bef1b7f6a07067a138b003628e1d0df9.ppt

- Количество слайдов: 23

![Computerized Maintenance Management System Presented By [Presenter Name] [Presenter Title] 1| Computerized Maintenance Management Computerized Maintenance Management System Presented By [Presenter Name] [Presenter Title] 1| Computerized Maintenance Management](https://present5.com/presentation/bef1b7f6a07067a138b003628e1d0df9/image-1.jpg)

Computerized Maintenance Management System Presented By [Presenter Name] [Presenter Title] 1| Computerized Maintenance Management System | 18 March 2018

Introduction - summary l Topic placement within HTM tools l Definition of CMMS l Importance and purpose of CMMS l CMMS implementation l CMMS modules l Evaluating commercial CMMS l Design plan of locally developed CMMS 2| Computerized Maintenance Management System | 18 March 2018 l Challenges facing the implementation of CMMS l Available resources l Case study from Jordan l Working group session l Acknowledgments and contact

Topic placement l CMMS is found within the maintenance block in the flow chart (next slide). It can be used to automate: – – Inventory management of equipment and spare parts Corrective maintenance including all phases of the work order Preventive maintenance programs Follow up of equipment status l Other elements can also be included to establish a fully automated HTM such as: – needs assessments – donated or procured equipment – equipment replacement 3| Computerized Maintenance Management System | 18 March 2018

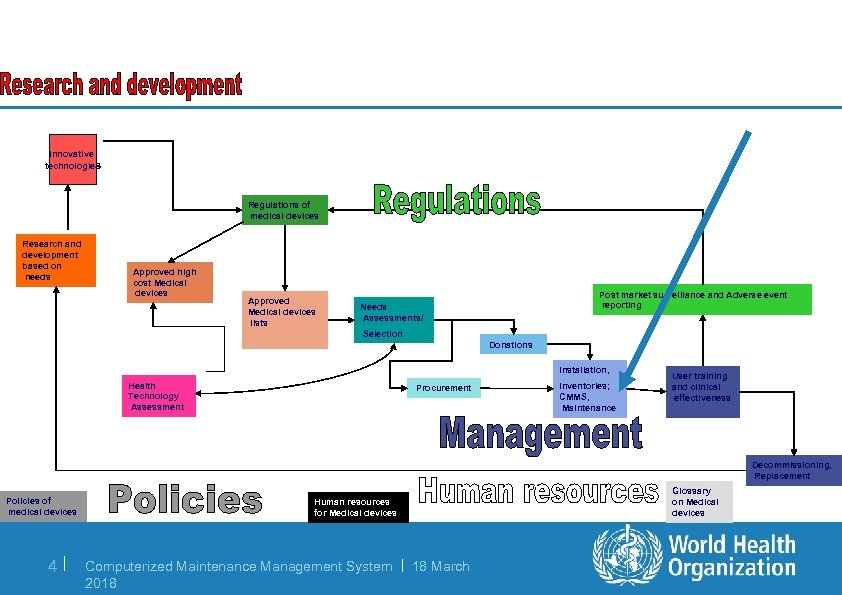

Innovative technologies Regulations of medical devices Research and development based on needs Approved high cost Medical devices Approved Medical devices lists Post market surveillance and Adverse event reporting Needs Assessments/ Selection Donations Installation, Health Technology Assessment Procurement Inventories; CMMS, Maintenance User training and clinical effectiveness Decommissioning, Replacement Policies of medical devices 4| Human resources for Medical devices Computerized Maintenance Management System | 18 March 2018 Glossary on Medical devices

Definition • Definition of Computerized Maintenance Management System (CMMS) − CMMS is a software package that maintains a computer database of information about maintenance operations − In HTM, the CMMS is used by clinical engineers to collect, store and analyze data on the inventory, corrective and preventive maintenance in addition to other activities related to medical devices • HTM involves complex parameters: − Class No, Priority, risk, down time, … − HTA, safety of patient & clinical staff, adverse events, … 5| Computerized Maintenance Management System | 18 March 2018

