3873f7293901745bd889f60e25955511.ppt

- Количество слайдов: 14

Conceptual Design for NCSX Auxiliary Systems NCSX Heating, Fueling, Wall Conditioning and Vacuum Systems NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 1

Conceptual Design for NCSX Auxiliary Systems NCSX Heating, Fueling, Wall Conditioning and Vacuum Systems NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 1

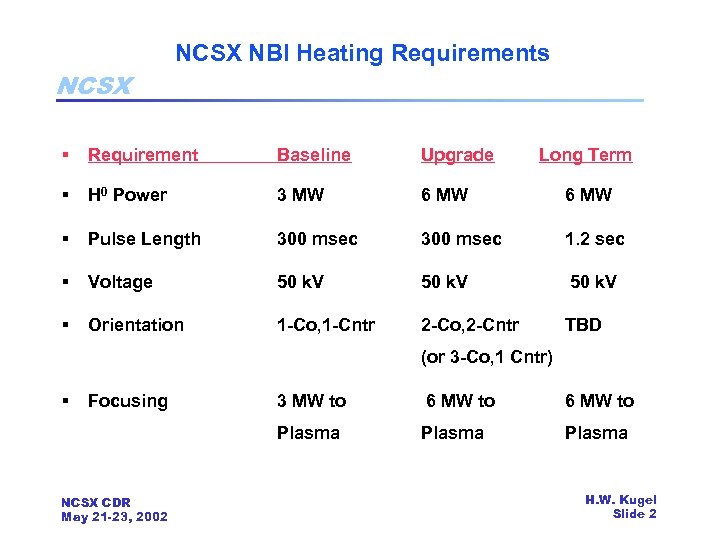

NCSX NBI Heating Requirements § Requirement Baseline Upgrade § H 0 Power 3 MW 6 MW § Pulse Length 300 msec 1. 2 sec § Voltage 50 k. V § Orientation 1 -Co, 1 -Cntr 2 -Co, 2 -Cntr TBD Long Term (or 3 -Co, 1 Cntr) § Focusing 6 MW to Plasma NCSX CDR May 21 -23, 2002 3 MW to Plasma H. W. Kugel Slide 2

NCSX NBI Heating Requirements § Requirement Baseline Upgrade § H 0 Power 3 MW 6 MW § Pulse Length 300 msec 1. 2 sec § Voltage 50 k. V § Orientation 1 -Co, 1 -Cntr 2 -Co, 2 -Cntr TBD Long Term (or 3 -Co, 1 Cntr) § Focusing 6 MW to Plasma NCSX CDR May 21 -23, 2002 3 MW to Plasma H. W. Kugel Slide 2

Neutral Beam System Design Description: The Design Will Provide the Required Performance NCSX §NBI Alignment Provides for: § Balanced co- and cntr- injection for control of NB driven currents and rotation. § NBI Ports Located for: § Maximizing absorption of injected power on the desired plasma region. § Minimizing effects on injected species. § Minimizing injected power absorption on ports on opposite wall. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 3

Neutral Beam System Design Description: The Design Will Provide the Required Performance NCSX §NBI Alignment Provides for: § Balanced co- and cntr- injection for control of NB driven currents and rotation. § NBI Ports Located for: § Maximizing absorption of injected power on the desired plasma region. § Minimizing effects on injected species. § Minimizing injected power absorption on ports on opposite wall. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 3

Neutral Beam injection Pulse Length Plan NCSX §PBX-M NBI systems pulse lengths were typically ~300 ms. §The NB power handling surfaces were engineered to operate to 500 msec pulse lengths at the full power, peak power density of 3 k. W/cm 2 § ORNL found that beyond 400 ms, the Ion source Idecel increased too much. § A control technique was developed. §ORNL operated one ion source with H 0 to 500 msec at ~1. 5 MW § With this, PBX-M demonstrated 500 msec at reduced power (4 MW total ) § Each NBI demonstrated to operate with D 0 at ~40 KV, 1 MW, to 500 msec. Operation to higher powers at 500 msec is feasible for both H 0 and D 0 § MAST using similar ORNL NBI plans to upgrade to 1. 5 -3 sec pulses. § NCSX will adopt this technology for long pulse NBI NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 4

