Compounds Wire & Cables Think Global Technology 2012 Start >>

Contents Introduce The Company Products Quality Control System Chapter 1 Chapter 2 Chapter 3

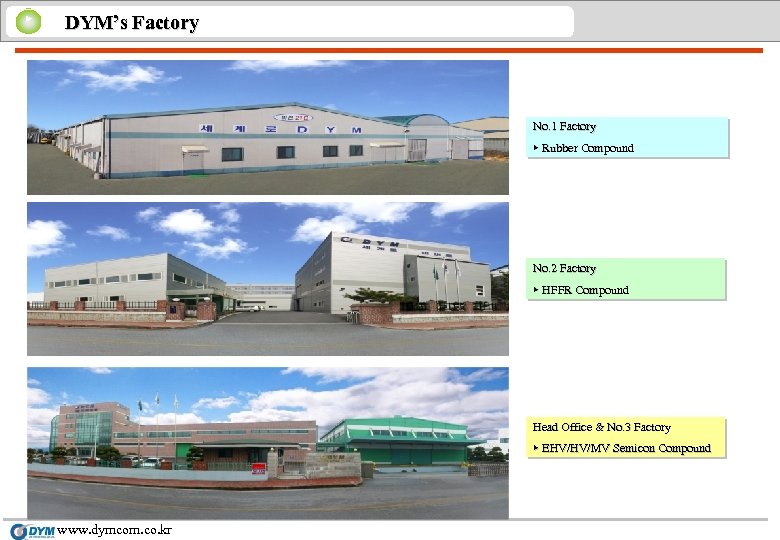

▶ DYM’s Factory No. 1 Factory ▶ Rubber Compound No. 2 Factory ▶ HFFR Compound Head Office & No. 3 Factory ▶ EHV/HV/MV Semicon Compound www. dymcom. co. kr

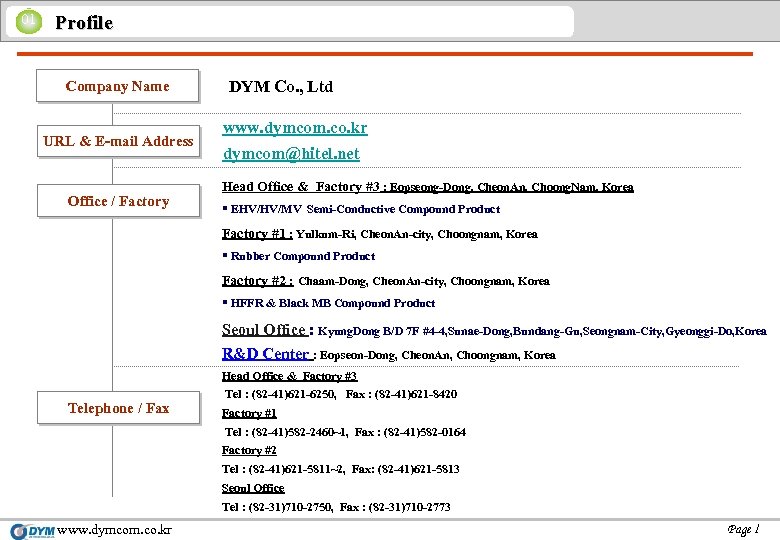

01 Profile Company Name URL & E-mail Address Office / Factory DYM Co. , Ltd www. dymcom. co. kr dymcom@hitel. net Head Office & Factory #3 : Eopseong-Dong, Cheon. An, Choong. Nam, Korea § EHV/HV/MV Semi-Conductive Compound Product Factory #1 : Yulkum-Ri, Cheon. An-city, Choongnam, Korea § Rubber Compound Product Factory #2 : Chaam-Dong, Cheon. An-city, Choongnam, Korea § HFFR & Black MB Compound Product Seoul Office : Kyung. Dong B/D 7 F #4 -4, Sunae-Dong, Bundang-Gu, Seongnam-City, Gyeonggi-Do, Korea R&D Center : Eopseon-Dong, Cheon. An, Choongnam, Korea Head Office & Factory #3 Telephone / Fax Tel : (82 -41)621 -6250, Fax : (82 -41)621 -8420 Factory #1 Tel : (82 -41)582 -2460~1, Fax : (82 -41)582 -0164 Factory #2 Tel : (82 -41)621 -5811~2, Fax: (82 -41)621 -5813 Seoul Office Tel : (82 -31)710 -2750, Fax : (82 -31)710 -2773 www. dymcom. co. kr Page 1

