2602176cfc119f05ec47c4c9c76b849f.ppt

- Количество слайдов: 31

CONDENSATION Predicting Interstitial Condensation

CONDENSATION Predicting Interstitial Condensation

Interstitial Condensation This is condensation that occurs within the fabric of a composite construction such as walls and roofs. Interstitial condensation risk can be estimated from a knowledge of thermal and vapour characteristics of the building fabric and the environment.

Interstitial Condensation This is condensation that occurs within the fabric of a composite construction such as walls and roofs. Interstitial condensation risk can be estimated from a knowledge of thermal and vapour characteristics of the building fabric and the environment.

How? By plotting the temperature profile and the dew-point profile as they pass through the element of the building

How? By plotting the temperature profile and the dew-point profile as they pass through the element of the building

How? Dewpoint This is the critical point where the air is saturated. Dependent on the amount of water vapour present in the air.

How? Dewpoint This is the critical point where the air is saturated. Dependent on the amount of water vapour present in the air.

Why? üTo determine the likelihood of interstitial condensation occurring within the fabric üTo be able to design against this likelihood and eliminate possible risk

Why? üTo determine the likelihood of interstitial condensation occurring within the fabric üTo be able to design against this likelihood and eliminate possible risk

Method By: § Calculation § Use of psychometric chart § Use of manufacturers’ literature § Graphically

Method By: § Calculation § Use of psychometric chart § Use of manufacturers’ literature § Graphically

6 Step process 1. 2. 3. 4. 5. Calculate overall temperature drop Calculate Thermal Resistance (if not given) Calculate temperature drop across elements Plot temperatures Calculate Moisture conditions of external & internal environment 6. Find Vapour Resistance using Psychometric Charts 7. Calculate vapour pressure drop across layers 8. Determine dewpoint temperature at boundary of each element 9. Plot dew-point 10. Analyse & conclude

6 Step process 1. 2. 3. 4. 5. Calculate overall temperature drop Calculate Thermal Resistance (if not given) Calculate temperature drop across elements Plot temperatures Calculate Moisture conditions of external & internal environment 6. Find Vapour Resistance using Psychometric Charts 7. Calculate vapour pressure drop across layers 8. Determine dewpoint temperature at boundary of each element 9. Plot dew-point 10. Analyse & conclude

Example

Example

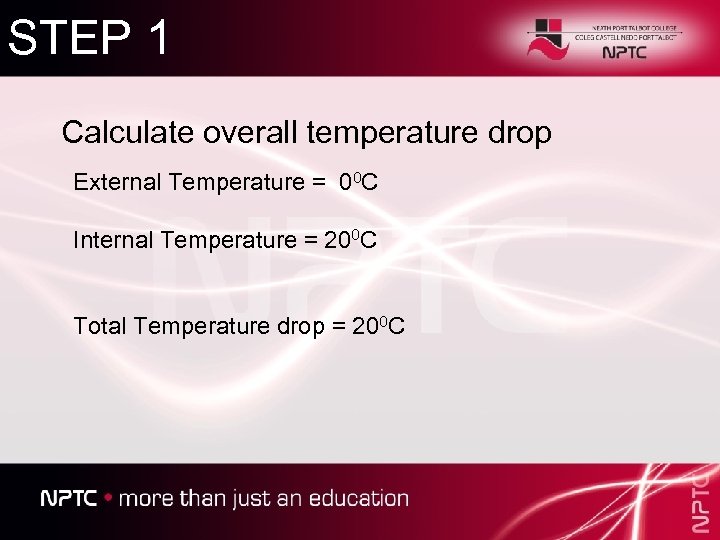

STEP 1 Calculate overall temperature drop External Temperature = 00 C Internal Temperature = 200 C Total Temperature drop = 200 C

STEP 1 Calculate overall temperature drop External Temperature = 00 C Internal Temperature = 200 C Total Temperature drop = 200 C

