18e57d5f73de4c101908899550d44756.ppt

- Количество слайдов: 14

Concept Level Project Plan P 08405 – Novel Materials Technology Matthew Wavrek (ME) EDGE™

Concept Level Project Plan P 08405 – Novel Materials Technology Matthew Wavrek (ME) EDGE™

• • • Concept Level Project Plan Project Name – Novel Materials Technology Project Number – P 08405 Project Family – Sustainable Technologies for the Third World Track – Sustainable products, systems, and technologies Start Term – 2007 -2 for Senior Design I End Term – 2007 -3 for Senior Design II Faculty Guide – Dr. Benjamin Varela (ME) is confirmed Faculty Consultant – Dr. Hany Ghoneim (ME) is my choice Faculty Consultant – Dr. Vincent Amuso (EE) is my choice Primary Customer – Dr. Ben Varela is confirmed EDGE™

• • • Concept Level Project Plan Project Name – Novel Materials Technology Project Number – P 08405 Project Family – Sustainable Technologies for the Third World Track – Sustainable products, systems, and technologies Start Term – 2007 -2 for Senior Design I End Term – 2007 -3 for Senior Design II Faculty Guide – Dr. Benjamin Varela (ME) is confirmed Faculty Consultant – Dr. Hany Ghoneim (ME) is my choice Faculty Consultant – Dr. Vincent Amuso (EE) is my choice Primary Customer – Dr. Ben Varela is confirmed EDGE™

Phase 0: Planning Mission Statement Product Description The product being developed for this Senior Design project is an environmental chamber. The chamber will have to be able to sustain a static environment. At minimum, a constant vacuum and temperature regulation system will be employed by the chamber. This chamber will be used to test composite materials, foams, and other materials under development by Dr. Varela and Dr. Ghoneim. Key Business Goals The primary business goals of this product are to: provide a medium to test materials under development for Third World applications. Materials are being developed to make costs of construction and assembly in the Third World more affordable. These materials could help build up Third World economies and increase the quality of life there. Primary Market The primary market for this product is the RIT mechanical engineering department and its materials research faculty. This is a special product, a cheaper and more customizable version of current industry products, for creating a static environment to test materials under research. Secondary Market Secondary markets for this product may include customers, future manufacturers, and contractors associated with the research of Dr. Varela and Dr. Ghoneim. Another possibility for a secondary market is other small testing labs or universities who could benefit from having a static environment test chamber. Stakeholders in the design of our product include the following: –End users-Dr. Varela and Dr. Ghonheim –Suppliers-Companies that manufacture components and materials –Manufacturers-RIT SD Team, –RIT Students-future use in materials classes/research –RIT ME Dept. -new lab and research equipment –Third World countries-will use developed materials and technology EDGE™

Phase 0: Planning Mission Statement Product Description The product being developed for this Senior Design project is an environmental chamber. The chamber will have to be able to sustain a static environment. At minimum, a constant vacuum and temperature regulation system will be employed by the chamber. This chamber will be used to test composite materials, foams, and other materials under development by Dr. Varela and Dr. Ghoneim. Key Business Goals The primary business goals of this product are to: provide a medium to test materials under development for Third World applications. Materials are being developed to make costs of construction and assembly in the Third World more affordable. These materials could help build up Third World economies and increase the quality of life there. Primary Market The primary market for this product is the RIT mechanical engineering department and its materials research faculty. This is a special product, a cheaper and more customizable version of current industry products, for creating a static environment to test materials under research. Secondary Market Secondary markets for this product may include customers, future manufacturers, and contractors associated with the research of Dr. Varela and Dr. Ghoneim. Another possibility for a secondary market is other small testing labs or universities who could benefit from having a static environment test chamber. Stakeholders in the design of our product include the following: –End users-Dr. Varela and Dr. Ghonheim –Suppliers-Companies that manufacture components and materials –Manufacturers-RIT SD Team, –RIT Students-future use in materials classes/research –RIT ME Dept. -new lab and research equipment –Third World countries-will use developed materials and technology EDGE™

