5303bc7cbcca0f764c7e906f55d7d44e.ppt

- Количество слайдов: 24

Conceptual Design Study - Cryogenic Requirements • • • How to decide the layout of ILC cryogenic system Conceptual design of cryogenic system Layout of cryogenic system for site A & B Helium inventory Cooling water for cryogenic system Summary & Future Plan May 31, 2010 K. Hosoyama

Conceptual Design Study - Cryogenic Requirements • • • How to decide the layout of ILC cryogenic system Conceptual design of cryogenic system Layout of cryogenic system for site A & B Helium inventory Cooling water for cryogenic system Summary & Future Plan May 31, 2010 K. Hosoyama

How to decide the layout of cryogenic facility ? Key Issues l 2 K cold boxes must be installed in the tunnel at 5 km intervals l Installation, maintenance & repair of large components: compressor unit, cold box l Safety in case of helium gas leakage l Construction & operation cost l Use the access tunnel and assembling area of TBM effectively !

How to decide the layout of cryogenic facility ? Key Issues l 2 K cold boxes must be installed in the tunnel at 5 km intervals l Installation, maintenance & repair of large components: compressor unit, cold box l Safety in case of helium gas leakage l Construction & operation cost l Use the access tunnel and assembling area of TBM effectively !

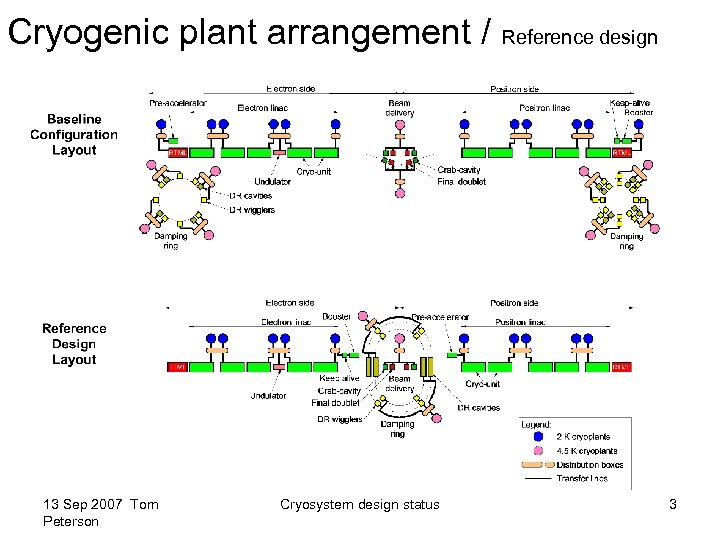

Cryogenic plant arrangement / Reference design 13 Sep 2007 Tom Peterson Cryosystem design status 3

Cryogenic plant arrangement / Reference design 13 Sep 2007 Tom Peterson Cryosystem design status 3