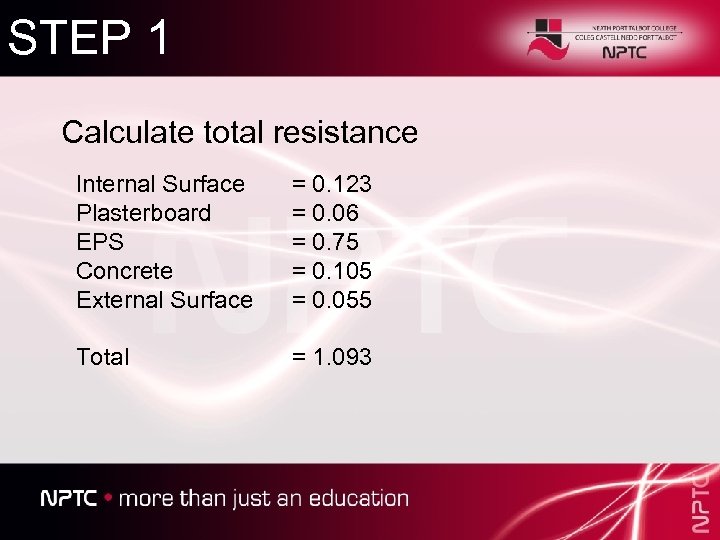

STEP 1 Calculate total resistance Internal Surface Plasterboard EPS Concrete External Surface = 0. 123 = 0. 06 = 0. 75 = 0. 105 = 0. 055 Total = 1. 093

STEP 1 Calculate total resistance Internal Surface Plasterboard EPS Concrete External Surface = 0. 123 = 0. 06 = 0. 75 = 0. 105 = 0. 055 Total = 1. 093

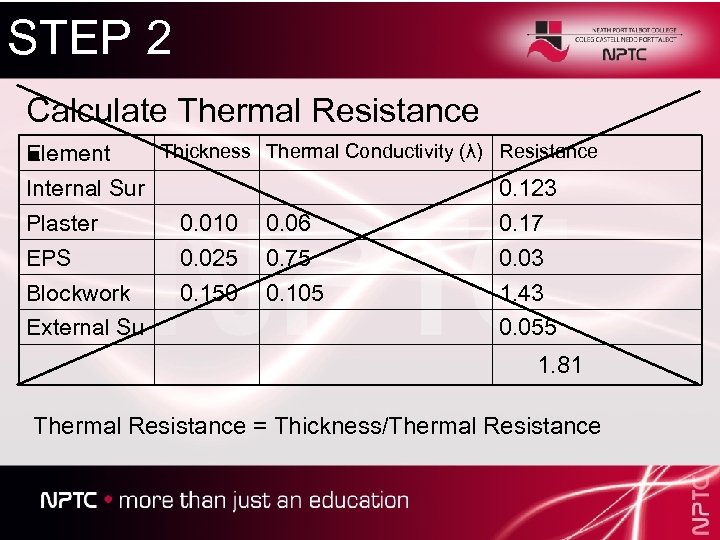

STEP 2 Calculate Thermal Resistance Thickness Thermal Conductivity (λ) Element § Internal Sur Resistance 0. 123 Plaster 0. 010 0. 06 0. 17 EPS 0. 025 0. 75 0. 03 Blockwork 0. 150 0. 105 1. 43 External Su 0. 055 1. 81 Thermal Resistance = Thickness/Thermal Resistance

STEP 2 Calculate Thermal Resistance Thickness Thermal Conductivity (λ) Element § Internal Sur Resistance 0. 123 Plaster 0. 010 0. 06 0. 17 EPS 0. 025 0. 75 0. 03 Blockwork 0. 150 0. 105 1. 43 External Su 0. 055 1. 81 Thermal Resistance = Thickness/Thermal Resistance

