f5f129bcc5d7a28e9ea5892c3fa73861.ppt

- Количество слайдов: 19

Configuration Management J. M. Mc. Carthy Fall 2003 § Overview of Configuration Management § Engineering Documents § Form of an Engineering Document § Part Number Structure § Bill of Material § Mini Baja Examples § Change Control Process

Configuration Management J. M. Mc. Carthy Fall 2003 § Overview of Configuration Management § Engineering Documents § Form of an Engineering Document § Part Number Structure § Bill of Material § Mini Baja Examples § Change Control Process

Overview of Configuration Management Organize Engineering information • Provide a systematic or organized approach to planning, identifying, controlling, and accounting for the status of a product’s configuration from its inception throughout its intended life. Assign Part Number • Provide numbering system to identify the components and types of documentation for a product. Release Documents • Identify part specifications are complete and to be integrated into the system Bill of Materials. Change Control • Maintain the system by which design changes are requested, completed and integrated into the Bill of Materials.

Overview of Configuration Management Organize Engineering information • Provide a systematic or organized approach to planning, identifying, controlling, and accounting for the status of a product’s configuration from its inception throughout its intended life. Assign Part Number • Provide numbering system to identify the components and types of documentation for a product. Release Documents • Identify part specifications are complete and to be integrated into the system Bill of Materials. Change Control • Maintain the system by which design changes are requested, completed and integrated into the Bill of Materials.

Engineering Documents Requirements Document (Input) • Design input means the physical and performance requirements of a product that are used as a basis for product design. Assembly Drawings • • • The assembly pictorial Assembled dimensions and tolerances Notes and Specifications Part Drawings (Fabricated) • Specification of the features and characteristics of a part to be manufactured. Dimensions and tolerances and material must be prescribed. Part Specifications (Buy) • Specification of the features and characteristics of a purchased part. Parts Lists • List of all the parts needed for an assembly. Verification Tests • • Verify performance of the design against every requirement (input). Features, Performance, and Safety (personnel impact, electrical shock, and fire)

Engineering Documents Requirements Document (Input) • Design input means the physical and performance requirements of a product that are used as a basis for product design. Assembly Drawings • • • The assembly pictorial Assembled dimensions and tolerances Notes and Specifications Part Drawings (Fabricated) • Specification of the features and characteristics of a part to be manufactured. Dimensions and tolerances and material must be prescribed. Part Specifications (Buy) • Specification of the features and characteristics of a purchased part. Parts Lists • List of all the parts needed for an assembly. Verification Tests • • Verify performance of the design against every requirement (input). Features, Performance, and Safety (personnel impact, electrical shock, and fire)

Engineering Documents Approved Manufacture List (APL) • Specification Control Drawings that show the acceptable supplier(s) for each part number. This list is refer to as APL. • Drawings do not have to be revised each time a supplier is added or deleted. • Must be controlled in such a way that Design Engineering, Manufacturing, and Quality Assurance, all agree to any vendor changes on the list. • Specification Control Drawings can negotiate a better package for the company when the supplier does not know who the competition is. Bill of Materials (BOM) • • • One single data base Must be 100% accurate Allows the accurate determination of the cost each specific product. Important a tool for defining the system that is for sale. Allows accurate scheduling of manufacturing.

Engineering Documents Approved Manufacture List (APL) • Specification Control Drawings that show the acceptable supplier(s) for each part number. This list is refer to as APL. • Drawings do not have to be revised each time a supplier is added or deleted. • Must be controlled in such a way that Design Engineering, Manufacturing, and Quality Assurance, all agree to any vendor changes on the list. • Specification Control Drawings can negotiate a better package for the company when the supplier does not know who the competition is. Bill of Materials (BOM) • • • One single data base Must be 100% accurate Allows the accurate determination of the cost each specific product. Important a tool for defining the system that is for sale. Allows accurate scheduling of manufacturing.