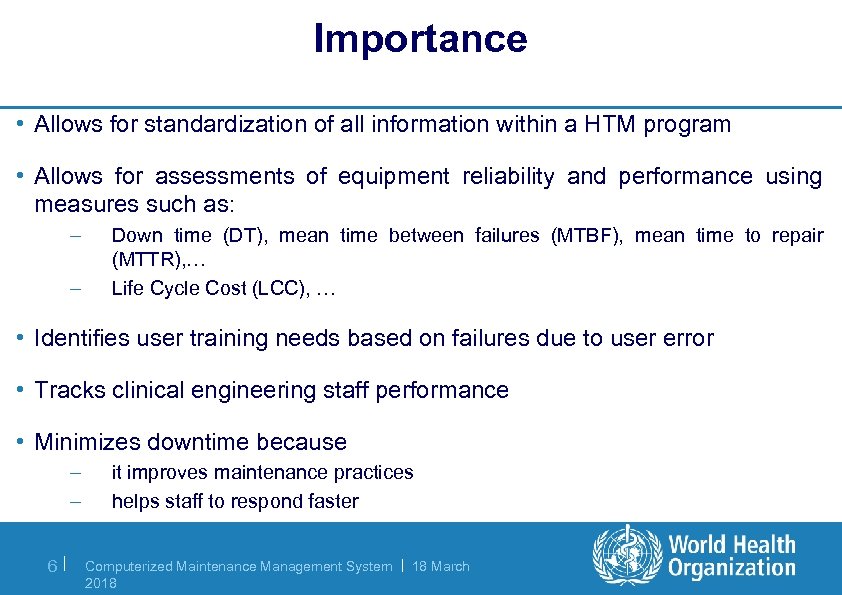

Importance • Allows for standardization of all information within a HTM program • Allows for assessments of equipment reliability and performance using measures such as: – – Down time (DT), mean time between failures (MTBF), mean time to repair (MTTR), … Life Cycle Cost (LCC), … • Identifies user training needs based on failures due to user error • Tracks clinical engineering staff performance • Minimizes downtime because – – 6| it improves maintenance practices helps staff to respond faster Computerized Maintenance Management System | 18 March 2018

Purpose of document l The purpose of this document is to provide a tool to guide clinical engineers, in adopting and implementing a CMMS. l The reader will get an understanding of the CMMS different components. l The reader will get an understanding on how to select or locally develop a CMMS that best suits their needs. l High-level managers and policy makers may wish to read this document to further their understanding of managing medical equipment and to enable informed decision-making. 7| Computerized Maintenance Management System | 18 March 2018

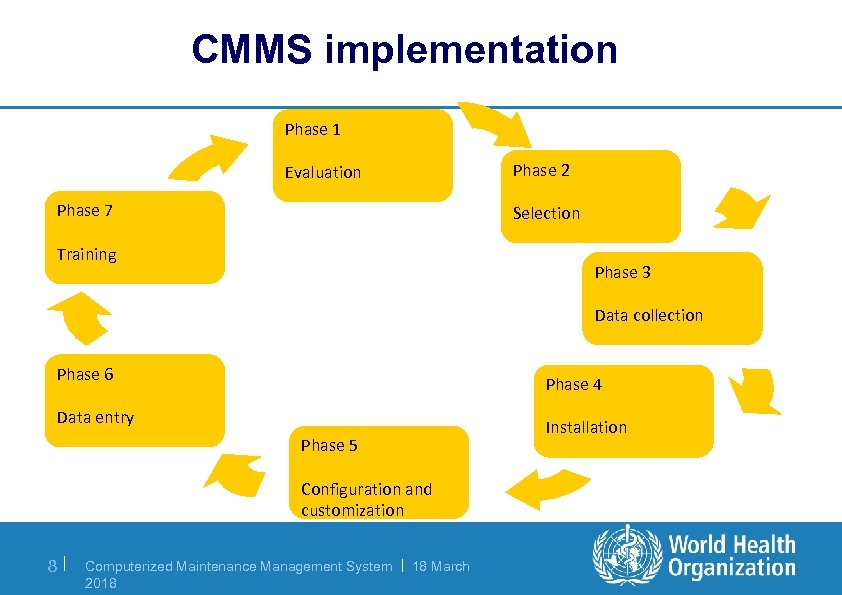

CMMS implementation Phase 1 Evaluation Phase 7 Phase 2 Selection Training Phase 3 Data collection Phase 6 Phase 4 Data entry Phase 5 Configuration and customization 8| Computerized Maintenance Management System | 18 March 2018 Installation

