b1a20b11ba6b48871105cf72df25a605.ppt

- Количество слайдов: 37

CONRAD – Oils Sands Process Water Workshop Membrane Technology for Treatment of Process Affected Waters Hadi Husain and Steve Kroll ZENON Environmental Inc. , Canada

Ultrafiltration has come of age for Industrial and Municipal Water and Wastewater Treatment n n n n This has resulted from progressive improvements in permeability, and reduction in production cost. ZENON is focused on use of membranes for water and wastewater treatment We have played a key role in this transformation through invention and evolution of our Zee. Weed® immersed membranes and the Zeno. Gem® bioreactor Largest Zee. Weed® water filtration plant, when fully operational, will produce in 75, 000 m 3/d water Largest industrial recycle plant produces 26, 000 m 3/d tertiary water for RO at a Mexican refinery Largest Zeno. Gem® plant treats up to 19, 000 m 3/d Very high level of reliability has been achieved, with most plants designed for a 24 h/d, 365 d/y basis.

MF/UF Membranes in Water Treatment Inherited features from RO and older UF technologies Low permeability membrane Small/expensive module High flux High cross-flow velocity High operating pressure Membranes in pressure vessels Complex system Current trend High permeability membrane Large/low cost module Moderate flux Direct (dead-end) filtration Air to enhance solids removal Low operating pressure Shell-less membranes Simple system

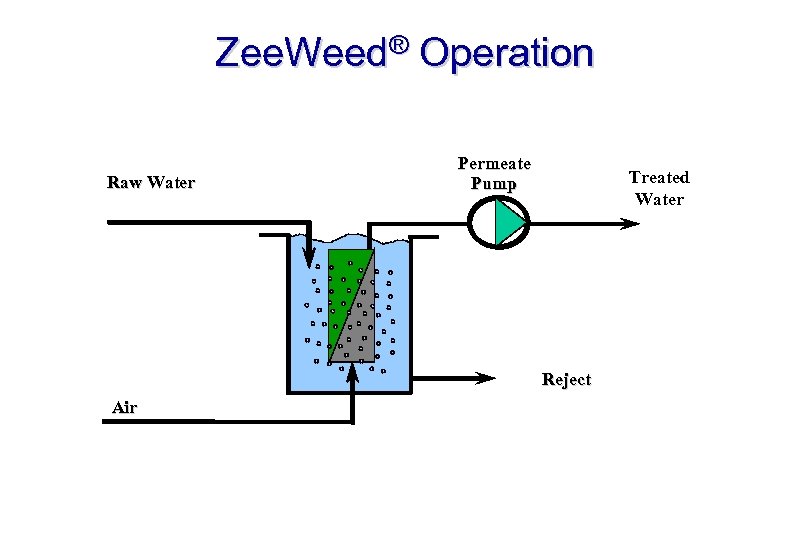

Zee. Weed® Operation Raw Water Permeate Pump Treated Water Reject Air

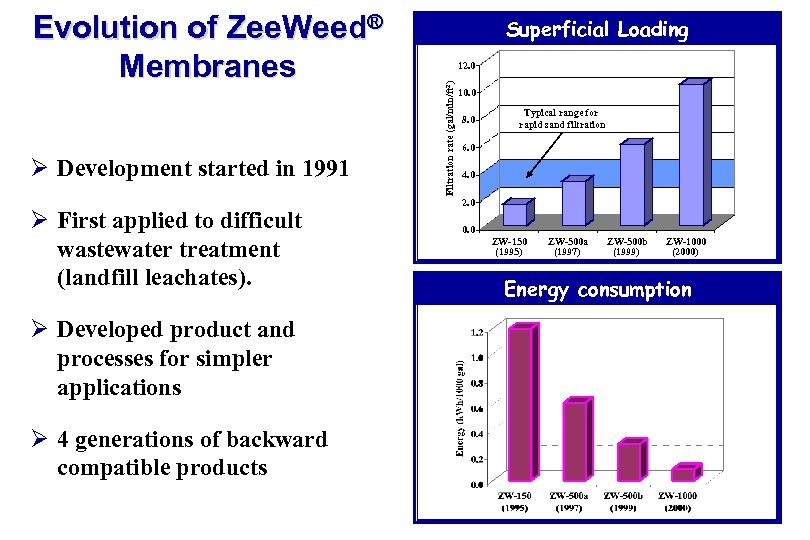

Ø Development started in 1991 Ø First applied to difficult wastewater treatment (landfill leachates). Ø Developed product and processes for simpler applications Ø 4 generations of backward compatible products Superficial Loading 12. 0 Filtration rate (gal/min/ft 2) Evolution of Zee. Weed® Membranes 10. 0 8. 0 Typical range for rapid sand filtration 6. 0 4. 0 2. 0 0. 0 ZW-150 (1995) ZW-500 a (1997) ZW-500 b (1999) ZW-1000 (2000) Energy consumption