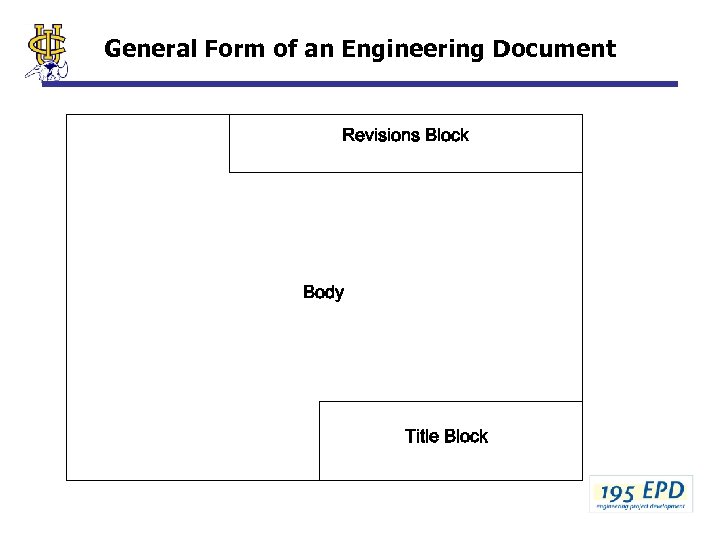

General Form of an Engineering Document Revisions Block Body Title Block

General Form of an Engineering Document Revisions Block Body Title Block

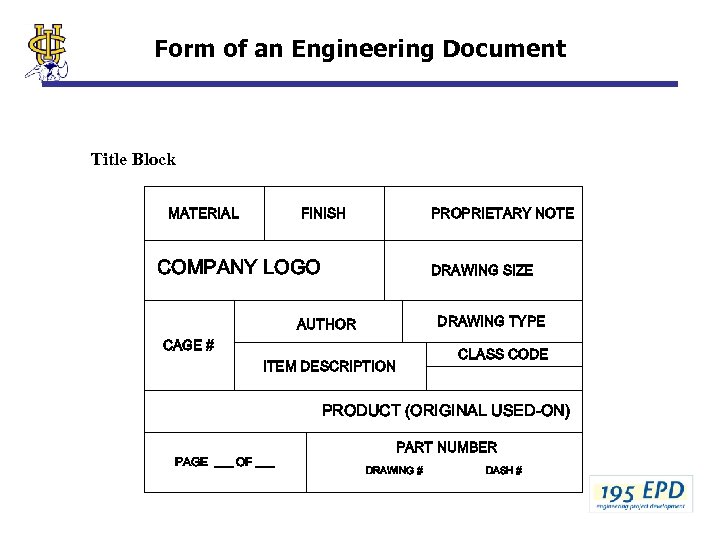

Form of an Engineering Document Title Block MATERIAL FINISH PROPRIETARY NOTE COMPANY LOGO DRAWING SIZE DRAWING TYPE AUTHOR CAGE # ITEM DESCRIPTION CLASS CODE PRODUCT (ORIGINAL USED-ON) PAGE ___ OF ___ PART NUMBER DRAWING # DASH #

Form of an Engineering Document Title Block MATERIAL FINISH PROPRIETARY NOTE COMPANY LOGO DRAWING SIZE DRAWING TYPE AUTHOR CAGE # ITEM DESCRIPTION CLASS CODE PRODUCT (ORIGINAL USED-ON) PAGE ___ OF ___ PART NUMBER DRAWING # DASH #

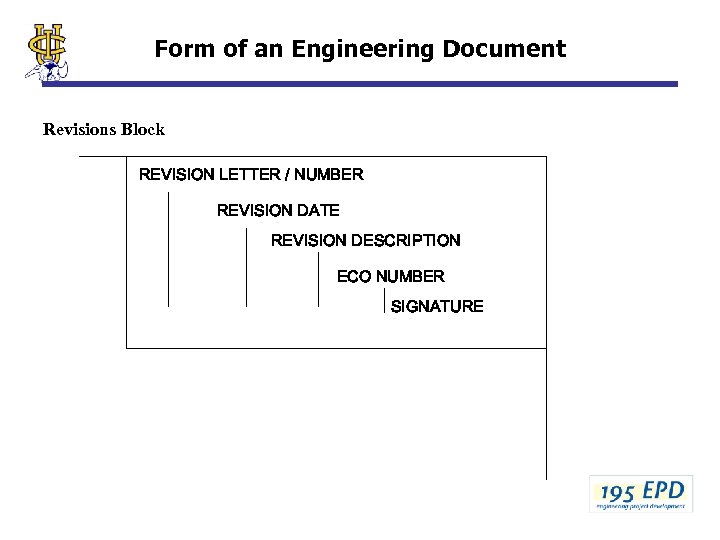

Form of an Engineering Document Revisions Block REVISION LETTER / NUMBER REVISION DATE REVISION DESCRIPTION ECO NUMBER SIGNATURE