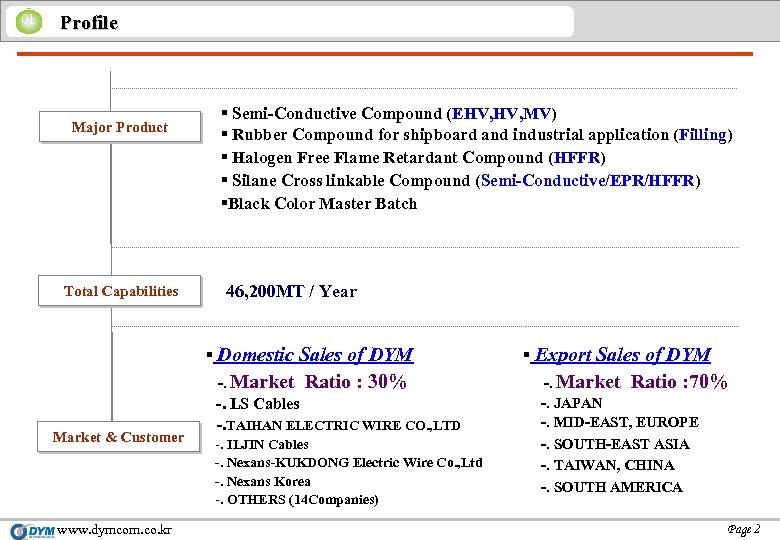

01 Profile Major Product Total Capabilities § Semi-Conductive Compound (EHV, MV) § Rubber Compound for shipboard and industrial application (Filling) § Halogen Free Flame Retardant Compound (HFFR) § Silane Cross linkable Compound (Semi-Conductive/EPR/HFFR) §Black Color Master Batch 46, 200 MT / Year § Domestic Sales of DYM -. Market Ratio : 30% www. dymcom. co. kr -. Market Ratio : 70% -. LS Cables Market & Customer § Export Sales of DYM -. JAPAN -. MID-EAST, EUROPE -. SOUTH-EAST ASIA -. TAIWAN, CHINA -. SOUTH AMERICA -. TAIHAN ELECTRIC WIRE CO. , LTD -. ILJIN Cables -. Nexans-KUKDONG Electric Wire Co. , Ltd -. Nexans Korea -. OTHERS (14 Companies) Page 2

01 Profile www. dymcom. co. kr Page 3

01 Profile www. dymcom. co. kr Page 4

01 Profile www. dymcom. co. kr Page 5

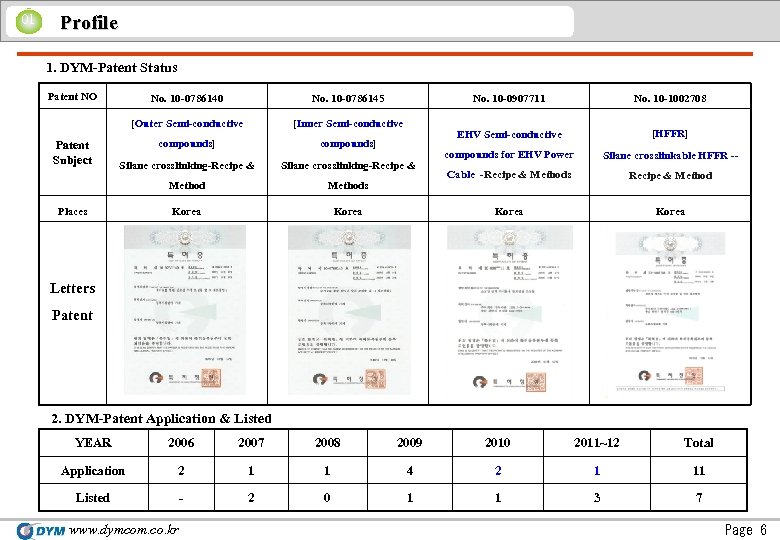

01 Profile 1. DYM-Patent Status Patent NO No. 10 -0786145 [Outer Semi-conductive [Inner Semi-conductive compounds] Silane crosslinking-Recipe & Method Patent Subject No. 10 -0786140 Methods Korea Places No. 10 -0907711 No. 10 -1002708 EHV Semi-conductive [HFFR] compounds for EHV Power Silane crosslinkable HFFR -- Cable -Recipe & Methods Recipe & Method Korea Letters Patent 2. DYM-Patent Application & Listed YEAR 2006 2007 2008 2009 2010 2011~12 Total Application 2 1 1 4 2 1 11 Listed - 2 0 1 1 3 7 www. dymcom. co. kr Page 6

![01 Profile 1. DYM-Patent Status Patent NO No. 1020090070655 No. 1020080062620 No. 1020090067855 [HFFR] 01 Profile 1. DYM-Patent Status Patent NO No. 1020090070655 No. 1020080062620 No. 1020090067855 [HFFR]](https://present5.com/presentation/26323ba5feb1e9790191bb65881bbd90/image-10.jpg)

01 Profile 1. DYM-Patent Status Patent NO No. 1020090070655 No. 1020080062620 No. 1020090067855 [HFFR] Composition for Preparing Resin Composition for Producing of Halogen-Free Fire Retardant Resin Insulating Material with Flame Composition –Recipe & Methods Patent Subject Development Roller, Development Roller Using the Same, and Method for Retardant -Recipe & Methods Preparing Thereof -Recipe & Method Places Korea Letters Patent www. dymcom. co. kr Page 7