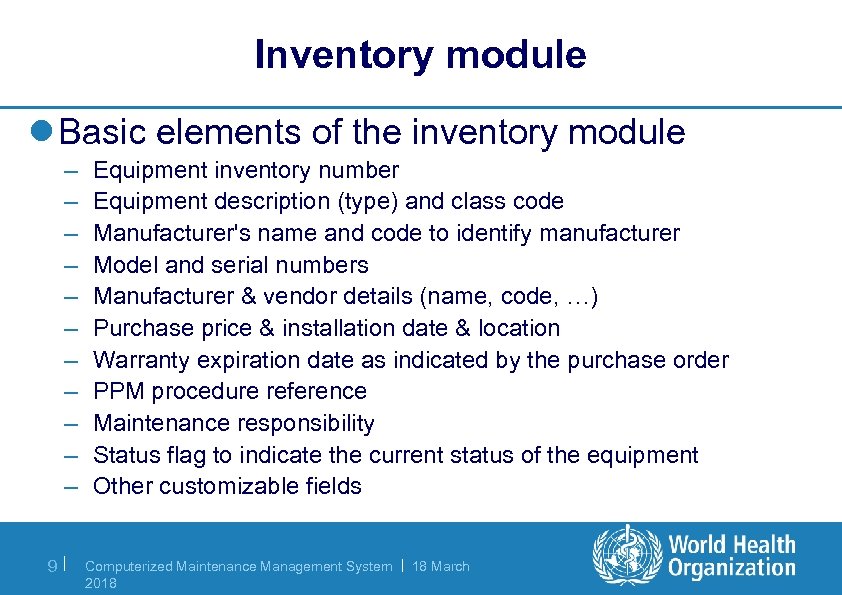

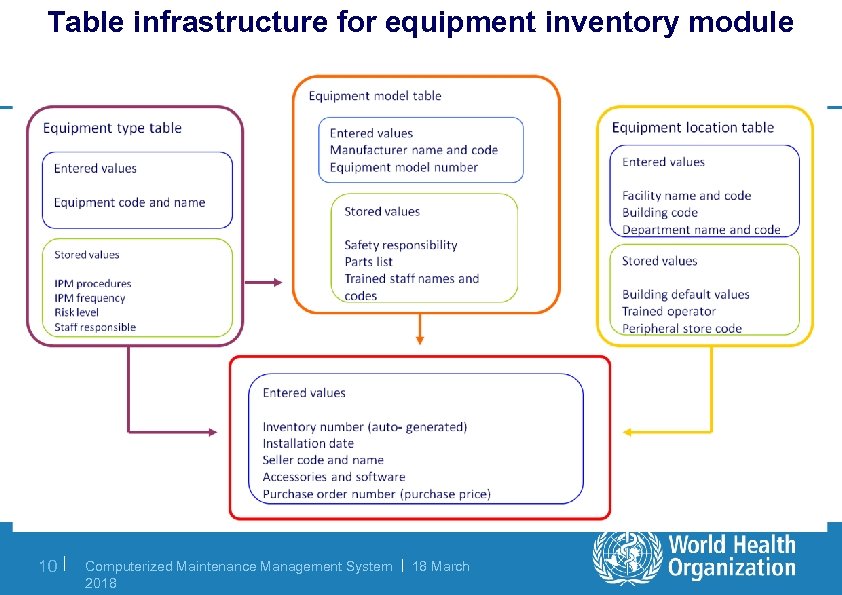

Inventory module l Basic elements of the inventory module – – – 9| Equipment inventory number Equipment description (type) and class code Manufacturer's name and code to identify manufacturer Model and serial numbers Manufacturer & vendor details (name, code, …) Purchase price & installation date & location Warranty expiration date as indicated by the purchase order PPM procedure reference Maintenance responsibility Status flag to indicate the current status of the equipment Other customizable fields Computerized Maintenance Management System | 18 March 2018