Form of an Engineering Document Revisions Block REVISION LETTER / NUMBER REVISION DATE REVISION DESCRIPTION ECO NUMBER SIGNATURE

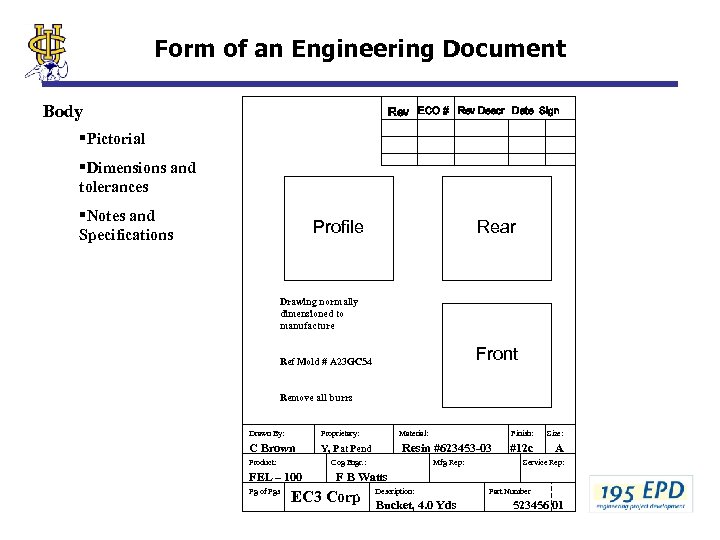

Form of an Engineering Document Body Rev ECO # Rev Descr Date Sign §Pictorial §Dimensions and tolerances §Notes and Specifications Profile Rear Drawing normally dimensioned to manufacture Front Ref Mold # A 23 GC 54 Remove all burrs Drawn By: Proprietary: C Brown Y, Pat Pend Product: Cog Engr. : FEL – 100 Pg of Pgs Material: Finish: Size: Resin #623453 -03 #12 c A Mfg Rep: Service Rep: F B Watts Description: EC 3 Corp Bucket, 4. 0 Yds Part Number 523456 01

Form of an Engineering Document Body Rev ECO # Rev Descr Date Sign §Pictorial §Dimensions and tolerances §Notes and Specifications Profile Rear Drawing normally dimensioned to manufacture Front Ref Mold # A 23 GC 54 Remove all burrs Drawn By: Proprietary: C Brown Y, Pat Pend Product: Cog Engr. : FEL – 100 Pg of Pgs Material: Finish: Size: Resin #623453 -03 #12 c A Mfg Rep: Service Rep: F B Watts Description: EC 3 Corp Bucket, 4. 0 Yds Part Number 523456 01

