Q After: With sign-offs, this modified process takes between thirty and forty-five minutes to complete. 23 23

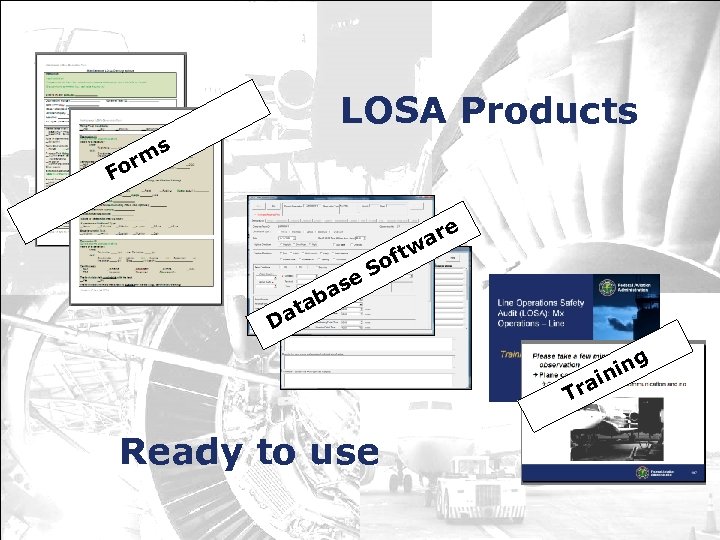

LOSA Products ms r Fo e r wa t of e. S s ba a at D ing ain Tr Ready to use 24

LOSA Products ms r Fo e r wa t of e. S s ba a at D ing ain Tr Ready to use 24

or F s m 25

or F s m 25

LOSA Forms Q Developed by reviewing and aggregating procedures from flight deck LOSA (or similar programs) and related M-LOSA & R-LOSA references. Q Refined during extensive taskforce discussions & beta testing. 26

LOSA Forms Q Developed by reviewing and aggregating procedures from flight deck LOSA (or similar programs) and related M-LOSA & R-LOSA references. Q Refined during extensive taskforce discussions & beta testing. 26

g in in ra T 27

g in in ra T 27

LOSA Training Q LOSA Awareness Q LOSA Procedures Q Scenario-based Practice Q Database Familiarization 28

LOSA Training Q LOSA Awareness Q LOSA Procedures Q Scenario-based Practice Q Database Familiarization 28

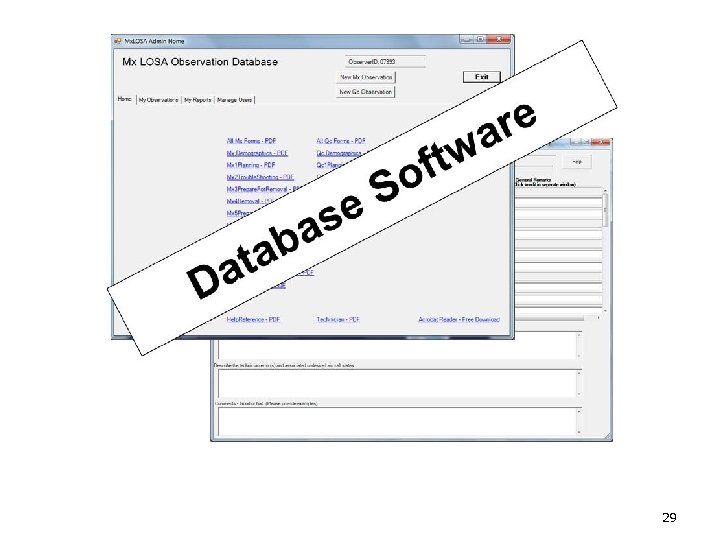

29

29

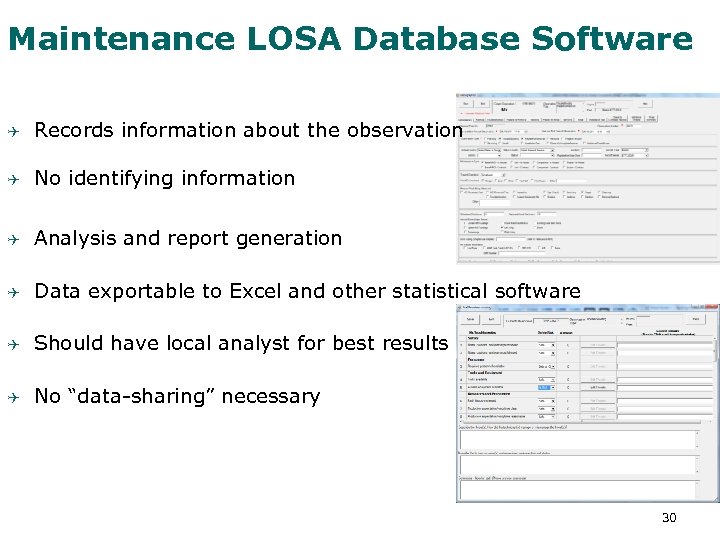

Maintenance LOSA Database Software Q Records information about the observation Q No identifying information Q Analysis and report generation Q Data exportable to Excel and other statistical software Q Should have local analyst for best results Q No “data-sharing” necessary 30