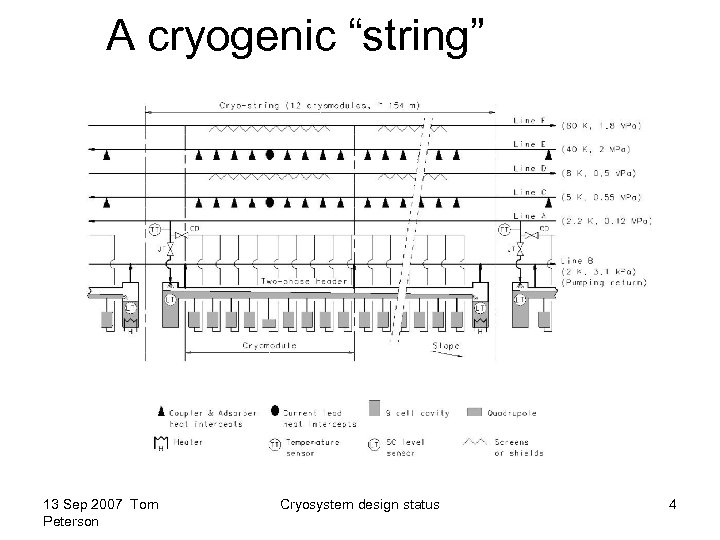

A cryogenic “string” 13 Sep 2007 Tom Peterson Cryosystem design status 4

A cryogenic “string” 13 Sep 2007 Tom Peterson Cryosystem design status 4

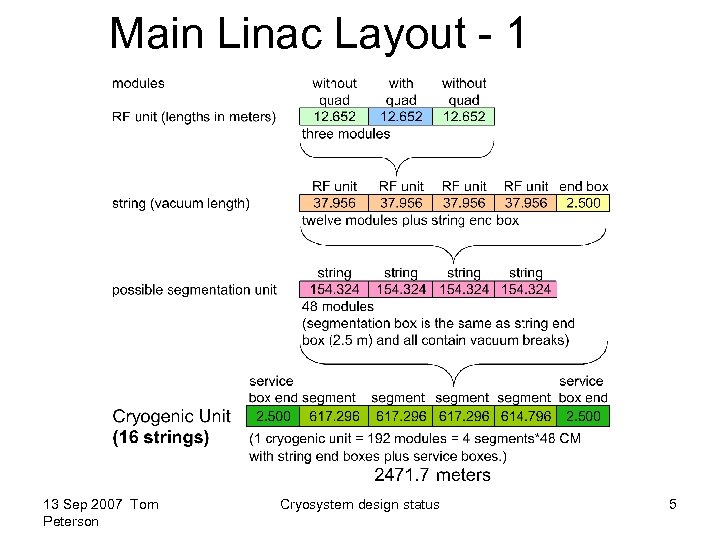

Main Linac Layout - 1 13 Sep 2007 Tom Peterson Cryosystem design status 5

Main Linac Layout - 1 13 Sep 2007 Tom Peterson Cryosystem design status 5

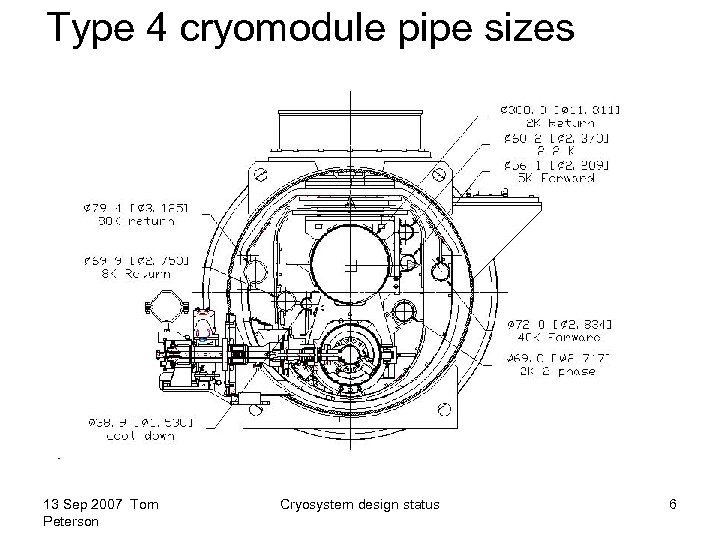

Type 4 cryomodule pipe sizes 13 Sep 2007 Tom Peterson Cryosystem design status 6

Type 4 cryomodule pipe sizes 13 Sep 2007 Tom Peterson Cryosystem design status 6

![Properties of Helium Enthalpy of Helium Vapor Pressure of Saturated Helium Pressure [bar] Enthalpy Properties of Helium Enthalpy of Helium Vapor Pressure of Saturated Helium Pressure [bar] Enthalpy](https://present5.com/presentation/5303bc7cbcca0f764c7e906f55d7d44e/image-7.jpg) Properties of Helium Enthalpy of Helium Vapor Pressure of Saturated Helium Pressure [bar] Enthalpy [ J / g] Gas State Temperature [K] 20 J / g Temperature [K] 1 W 2. 0 K 4. 2 K 0. 031 bar Ratio of Gas Volume 1 / 0. 031 = 32 Cooling Power 1. 4 l / hr Liq. He Consumption 2 K cooling power is limited by pressure drop Dp at cold pumping pipe.

Properties of Helium Enthalpy of Helium Vapor Pressure of Saturated Helium Pressure [bar] Enthalpy [ J / g] Gas State Temperature [K] 20 J / g Temperature [K] 1 W 2. 0 K 4. 2 K 0. 031 bar Ratio of Gas Volume 1 / 0. 031 = 32 Cooling Power 1. 4 l / hr Liq. He Consumption 2 K cooling power is limited by pressure drop Dp at cold pumping pipe.

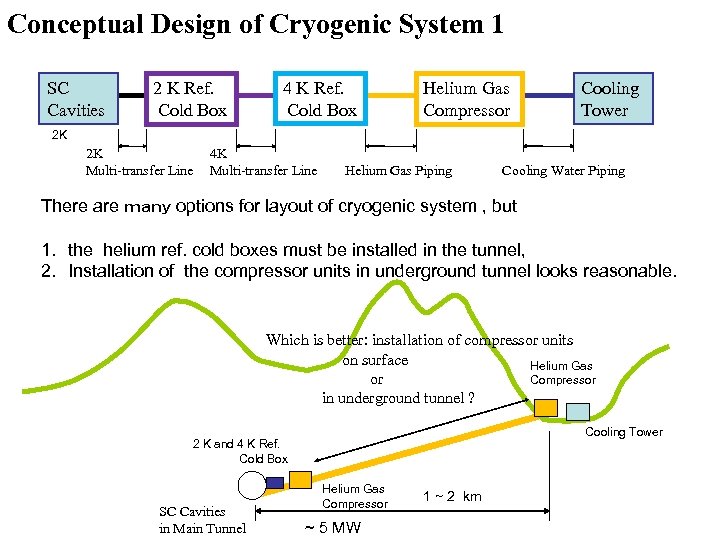

Conceptual Design of Cryogenic System 1 SC Cavities 2 K Ref. Cold Box 4 K Ref. Cold Box Helium Gas Compressor Cooling Tower 2 K 2 K Multi-transfer Line 4 K Multi-transfer Line Helium Gas Piping Cooling Water Piping There are many options for layout of cryogenic system , but 1. the helium ref. cold boxes must be installed in the tunnel, 2. Installation of the compressor units in underground tunnel looks reasonable. Which is better: installation of compressor units on surface Helium Gas or Compressor in underground tunnel ? Cooling Tower 2 K and 4 K Ref. Cold Box SC Cavities in Main Tunnel Helium Gas Compressor ~ 5 MW 1 ~ 2 km

Conceptual Design of Cryogenic System 1 SC Cavities 2 K Ref. Cold Box 4 K Ref. Cold Box Helium Gas Compressor Cooling Tower 2 K 2 K Multi-transfer Line 4 K Multi-transfer Line Helium Gas Piping Cooling Water Piping There are many options for layout of cryogenic system , but 1. the helium ref. cold boxes must be installed in the tunnel, 2. Installation of the compressor units in underground tunnel looks reasonable. Which is better: installation of compressor units on surface Helium Gas or Compressor in underground tunnel ? Cooling Tower 2 K and 4 K Ref. Cold Box SC Cavities in Main Tunnel Helium Gas Compressor ~ 5 MW 1 ~ 2 km

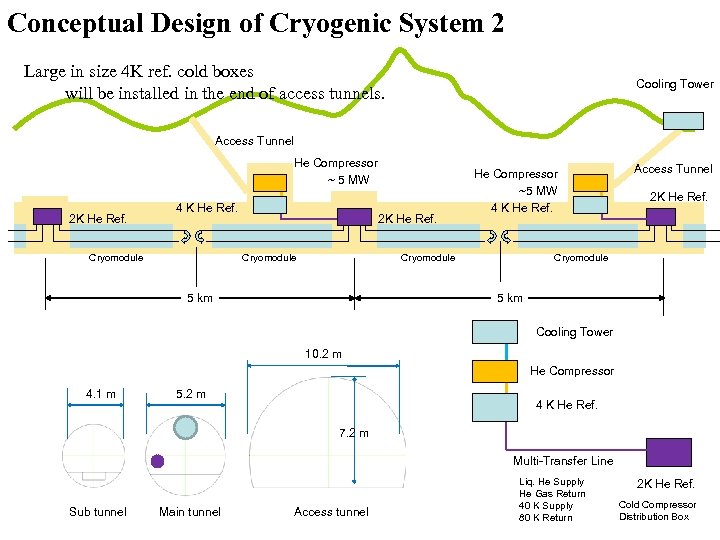

Conceptual Design of Cryogenic System 2 Large in size 4 K ref. cold boxes will be installed in the end of access tunnels. Cooling Tower Access Tunnel He Compressor ~ 5 MW 2 K He Ref. 4 K He Ref. Cryomodule 2 K He Ref. Cryomodule He Compressor ~5 MW 4 K He Ref. Cryomodule 5 km Access Tunnel 2 K He Ref. Cryomodule 5 km Cooling Tower 10. 2 m He Compressor 4. 1 m 5. 2 m 4 K He Ref. 7. 2 m Multi-Transfer Line Sub tunnel Main tunnel Access tunnel Liq. He Supply He Gas Return 40 K Supply 80 K Return 2 K He Ref. Cold Compressor Distribution Box