Table infrastructure for equipment inventory module 10 | Computerized Maintenance Management System | 18 March 2018

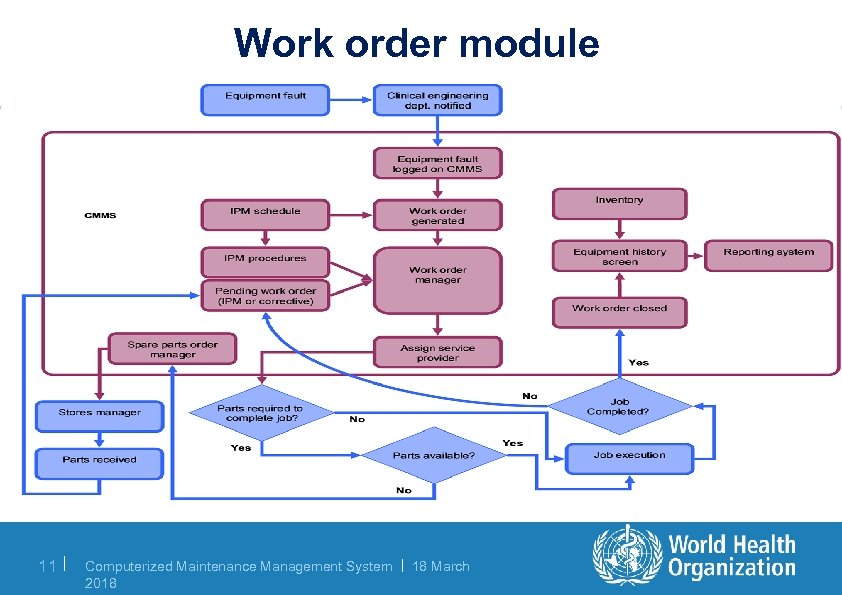

Work order module 11 | Computerized Maintenance Management System | 18 March 2018

Other possible modules l Contracts management module l Spare parts management module l Quality assurance – Technical (safety of medical equipment) – Equipment performance – DT, LCC, compliance, failure analysis – Cost monitoring l Planning (needs planning, technical specifications) l. Other modules according to size, structure and scope of responsibilities of the clinical engineering department 12 | Computerized Maintenance Management System | 18 March 2018

Reporting • Types of CMMS reports − Pre defined − Customized • Export report selected data fields in different formats for report generation by (e. g. MS Excel, MS Access, Fox Pro, etc. ) • Characteristics of the reporting system: − − 13 | Speed of report generation Range covered by reports Flexibility of customizable reports Ease of use and simplicity Computerized Maintenance Management System | 18 March 2018