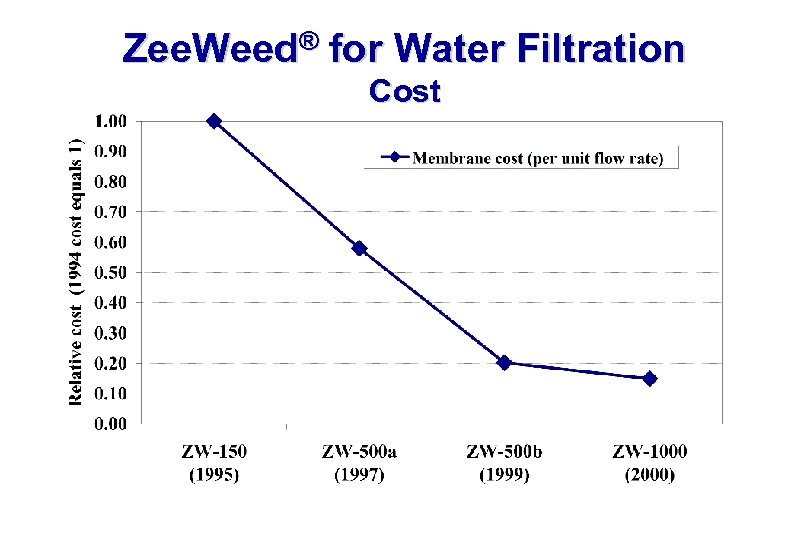

Zee. Weed® for Water Filtration Cost

(000’s m 3/day) Zee. Weed® Water Filtration Capacity 122% Annual Growth Year * As of March 30, 2000