Neutral Beam injection Pulse Length Plan NCSX §PBX-M NBI systems pulse lengths were typically ~300 ms. §The NB power handling surfaces were engineered to operate to 500 msec pulse lengths at the full power, peak power density of 3 k. W/cm 2 § ORNL found that beyond 400 ms, the Ion source Idecel increased too much. § A control technique was developed. §ORNL operated one ion source with H 0 to 500 msec at ~1. 5 MW § With this, PBX-M demonstrated 500 msec at reduced power (4 MW total ) § Each NBI demonstrated to operate with D 0 at ~40 KV, 1 MW, to 500 msec. Operation to higher powers at 500 msec is feasible for both H 0 and D 0 § MAST using similar ORNL NBI plans to upgrade to 1. 5 -3 sec pulses. § NCSX will adopt this technology for long pulse NBI NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 4

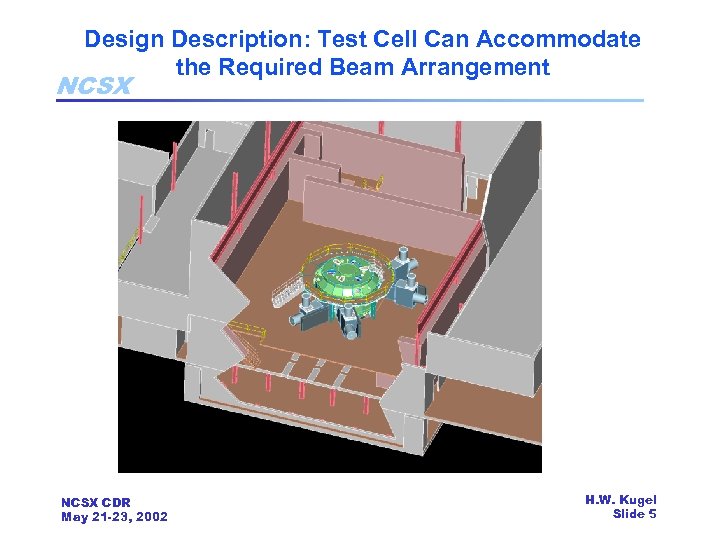

Design Description: Test Cell Can Accommodate the Required Beam Arrangement NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 5

Design Description: Test Cell Can Accommodate the Required Beam Arrangement NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 5

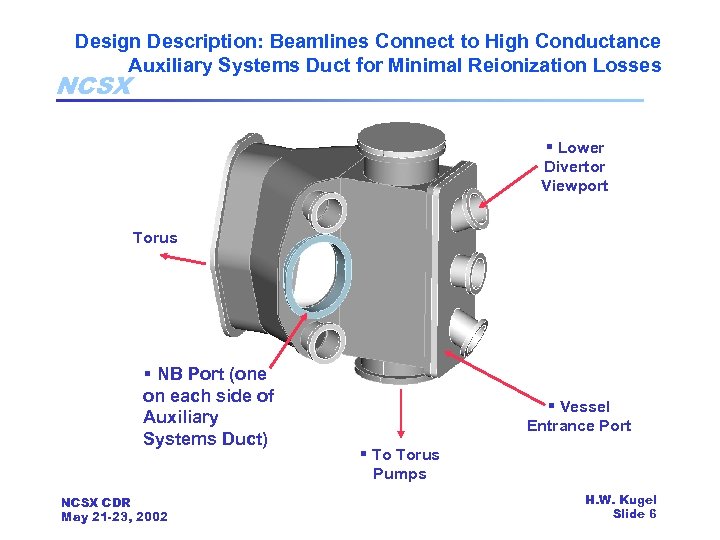

Design Description: Beamlines Connect to High Conductance Auxiliary Systems Duct for Minimal Reionization Losses NCSX § Lower Divertor Viewport Torus § NB Port (one on each side of Auxiliary Systems Duct) NCSX CDR May 21 -23, 2002 § Vessel Entrance Port § To Torus Pumps H. W. Kugel Slide 6

Design Description: Beamlines Connect to High Conductance Auxiliary Systems Duct for Minimal Reionization Losses NCSX § Lower Divertor Viewport Torus § NB Port (one on each side of Auxiliary Systems Duct) NCSX CDR May 21 -23, 2002 § Vessel Entrance Port § To Torus Pumps H. W. Kugel Slide 6