Conceptual Design of Cryogenic System 2 Large in size 4 K ref. cold boxes will be installed in the end of access tunnels. Cooling Tower Access Tunnel He Compressor ~ 5 MW 2 K He Ref. 4 K He Ref. Cryomodule 2 K He Ref. Cryomodule He Compressor ~5 MW 4 K He Ref. Cryomodule 5 km Access Tunnel 2 K He Ref. Cryomodule 5 km Cooling Tower 10. 2 m He Compressor 4. 1 m 5. 2 m 4 K He Ref. 7. 2 m Multi-Transfer Line Sub tunnel Main tunnel Access tunnel Liq. He Supply He Gas Return 40 K Supply 80 K Return 2 K He Ref. Cold Compressor Distribution Box

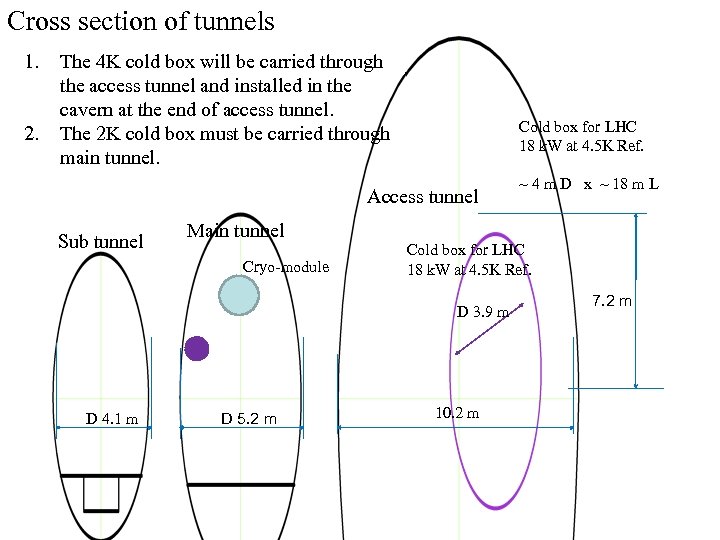

Cross section of tunnels 1. 2. The 4 K cold box will be carried through the access tunnel and installed in the cavern at the end of access tunnel. The 2 K cold box must be carried through main tunnel. Cold box for LHC 18 k. W at 4. 5 K Ref. Access tunnel Sub tunnel Main tunnel Cryo-module Cold box for LHC 18 k. W at 4. 5 K Ref. D 3. 9 m D 4. 1 m ~ 4 m D x ~ 18 m L D 5. 2 m 10. 2 m 7. 2 m

Cross section of tunnels 1. 2. The 4 K cold box will be carried through the access tunnel and installed in the cavern at the end of access tunnel. The 2 K cold box must be carried through main tunnel. Cold box for LHC 18 k. W at 4. 5 K Ref. Access tunnel Sub tunnel Main tunnel Cryo-module Cold box for LHC 18 k. W at 4. 5 K Ref. D 3. 9 m D 4. 1 m ~ 4 m D x ~ 18 m L D 5. 2 m 10. 2 m 7. 2 m

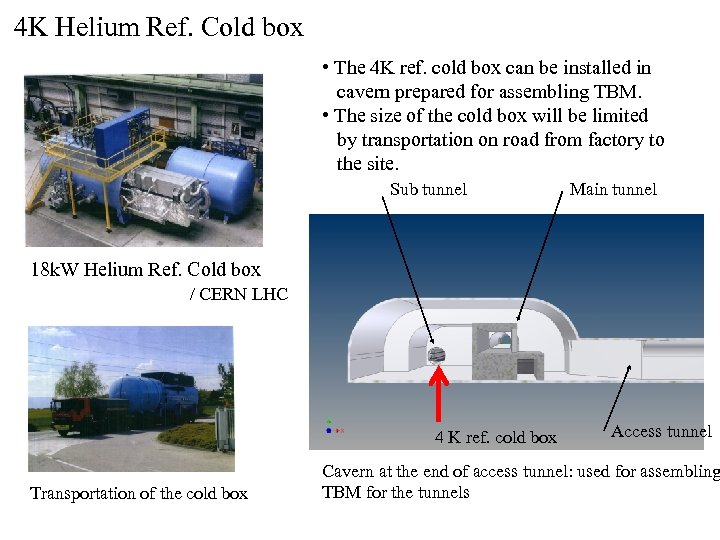

4 K Helium Ref. Cold box • The 4 K ref. cold box can be installed in cavern prepared for assembling TBM. • The size of the cold box will be limited by transportation on road from factory to the site. Sub tunnel Main tunnel 18 k. W Helium Ref. Cold box / CERN LHC 4 K ref. cold box Transportation of the cold box Access tunnel Cavern at the end of access tunnel: used for assembling TBM for the tunnels

4 K Helium Ref. Cold box • The 4 K ref. cold box can be installed in cavern prepared for assembling TBM. • The size of the cold box will be limited by transportation on road from factory to the site. Sub tunnel Main tunnel 18 k. W Helium Ref. Cold box / CERN LHC 4 K ref. cold box Transportation of the cold box Access tunnel Cavern at the end of access tunnel: used for assembling TBM for the tunnels