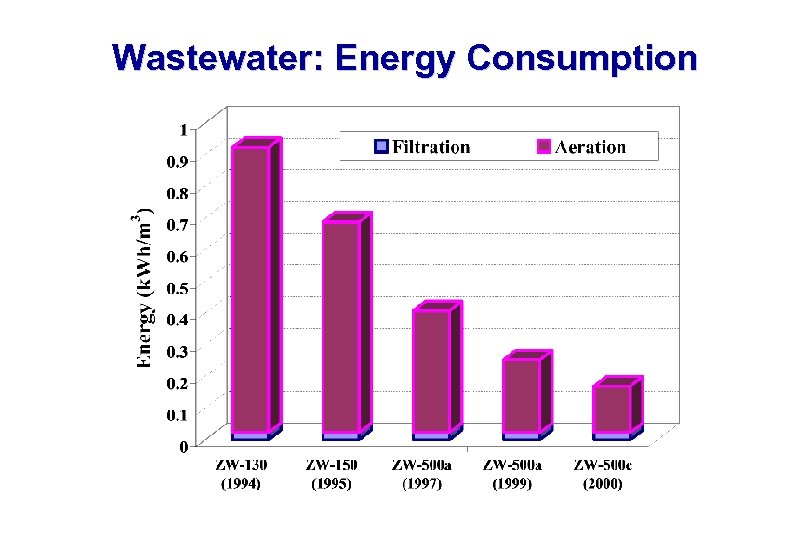

Wastewater: Energy Consumption

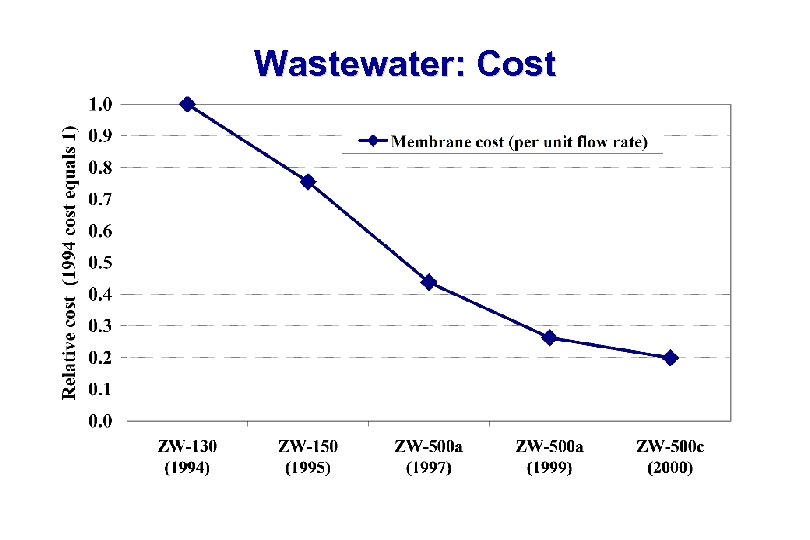

Wastewater: Cost

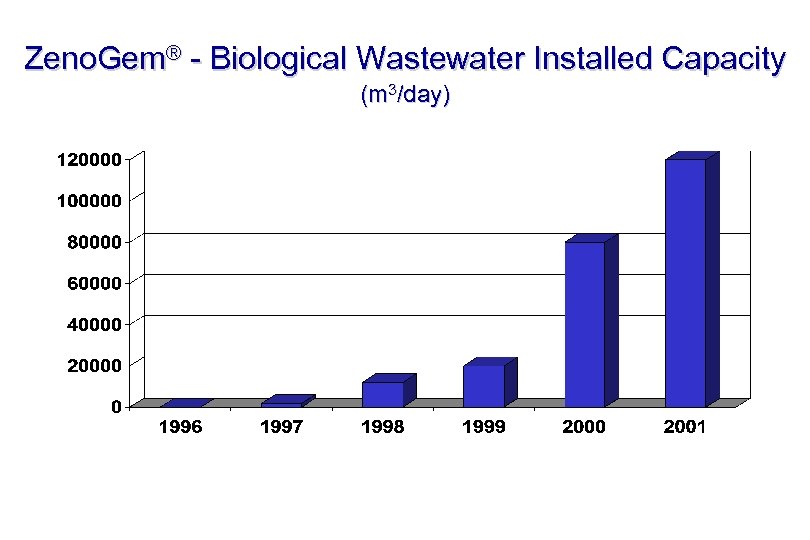

Zeno. Gem® - Biological Wastewater Installed Capacity (m 3/day)

Zee. Weed® Based Plants are Highly Reliable n n We have developed strong fibres with high permeability. This, combined with operation under low delta p and mild aeration enhances reliability, reduces energy use and increases membrane life For direct filtration of low solids water, low delta p operation permits the use of unsupported, small, low cost hollow fibres Inner support material and the outer polymer coating imparts high strength, toughness and durability to the hollow fibre product used for high solids application Immersed membrane configuration, combined with innovative module designs and aeration techniques result in stable operation in high solids environment

The Zee. Weed® Membrane Ø Supported hollow fibre with outside-in flow (0. 9 mm ID, 1. 9 mm OD) Ø Chlorine-resistant polymeric membrane Ø Pore size of 0. 04 µm nominal in the ultrafiltration range Ø Permeate drawn by suction on the permeate side Ø Air bubbling induces turbulence to keep membrane clean

Zee. Weed® Applications - Membrane Bioreactor (Zeno. Gem®) for wastewater treatment - Direct filtration (surface water, well water, secondary effluent, process water ) - Filtration coupled with coagulation/ oxidation/ powdered activated carbon