Phase 0: Planning Staffing Requirements Mechanical Engineers 2 The Mechanical Engineers on this project will be responsible for sourcing the hardware and materials for this project and designing the physical parts of the pump and chamber housing, while also completing necessary calculations to ensure reliable operation of the system. Knowledge of fluids, design of machine elements, and CAD skills will mainly be used for these tasks, among many other skills. Rich Arlotta has expressed interest in becoming a team member on this project. Electrical Engineers 2 The electrical engineers will be responsible for the temperature and pressure regulation system for the environmental chamber, as well as the electrical interface for the necessary sensors and power supply. Skills in circuits, controls, and system design and coding will be used to design and run a regulation system to ensure a static environment in the system. No students identified at this time. Hoping to get recommendations from EE faculty. Industrial and Systems Engineers 1 possible A systems engineer on this design team would assist in designing and interfacing all systems (ie: mechanical, electrical, control) to ensure that they work in sync with one another. Assisting in necessary calculations and systems testing would be a secondary task. Design and applications of controls, design for manufacture, and assembly skills would be used by this team member. No students identified at this time. Planning to get a recommendation from Dr. James Taylor. Computer Engineers 1 A data logging and control system for this project will be the responsibility of the computer engineer. Controls applications, programming, and interfacing are the main skill set that will be put to work by the CE on this project. No students identified at this time. Business Majors 0 Until secondary market applications are realized this product is a one-off prototype. A business student may be able to develop a market strategy and business plan should this project take on another dimension of production for commercial sales and applications. EDGE™

Phase 0: Planning Staffing Requirements Mechanical Engineers 2 The Mechanical Engineers on this project will be responsible for sourcing the hardware and materials for this project and designing the physical parts of the pump and chamber housing, while also completing necessary calculations to ensure reliable operation of the system. Knowledge of fluids, design of machine elements, and CAD skills will mainly be used for these tasks, among many other skills. Rich Arlotta has expressed interest in becoming a team member on this project. Electrical Engineers 2 The electrical engineers will be responsible for the temperature and pressure regulation system for the environmental chamber, as well as the electrical interface for the necessary sensors and power supply. Skills in circuits, controls, and system design and coding will be used to design and run a regulation system to ensure a static environment in the system. No students identified at this time. Hoping to get recommendations from EE faculty. Industrial and Systems Engineers 1 possible A systems engineer on this design team would assist in designing and interfacing all systems (ie: mechanical, electrical, control) to ensure that they work in sync with one another. Assisting in necessary calculations and systems testing would be a secondary task. Design and applications of controls, design for manufacture, and assembly skills would be used by this team member. No students identified at this time. Planning to get a recommendation from Dr. James Taylor. Computer Engineers 1 A data logging and control system for this project will be the responsibility of the computer engineer. Controls applications, programming, and interfacing are the main skill set that will be put to work by the CE on this project. No students identified at this time. Business Majors 0 Until secondary market applications are realized this product is a one-off prototype. A business student may be able to develop a market strategy and business plan should this project take on another dimension of production for commercial sales and applications. EDGE™

Phase 0: Planning Resource Requirements People 4 groups The groups of people that the success of this project will be contingent on are: users, component suppliers, machinists, and testing equipment industry experts (not including the Senior Design Team). On time delivery of components and knowledge will be crucial. Environment 1 Environment A dedicated laboratory space for this project will be needed. The space must have power, internet, and air access. As the project progresses, the chamber will be built and assembled in this space; it will have to be left alone by anyone but the Design Team. Limited swipe access to this space would be preferred. Equipment Many pieces of equipment will be required for the duration of this project. A computer, DAQ, and wiring will be needed for environment observation through the chamber regulation system. General hand tools (socket set, screwdrivers, …), drill, saws, and work space will be needed for fabrication and assembly of the chamber. A computer will also be needed for: logging data, uploading team information to the team website, programming a control system, and interfacing all chamber controls. An effort to procure these supplies has not been made yet. Machine tools in the shop will be necessary for fabrication of parts. Materials A vacuum pump will be the main component of this project. Dr. Varela has identified the pump he would like to use and it should be ordered now to arrive in week one of Senior Design, because all other components will be adapted around the pump. Acrylic, Lexan, or some other glass/plastic will need to be ordered for the chamber material. Parts for a clamping system, if desired inside the chamber, will also need to be sourced and ordered—this may be a long lead time item as well. Fastening and sealing hardware will be critical to this project and will be ordered early on in Senior Design I. No shop stock, except possibly fasteners, is expected to be used in this project. EDGE™