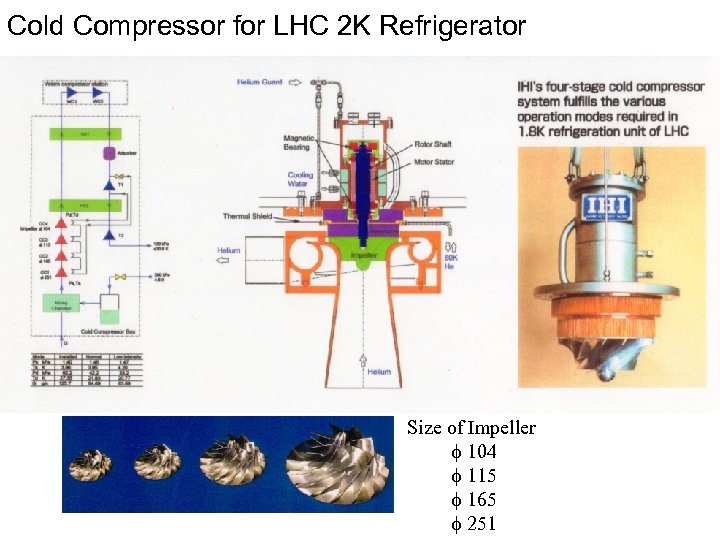

Cold Compressor for LHC 2 K Refrigerator Size of Impeller f 104 f 115 f 165 f 251

Cold Compressor for LHC 2 K Refrigerator Size of Impeller f 104 f 115 f 165 f 251

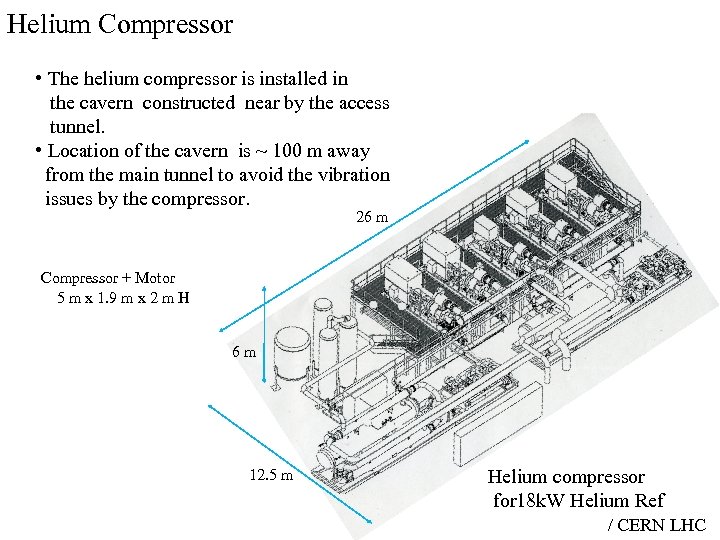

Helium Compressor • The helium compressor is installed in the cavern constructed near by the access tunnel. • Location of the cavern is ~ 100 m away from the main tunnel to avoid the vibration issues by the compressor. 26 m Compressor + Motor 5 m x 1. 9 m x 2 m H 6 m 12. 5 m Helium compressor for 18 k. W Helium Ref / CERN LHC

Helium Compressor • The helium compressor is installed in the cavern constructed near by the access tunnel. • Location of the cavern is ~ 100 m away from the main tunnel to avoid the vibration issues by the compressor. 26 m Compressor + Motor 5 m x 1. 9 m x 2 m H 6 m 12. 5 m Helium compressor for 18 k. W Helium Ref / CERN LHC

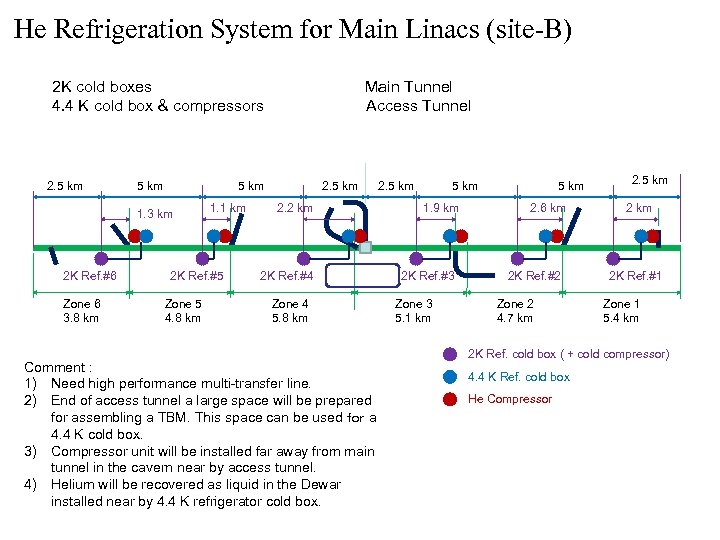

He Refrigeration System for Main Linacs (site-B) 2 K cold boxes 4. 4 K cold box & compressors Main Tunnel Access Tunnel 2. 5 km 1. 3 km 2 K Ref. #6 Zone 6 3. 8 km 1. 1 km 2 K Ref. #5 Zone 5 4. 8 km 2. 5 km 2. 2 km 2 K Ref. #4 Zone 4 5. 8 km Comment : 1) Need high performance multi-transfer line. 2) End of access tunnel a large space will be prepared for assembling a TBM. This space can be used for a 4. 4 K cold box. 3) Compressor unit will be installed far away from main tunnel in the cavern near by access tunnel. 4) Helium will be recovered as liquid in the Dewar installed near by 4. 4 K refrigerator cold box. 2. 5 km 1. 9 km 2 K Ref. #3 Zone 3 5. 1 km 5 km 2. 6 km 2 K Ref. #2 Zone 2 4. 7 km 2. 5 km 2 K Ref. #1 Zone 1 5. 4 km 2 K Ref. cold box ( + cold compressor) 4. 4 K Ref. cold box He Compressor

He Refrigeration System for Main Linacs (site-B) 2 K cold boxes 4. 4 K cold box & compressors Main Tunnel Access Tunnel 2. 5 km 1. 3 km 2 K Ref. #6 Zone 6 3. 8 km 1. 1 km 2 K Ref. #5 Zone 5 4. 8 km 2. 5 km 2. 2 km 2 K Ref. #4 Zone 4 5. 8 km Comment : 1) Need high performance multi-transfer line. 2) End of access tunnel a large space will be prepared for assembling a TBM. This space can be used for a 4. 4 K cold box. 3) Compressor unit will be installed far away from main tunnel in the cavern near by access tunnel. 4) Helium will be recovered as liquid in the Dewar installed near by 4. 4 K refrigerator cold box. 2. 5 km 1. 9 km 2 K Ref. #3 Zone 3 5. 1 km 5 km 2. 6 km 2 K Ref. #2 Zone 2 4. 7 km 2. 5 km 2 K Ref. #1 Zone 1 5. 4 km 2 K Ref. cold box ( + cold compressor) 4. 4 K Ref. cold box He Compressor