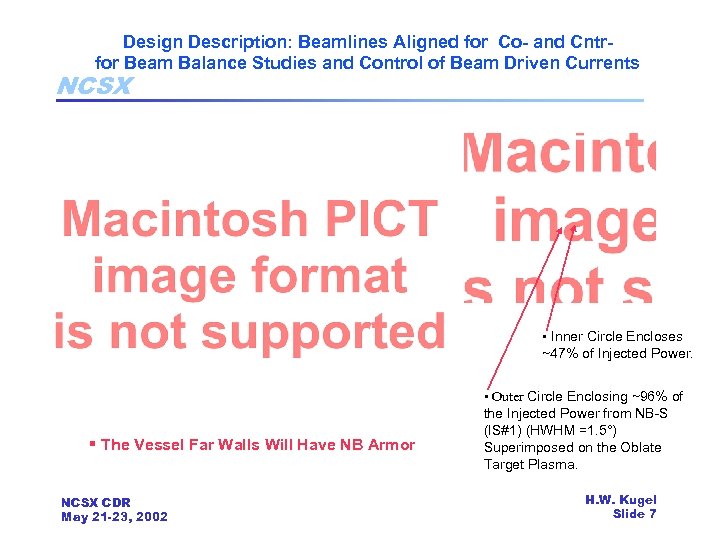

Design Description: Beamlines Aligned for Co- and Cntrfor Beam Balance Studies and Control of Beam Driven Currents NCSX • Inner Circle Encloses ~47% of Injected Power. § The Vessel Far Walls Will Have NB Armor NCSX CDR May 21 -23, 2002 • Outer Circle Enclosing ~96% of the Injected Power from NB-S (IS#1) (HWHM =1. 5°) Superimposed on the Oblate Target Plasma. H. W. Kugel Slide 7

Design Description: Beamlines Aligned for Co- and Cntrfor Beam Balance Studies and Control of Beam Driven Currents NCSX • Inner Circle Encloses ~47% of Injected Power. § The Vessel Far Walls Will Have NB Armor NCSX CDR May 21 -23, 2002 • Outer Circle Enclosing ~96% of the Injected Power from NB-S (IS#1) (HWHM =1. 5°) Superimposed on the Oblate Target Plasma. H. W. Kugel Slide 7

NBI Design Definition Includes Scope, Schedule, Costs, Risks, and Measures for Risk Reduction NCSX § Scope Prior to First Plasma: §Repair and refurbish existing Beamline hardware §Repair and refurbish existing Power Systems §Install Beamlines on NCSX §Make all cabling and other connections §Achieve Beamline operating vacuum § Design strategy: will apply methodologies and procedures developed during previous 17 year operating history. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 8

NBI Design Definition Includes Scope, Schedule, Costs, Risks, and Measures for Risk Reduction NCSX § Scope Prior to First Plasma: §Repair and refurbish existing Beamline hardware §Repair and refurbish existing Power Systems §Install Beamlines on NCSX §Make all cabling and other connections §Achieve Beamline operating vacuum § Design strategy: will apply methodologies and procedures developed during previous 17 year operating history. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 8

NCSX Fueling Requirements, Design Description and Performance NCSX § 2 to 4 Injectors for 200 -400 torr-liter/sec of H 2, D 2 or He. § Flexibility for easy changing of gas plenum volumes, or adding additional injectors at selected vessel locations. § Will re-use parts from the existing PBX-M Gas Fueling system. § Controls will be upgraded with a modern PLC using the proven NSTX design. § Procurement and fabrication records from the high performance NSTX design will help to implement the design. § Will accommodate Pellet Injector as future upgrade. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 9

NCSX Fueling Requirements, Design Description and Performance NCSX § 2 to 4 Injectors for 200 -400 torr-liter/sec of H 2, D 2 or He. § Flexibility for easy changing of gas plenum volumes, or adding additional injectors at selected vessel locations. § Will re-use parts from the existing PBX-M Gas Fueling system. § Controls will be upgraded with a modern PLC using the proven NSTX design. § Procurement and fabrication records from the high performance NSTX design will help to implement the design. § Will accommodate Pellet Injector as future upgrade. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 9