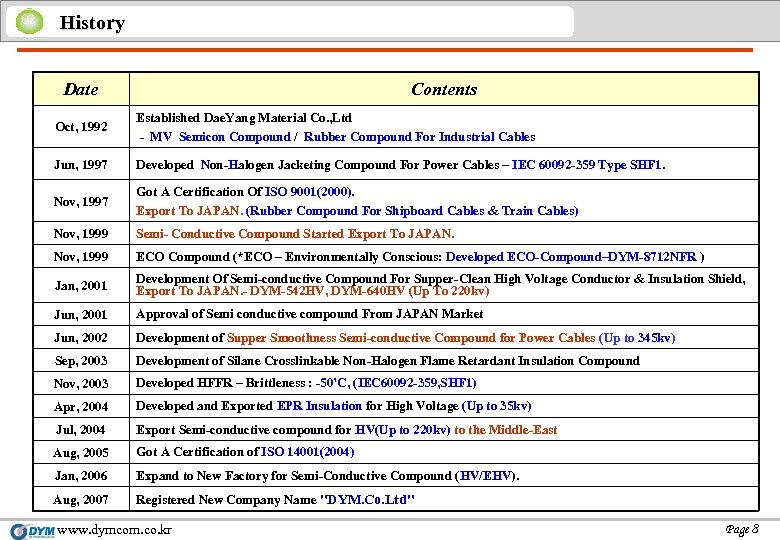

02 History Date Contents Oct, 1992 Established Dae. Yang Material Co. , Ltd - MV Semicon Compound / Rubber Compound For Industrial Cables Jun, 1997 Developed Non-Halogen Jacketing Compound For Power Cables – IEC 60092 -359 Type SHF 1. Nov, 1997 Got A Certification Of ISO 9001(2000). Export To JAPAN. (Rubber Compound For Shipboard Cables & Train Cables) Nov, 1999 Semi- Conductive Compound Started Export To JAPAN. Nov, 1999 ECO Compound (*ECO – Environmentally Conscious: Developed ECO-Compound–DYM-8712 NFR ) Jan, 2001 Development Of Semi-conductive Compound For Supper-Clean High Voltage Conductor & Insulation Shield, Export To JAPAN. - DYM-542 HV, DYM-640 HV (Up To 220 kv) Jun, 2001 Approval of Semi conductive compound From JAPAN Market Jun, 2002 Development of Supper Smoothness Semi-conductive Compound for Power Cables (Up to 345 kv) Sep, 2003 Development of Silane Crosslinkable Non-Halogen Flame Retardant Insulation Compound Nov, 2003 Developed HFFR – Brittleness : -50’C, (IEC 60092 -359, SHF 1) Apr, 2004 Developed and Exported EPR Insulation for High Voltage (Up to 35 kv) Jul, 2004 Export Semi-conductive compound for HV(Up to 220 kv) to the Middle-East Aug, 2005 Got A Certification of ISO 14001(2004) Jan, 2006 Expand to New Factory for Semi-Conductive Compound (HV/EHV). Aug, 2007 Registered New Company Name "DYM. Co. Ltd" www. dymcom. co. kr Page 8

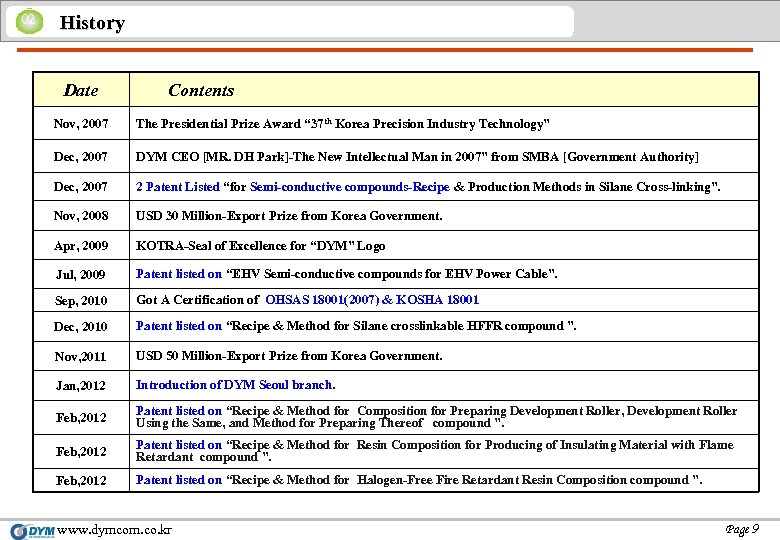

02 History Date Contents Nov, 2007 The Presidential Prize Award “ 37 th Korea Precision Industry Technology” Dec, 2007 DYM CEO [MR. DH Park]-The New Intellectual Man in 2007” from SMBA [Government Authority] Dec, 2007 2 Patent Listed “for Semi-conductive compounds-Recipe & Production Methods in Silane Cross-linking”. Nov, 2008 USD 30 Million-Export Prize from Korea Government. Apr, 2009 KOTRA-Seal of Excellence for “DYM” Logo Jul, 2009 Patent listed on “EHV Semi-conductive compounds for EHV Power Cable”. Sep, 2010 Got A Certification of OHSAS 18001(2007) & KOSHA 18001 Dec, 2010 Patent listed on “Recipe & Method for Silane crosslinkable HFFR compound ”. Nov, 2011 USD 50 Million-Export Prize from Korea Government. Jan, 2012 Introduction of DYM Seoul branch. Feb, 2012 Patent listed on “Recipe & Method for Composition for Preparing Development Roller, Development Roller Using the Same, and Method for Preparing Thereof compound ”. Feb, 2012 Patent listed on “Recipe & Method for Resin Composition for Producing of Insulating Material with Flame Retardant compound ”. Feb, 2012 Patent listed on “Recipe & Method for Halogen-Free Fire Retardant Resin Composition compound ”. www. dymcom. co. kr Page 9

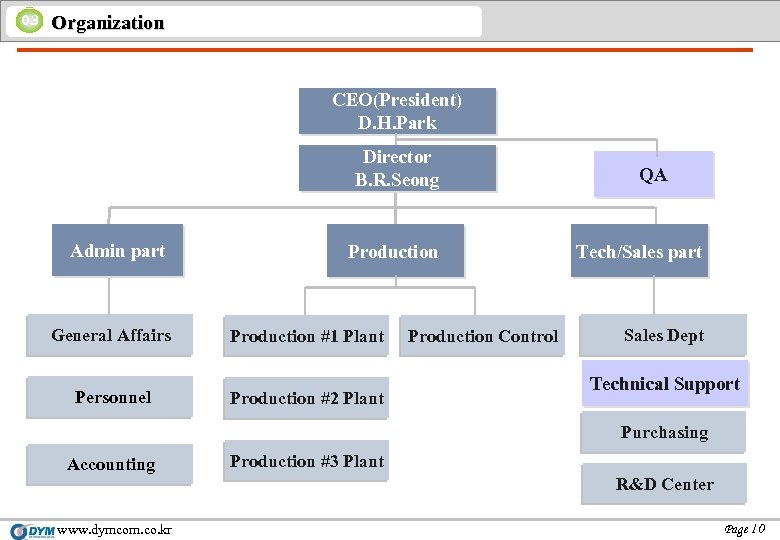

03 Organization CEO(President) D. H. Park Director B. R. Seong Admin part General Affairs Personnel Production #1 Plant Production #2 Plant Production Control QA Tech/Sales part Sales Dept Technical Support Purchasing Accounting www. dymcom. co. kr Production #3 Plant R&D Center Page 10