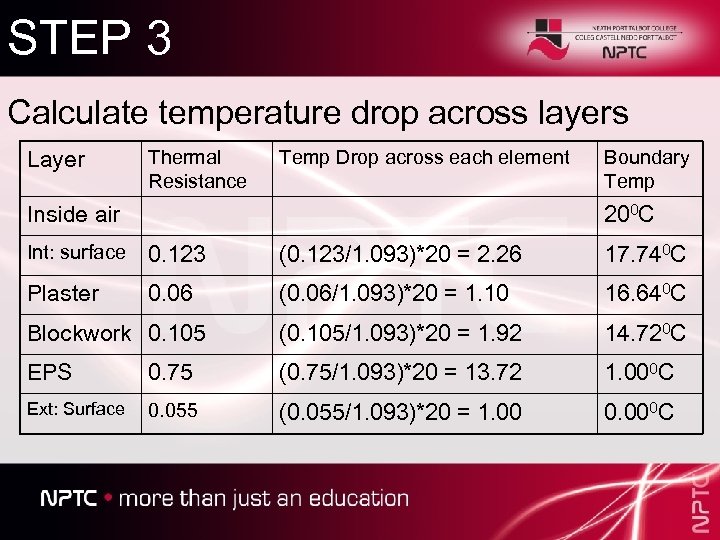

STEP 3 Calculate temperature drop across layers Layer Thermal Resistance Temp Drop across each element Inside air Boundary Temp 200 C Int: surface 0. 123 (0. 123/1. 093)*20 = 2. 26 17. 740 C Plaster 0. 06 (0. 06/1. 093)*20 = 1. 10 16. 640 C Blockwork 0. 105 (0. 105/1. 093)*20 = 1. 92 14. 720 C EPS 0. 75 (0. 75/1. 093)*20 = 13. 72 1. 000 C Ext: Surface 0. 055 (0. 055/1. 093)*20 = 1. 00 0. 000 C

STEP 3 Calculate temperature drop across layers Layer Thermal Resistance Temp Drop across each element Inside air Boundary Temp 200 C Int: surface 0. 123 (0. 123/1. 093)*20 = 2. 26 17. 740 C Plaster 0. 06 (0. 06/1. 093)*20 = 1. 10 16. 640 C Blockwork 0. 105 (0. 105/1. 093)*20 = 1. 92 14. 720 C EPS 0. 75 (0. 75/1. 093)*20 = 13. 72 1. 000 C Ext: Surface 0. 055 (0. 055/1. 093)*20 = 1. 00 0. 000 C

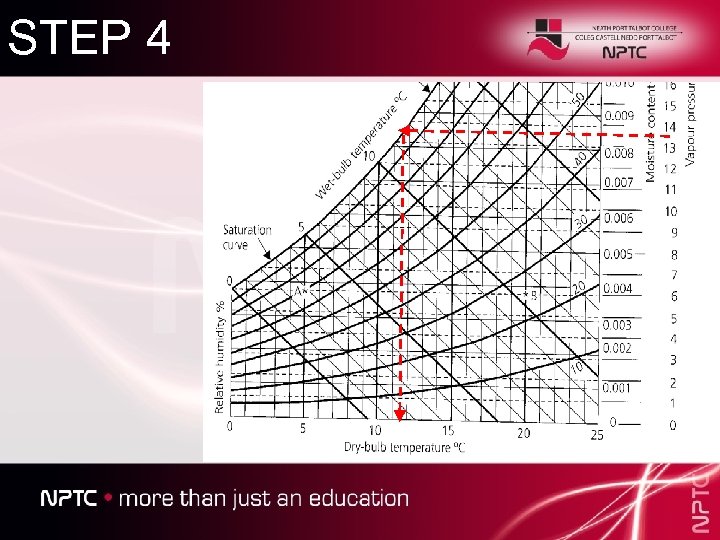

STEP 4 1. Draw a scaled section of the construction 2. Plot the boundary temperatures from step 2 on the section 3. Join the temperatures together to create a profile

STEP 4 1. Draw a scaled section of the construction 2. Plot the boundary temperatures from step 2 on the section 3. Join the temperatures together to create a profile

STEP 5 1. Find internal vapour pressure. • Internal temp = 20 o. C • Humidity = 59% • External temp = 00 C • Humidity = 100%

STEP 5 1. Find internal vapour pressure. • Internal temp = 20 o. C • Humidity = 59% • External temp = 00 C • Humidity = 100%