NCSX Wall Conditioning Requirements, Design Description and Performance NCSX § Glow Discharge Cleaning (GDC) during maintenance, Bakeout, and between discharges as required. § One fixed wall anode and one biased dual pre-ionization filament in each sector. § H 2, D 2 or He pressures of ~2 -4 m. Torr, positive bias of ~500 v applied between the anode (+) and the vessel (-). § Pre-ionization electrons facilitate breakdown of ioniztion at the desired operating pressure and voltage to simplify controls. § Design will capitalize on recent NSTX experience with designing, procuring, and installing a similar system. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 10

NCSX Wall Conditioning Requirements, Design Description and Performance NCSX § Glow Discharge Cleaning (GDC) during maintenance, Bakeout, and between discharges as required. § One fixed wall anode and one biased dual pre-ionization filament in each sector. § H 2, D 2 or He pressures of ~2 -4 m. Torr, positive bias of ~500 v applied between the anode (+) and the vessel (-). § Pre-ionization electrons facilitate breakdown of ioniztion at the desired operating pressure and voltage to simplify controls. § Design will capitalize on recent NSTX experience with designing, procuring, and installing a similar system. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 10

NCSX Vacuum Requirements, Design Description and Performance NCSX § Produce base pressures of at least 2 x 10 -8 torr. § Will re-use parts from the existing PBX-M Torus Vacuum Pumping System. – Four PBX-M 1500 l/s turbo-molecular pumps, configured for total pumping speed of at least 2600 l/s (PDX). – Four Welch Model 1398 belt driven backing pumps. – One Kinney 500 belt driven roughing pump. – Gate valves, flanges, instrumentation. § New Residual Gas Analyzer. § Controls will be upgraded with a modern PLC using the proven NSTX design. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 11

NCSX Vacuum Requirements, Design Description and Performance NCSX § Produce base pressures of at least 2 x 10 -8 torr. § Will re-use parts from the existing PBX-M Torus Vacuum Pumping System. – Four PBX-M 1500 l/s turbo-molecular pumps, configured for total pumping speed of at least 2600 l/s (PDX). – Four Welch Model 1398 belt driven backing pumps. – One Kinney 500 belt driven roughing pump. – Gate valves, flanges, instrumentation. § New Residual Gas Analyzer. § Controls will be upgraded with a modern PLC using the proven NSTX design. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 11

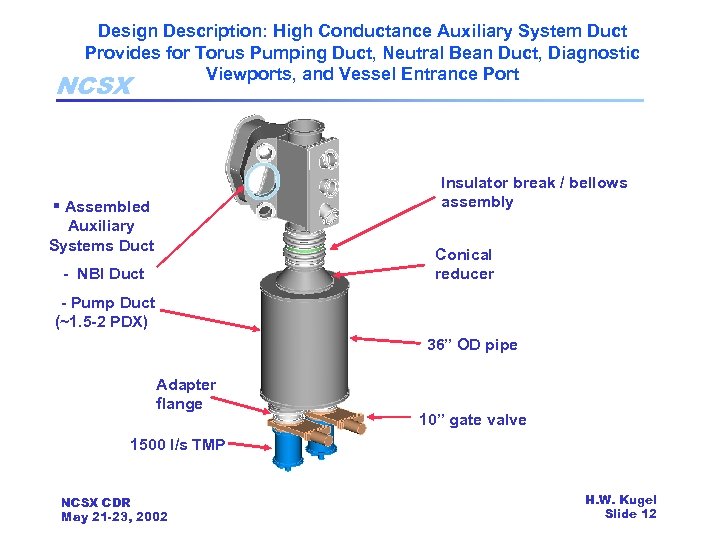

Design Description: High Conductance Auxiliary System Duct Provides for Torus Pumping Duct, Neutral Bean Duct, Diagnostic Viewports, and Vessel Entrance Port NCSX Insulator break / bellows assembly § Assembled Auxiliary Systems Duct Conical reducer - NBI Duct - Pump Duct (~1. 5 -2 PDX) 36” OD pipe Adapter flange 10” gate valve 1500 l/s TMP NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 12

Design Description: High Conductance Auxiliary System Duct Provides for Torus Pumping Duct, Neutral Bean Duct, Diagnostic Viewports, and Vessel Entrance Port NCSX Insulator break / bellows assembly § Assembled Auxiliary Systems Duct Conical reducer - NBI Duct - Pump Duct (~1. 5 -2 PDX) 36” OD pipe Adapter flange 10” gate valve 1500 l/s TMP NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 12