Phase 0: Planning Resource Requirements People 4 groups The groups of people that the success of this project will be contingent on are: users, component suppliers, machinists, and testing equipment industry experts (not including the Senior Design Team). On time delivery of components and knowledge will be crucial. Environment 1 Environment A dedicated laboratory space for this project will be needed. The space must have power, internet, and air access. As the project progresses, the chamber will be built and assembled in this space; it will have to be left alone by anyone but the Design Team. Limited swipe access to this space would be preferred. Equipment Many pieces of equipment will be required for the duration of this project. A computer, DAQ, and wiring will be needed for environment observation through the chamber regulation system. General hand tools (socket set, screwdrivers, …), drill, saws, and work space will be needed for fabrication and assembly of the chamber. A computer will also be needed for: logging data, uploading team information to the team website, programming a control system, and interfacing all chamber controls. An effort to procure these supplies has not been made yet. Machine tools in the shop will be necessary for fabrication of parts. Materials A vacuum pump will be the main component of this project. Dr. Varela has identified the pump he would like to use and it should be ordered now to arrive in week one of Senior Design, because all other components will be adapted around the pump. Acrylic, Lexan, or some other glass/plastic will need to be ordered for the chamber material. Parts for a clamping system, if desired inside the chamber, will also need to be sourced and ordered—this may be a long lead time item as well. Fastening and sealing hardware will be critical to this project and will be ordered early on in Senior Design I. No shop stock, except possibly fasteners, is expected to be used in this project. EDGE™

Phase 1: Concept Development Identify Customer Needs - Interviews Primary Customers 2 Customers I have briefly spoken with Dr. Varela and was given an overview of the project and a few primary needs. I am interviewing both customers—Dr. Varela and Dr. Ghoneim this week and will be recording data in transcript form and possibly recording data in audio format. Interview data will posted on the project website shortly after. I hope to gain more customer needs, industry contacts, and benchmarking ideas from these two interviews. I also hope to get recommendations for potential team members as well. Other Stakeholders 2 groups I plan to interview other faculty members at RIT involved in materials research, such as Dr. Debartolo. Also, interviewing some EE and CE faculty about the regulation and control systems ideas for the chamber could provide insight for team members to recruit and methods to develop the system. Audio recordings and transcripts of the interviews will be taken to preserve data. These interviews will be scheduled after primary customer interviews. Past Senior Design Teams 4 While no directly relevant projects of the same kind have occurred in past Design groups, four related projects from the same family have. Projects: 02021, 07402, and 07403 are related third world projects from 2007 and one laboratory equipment project from 2002. P 07402 is a great reference for PRP detail and layout—very detailed and expanded. All related projects enhanced knowledge of potential customers and stakeholders. Needs assessment and interview approach knowledge was gained from the 07’ Archive projects as well. The 02’ lab equipment project broached the subjects of regulations and suppliers. Suggested team values and norms ideas were well represented among a few of these projects as well. EDGE™

Phase 1: Concept Development Identify Customer Needs - Interviews Primary Customers 2 Customers I have briefly spoken with Dr. Varela and was given an overview of the project and a few primary needs. I am interviewing both customers—Dr. Varela and Dr. Ghoneim this week and will be recording data in transcript form and possibly recording data in audio format. Interview data will posted on the project website shortly after. I hope to gain more customer needs, industry contacts, and benchmarking ideas from these two interviews. I also hope to get recommendations for potential team members as well. Other Stakeholders 2 groups I plan to interview other faculty members at RIT involved in materials research, such as Dr. Debartolo. Also, interviewing some EE and CE faculty about the regulation and control systems ideas for the chamber could provide insight for team members to recruit and methods to develop the system. Audio recordings and transcripts of the interviews will be taken to preserve data. These interviews will be scheduled after primary customer interviews. Past Senior Design Teams 4 While no directly relevant projects of the same kind have occurred in past Design groups, four related projects from the same family have. Projects: 02021, 07402, and 07403 are related third world projects from 2007 and one laboratory equipment project from 2002. P 07402 is a great reference for PRP detail and layout—very detailed and expanded. All related projects enhanced knowledge of potential customers and stakeholders. Needs assessment and interview approach knowledge was gained from the 07’ Archive projects as well. The 02’ lab equipment project broached the subjects of regulations and suppliers. Suggested team values and norms ideas were well represented among a few of these projects as well. EDGE™