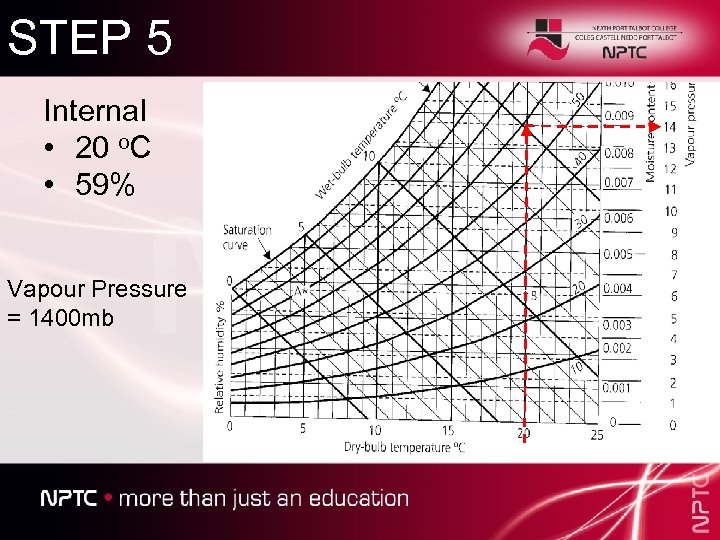

STEP 5 Internal • 20 o. C • 59% Vapour Pressure = 1400 mb

STEP 5 Internal • 20 o. C • 59% Vapour Pressure = 1400 mb

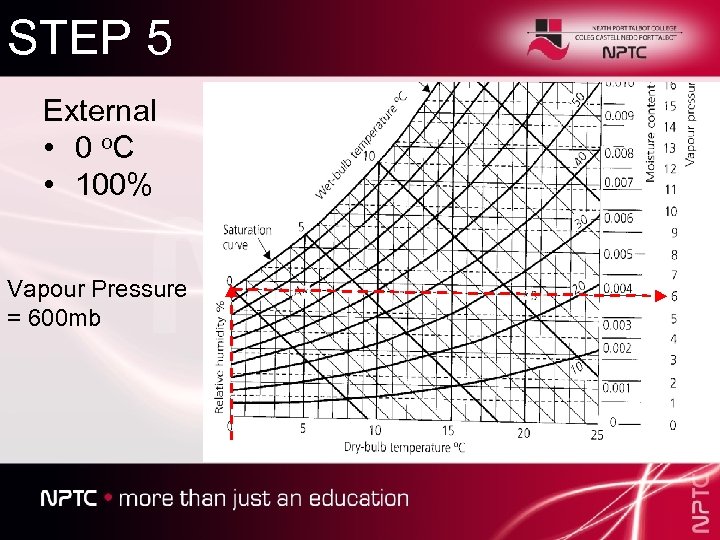

STEP 5 External • 0 o. C • 100% Vapour Pressure = 600 mb

STEP 5 External • 0 o. C • 100% Vapour Pressure = 600 mb

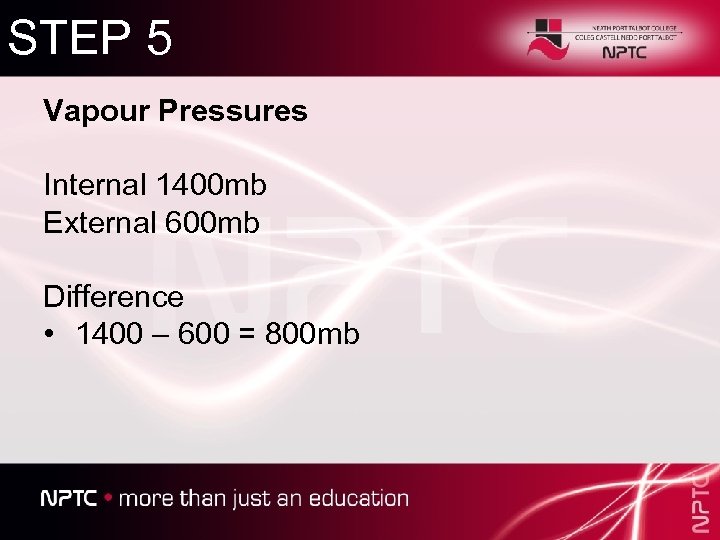

STEP 5 Vapour Pressures Internal 1400 mb External 600 mb Difference • 1400 – 600 = 800 mb

STEP 5 Vapour Pressures Internal 1400 mb External 600 mb Difference • 1400 – 600 = 800 mb