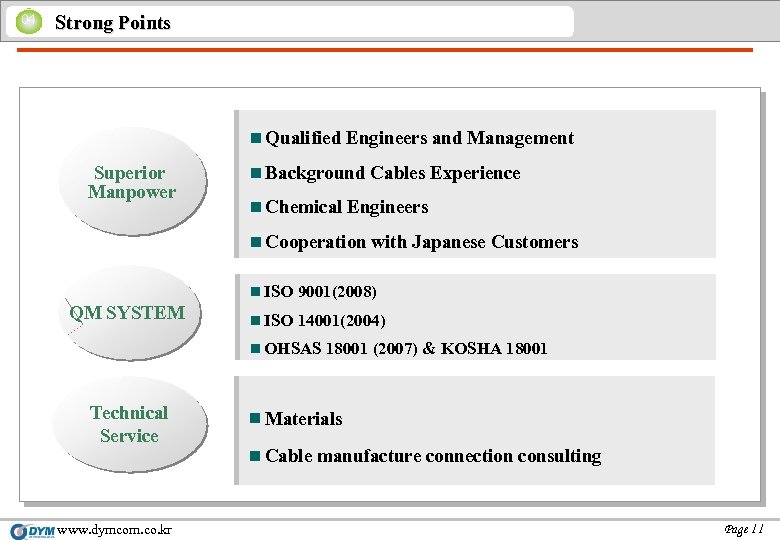

04 Strong Points Qualified Engineers and Management Superior Manpower Background Cables Experience Chemical Engineers Cooperation with Japanese Customers QM SYSTEM ISO 9001(2008) ISO 14001(2004) OHSAS 18001 (2007) & KOSHA 18001 Technical Service www. dymcom. co. kr Materials Cable manufacture connection consulting Page 11