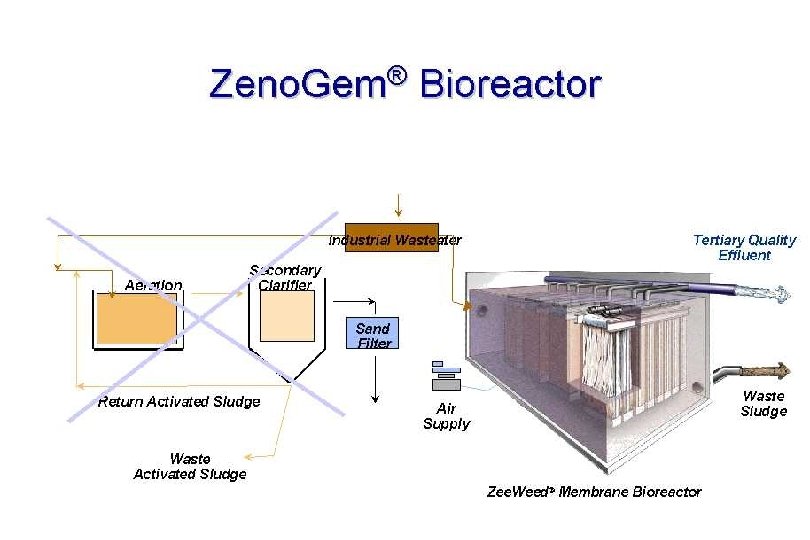

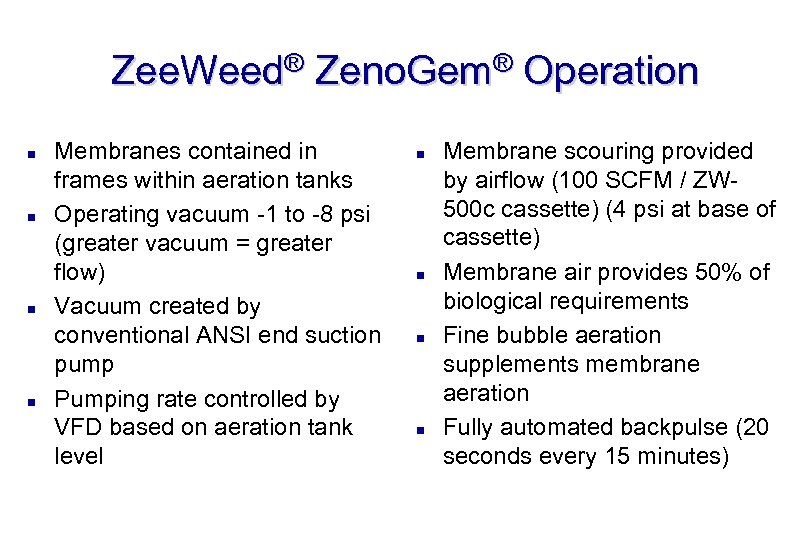

Zee. Weed® Zeno. Gem® Operation n n Membranes contained in frames within aeration tanks Operating vacuum -1 to -8 psi (greater vacuum = greater flow) Vacuum created by conventional ANSI end suction pump Pumping rate controlled by VFD based on aeration tank level n n Membrane scouring provided by airflow (100 SCFM / ZW 500 c cassette) (4 psi at base of cassette) Membrane air provides 50% of biological requirements Fine bubble aeration supplements membrane aeration Fully automated backpulse (20 seconds every 15 minutes)

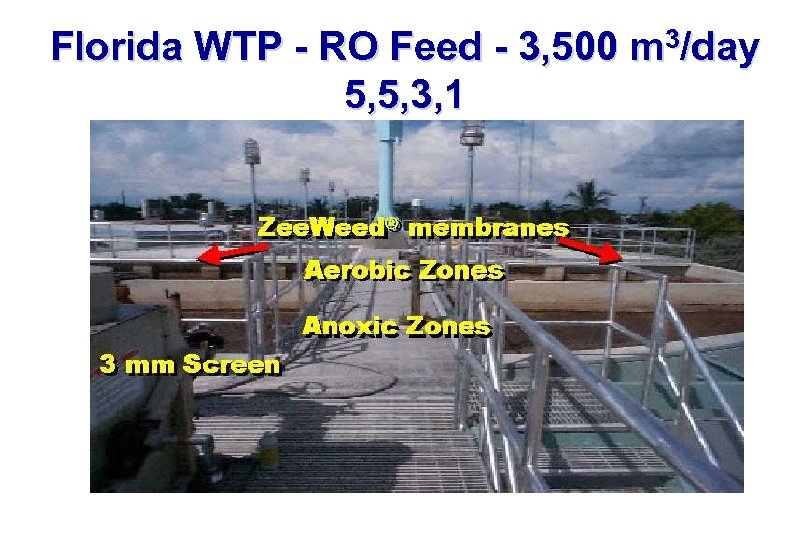

Zeno. Gem® for Water Reuse RO Pre-treatment in Florida Ø Ø Ø Location: Florida Keys Municipality required very high effluent quality, at all times to: • Protect marine life • Irrigate golf course What was considered: • Activated sludge • SBR • Zeno. Gem®

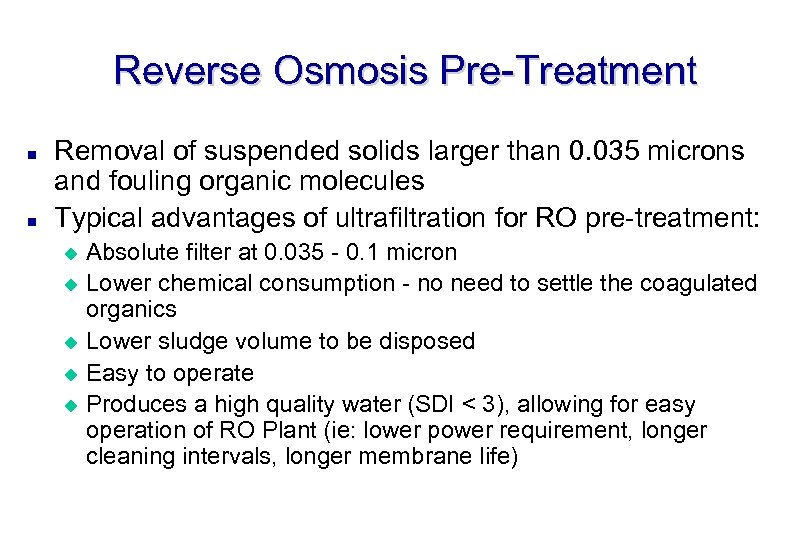

Reverse Osmosis Pre-Treatment n n Removal of suspended solids larger than 0. 035 microns and fouling organic molecules Typical advantages of ultrafiltration for RO pre-treatment: Absolute filter at 0. 035 - 0. 1 micron u Lower chemical consumption - no need to settle the coagulated organics u Lower sludge volume to be disposed u Easy to operate u Produces a high quality water (SDI < 3), allowing for easy operation of RO Plant (ie: lower power requirement, longer cleaning intervals, longer membrane life) u