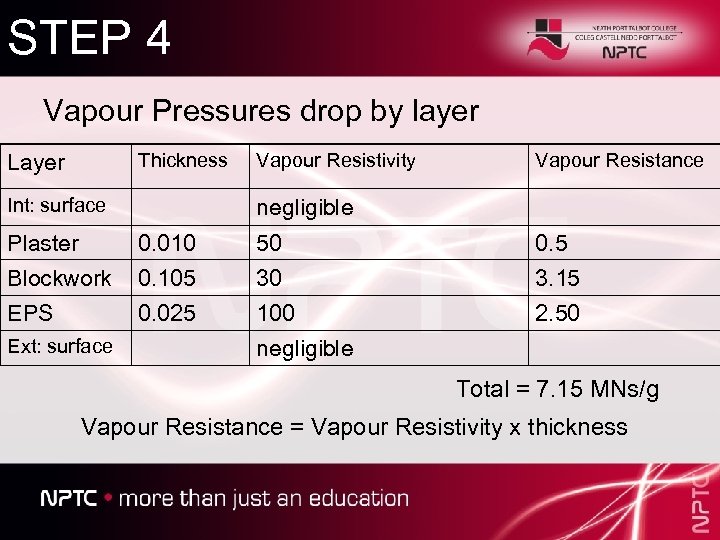

STEP 4 Vapour Pressures drop by layer Thickness Layer Int: surface Vapour Resistivity Vapour Resistance negligible Plaster 0. 010 50 0. 5 Blockwork 0. 105 30 3. 15 EPS 0. 025 100 2. 50 Ext: surface negligible Total = 7. 15 MNs/g Vapour Resistance = Vapour Resistivity x thickness

STEP 4 Vapour Pressures drop by layer Thickness Layer Int: surface Vapour Resistivity Vapour Resistance negligible Plaster 0. 010 50 0. 5 Blockwork 0. 105 30 3. 15 EPS 0. 025 100 2. 50 Ext: surface negligible Total = 7. 15 MNs/g Vapour Resistance = Vapour Resistivity x thickness

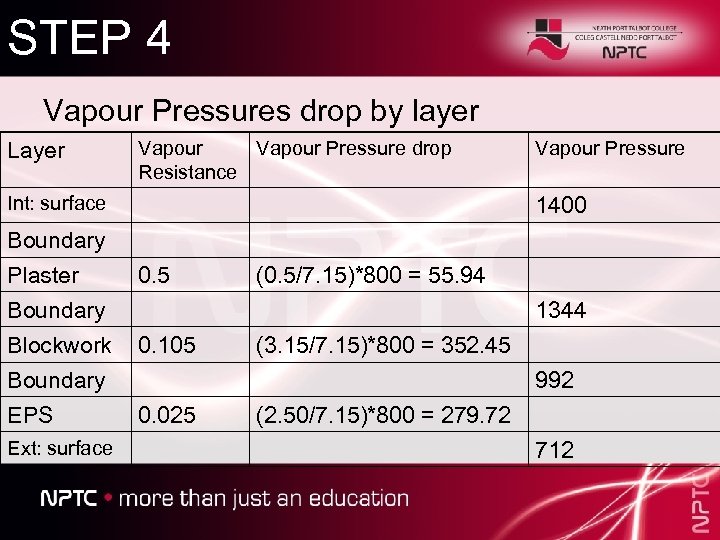

STEP 4 Vapour Pressures drop by layer Layer Vapour Pressure drop Resistance Int: surface Vapour Pressure 1400 Boundary Plaster 0. 5 (0. 5/7. 15)*800 = 55. 94 Boundary Blockwork 1344 0. 105 (3. 15/7. 15)*800 = 352. 45 Boundary EPS Ext: surface 992 0. 025 (2. 50/7. 15)*800 = 279. 72 712

STEP 4 Vapour Pressures drop by layer Layer Vapour Pressure drop Resistance Int: surface Vapour Pressure 1400 Boundary Plaster 0. 5 (0. 5/7. 15)*800 = 55. 94 Boundary Blockwork 1344 0. 105 (3. 15/7. 15)*800 = 352. 45 Boundary EPS Ext: surface 992 0. 025 (2. 50/7. 15)*800 = 279. 72 712

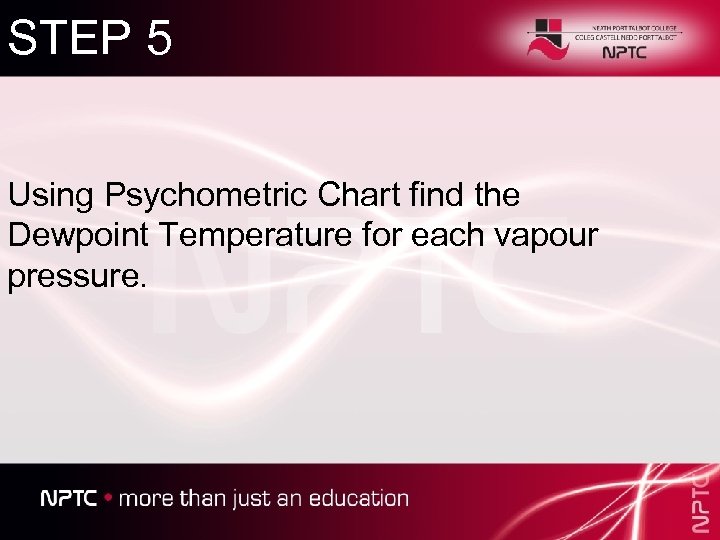

STEP 5 Using Psychometric Chart find the Dewpoint Temperature for each vapour pressure.