Phase 1: Concept Development Identify Customer Needs - Benchmarking Competitive or Cooperative Solutions In process of source and identification of products: I am in the process of researching current related test chamber designs and applications. With the price associated with existing materials testing equipment, a full benchmarking session with product tear down seems unlikely. A visit to a manufacturer site or a product user site would be of great benefit, if it is possible to work out (logistics, trade secrets issues). Internet research and identifications of processes, components, and associated products will be done extensively if benchmarking of a physical product is not possible. Integrated system technologies will also be researched and benchmarked. Internet Search Providers of test chamber equipment and associated components, technologies, and information: http: //www. lre. com/test/environmental-chambers-main. htm? gclid=CLn. N 57 Dg 144 CFQSOFQod. I 03 v. Ag http: //www. espec. com/ http: //www. tenney. com/Tenney/environmental-chamber-comparison. asp? src=gaw http: //en. wikipedia. org/wiki/Environmental_test_chambers http: //en. wikipedia. org/wiki/Vacuum_pump http: //www. temperatures. com/sensors. html Technical Literature Search Database articles from Wallace Library Database Searches: 1) Gibbons, D. C. Environmental Chamber Temperature Calibration: Which Method to Use? . Journal of the IEST (Online) v. 49 no. 2 (October 2006) p. 8 -15 2) Hale, J. M. , et. al. , An environmental chamber for tensile testing coupon specimens in the presence of aggressive media at elevated temperatures and pressures. Experimental Techniques v. 22 no. 5 (September/October 1998) p. 13 -16 3) Environmental chambers and measurement. Science v. 247 no. pt 2 (March 23 1990) p. G 67 -8 **Results obtained using keywords: environmental test chambers, in Wilson Omnifile database through RIT Library** Books about materials standards and composites testing: 1) Compilation of ASTM standard definitions, Philadelphia, PA : ASTM, c 1994, vi, 596 p. ; 28 cm 2) Advanced ceramic matrix composites : design approaches, testing and life prediction methods, Lancaster, PA : Technomic Pub. Co. , c 1996 x, 226 p. : ill. ; 23 cm 3) Dynamic response and behavior of composites : presented at the 1995 ASME International Mechanical En, New York, N. Y. : American Society of Mechanical Engineers, c 1995 v, 155 p. : ill. ; 28 cm EDGE™

Phase 1: Concept Development Identify Customer Needs - Benchmarking Competitive or Cooperative Solutions In process of source and identification of products: I am in the process of researching current related test chamber designs and applications. With the price associated with existing materials testing equipment, a full benchmarking session with product tear down seems unlikely. A visit to a manufacturer site or a product user site would be of great benefit, if it is possible to work out (logistics, trade secrets issues). Internet research and identifications of processes, components, and associated products will be done extensively if benchmarking of a physical product is not possible. Integrated system technologies will also be researched and benchmarked. Internet Search Providers of test chamber equipment and associated components, technologies, and information: http: //www. lre. com/test/environmental-chambers-main. htm? gclid=CLn. N 57 Dg 144 CFQSOFQod. I 03 v. Ag http: //www. espec. com/ http: //www. tenney. com/Tenney/environmental-chamber-comparison. asp? src=gaw http: //en. wikipedia. org/wiki/Environmental_test_chambers http: //en. wikipedia. org/wiki/Vacuum_pump http: //www. temperatures. com/sensors. html Technical Literature Search Database articles from Wallace Library Database Searches: 1) Gibbons, D. C. Environmental Chamber Temperature Calibration: Which Method to Use? . Journal of the IEST (Online) v. 49 no. 2 (October 2006) p. 8 -15 2) Hale, J. M. , et. al. , An environmental chamber for tensile testing coupon specimens in the presence of aggressive media at elevated temperatures and pressures. Experimental Techniques v. 22 no. 5 (September/October 1998) p. 13 -16 3) Environmental chambers and measurement. Science v. 247 no. pt 2 (March 23 1990) p. G 67 -8 **Results obtained using keywords: environmental test chambers, in Wilson Omnifile database through RIT Library** Books about materials standards and composites testing: 1) Compilation of ASTM standard definitions, Philadelphia, PA : ASTM, c 1994, vi, 596 p. ; 28 cm 2) Advanced ceramic matrix composites : design approaches, testing and life prediction methods, Lancaster, PA : Technomic Pub. Co. , c 1996 x, 226 p. : ill. ; 23 cm 3) Dynamic response and behavior of composites : presented at the 1995 ASME International Mechanical En, New York, N. Y. : American Society of Mechanical Engineers, c 1995 v, 155 p. : ill. ; 28 cm EDGE™