Florida WTP - RO Feed - 3, 500 m 3/day 5, 5, 3, 1

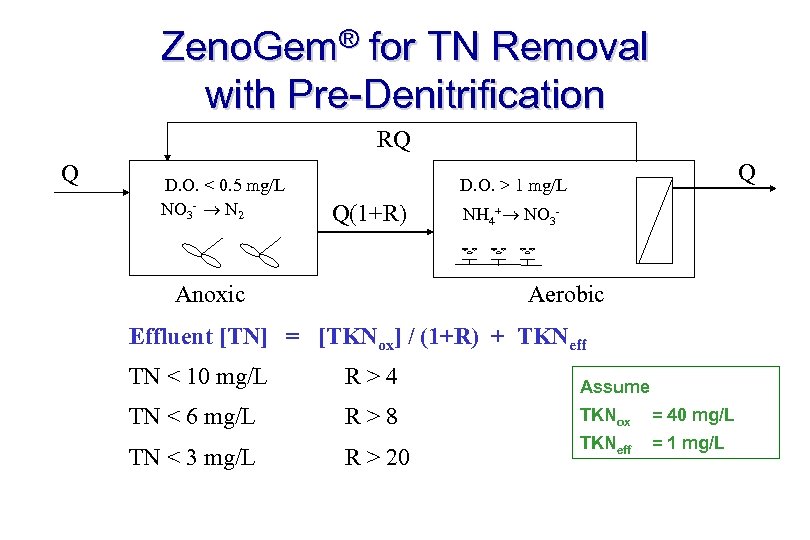

Zeno. Gem® for TN Removal with Pre-Denitrification RQ Q D. O. < 0. 5 mg/L NO 3 - N 2 Q D. O. > 1 mg/L Q(1+R) Anoxic NH 4+ NO 3 - Aerobic Effluent [TN] = [TKNox] / (1+R) + TKNeff TN < 10 mg/L R>4 Assume TN < 6 mg/L R>8 TKNox = 40 mg/L TKNeff = 1 mg/L TN < 3 mg/L R > 20