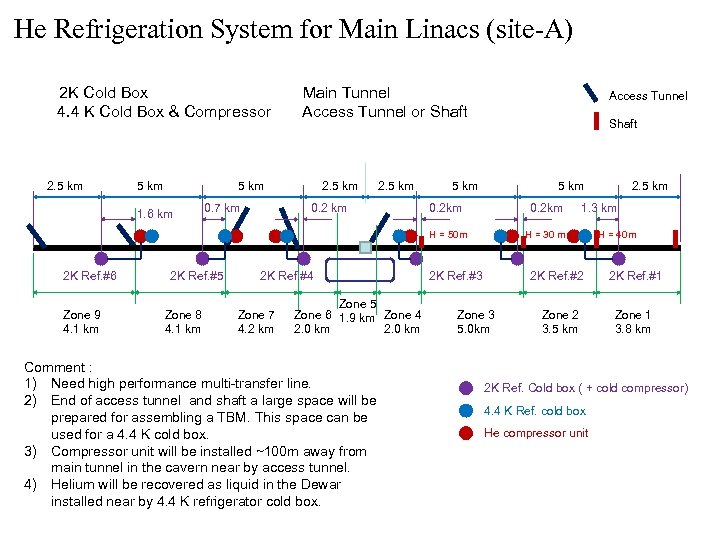

He Refrigeration System for Main Linacs (site-A) 2 K Cold Box 4. 4 K Cold Box & Compressor 2. 5 km Main Tunnel Access Tunnel or Shaft 5 km 2 K Ref. #6 Zone 9 4. 1 km 2 K Ref. #5 Zone 8 4. 1 km 0. 2 km Shaft 5 km 2 K Ref. #4 Zone 7 4. 2 km Zone 5 Zone 6 1. 9 km Zone 4 2. 0 km Comment : 1) Need high performance multi-transfer line. 2) End of access tunnel and shaft a large space will be prepared for assembling a TBM. This space can be used for a 4. 4 K cold box. 3) Compressor unit will be installed ~100 m away from main tunnel in the cavern near by access tunnel. 4) Helium will be recovered as liquid in the Dewar installed near by 4. 4 K refrigerator cold box. 0. 2 km H = 50 m 1. 6 km 0. 7 km 2. 5 km Access Tunnel H = 30 m 2 K Ref. #3 2. 5 km 1. 3 km H = 40 m 2 K Ref. #2 Zone 3 5. 0 km 2 K Ref. #1 Zone 2 3. 5 km Zone 1 3. 8 km 2 K Ref. Cold box ( + cold compressor) 4. 4 K Ref. cold box He compressor unit

He Refrigeration System for Main Linacs (site-A) 2 K Cold Box 4. 4 K Cold Box & Compressor 2. 5 km Main Tunnel Access Tunnel or Shaft 5 km 2 K Ref. #6 Zone 9 4. 1 km 2 K Ref. #5 Zone 8 4. 1 km 0. 2 km Shaft 5 km 2 K Ref. #4 Zone 7 4. 2 km Zone 5 Zone 6 1. 9 km Zone 4 2. 0 km Comment : 1) Need high performance multi-transfer line. 2) End of access tunnel and shaft a large space will be prepared for assembling a TBM. This space can be used for a 4. 4 K cold box. 3) Compressor unit will be installed ~100 m away from main tunnel in the cavern near by access tunnel. 4) Helium will be recovered as liquid in the Dewar installed near by 4. 4 K refrigerator cold box. 0. 2 km H = 50 m 1. 6 km 0. 7 km 2. 5 km Access Tunnel H = 30 m 2 K Ref. #3 2. 5 km 1. 3 km H = 40 m 2 K Ref. #2 Zone 3 5. 0 km 2 K Ref. #1 Zone 2 3. 5 km Zone 1 3. 8 km 2 K Ref. Cold box ( + cold compressor) 4. 4 K Ref. cold box He compressor unit

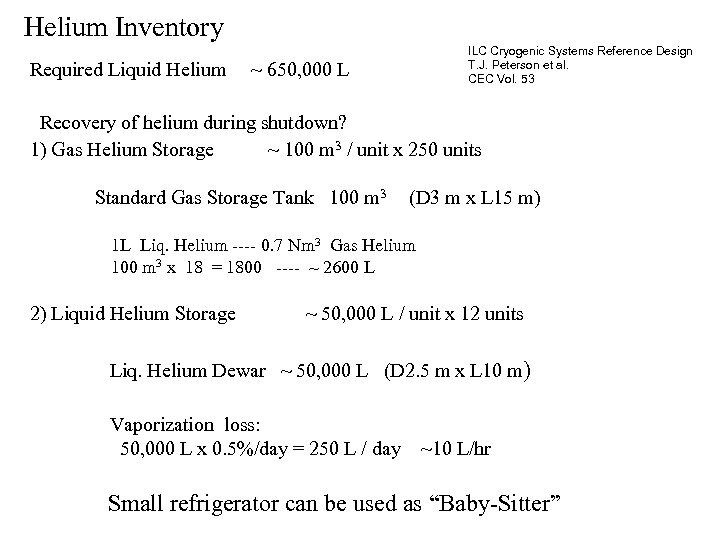

Helium Inventory Required Liquid Helium ILC Cryogenic Systems Reference Design T. J. Peterson et al. CEC Vol. 53 ~ 650, 000 L Recovery of helium during shutdown? 1) Gas Helium Storage ~ 100 m 3 / unit x 250 units Standard Gas Storage Tank 100 m 3 (D 3 m x L 15 m) 1 L Liq. Helium ---- 0. 7 Nm 3 Gas Helium 100 m 3 x 18 = 1800 ---- ~ 2600 L 2) Liquid Helium Storage ~ 50, 000 L / unit x 12 units Liq. Helium Dewar ~ 50, 000 L (D 2. 5 m x L 10 m) Vaporization loss: 50, 000 L x 0. 5%/day = 250 L / day ~10 L/hr Small refrigerator can be used as “Baby-Sitter”