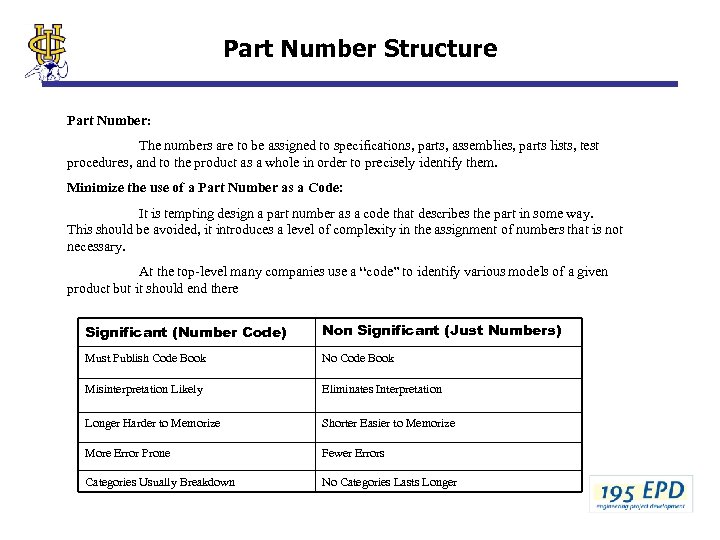

Part Number Structure Part Number: The numbers are to be assigned to specifications, parts, assemblies, parts lists, test procedures, and to the product as a whole in order to precisely identify them. Minimize the use of a Part Number as a Code: It is tempting design a part number as a code that describes the part in some way. This should be avoided, it introduces a level of complexity in the assignment of numbers that is not necessary. At the top-level many companies use a “code” to identify various models of a given product but it should end there Significant (Number Code) Non Significant (Just Numbers) Must Publish Code Book No Code Book Misinterpretation Likely Eliminates Interpretation Longer Harder to Memorize Shorter Easier to Memorize More Error Prone Fewer Errors Categories Usually Breakdown No Categories Lasts Longer

Part Number Structure Part Number: The numbers are to be assigned to specifications, parts, assemblies, parts lists, test procedures, and to the product as a whole in order to precisely identify them. Minimize the use of a Part Number as a Code: It is tempting design a part number as a code that describes the part in some way. This should be avoided, it introduces a level of complexity in the assignment of numbers that is not necessary. At the top-level many companies use a “code” to identify various models of a given product but it should end there Significant (Number Code) Non Significant (Just Numbers) Must Publish Code Book No Code Book Misinterpretation Likely Eliminates Interpretation Longer Harder to Memorize Shorter Easier to Memorize More Error Prone Fewer Errors Categories Usually Breakdown No Categories Lasts Longer

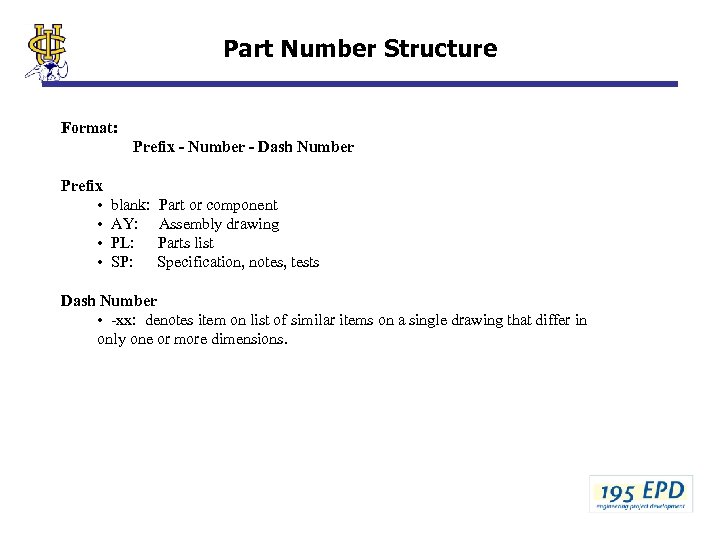

Part Number Structure Format: Prefix - Number - Dash Number Prefix • blank: Part or component • AY: Assembly drawing • PL: Parts list • SP: Specification, notes, tests Dash Number • -xx: denotes item on list of similar items on a single drawing that differ in only one or more dimensions.

Part Number Structure Format: Prefix - Number - Dash Number Prefix • blank: Part or component • AY: Assembly drawing • PL: Parts list • SP: Specification, notes, tests Dash Number • -xx: denotes item on list of similar items on a single drawing that differ in only one or more dimensions.

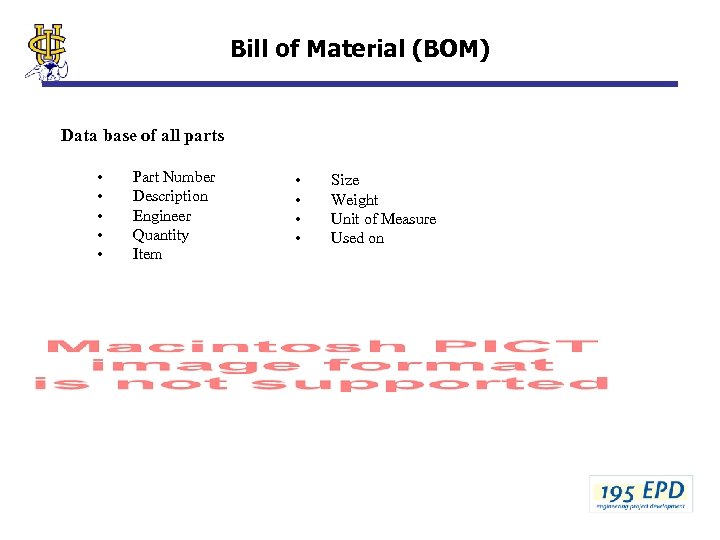

Bill of Material (BOM) Data base of all parts • • • Part Number Description Engineer Quantity Item • • Size Weight Unit of Measure Used on