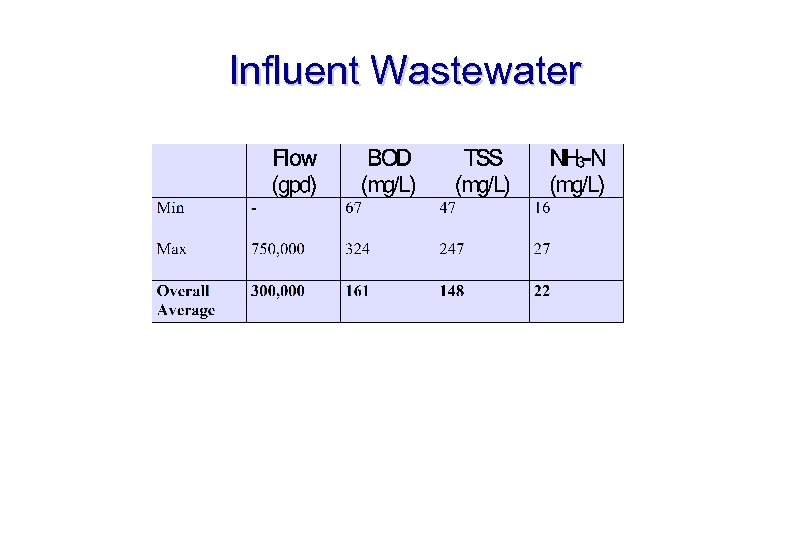

Influent Wastewater

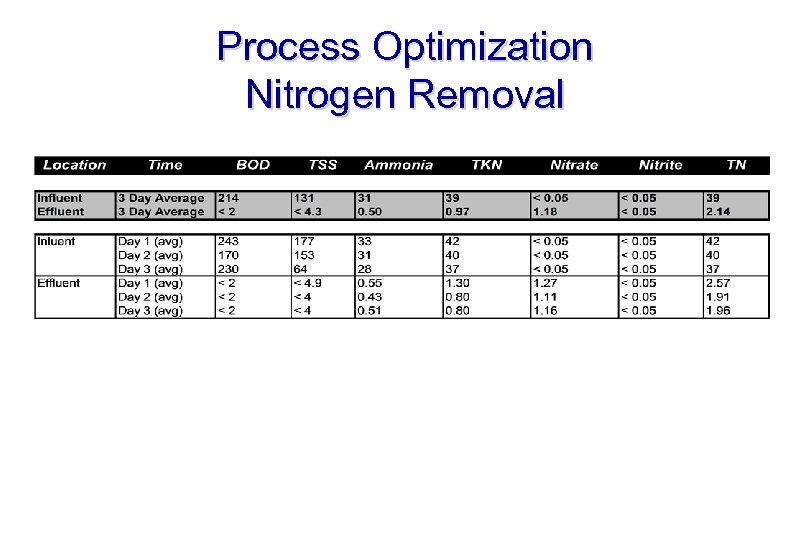

Process Optimization Nitrogen Removal

Florida WW Plant RO Conductivity Removal Efficiency

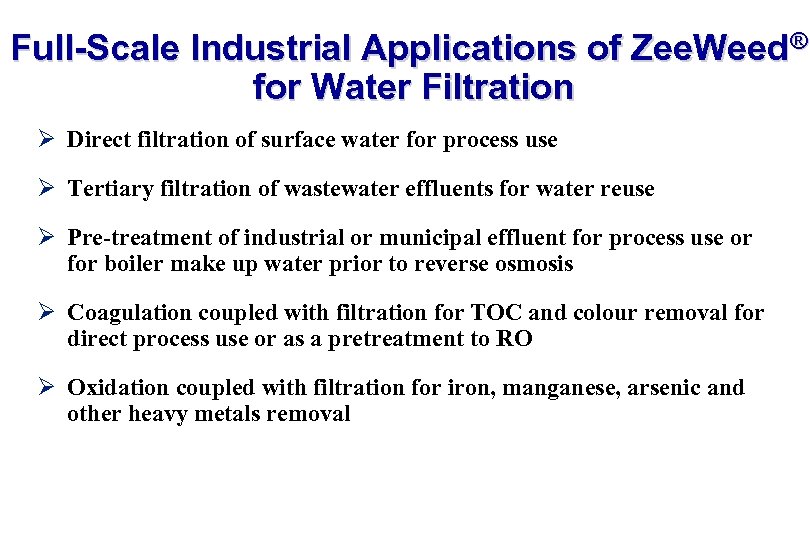

Full-Scale Industrial Applications of Zee. Weed® for Water Filtration Ø Direct filtration of surface water for process use Ø Tertiary filtration of wastewater effluents for water reuse Ø Pre-treatment of industrial or municipal effluent for process use or for boiler make up water prior to reverse osmosis Ø Coagulation coupled with filtration for TOC and colour removal for direct process use or as a pretreatment to RO Ø Oxidation coupled with filtration for iron, manganese, arsenic and other heavy metals removal

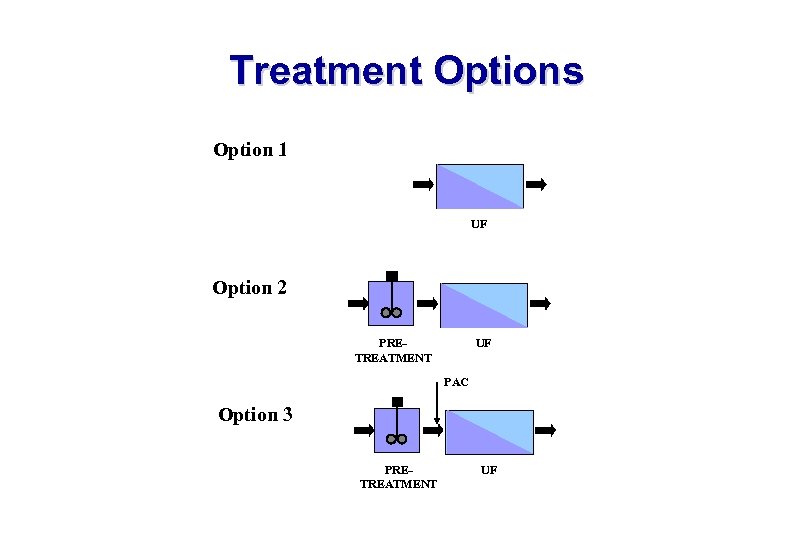

Treatment Options Option 1 UF Option 2 PRETREATMENT UF PAC Option 3 PRETREATMENT UF

Zee. Weed® for Filtration Applications Coagulation coupled with filtration for TOC and colour removal