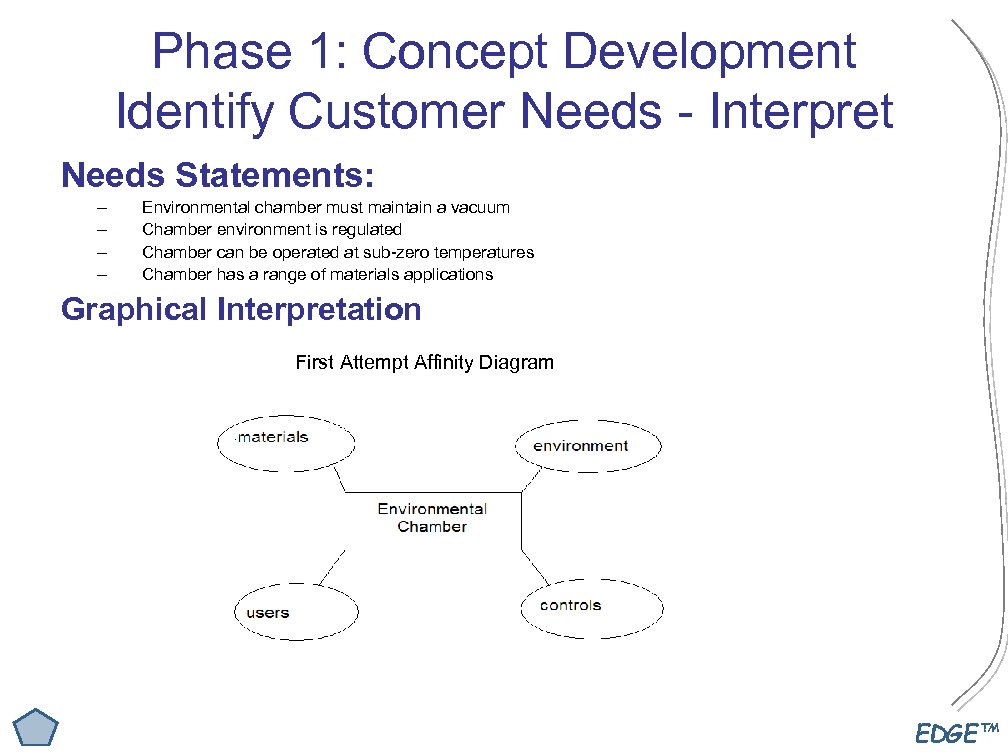

Phase 1: Concept Development Identify Customer Needs - Interpret Needs Statements: – – Environmental chamber must maintain a vacuum Chamber environment is regulated Chamber can be operated at sub-zero temperatures Chamber has a range of materials applications Graphical Interpretation First Attempt Affinity Diagram EDGE™

Phase 1: Concept Development Identify Customer Needs - Interpret Needs Statements: – – Environmental chamber must maintain a vacuum Chamber environment is regulated Chamber can be operated at sub-zero temperatures Chamber has a range of materials applications Graphical Interpretation First Attempt Affinity Diagram EDGE™

