91d454fb44b44b8c5277506d3f95c428.ppt

- Количество слайдов: 2

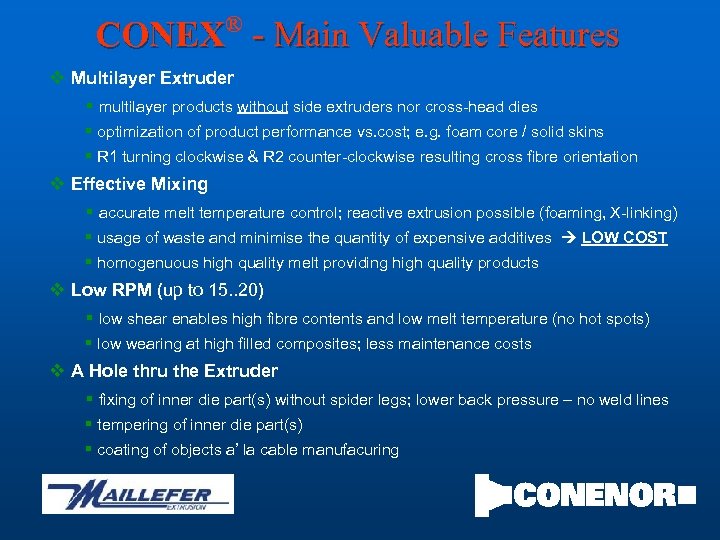

® CONEX - Main Valuable Features v Multilayer Extruder § multilayer products without side extruders nor cross-head dies § optimization of product performance vs. cost; e. g. foam core / solid skins § R 1 turning clockwise & R 2 counter-clockwise resulting cross fibre orientation v Effective Mixing § accurate melt temperature control; reactive extrusion possible (foaming, X-linking) § usage of waste and minimise the quantity of expensive additives LOW COST § homogenuous high quality melt providing high quality products v Low RPM (up to 15. . 20) § low shear enables high fibre contents and low melt temperature (no hot spots) § low wearing at high filled composites; less maintenance costs v A Hole thru the Extruder § fixing of inner die part(s) without spider legs; lower back pressure – no weld lines § tempering of inner die part(s) § coating of objects a’ la cable manufacuring

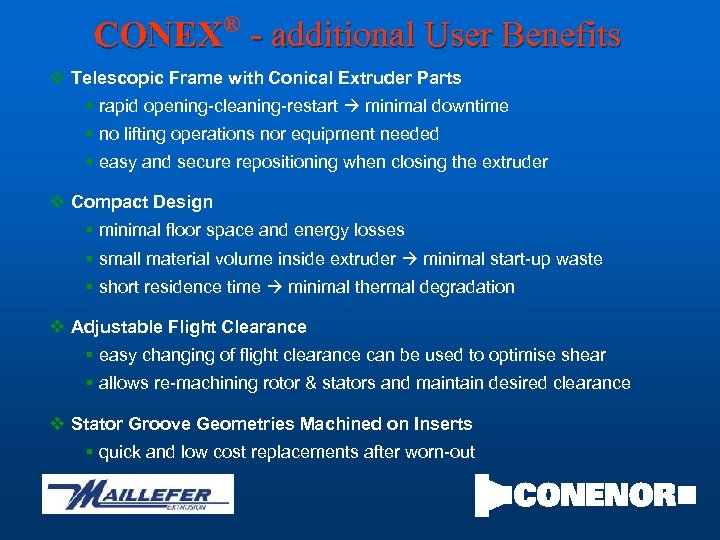

® CONEX - additional User Benefits v Telescopic Frame with Conical Extruder Parts § rapid opening-cleaning-restart minimal downtime § no lifting operations nor equipment needed § easy and secure repositioning when closing the extruder v Compact Design § minimal floor space and energy losses § small material volume inside extruder minimal start-up waste § short residence time minimal thermal degradation v Adjustable Flight Clearance § easy changing of flight clearance can be used to optimise shear § allows re-machining rotor & stators and maintain desired clearance v Stator Groove Geometries Machined on Inserts § quick and low cost replacements after worn-out

91d454fb44b44b8c5277506d3f95c428.ppt