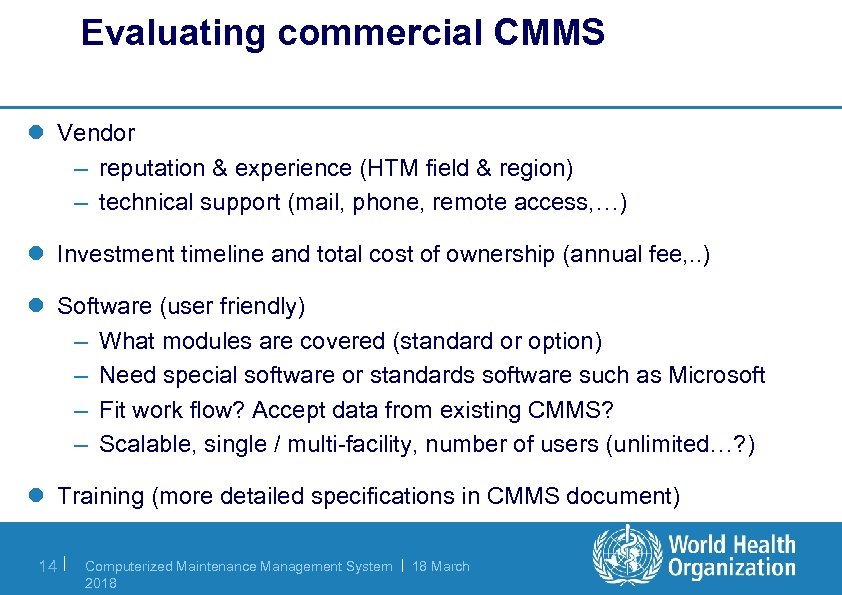

Evaluating commercial CMMS l Vendor – reputation & experience (HTM field & region) – technical support (mail, phone, remote access, …) l Investment timeline and total cost of ownership (annual fee, . . ) l Software (user friendly) – What modules are covered (standard or option) – Need special software or standards software such as Microsoft – Fit work flow? Accept data from existing CMMS? – Scalable, single / multi-facility, number of users (unlimited…? ) l Training (more detailed specifications in CMMS document) 14 | Computerized Maintenance Management System | 18 March 2018

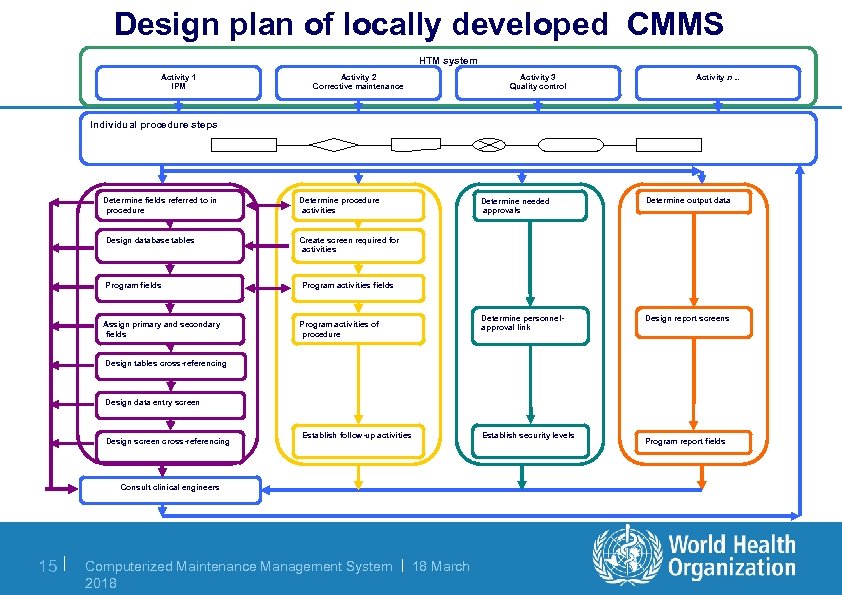

Design plan of locally developed CMMS HTM system Activity 1 IPM Activity 2 Corrective maintenance Activity 3 Quality control Activity n … Individual procedure steps Determine fields referred to in procedure Determine procedure activities Design database tables Program activities of procedure Determine personnelapproval link Design report screens Program activities fields Assign primary and secondary fields Determine output data Create screen required for activities Program fields Determine needed approvals Design tables cross-referencing Design data entry screen Design screen cross-referencing Establish follow-up activities Consult clinical engineers 15 | Computerized Maintenance Management System | 18 March 2018 Establish security levels Program report fields