Bill of Material (BOM) Data base of all parts • • • Part Number Description Engineer Quantity Item • • Size Weight Unit of Measure Used on

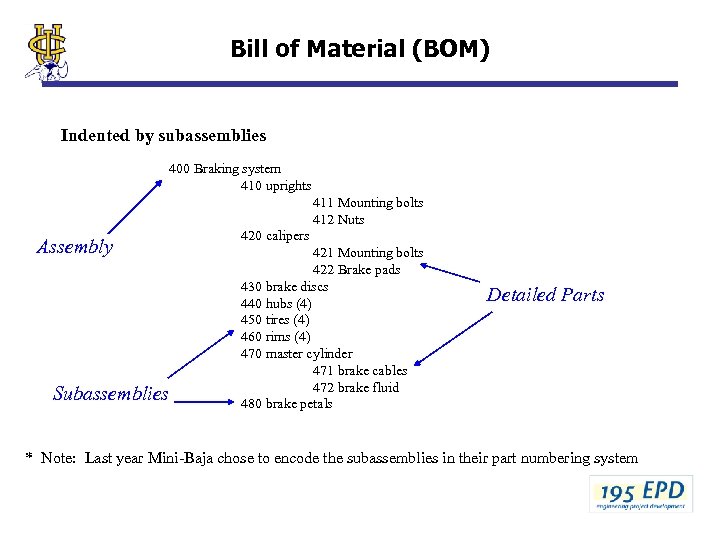

Bill of Material (BOM) Indented by subassemblies 400 Braking system 410 uprights 411 Mounting bolts 412 Nuts Assembly Subassemblies 420 calipers 421 Mounting bolts 422 Brake pads 430 brake discs 440 hubs (4) 450 tires (4) 460 rims (4) 470 master cylinder 471 brake cables 472 brake fluid 480 brake petals Detailed Parts * Note: Last year Mini-Baja chose to encode the subassemblies in their part numbering system

Bill of Material (BOM) Indented by subassemblies 400 Braking system 410 uprights 411 Mounting bolts 412 Nuts Assembly Subassemblies 420 calipers 421 Mounting bolts 422 Brake pads 430 brake discs 440 hubs (4) 450 tires (4) 460 rims (4) 470 master cylinder 471 brake cables 472 brake fluid 480 brake petals Detailed Parts * Note: Last year Mini-Baja chose to encode the subassemblies in their part numbering system

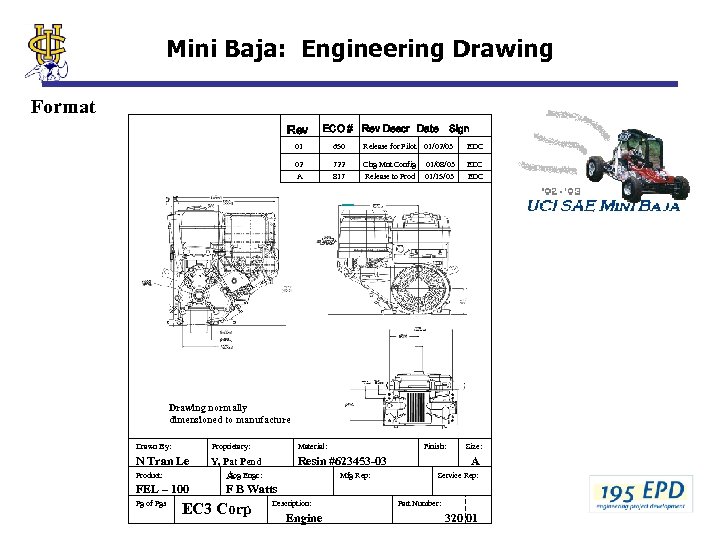

Mini Baja: Engineering Drawing Format Rev ECO # Rev Descr Date Sign 01 650 Release for Pilot 01/02/03 EDC 02 722 Chg Mnt Config 01/08/03 EDC A 817 Release to Prod 01/15/03 EDC Profile Rear Front Drawing normally dimensioned to manufacture Drawn By: Proprietary: N Tran Le FEL – 100 Pg of Pgs Y, Pat Pend Cog Engr. : A Product: Material: Finish: Size: Resin #623453 -03 Mfg Rep: A Service Rep: F B Watts Description: EC 3 Corp Engine Part Number: 320 01