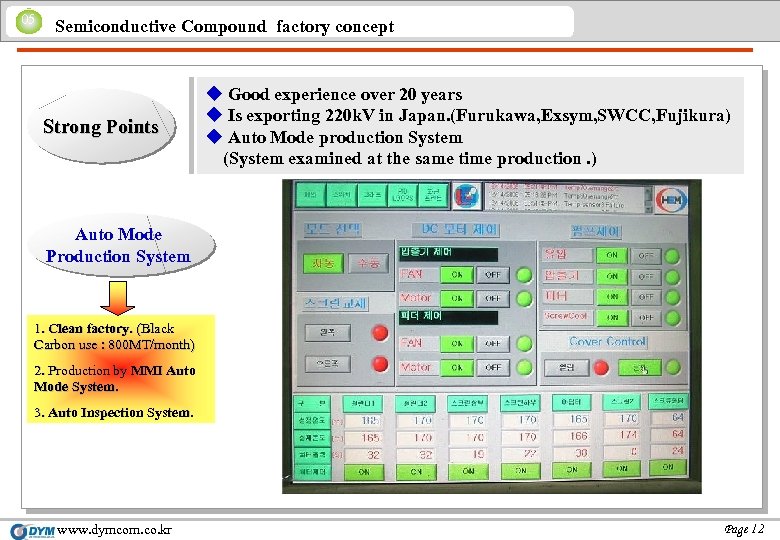

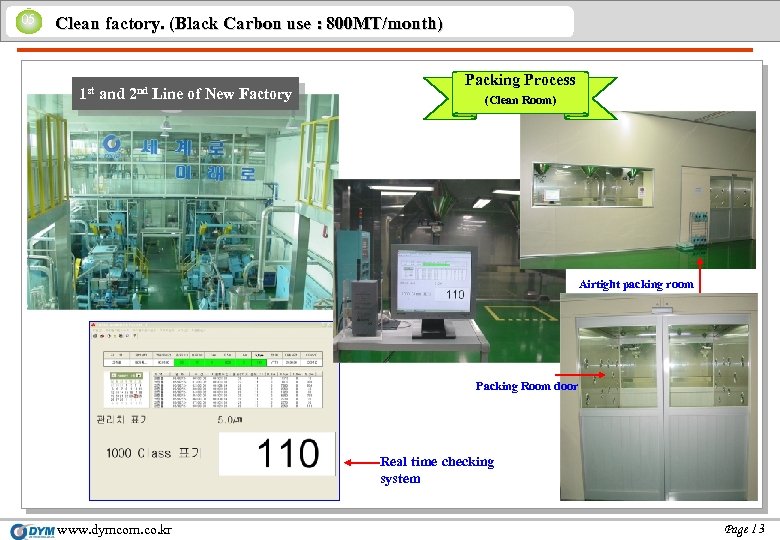

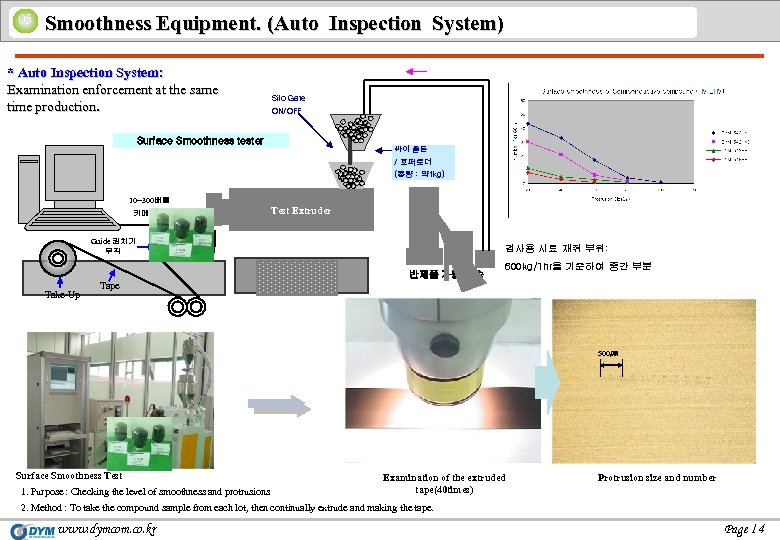

05 Semiconductive Compound factory concept Strong Points u Good experience over 20 years u Is exporting 220 k. V in Japan. (Furukawa, Exsym, SWCC, Fujikura) u Auto Mode production System (System examined at the same time production. ) Auto Mode Production System 1. Clean factory. (Black Carbon use : 800 MT/month) 2. Production by MMI Auto Mode System. 3. Auto Inspection System. www. dymcom. co. kr Page 12

05 Clean factory. (Black Carbon use : 800 MT/month) Packing Process 1 st and 2 nd Line of New Factory (Clean Room) Airtight packing room Packing Room door Real time checking system www. dymcom. co. kr Page 13

05 Smoothness Equipment. (Auto Inspection System) * Auto Inspection System: Examination enforcement at the same time production. Silo Gate ON/OFF Surface Smoothness tester 싸이 클론 / 호퍼로더 (용량 : 약 1 kg) 10~300배율 카메라 ☞ Test Extruder Guide 권치기 부착 Take-Up Tape 검사용 시료 채취 부위: 반제품 자동 이송 600 kg/1 hr을 기준하여 중간 부분 500㎛ Surface Smoothness Test 1. Purpose : Checking the level of smoothness and protrusions Examination of the extruded tape(40 times) Protrusion size and number 2. Method : To take the compound sample from each lot, then continually extrude and making the tape. www. dymcom. co. kr Page 14

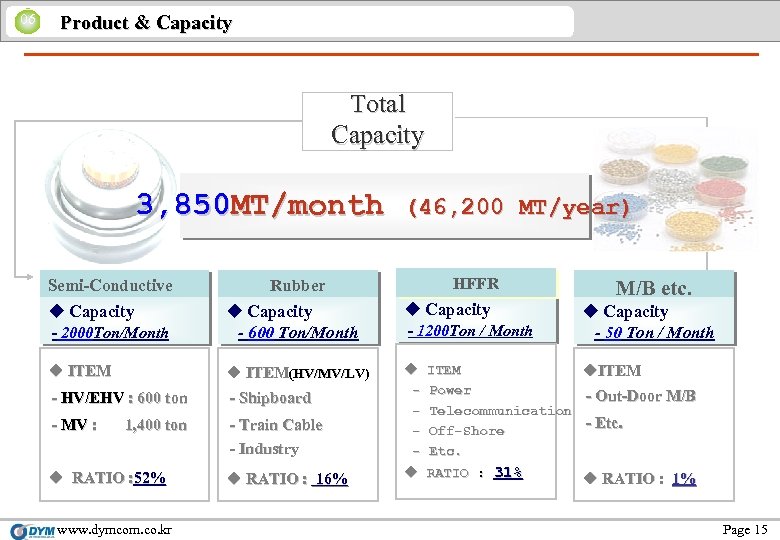

06 Product & Capacity Total Capacity 3, 850 MT/month Semi-Conductive (46, 200 MT/year) HFFR Rubber M/B etc. u Capacity - 2000 Ton/Month u Capacity - 600 Ton/Month u Capacity - 1200 Ton / Month u Capacity - 50 Ton / Month u ITEM(HV/MV/LV) - Shipboard u u ITEM Power Telecommunication Off-Shore Etc. u. ITEM - Out-Door M/B RATIO : 31% u RATIO : 1% - HV/EHV : 600 ton - MV : 1, 400 ton - Train Cable - Industry u RATIO : 52% u RATIO : 16% www. dymcom. co. kr - Etc. Page 15