STEP 5 Using Psychometric Chart find the Dewpoint Temperature for each vapour pressure.

STEP 4

STEP 4

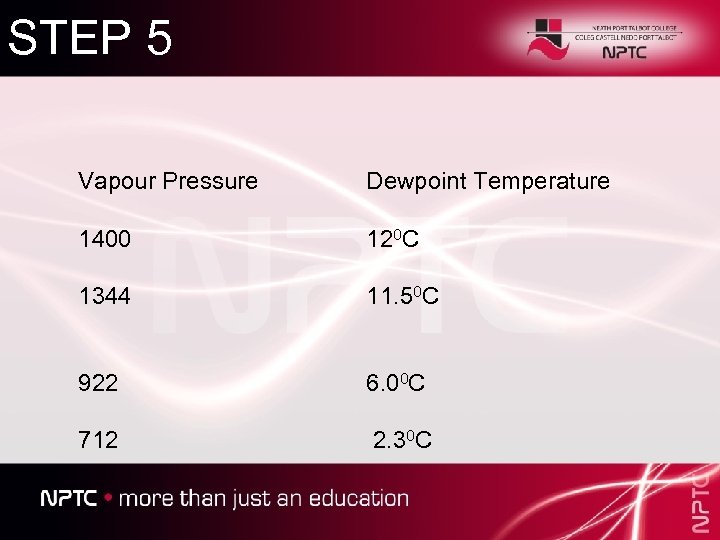

STEP 5 Vapour Pressure Dewpoint Temperature 1400 120 C 1344 11. 50 C 922 6. 00 C 712 2. 30 C

STEP 5 Vapour Pressure Dewpoint Temperature 1400 120 C 1344 11. 50 C 922 6. 00 C 712 2. 30 C

STEP 5 Plot the Dew-point temperatures on section and join temperatures to create profile

STEP 5 Plot the Dew-point temperatures on section and join temperatures to create profile

STEP 5 Plot the Dew-point temperatures on section and join temperatures to create profile

STEP 5 Plot the Dew-point temperatures on section and join temperatures to create profile

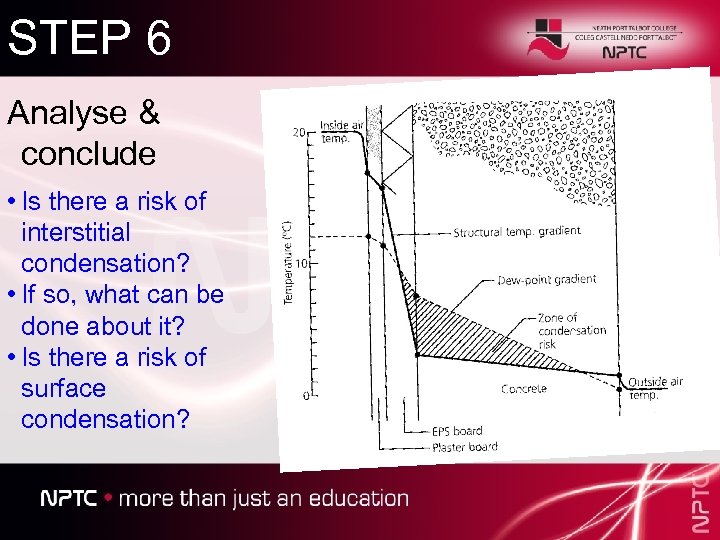

STEP 6 Analyse & conclude • Is there a risk of interstitial condensation? • If so, what can be done about it? • Is there a risk of surface condensation?

STEP 6 Analyse & conclude • Is there a risk of interstitial condensation? • If so, what can be done about it? • Is there a risk of surface condensation?

Next? ? ?

Next? ? ?