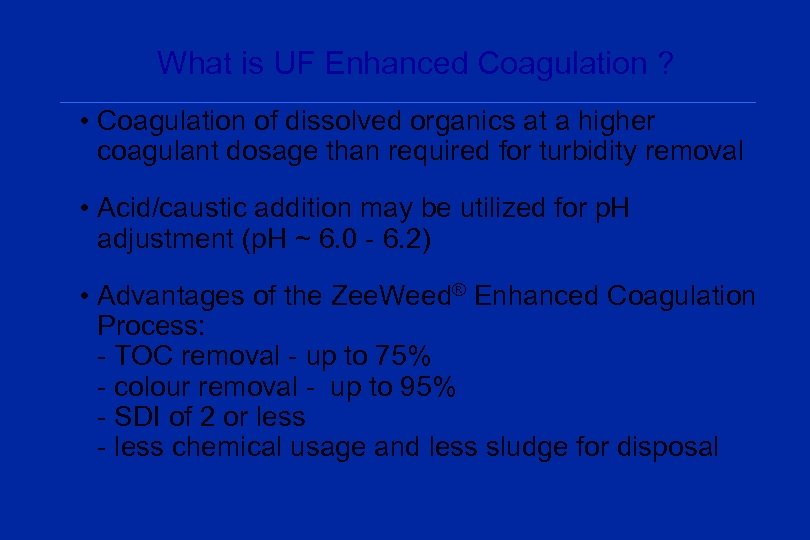

What is UF Enhanced Coagulation ? • Coagulation of dissolved organics at a higher coagulant dosage than required for turbidity removal • Acid/caustic addition may be utilized for p. H adjustment (p. H ~ 6. 0 - 6. 2) • Advantages of the Zee. Weed® Enhanced Coagulation Process: - TOC removal - up to 75% - colour removal - up to 95% - SDI of 2 or less - less chemical usage and less sludge for disposal

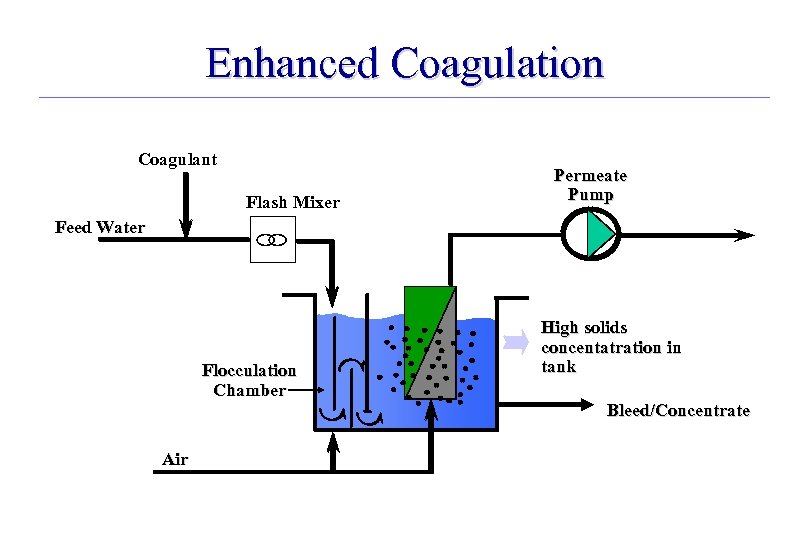

Enhanced Coagulation Coagulant Flash Mixer Permeate Pump Feed Water Flocculation Chamber Air High solids concentatration in tank Bleed/Concentrate

ZW Pretreatment for Boiler Water RO Feed in a Northern Alberta Application (Ferric chloride dosage: 50 -60 mg/l)

Zee. Weed® / Powdered Activated Carbon (PAC) n n Activated carbon is used to ZW tank to adsorb organic impurities. Dosage rates and retention time of activated carbon in Zee. Weed tank is managed to provide the best conditions for removal of a specific contaminant, and its adsorption rates on carbon ZW has a high tolerance for solids. Systems operate at up to 30 g/l of suspended solids. Aeration provides mixing. We have found that permeability can actually improve with the addition of activated carbon