Mini Baja: Engineering Drawing Format Rev ECO # Rev Descr Date Sign 01 650 Release for Pilot 01/02/03 EDC 02 722 Chg Mnt Config 01/08/03 EDC A 817 Release to Prod 01/15/03 EDC Profile Rear Front Drawing normally dimensioned to manufacture Drawn By: Proprietary: N Tran Le FEL – 100 Pg of Pgs Y, Pat Pend Cog Engr. : A Product: Material: Finish: Size: Resin #623453 -03 Mfg Rep: A Service Rep: F B Watts Description: EC 3 Corp Engine Part Number: 320 01

Mini Baja: Part Numbers Parts List

Mini Baja: Part Numbers Parts List

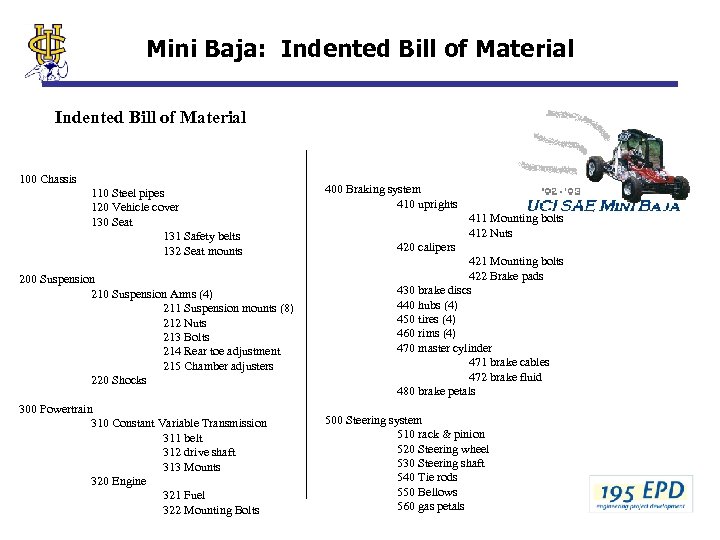

Mini Baja: Indented Bill of Material 100 Chassis 110 Steel pipes 120 Vehicle cover 130 Seat 131 Safety belts 132 Seat mounts 200 Suspension 210 Suspension Arms (4) 211 Suspension mounts (8) 212 Nuts 213 Bolts 214 Rear toe adjustment 215 Chamber adjusters 220 Shocks 300 Powertrain 310 Constant Variable Transmission 311 belt 312 drive shaft 313 Mounts 320 Engine 321 Fuel 322 Mounting Bolts 400 Braking system 410 uprights 411 Mounting bolts 412 Nuts 420 calipers 421 Mounting bolts 422 Brake pads 430 brake discs 440 hubs (4) 450 tires (4) 460 rims (4) 470 master cylinder 471 brake cables 472 brake fluid 480 brake petals 500 Steering system 510 rack & pinion 520 Steering wheel 530 Steering shaft 540 Tie rods 550 Bellows 560 gas petals

Mini Baja: Indented Bill of Material 100 Chassis 110 Steel pipes 120 Vehicle cover 130 Seat 131 Safety belts 132 Seat mounts 200 Suspension 210 Suspension Arms (4) 211 Suspension mounts (8) 212 Nuts 213 Bolts 214 Rear toe adjustment 215 Chamber adjusters 220 Shocks 300 Powertrain 310 Constant Variable Transmission 311 belt 312 drive shaft 313 Mounts 320 Engine 321 Fuel 322 Mounting Bolts 400 Braking system 410 uprights 411 Mounting bolts 412 Nuts 420 calipers 421 Mounting bolts 422 Brake pads 430 brake discs 440 hubs (4) 450 tires (4) 460 rims (4) 470 master cylinder 471 brake cables 472 brake fluid 480 brake petals 500 Steering system 510 rack & pinion 520 Steering wheel 530 Steering shaft 540 Tie rods 550 Bellows 560 gas petals