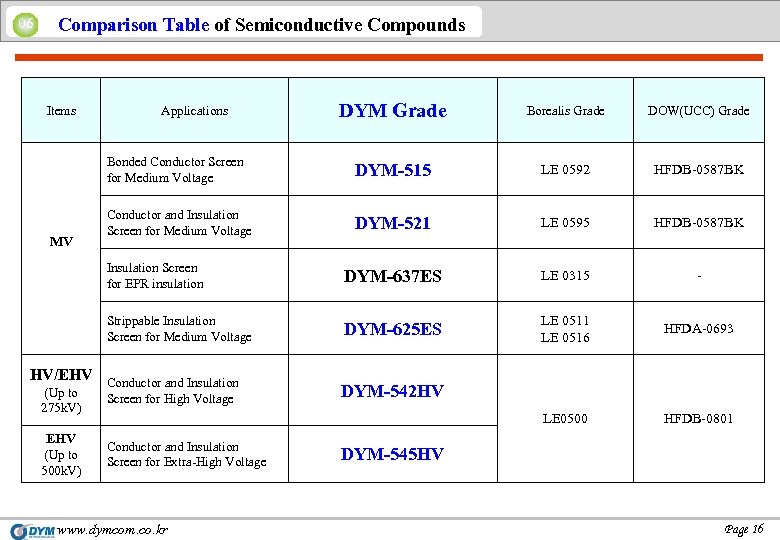

06 Comparison Table of Semiconductive Compounds Borealis Grade DOW(UCC) Grade DYM-515 LE 0592 HFDB-0587 BK Conductor and Insulation Screen for Medium Voltage DYM-521 LE 0595 HFDB-0587 BK Insulation Screen for EPR insulation DYM-637 ES LE 0315 - Strippable Insulation Screen for Medium Voltage MV DYM Grade Bonded Conductor Screen for Medium Voltage Items DYM-625 ES LE 0511 LE 0516 HFDA-0693 LE 0500 HFDB-0801 Applications HV/EHV Conductor and Insulation (Up to 275 k. V) EHV (Up to 500 k. V) Screen for High Voltage Conductor and Insulation Screen for Extra-High Voltage www. dymcom. co. kr DYM-542 HV DYM-545 HV Page 16

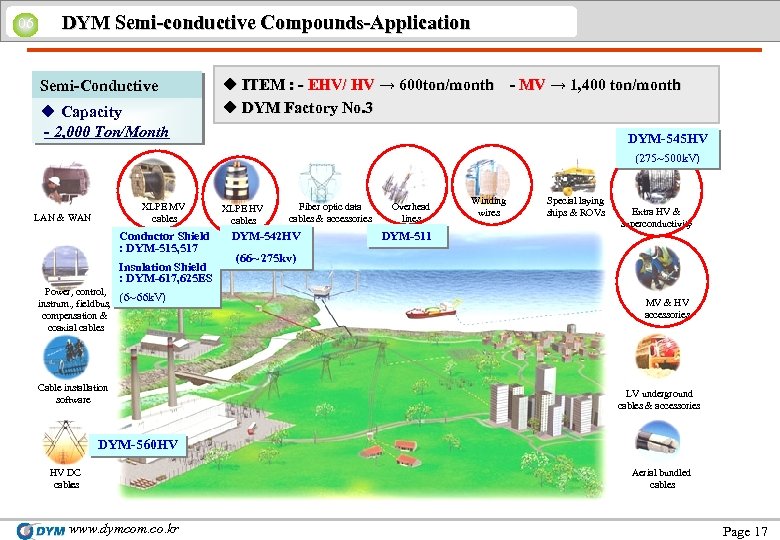

06 DYM Semi-conductive Compounds-Application Semi-Conductive u Capacity - 2, 000 Ton/Month u ITEM : - EHV/ HV → 600 ton/month - MV → 1, 400 ton/month u DYM Factory No. 3 DYM-545 HV (275~500 k. V) XLPE MV cables LAN & WAN Conductor Shield : DYM-515, 517 Insulation Shield : DYM-617, 625 ES Power, control, instrum. , fieldbus, compensation & coaxial cables (6~66 k. V) Cable installation software XLPE HV cables Fiber optic data cables & accessories DYM-542 HV Overhead lines DYM-511 Winding wires Special laying ships & ROVs Extra HV & superconductivity (66~ 275 kv) MV & HV accessories LV underground cables & accessories DYM-560 HV HV DC cables www. dymcom. co. kr Aerial bundled cables Page 17

06 HFFR Compound DYM's HFFR distribution Thermoplastic Insulation (Non-Cure) Thermosetting DYM-7660 NFR, DYM-7661 NFR, DYM-7851 NFR, DYM-7852 NFR, DYM-7853 NFR. DYM-7620 NFR, DYM-7650 NFR, DYM-7651 NFR, DYM-7653 NFR. (Cure-Electric beam) Thermoplastic Jacketing ATH +etc MDH +etc DYM-8650 NFR, DYM-8651 NFR, DYM-8653 NFR. DYM-8655 NFR, DYM-8656 NFR, DYM-8657 NFR, DYM-8658 NFR, DYM-8659 NFR, DYM-8660 NFR, DYM-8661 NFR, DYM-8662 NFR. DYM-8663 NFR, DYM-8843 NFR, DYM-8844 NFR, DYM-8845 NFR, DYM-8853 NFR. DYM-8860 NFR, DYM-8861 NFR, DYM-8890 NFR, DYM-8895 NFR. Insulation Silane Curing DYM-7610 NFR, DYM-7611 NFR, DYM-7612 NFR. Jacketing DYM-8610 NFR, DYM-8611 NFR. Semicon www. dymcom. co. kr DYM-500, DYM-600. Page 18

06 DYM HFFR Compounds-Application HFFR u Capacity - 1200 Ton / Month u ITEM : - Jacketing [Power/Shipboard/Telecom] → 1, 000 ton/month - Insulating [Automobile Wire] → 200 ton/month u DYM Factory No. 2 Shipboard Cable → DYM-8650 NFR, 8658 NFR, 8890 NFR Conductor (Cu or Al) Insulation (PE or XLPE) Screen (Al/PS tape) Power Cable → DYM-8658 NFR, 8843 NFR Telecomm Cable → DYM-8658 NFR, 8845 NFR Filler (PP yarn) UL Wire → DYM-7650 NFR, 7651 NFR Screen (Cu braid) Automobile Wire → DYM-7653 NFR Mobile phone Wire →DYM-7852 NFR Sheath /Jacketing (HFFR: DYM-8658 NFR) www. dymcom. co. kr Page 19