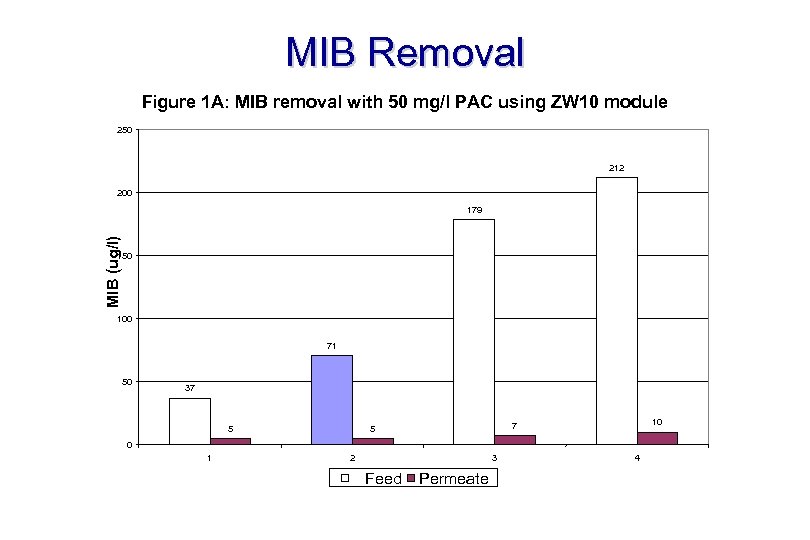

MIB Removal Figure 1 A: MIB removal with 50 mg/l PAC using ZW 10 module 250 212 200 MIB (ug/l) 179 150 100 71 50 37 5 10 7 5 0 1 2 3 Feed Permeate 4

Zee. Weed® for Filtration Applications Tertiary filtration of secondary effluents for water reuse

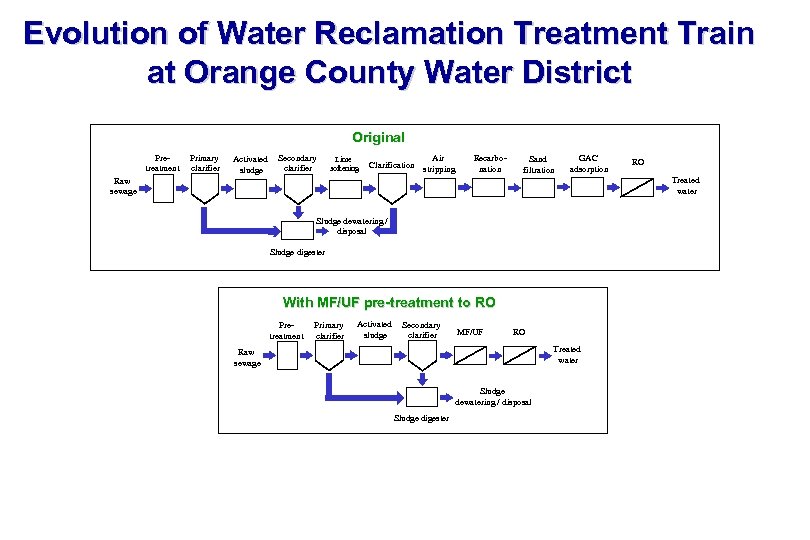

Evolution of Water Reclamation Treatment Train at Orange County Water District Original Pretreatment Primary clarifier Activated sludge Secondary clarifier Lime softening Air Clarification stripping Recarbonation Sand filtration GAC adsorption RO Treated water Raw sewage Sludge dewatering / disposal Sludge digester With MF/UF pre-treatment to RO Pretreatment Primary clarifier Activated sludge Secondary clarifier MF/UF RO Treated water Raw sewage Sludge dewatering / disposal Sludge digester

Case Study: Poland Secondary Effluent Reuse Ø Pretreatment of municipal secondary effluent RO to industrial cooling circuit feedwater Ø Operating since September 1999 Ø Plant Capacity: 5, 400 m 3/d Ø Permeate SDI < 2

Zee. Weed®/RO Pilot Program for Process Affected Waters n Zee. Weed offers the following advantages for water recycle at SCL: u u u n Pilot program focusing on three Zee. Weed® configurations: u u u n 0. 04 micron ultrafiltration Consistent, high quality effluent with significant reduction of RO biofouling High recovery Low SDI, leading to improved RO operation High MLSS loading in bioreactor leading to superior nitrification Physical chemical treatment for O&G and suspended solids Physical chemical with PAC addition to the Zee. Weed tank to further enhance O&G removal Zeno. Gem® with nitrification for ammonia and toxicity reduction Reverse Osmosis for TDS reduction to be piloted with each of the above

Pilot Program Targets and Schedule n n n n SDI of 2 or less Zee. Weed system recovery of >90% RO recovery >80% Ammonia less than 1 mg/l in biological nitrification ZW permeate turbidity of less than 0. 1 NTU RO salt rejection of >99% Total program duration of six months starting today

Conclusions Ø The Zee. Weed technology is highly suited to RO pretreatment for recycle of SCL’s process affected water streams Ø It provides 0. 04 micron barrier to suspended matter, and combined with physical chemical or biological processes, can remove a wide variety of contaminants effectively and consistently Ø Low pressure operation, low energy use, and high recovery potential make this technology particularly suitable for this application Ø Pilot program is underway to apply ZW-RO, in combination with physical – chemical and biological pretreatment for recycle of process affected waters for boiler water make-up and other potential reuse applictions

b1a20b11ba6b48871105cf72df25a605.ppt