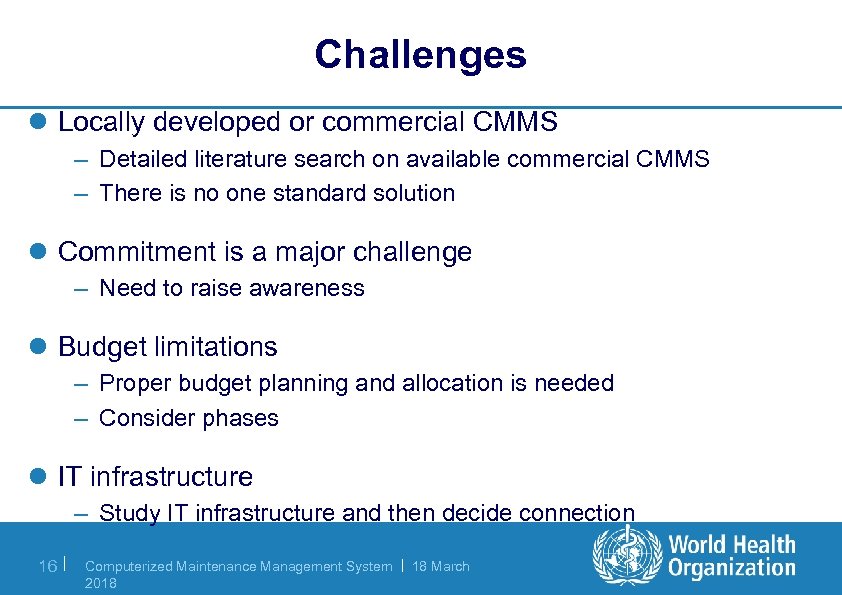

Challenges l Locally developed or commercial CMMS – Detailed literature search on available commercial CMMS – There is no one standard solution l Commitment is a major challenge – Need to raise awareness l Budget limitations – Proper budget planning and allocation is needed – Consider phases l IT infrastructure – Study IT infrastructure and then decide connection 16 | Computerized Maintenance Management System | 18 March 2018

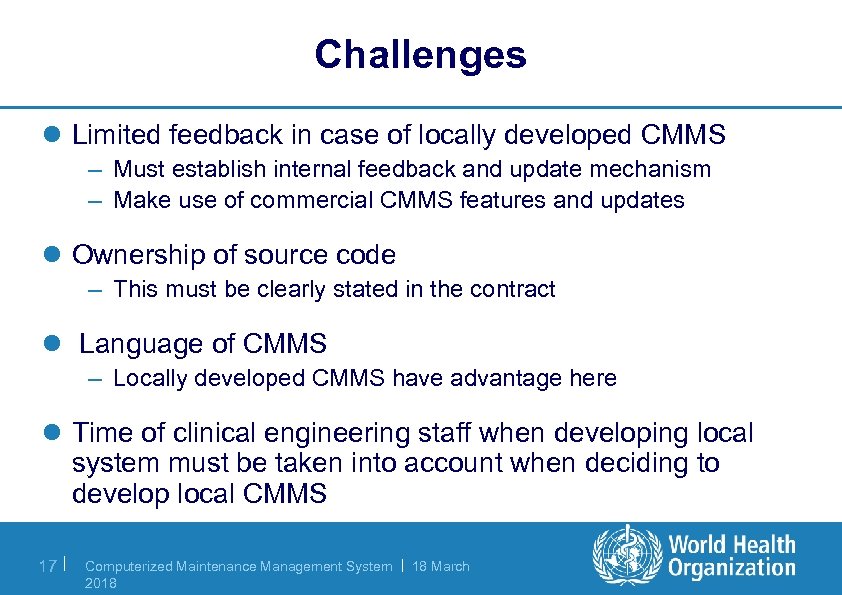

Challenges l Limited feedback in case of locally developed CMMS – Must establish internal feedback and update mechanism – Make use of commercial CMMS features and updates l Ownership of source code – This must be clearly stated in the contract l Language of CMMS – Locally developed CMMS have advantage here l Time of clinical engineering staff when developing local system must be taken into account when deciding to develop local CMMS 17 | Computerized Maintenance Management System | 18 March 2018