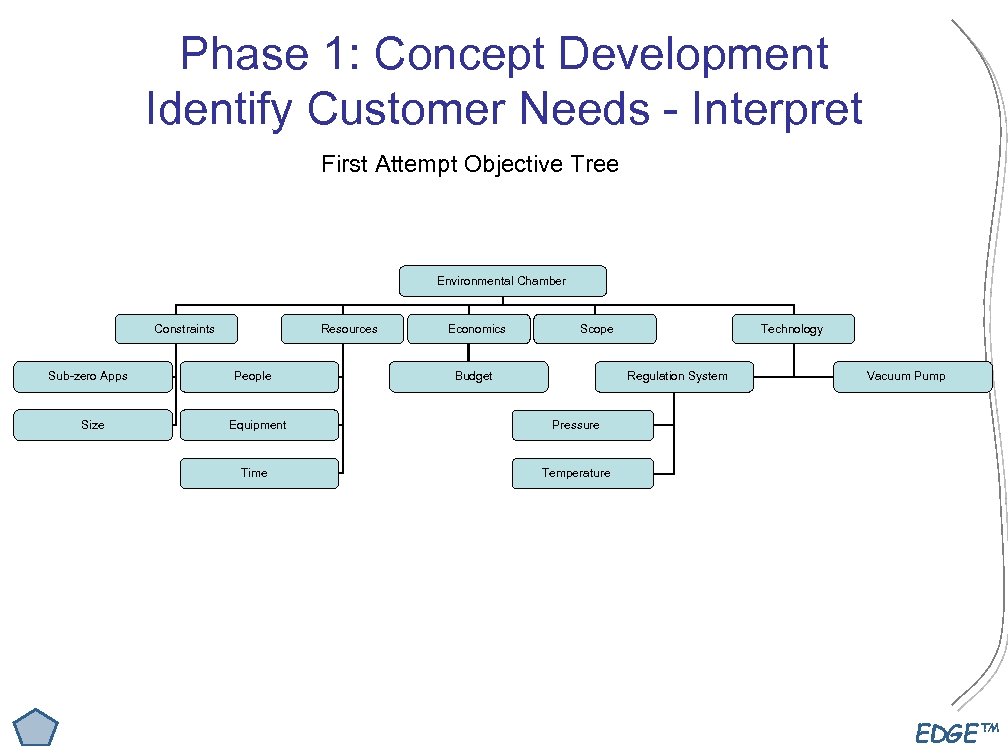

Phase 1: Concept Development Identify Customer Needs - Interpret First Attempt Objective Tree Environmental Chamber Constraints Sub-zero Apps Size Resources People Economics Scope Budget Technology Regulation System Equipment Pressure Time Vacuum Pump Temperature EDGE™

Phase 1: Concept Development Identify Customer Needs - Interpret First Attempt Objective Tree Environmental Chamber Constraints Sub-zero Apps Size Resources People Economics Scope Budget Technology Regulation System Equipment Pressure Time Vacuum Pump Temperature EDGE™