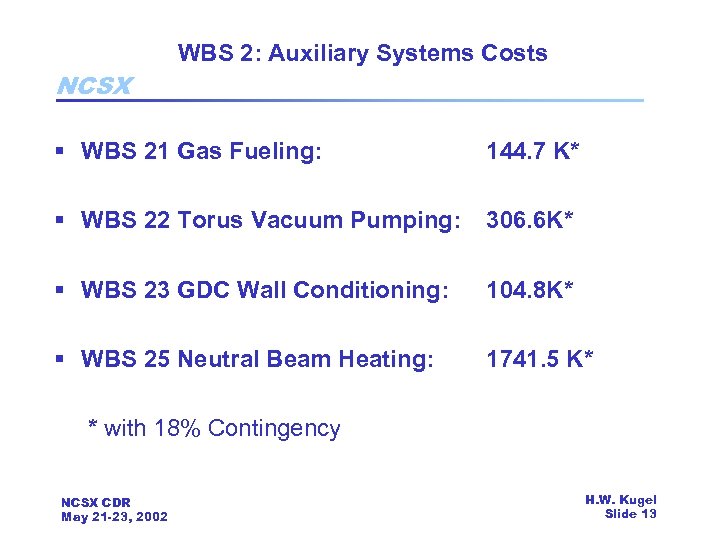

NCSX WBS 2: Auxiliary Systems Costs § WBS 21 Gas Fueling: 144. 7 K* § WBS 22 Torus Vacuum Pumping: 306. 6 K* § WBS 23 GDC Wall Conditioning: 104. 8 K* § WBS 25 Neutral Beam Heating: 1741. 5 K* * with 18% Contingency NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 13

NCSX WBS 2: Auxiliary Systems Costs § WBS 21 Gas Fueling: 144. 7 K* § WBS 22 Torus Vacuum Pumping: 306. 6 K* § WBS 23 GDC Wall Conditioning: 104. 8 K* § WBS 25 Neutral Beam Heating: 1741. 5 K* * with 18% Contingency NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 13

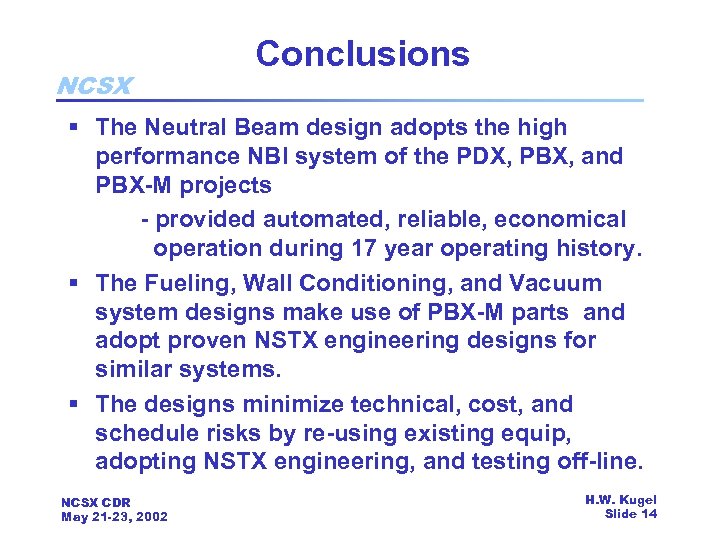

NCSX Conclusions § The Neutral Beam design adopts the high performance NBI system of the PDX, PBX, and PBX-M projects - provided automated, reliable, economical operation during 17 year operating history. § The Fueling, Wall Conditioning, and Vacuum system designs make use of PBX-M parts and adopt proven NSTX engineering designs for similar systems. § The designs minimize technical, cost, and schedule risks by re-using existing equip, adopting NSTX engineering, and testing off-line. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 14

NCSX Conclusions § The Neutral Beam design adopts the high performance NBI system of the PDX, PBX, and PBX-M projects - provided automated, reliable, economical operation during 17 year operating history. § The Fueling, Wall Conditioning, and Vacuum system designs make use of PBX-M parts and adopt proven NSTX engineering designs for similar systems. § The designs minimize technical, cost, and schedule risks by re-using existing equip, adopting NSTX engineering, and testing off-line. NCSX CDR May 21 -23, 2002 H. W. Kugel Slide 14