Helium Inventory Required Liquid Helium ILC Cryogenic Systems Reference Design T. J. Peterson et al. CEC Vol. 53 ~ 650, 000 L Recovery of helium during shutdown? 1) Gas Helium Storage ~ 100 m 3 / unit x 250 units Standard Gas Storage Tank 100 m 3 (D 3 m x L 15 m) 1 L Liq. Helium ---- 0. 7 Nm 3 Gas Helium 100 m 3 x 18 = 1800 ---- ~ 2600 L 2) Liquid Helium Storage ~ 50, 000 L / unit x 12 units Liq. Helium Dewar ~ 50, 000 L (D 2. 5 m x L 10 m) Vaporization loss: 50, 000 L x 0. 5%/day = 250 L / day ~10 L/hr Small refrigerator can be used as “Baby-Sitter”

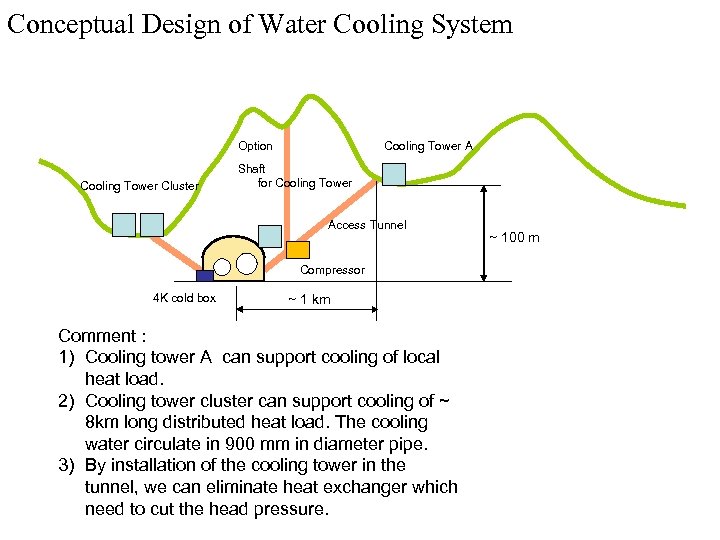

Conceptual Design of Water Cooling System Option Cooling Tower Cluster Cooling Tower A Shaft for Cooling Tower Access Tunnel Compressor 4 K cold box ~ 1 km Comment : 1) Cooling tower A can support cooling of local heat load. 2) Cooling tower cluster can support cooling of ~ 8 km long distributed heat load. The cooling water circulate in 900 mm in diameter pipe. 3) By installation of the cooling tower in the tunnel, we can eliminate heat exchanger which need to cut the head pressure. ~ 100 m

Conceptual Design of Water Cooling System Option Cooling Tower Cluster Cooling Tower A Shaft for Cooling Tower Access Tunnel Compressor 4 K cold box ~ 1 km Comment : 1) Cooling tower A can support cooling of local heat load. 2) Cooling tower cluster can support cooling of ~ 8 km long distributed heat load. The cooling water circulate in 900 mm in diameter pipe. 3) By installation of the cooling tower in the tunnel, we can eliminate heat exchanger which need to cut the head pressure. ~ 100 m

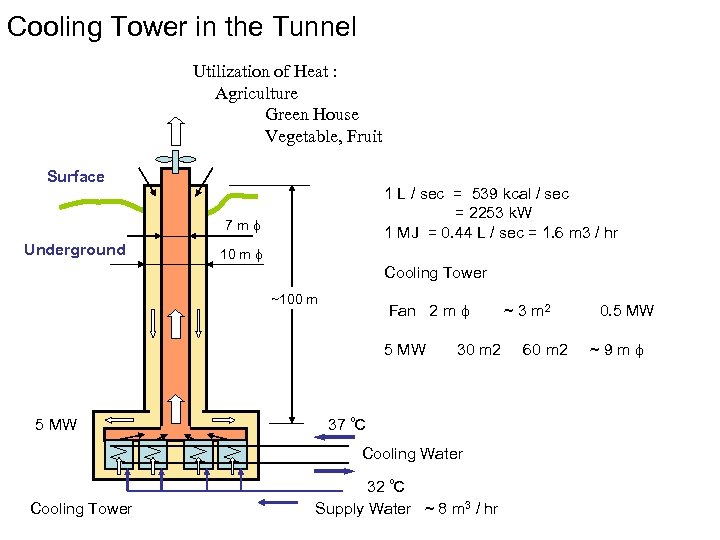

Cooling Tower in the Tunnel Utilization of Heat : Agriculture Green House Vegetable, Fruit Surface 1 L / sec = 539 kcal / sec = 2253 k. W 1 MJ = 0. 44 L / sec = 1. 6 m 3 / hr 7 mf Underground 10 m f Cooling Tower ~100 m Fan 2 m f 5 MW 30 m 2 37 ℃ Cooling Water Cooling Tower 32 ℃ Supply Water ~ 8 m 3 / hr ~ 3 m 2 60 m 2 0. 5 MW ~9 mf

Cooling Tower in the Tunnel Utilization of Heat : Agriculture Green House Vegetable, Fruit Surface 1 L / sec = 539 kcal / sec = 2253 k. W 1 MJ = 0. 44 L / sec = 1. 6 m 3 / hr 7 mf Underground 10 m f Cooling Tower ~100 m Fan 2 m f 5 MW 30 m 2 37 ℃ Cooling Water Cooling Tower 32 ℃ Supply Water ~ 8 m 3 / hr ~ 3 m 2 60 m 2 0. 5 MW ~9 mf

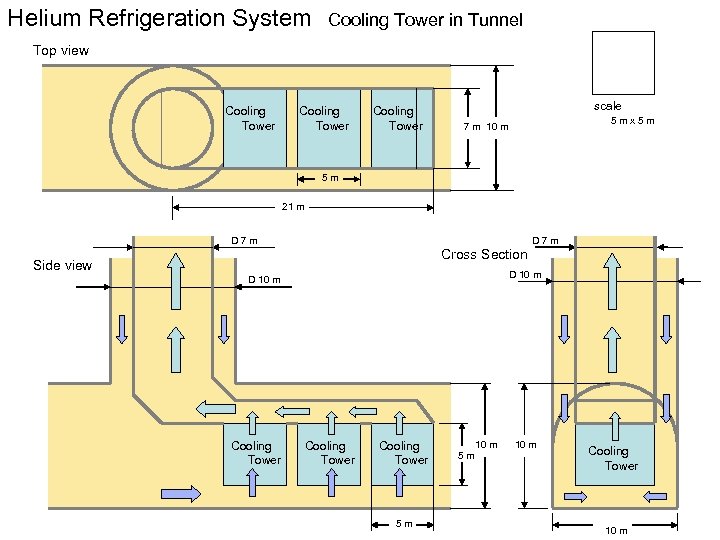

Helium Refrigeration System Cooling Tower in Tunnel Top view Cooling Tower scale 5 mx 5 m 7 m 10 m 5 m 21 m D 7 m Cross Section Side view D 10 m Cooling Tower 5 m 10 m Cooling Tower 10 m