06 Rubber Compound DYM's Rubber distribution HV & MV Insulation LV Special CR Jacketing CPE(CM) CSP(CSM) HFFR(SHF 2) HFFR-TR Insulation Bedding www. dymcom. co. kr DYP-6601 P, DYP-6602 P, DYP-6604 P(upto 69 kv), DYP-6618 P(upto 15 kv), DYP-6601 P, DYP-6602 P, DYP-6604 P(upto DYP-6608 R. DYP-6608 P(HEPR/HF-HEPR), DYP-6609 R(EPR/HF-EPR) DYP-6608 R. DYP-6620 R. DYP-6628 R, DYP-6642 P, DYI-7701 R(SE 1), DYI-7703 R, DYI-7705 R, DYM-801 FR, DYM-802 FR, DYM-803 FR, DYM-805 FR, DYM-806 FR(SH) DYM-801 FR, DYM-802 FR, DYM-803 FR, DYM-805 FR, DYS-8706 R(SH), DYP-10703 FR, DYP-10704 NFR(SHF 2), DYP-10705 NFR, DYM-8810 NFR, DYP-10703 FR, DYM-8710 FR, DYM-8711 NFR, DYM-8712 NFR, DYM-8713 NFR, DYM-8410 NFR, DYM-8451, DYM-8452, DYM-8452 NFR(Bedding), Page 20

06 DYM Rubber Compounds-Application Rubber u Capacity - 600 Ton/Month u ITEM : - HV [Power & Shipboard Cable] → 200 ton/month - LV [Shipboard & Railway Cable] → 400 ton/month u DYM Factory No. 1 DYM-8658 NFR Sheath : DYM-805 FR Winding wires Multimode optical fiber cables Telephone cables Insulation : DYP-6601 P DYP-6602 P/6604 P HV & LV energy cables Sheath : DYP 10704 NFR Thin-wall LV cables LV energy cables Hybrid energy & data cables Insulation: DYP-6608 R/6608 P DYP-6609 RC Maritime LAN cables Sensor measurement & fieldbus cables Insulation : DYM 803 FR Instrumentation & control cables Coaxial cables & Cat 7 solutions Insulation : DYM 7611 NFR www. dymcom. co. kr Page 21

06 Silane Cross Linkable Compound DYM's Silane Curing Compound distribution EPR DYM-7610 NFR. Insulation HF-XLPE DYM-7611 NFR, DYM-7615 NFR. SHF 1 DYM-8611 NFR. SFH 2 DYM-8610 NFR. Jacketing Semi. Conductive www. dymcom. co. kr Conductor Screen Insulation Screen DYM-500. DYM-600. Page 22

06 DYM-Technology “No. 1 in Korea” toward Globalization * The Highest Voltage Semicon Application In Korea: DYM-545 HV(upto 500 kv) * The Highest Voltage EPR Application in Korea: DYP-6601 P, DYP-6604 P(upto 69 kv) * The first Oil-resistance EPR (Down Well Pump Cable): DYP-6642 P * The first HFFR used ATH (22. 9 k. V FR-CNCO-W Sheath): DYM-8660 NFR(MV Jacket) * The first EPR Silane Cure : DYM-7610 NFR * The first SHF 2 Silane Cure: DYM-8610 NFR * The first Semicon Silane Cure: DYM-500, DYM-600. * Patent – 7 listed, 11 Application. / Brand logo listed- 8 www. dymcom. co. kr Page 23

07 Domestic Sales(2011’) Domestic – Our Customers -. LS Cables (befor LG Cable) -. TAIHAN Electric Wire Co. Ltd -. Nexans-KUKUDONG Electric Wire. Incheon(ICN) Airport -. Nexans-Korea -. IL Jin Cables -. Jin. Ro Industric Co. , Ltd • 2. 5 hour distant by car from ICN , southward • Located in Cheonan-city -. Seoul Electric Wire Co. , Ltd…Etc -. Cosmolink Electric Wire Co. , Ltd -. Tai. Han M&C Domestic Sales of DYM 30% -. DONGNAM Precision Ind. Co. , Ltd -. Etc www. dymcom. co. kr Page 24

07 The Global Market(2011’) ØGreece ØCroatia ØBulgaria ØSpain ØCzech ØUSA ØCanada ØUzbekistan ØRussia ØPoland ØDenmark ØChina ØFrance ØGermany Korea ØItaly ØPortugal ØSweden ØNorway ØFin·land ØJapan ØSaudi-Arabia ◈ ØQa·tar ØOman ØTaiwan ØDubai/Kuwait ØThailand ØVietnam ØIran ØLebanon ØMalaysia ØIndonesia ØSyria/Jordan ØColombia SWCC, Exsym. FEIC, FUJIKURA, FURUKAWA ØTurkey ØPe·ru ØAustralia ØMorocco ØVenezuela ØEgypt ØNèw Zéa·land ØIndia ØBrazil ØChile Export Sales of DYM 70% ØArgentina www. dymcom. co. kr Page 25

07 Sales Status by Year Sales Status of DYM by year(2000~2012) (unit: M$) Forcast of sales in 2012 From sales of 2000 1, 725% Increase (Annual average 29%) www. dymcom. co. kr Page 26

07 DYM Vision VISION : “ Green Compound Global Top Leader 2020 ” Sales Forecast 1. Sales Goal in 2015, 300 billion won(300 M$) 2. Sales Goal in 2020, 1 trillion won(1, 000 M$) 3. Achievement of Global Top for Semi-conductive materials by 2020 4. Achievement of Green Compound Global Top by 2020 Apart from SILANE & Moisture cured semi-conductive materials. Sales Goal www. dymcom. co. kr Page 28

08 Quality Assurance The quality guarantee system ISO 9001 ; 2008 + ISO 14001 ; 2004 + Customer’s Quality Requirement + International Specifications DYM’s Quality Assurance www. dymcom. co. kr Page 29

08 Quality Assurance The quality guarantee system OHSAS 18001 ; 2007 + KOSHA 18001 + Customer’s Quality Requirement + International Specifications DYM’s Quality Assurance www. dymcom. co. kr Page 30

Toward the successful future Thanks for your kind attention!