Maintenance LOSA Database Software Q Records information about the observation Q No identifying information Q Analysis and report generation Q Data exportable to Excel and other statistical software Q Should have local analyst for best results Q No “data-sharing” necessary 30

31

31

Steps to Implement LOSA 32

Steps to Implement LOSA 32

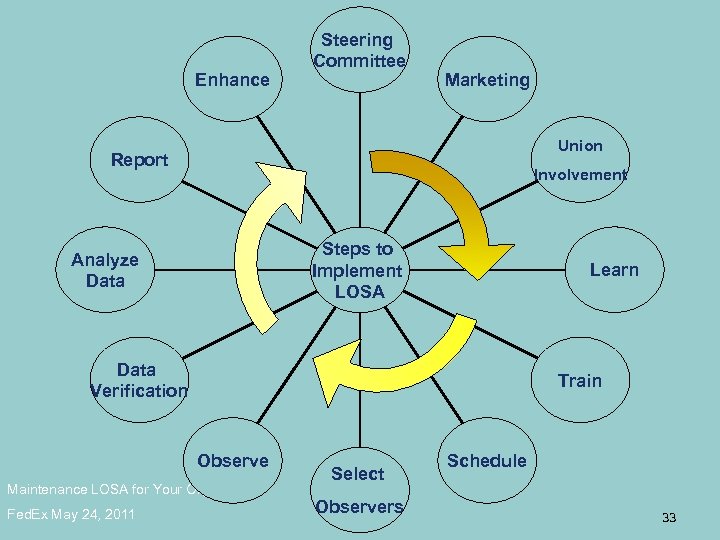

Enhance Steering Committee Marketing Union Report Involvement Steps to Implement LOSA Analyze Data Learn Data Verification Train Observe Maintenance LOSA for Your Organization Fed. Ex May 24, 2011 Select Observers Schedule 33

Enhance Steering Committee Marketing Union Report Involvement Steps to Implement LOSA Analyze Data Learn Data Verification Train Observe Maintenance LOSA for Your Organization Fed. Ex May 24, 2011 Select Observers Schedule 33

Strategies to Insure Trust and Respect Q Q Q Promote LOSA Emphasize that LOSA is not for disciplinary purposes and that the forms do not include any personal information. Select credible, respected observers. Ask crew if it is OK to do the LOSA observation. Communicate the LOSA results in a timely manner. Use the information—create action plans, implement changes, and evaluate results. 34

Strategies to Insure Trust and Respect Q Q Q Promote LOSA Emphasize that LOSA is not for disciplinary purposes and that the forms do not include any personal information. Select credible, respected observers. Ask crew if it is OK to do the LOSA observation. Communicate the LOSA results in a timely manner. Use the information—create action plans, implement changes, and evaluate results. 34

Key Reminders QEnsure Buy-in QFundamentals are critical QCommunication to everyone is critical QAvailable Training QConsistency is essential QOne false step with discipline is significant QStart small/target areas for improvement 35

Key Reminders QEnsure Buy-in QFundamentals are critical QCommunication to everyone is critical QAvailable Training QConsistency is essential QOne false step with discipline is significant QStart small/target areas for improvement 35

Conclusion Q The following products are available for implementing LOSA at airlines… Q Q Q Marketing materials (posters & brochures) Implementation Guideline Observation forms Database software Training LOSA is a predictive hazard identification system for your SMS that can: Q Q Q Reduce your costs, Improve safety, and Improve efficiency 36

Conclusion Q The following products are available for implementing LOSA at airlines… Q Q Q Marketing materials (posters & brochures) Implementation Guideline Observation forms Database software Training LOSA is a predictive hazard identification system for your SMS that can: Q Q Q Reduce your costs, Improve safety, and Improve efficiency 36

Questions/Comments? 37

Questions/Comments? 37

This concludes the introduction to Line Operations Safety Assessment. Visit the FAA’s Human Factors in Aviation Maintenance website: www. faa. gov/about/initiatives/maintenance_hf/losa/ Acknowledgements: ATA/FAA Maintenance and Ramp Human Factors Committee

This concludes the introduction to Line Operations Safety Assessment. Visit the FAA’s Human Factors in Aviation Maintenance website: www. faa. gov/about/initiatives/maintenance_hf/losa/ Acknowledgements: ATA/FAA Maintenance and Ramp Human Factors Committee