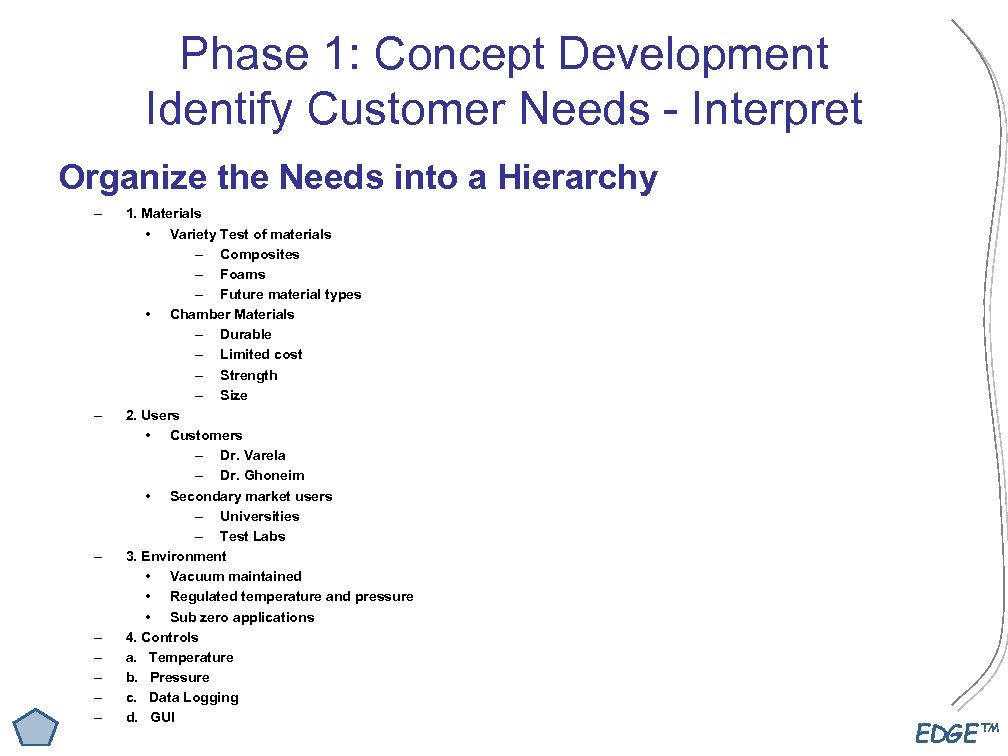

Phase 1: Concept Development Identify Customer Needs - Interpret Organize the Needs into a Hierarchy – – – – 1. Materials • Variety Test of materials – Composites – Foams – Future material types • Chamber Materials – Durable – Limited cost – Strength – Size 2. Users • Customers – Dr. Varela – Dr. Ghoneim • Secondary market users – Universities – Test Labs 3. Environment • Vacuum maintained • Regulated temperature and pressure • Sub zero applications 4. Controls a. Temperature b. Pressure c. Data Logging d. GUI EDGE™

Phase 1: Concept Development Identify Customer Needs - Interpret Organize the Needs into a Hierarchy – – – – 1. Materials • Variety Test of materials – Composites – Foams – Future material types • Chamber Materials – Durable – Limited cost – Strength – Size 2. Users • Customers – Dr. Varela – Dr. Ghoneim • Secondary market users – Universities – Test Labs 3. Environment • Vacuum maintained • Regulated temperature and pressure • Sub zero applications 4. Controls a. Temperature b. Pressure c. Data Logging d. GUI EDGE™