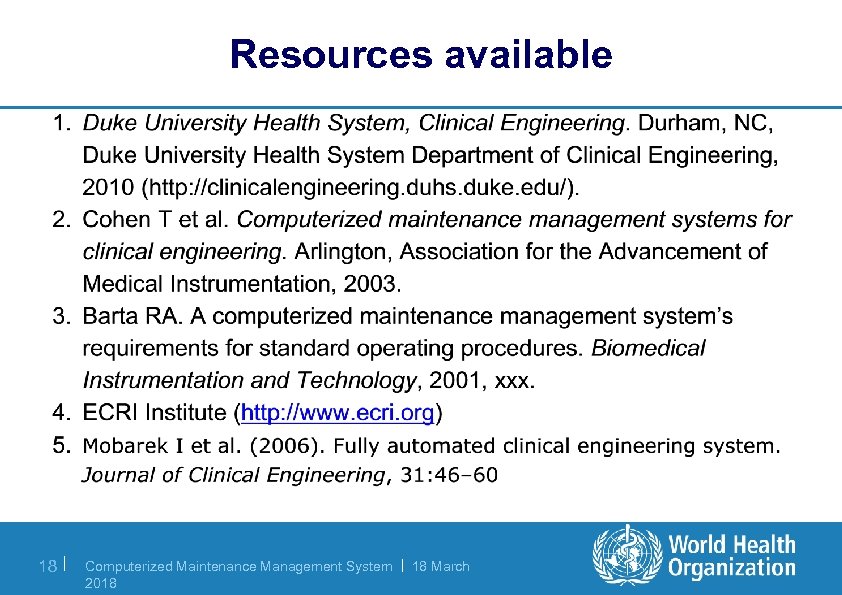

Resources available 18 | Computerized Maintenance Management System | 18 March 2018

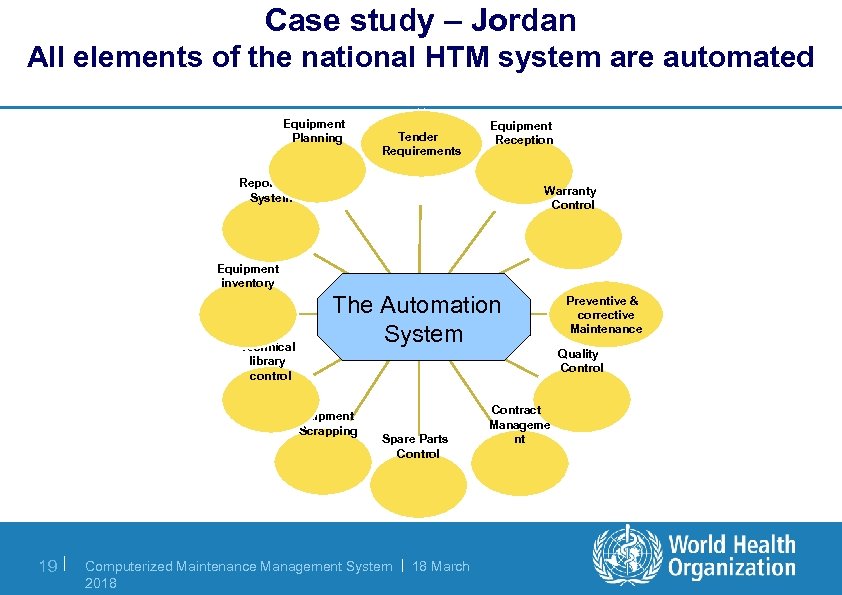

Case study – Jordan All elements of the national HTM system are automated Equipment Planning Tender Requirements Equipment Reception Reporting System Warranty Control Equipment inventory Technical library control The Automation System Equipment Scrapping 19 | Spare Parts Control Computerized Maintenance Management System | 18 March 2018 Contract Manageme nt Preventive & corrective Maintenance Quality Control