Helium Refrigeration System Cooling Tower in Tunnel Top view Cooling Tower scale 5 mx 5 m 7 m 10 m 5 m 21 m D 7 m Cross Section Side view D 10 m Cooling Tower 5 m 10 m Cooling Tower 10 m

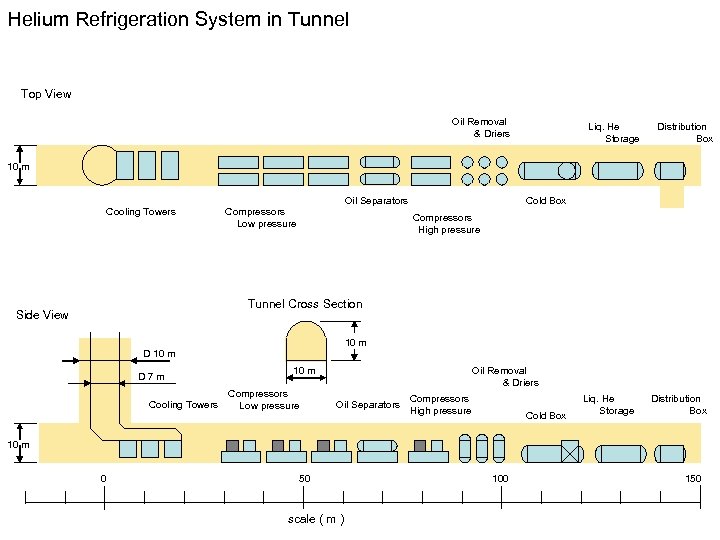

Helium Refrigeration System in Tunnel Top View Oil Removal & Driers Liq. He Storage Distribution Box 10 m Oil Separators Cooling Towers Compressors Low pressure Cold Box Compressors High pressure Tunnel Cross Section Side View 10 m D 7 m Cooling Towers 10 m Compressors Low pressure Oil Removal & Driers Oil Separators Compressors High pressure Cold Box Liq. He Storage Distribution Box 10 m 0 50 scale ( m ) 100 150

Helium Refrigeration System in Tunnel Top View Oil Removal & Driers Liq. He Storage Distribution Box 10 m Oil Separators Cooling Towers Compressors Low pressure Cold Box Compressors High pressure Tunnel Cross Section Side View 10 m D 7 m Cooling Towers 10 m Compressors Low pressure Oil Removal & Driers Oil Separators Compressors High pressure Cold Box Liq. He Storage Distribution Box 10 m 0 50 scale ( m ) 100 150

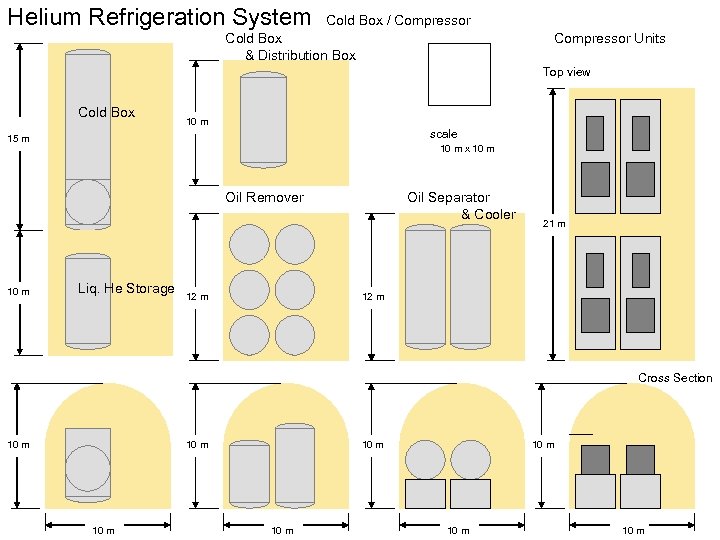

Helium Refrigeration System Cold Box / Compressor Cold Box & Distribution Box Compressor Units Top view Cold Box 10 m scale 15 m 10 m x 10 m Oil Remover 10 m Liq. He Storage 12 m Oil Separator & Cooler 21 m 12 m Cross Section 10 m 10 m

Helium Refrigeration System Cold Box / Compressor Cold Box & Distribution Box Compressor Units Top view Cold Box 10 m scale 15 m 10 m x 10 m Oil Remover 10 m Liq. He Storage 12 m Oil Separator & Cooler 21 m 12 m Cross Section 10 m 10 m

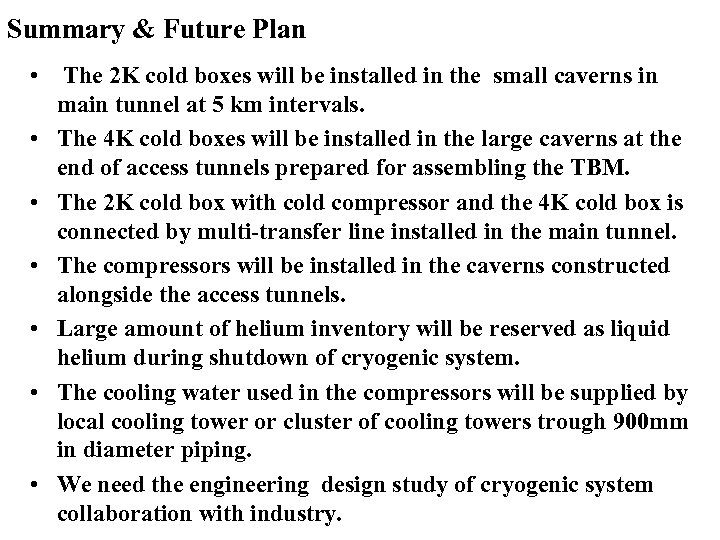

Summary & Future Plan • The 2 K cold boxes will be installed in the small caverns in main tunnel at 5 km intervals. • The 4 K cold boxes will be installed in the large caverns at the end of access tunnels prepared for assembling the TBM. • The 2 K cold box with cold compressor and the 4 K cold box is connected by multi-transfer line installed in the main tunnel. • The compressors will be installed in the caverns constructed alongside the access tunnels. • Large amount of helium inventory will be reserved as liquid helium during shutdown of cryogenic system. • The cooling water used in the compressors will be supplied by local cooling tower or cluster of cooling towers trough 900 mm in diameter piping. • We need the engineering design study of cryogenic system collaboration with industry.