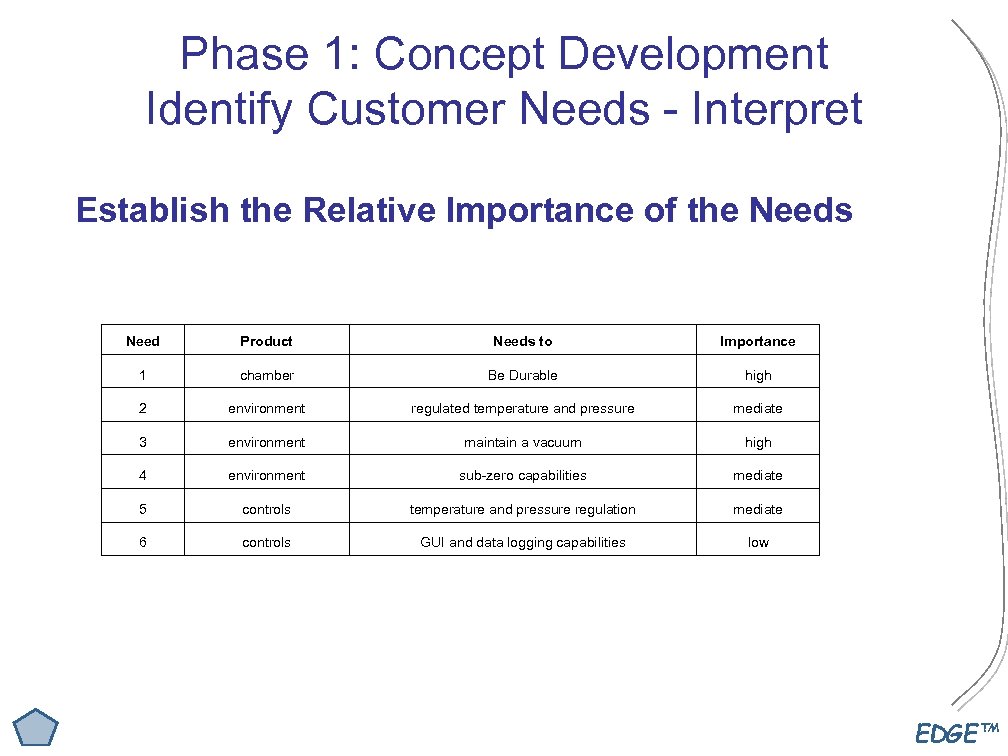

Phase 1: Concept Development Identify Customer Needs - Interpret Establish the Relative Importance of the Needs Need Product Needs to Importance 1 chamber Be Durable high 2 environment regulated temperature and pressure mediate 3 environment maintain a vacuum high 4 environment sub-zero capabilities mediate 5 controls temperature and pressure regulation mediate 6 controls GUI and data logging capabilities low EDGE™

Phase 1: Concept Development Identify Customer Needs - Interpret Establish the Relative Importance of the Needs Need Product Needs to Importance 1 chamber Be Durable high 2 environment regulated temperature and pressure mediate 3 environment maintain a vacuum high 4 environment sub-zero capabilities mediate 5 controls temperature and pressure regulation mediate 6 controls GUI and data logging capabilities low EDGE™

Phase 1: Concept Development Identify Customer Needs - Interpret Reflect on the Results and the Process At this point of the project, the basic needs of the customer have been identified. Different organizational formats have been employed to categorize, list, and weigh needs. Basic staffing and resource requirements have also been established. Information lists from internet, technical, and customer sources have been gathered. The next step in the process of the product concept development is to detail and expand the needs, resources, and structure of the project. More information searches, customer interviews, benchmarking activities will be carried out to refine data and requirements. EDGE™

Phase 1: Concept Development Identify Customer Needs - Interpret Reflect on the Results and the Process At this point of the project, the basic needs of the customer have been identified. Different organizational formats have been employed to categorize, list, and weigh needs. Basic staffing and resource requirements have also been established. Information lists from internet, technical, and customer sources have been gathered. The next step in the process of the product concept development is to detail and expand the needs, resources, and structure of the project. More information searches, customer interviews, benchmarking activities will be carried out to refine data and requirements. EDGE™

Future Plan Where do you go from here? • • • Conduct two interviews this week (09 -24 -07) with primary users: Dr. Varela and Dr. Ghonheim. I will then compile the customer needs and technical data they provide and post it on the team website. Plan interviews with RIT materials professors/staff and component suppliers for the environmental chamber. Expand on internet and library information searches to find possible standards or regulatory codes related to the project, as well as identify more similar products for benchmarking opportunities (beyond basic project knowledge—more details research and information) Identify suppliers of needed system components (chamber materials, regulatory system sensors, seal materials, …. ) Use needs data to expand information on chamber specifications, and create a detailed hierarchy of needs Begin talking to engineering students for project recruiting—to further establish staffing requirements and job descriptions EDGE™

Future Plan Where do you go from here? • • • Conduct two interviews this week (09 -24 -07) with primary users: Dr. Varela and Dr. Ghonheim. I will then compile the customer needs and technical data they provide and post it on the team website. Plan interviews with RIT materials professors/staff and component suppliers for the environmental chamber. Expand on internet and library information searches to find possible standards or regulatory codes related to the project, as well as identify more similar products for benchmarking opportunities (beyond basic project knowledge—more details research and information) Identify suppliers of needed system components (chamber materials, regulatory system sensors, seal materials, …. ) Use needs data to expand information on chamber specifications, and create a detailed hierarchy of needs Begin talking to engineering students for project recruiting—to further establish staffing requirements and job descriptions EDGE™

End of Presentation Any Questions? EDGE™

End of Presentation Any Questions? EDGE™