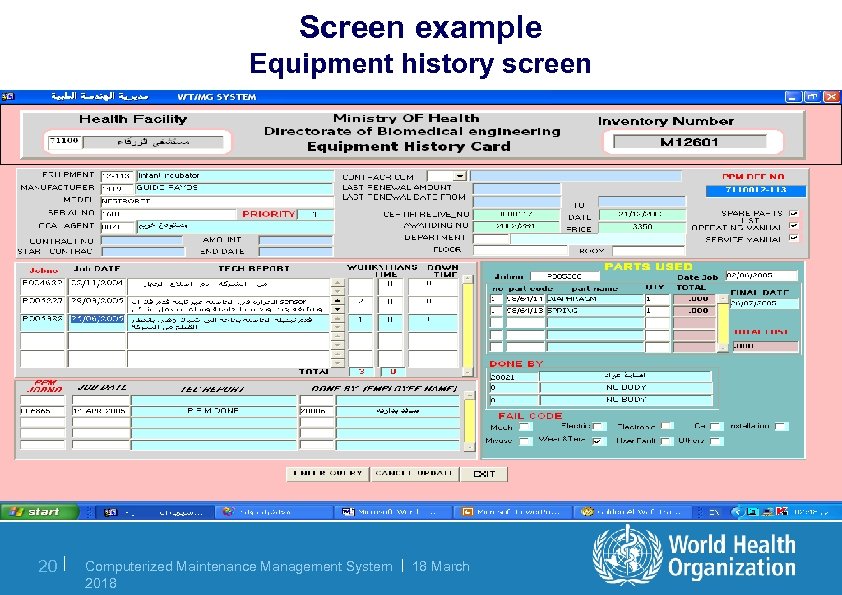

Screen example Equipment history screen 20 | Computerized Maintenance Management System | 18 March 2018

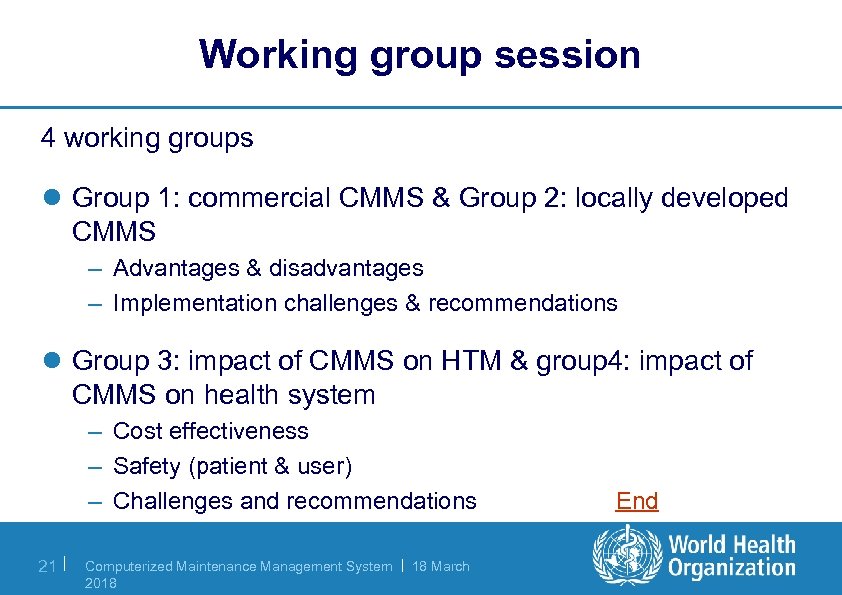

Working group session 4 working groups l Group 1: commercial CMMS & Group 2: locally developed CMMS – Advantages & disadvantages – Implementation challenges & recommendations l Group 3: impact of CMMS on HTM & group 4: impact of CMMS on health system – Cost effectiveness – Safety (patient & user) – Challenges and recommendations 21 | Computerized Maintenance Management System | 18 March 2018 End

WHO Medical Device technical Series Training module of : l Computerized maintenance management system l Developed by Dr Iyad Mobarek l April 2011 l Global Initiative on Health Technologies, WHO l Supported by the Bill & Melinda Gates Foundation 22 | Computerized Maintenance Management System | 18 March 2018

Thanks! Contacts: l http: //www. who. int/medical_devices/en/ l mailto: medicaldevices@who. int l Phone: + 41 22 791 1239 l Fax: +41 22 791 48 36 l Skype: WHOHQGVA 1 (then dial 11239) l Other: (presenters name and email) Objective: to ensure improved access, quality and use of medical devices. 23 | Computerized Maintenance Management System | 18 March 2018

bef1b7f6a07067a138b003628e1d0df9.ppt