Summary & Future Plan • The 2 K cold boxes will be installed in the small caverns in main tunnel at 5 km intervals. • The 4 K cold boxes will be installed in the large caverns at the end of access tunnels prepared for assembling the TBM. • The 2 K cold box with cold compressor and the 4 K cold box is connected by multi-transfer line installed in the main tunnel. • The compressors will be installed in the caverns constructed alongside the access tunnels. • Large amount of helium inventory will be reserved as liquid helium during shutdown of cryogenic system. • The cooling water used in the compressors will be supplied by local cooling tower or cluster of cooling towers trough 900 mm in diameter piping. • We need the engineering design study of cryogenic system collaboration with industry.

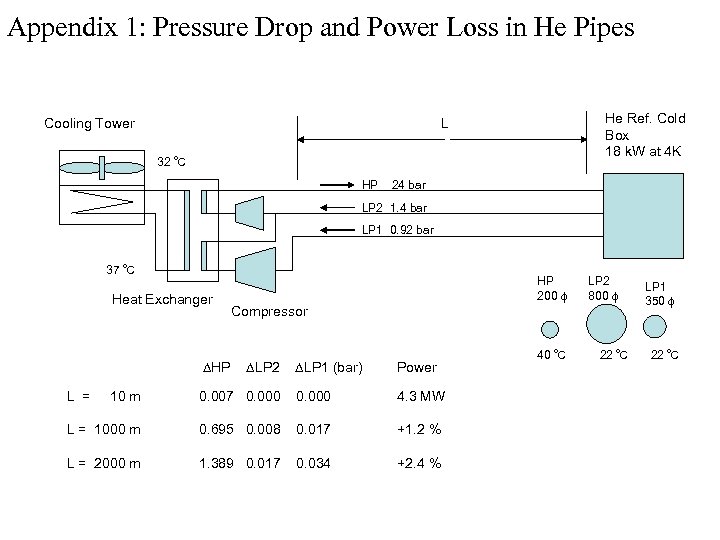

Appendix 1: Pressure Drop and Power Loss in He Pipes Cooling Tower He Ref. Cold Box 18 k. W at 4 K L 32 ℃ HP 24 bar LP 2 1. 4 bar LP 1 0. 92 bar 37 ℃ Heat Exchanger DHP L = HP 200 f LP 2 800 f Compressor DLP 2 DLP 1 (bar) Power 10 m 0. 007 0. 000 4. 3 MW L = 1000 m 0. 695 0. 008 0. 017 +1. 2 % L = 2000 m 1. 389 0. 017 0. 034 +2. 4 % 40 ℃ 22 ℃ LP 1 350 f 22 ℃

Appendix 1: Pressure Drop and Power Loss in He Pipes Cooling Tower He Ref. Cold Box 18 k. W at 4 K L 32 ℃ HP 24 bar LP 2 1. 4 bar LP 1 0. 92 bar 37 ℃ Heat Exchanger DHP L = HP 200 f LP 2 800 f Compressor DLP 2 DLP 1 (bar) Power 10 m 0. 007 0. 000 4. 3 MW L = 1000 m 0. 695 0. 008 0. 017 +1. 2 % L = 2000 m 1. 389 0. 017 0. 034 +2. 4 % 40 ℃ 22 ℃ LP 1 350 f 22 ℃

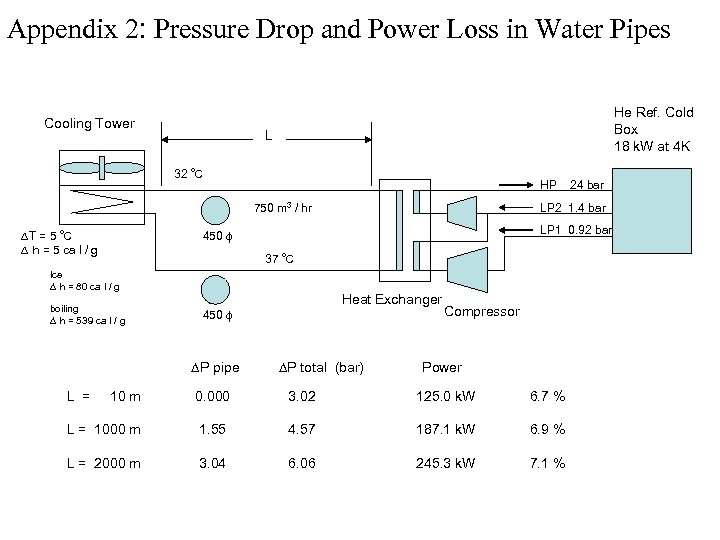

Appendix 2: Pressure Drop and Power Loss in Water Pipes Cooling Tower He Ref. Cold Box 18 k. W at 4 K L 32 ℃ HP 750 m 3 / hr LP 1 0. 92 bar 37 ℃ Ice D h = 80 ca l / g boiling D h = 539 ca l / g Heat Exchanger 450 f DP pipe L = LP 2 1. 4 bar 450 f DT = 5 ℃ D h = 5 ca l / g 24 bar DP total (bar) Compressor Power 10 m 0. 000 3. 02 125. 0 k. W 6. 7 % L = 1000 m 1. 55 4. 57 187. 1 k. W 6. 9 % L = 2000 m 3. 04 6. 06 245. 3 k. W 7. 1 %

Appendix 2: Pressure Drop and Power Loss in Water Pipes Cooling Tower He Ref. Cold Box 18 k. W at 4 K L 32 ℃ HP 750 m 3 / hr LP 1 0. 92 bar 37 ℃ Ice D h = 80 ca l / g boiling D h = 539 ca l / g Heat Exchanger 450 f DP pipe L = LP 2 1. 4 bar 450 f DT = 5 ℃ D h = 5 ca l / g 24 bar DP total (bar) Compressor Power 10 m 0. 000 3. 02 125. 0 k. W 6. 7 % L = 1000 m 1. 55 4. 57 187. 1 k. W 6. 9 % L = 2000 m 3. 04 6. 06 245. 3 k. W 7. 1 %