Release Process Product and Document Release The process that approves the integration a drawing, specification, or other document into the Bill of Material of the product. This means that identifying a part is a two step process. 1. Obtain a part number from Configuration Management as the parts is being designed. 2. Verify that the part is appropriate for the product and “Release to Manufacturing. ” Configuration Management has a list of all part numbers assigned, AND as separate list of part numbers in a give product called the Bill of Materials for that product. A “release memo” lists the documents associated with the part to be released with approval signatures by Engineering and Manufacturing. Revisions: • Prior to “Release” revisions to drawings and other documents should be identified with numbers, such as Rev 1, Rev 2. • After “Release” revisions should be identified with letters, Rev. A, Rev. B.

Release Process Product and Document Release The process that approves the integration a drawing, specification, or other document into the Bill of Material of the product. This means that identifying a part is a two step process. 1. Obtain a part number from Configuration Management as the parts is being designed. 2. Verify that the part is appropriate for the product and “Release to Manufacturing. ” Configuration Management has a list of all part numbers assigned, AND as separate list of part numbers in a give product called the Bill of Materials for that product. A “release memo” lists the documents associated with the part to be released with approval signatures by Engineering and Manufacturing. Revisions: • Prior to “Release” revisions to drawings and other documents should be identified with numbers, such as Rev 1, Rev 2. • After “Release” revisions should be identified with letters, Rev. A, Rev. B.

Change Control: The process of identifying and making changes to released parts and documents. Engineering Change Request (ECR): This is a numbered list of design changes requested by anyone associated with the organization. The usual sources are manufacturing, sales and service. Engineering Change Order (ECO): The document that identifies (1) the current part or document, and (2) the changed document, with a description of the reasons for the change. This is reviewe dby the “Change Control Board. ” The change approval is combined with the “release memo” for the part at which point the old part is removed and the new one integrated into the Bill of Materials.

Change Control: The process of identifying and making changes to released parts and documents. Engineering Change Request (ECR): This is a numbered list of design changes requested by anyone associated with the organization. The usual sources are manufacturing, sales and service. Engineering Change Order (ECO): The document that identifies (1) the current part or document, and (2) the changed document, with a description of the reasons for the change. This is reviewe dby the “Change Control Board. ” The change approval is combined with the “release memo” for the part at which point the old part is removed and the new one integrated into the Bill of Materials.

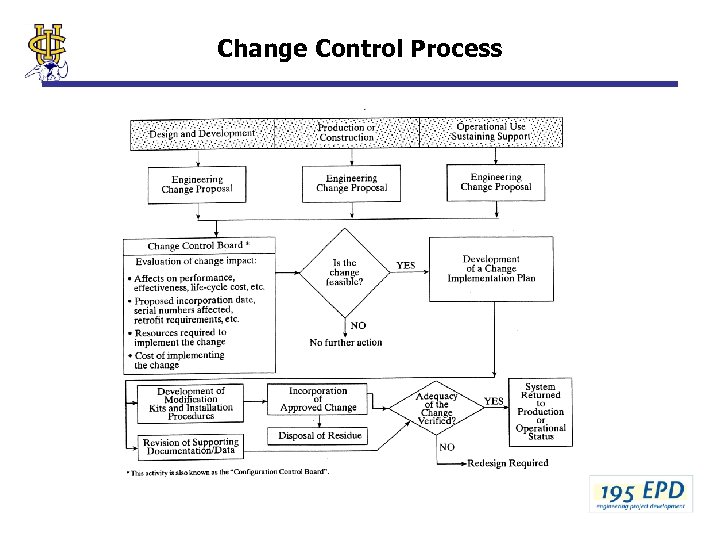

Change Control Process

Change Control Process

Configuration Management SOP ISO Standards require a Standard Operating Procedure for Configuration Management. All Standard Operating Procedures for a Company are to have the same format. For example: Purpose Scope Responsibilities Reference Documents Definitions Procedure Records Attachments (Flowchart)

Configuration Management SOP ISO Standards require a Standard Operating Procedure for Configuration Management. All Standard Operating Procedures for a Company are to have the same format. For example: Purpose Scope Responsibilities Reference Documents Definitions Procedure Records Attachments (Flowchart)