Contents Introduce the Company Products Quality Control System Chapter 1 Chapter 2 Chapter 3

01 Product & Capacity Total Capacity 3, 850 MT/month Semi-Conductive (46, 200 MT/year) HFFR Rubber u Capacity - 2000 Ton/Month u Capacity - 600 Ton/Month u Capacity u ITEM(HV/MV/LV) - Shipboard u u - HV/EHV : 600 ton - MV : 1, 400 ton - Train Cable - Industry u RATIO : 52% u RATIO : 16% www. dymcom. co. kr - 1200 Ton / Month M/B etc. u Capacity - 50 Ton / Month ITEM Power Telecommunication Off-Shore Etc. u. ITEM - Out-Door M/B RATIO : 31% u RATIO : 1% - Etc. Page 1

01 Semiconductive Compound factory concept Strong Points u Good experience over 20 years u Is exporting 220 k. V in Japan. (Furukawa, Exsym, SWCC, Fujikura) u Auto Mode production System (System examined at the same time production. ) Auto Mode Production System 1. Clean factory. (Black Carbon use : 800 MT/month) 2. Production by MMI Auto Mode System. 3. Auto Inspection System. www. dymcom. co. kr Page 2

01 Comparison Table of Semiconductive Compounds Borealis Grade DOW(UCC) Grade DYM-515 LE 0592 HFDB-0587 BK Conductor and Insulation Screen for Medium Voltage DYM-521 LE 0595 HFDB-0587 BK Insulation Screen for EPR insulation DYM-637 ES LE 0315 - Strippable Insulation Screen for Medium Voltage DYM-625 ES LE 0511 LE 0516 HFDA-0693 LE 0500 MV DYM Grade Bonded Conductor Screen for Medium Voltage Items HFDB-0801 Applications HV/EHV Conductor and Insulation (Up to 275 k. V) EHV (Up to 500 k. V) Screen for High Voltage Conductor and Insulation Screen for Extra-High Voltage www. dymcom. co. kr DYM-542 HV DYM-545 HV Page 3

Semiconductive compound for MV Power Cables 01 Conductor shield Bonded Conductor & Insulation shield DYM-515 DYM-521 DYM-625 ES DYM-637 ES Description Bonded Type Conductor & Insulation Bonded Type Easy Strippable Application Medium Voltage For EPR(DYP 6604 P) Insulation Good fluidity, high resistance to scorch, Non-staining Good fluidity, high resistance to scorch, Non-staining Suitable for long run extrusion without scorch For EPR insulation shielding of power cables. Product Grade Benefits Physical Properties (Mean Values) Insulation shield Test Method Units Density at 23℃ ASTM D 1505 g/㎤ 1. 14 1. 15 1. 16 1. 20 Tensile Strength(200㎜/min) ASTM D 638 MPa 19 14 12 Elongation at Break ASTM D 638 % 200 300 290 T·S ASTM D 638 % - 10 + 10 E·B ASTM D 638 % - 15 E. S. C. R 100% ASTM D 1693 hrs 〉200 Brittleness Temperature ASTM D 746 ℃ -50 -50 Moisture Content Karl Fischer PPm 〈500 〈1, 000 〈1000 23℃ ICEA S-66 -524 Ω·㎝ < 100 < 500 < 100 90℃ ICEA S-66 -524 Ω·㎝ < 500 < 1, 000 < 500 After aging. (Variation) (168 hrs× 135℃) Volume Resistivity www. dymcom. co. kr Page 4

01 Semiconductive compound for HV/EHV Power Cables High / Extra High Voltage DYM-542 HV DYM-545 HV Description Super Clean Furnace Black Acetylene Black Application Up to 275 k. V Up to 500 k. V Conductor & Insulation shield (Superior heat resistance) Product Grade Benefits Physical Properties (Mean Values) Test Method Units Density at 23℃ ASTM D 1505 g/㎤ 1. 14 Tensile Strength(200㎜/min) ASTM D 638 MPa >15 > 14 Elongation at Break ASTM D 638 % >200 > 250 T·S ASTM D 638 % <10 E·B ASTM D 638 % <15 E. S. C. R 100% ASTM D 1693 hrs 〉200 Brittleness Temperature ASTM D 746 ℃ -50 Moisture Content Karl Fischer PPm 〈300 23℃ ICEA S-66 -524 Ω·㎝ < 100 < 50 90℃ ICEA S-66 -524 Ω·㎝ < 300 < 100 After aging (Variation) (168 hrs× 135℃) Volume Resistivity www. dymcom. co. kr Page 5

02 HFFR Compound DYM's HFFR distribution Thermoplastic Insulation (Non-Cure) Thermosetting DYM-7660 NFR, DYM-7661 NFR, DYM-7852 NFR, DYM-7853 NFR. Radiation: DYM-7621 NFR, DYM-7650 NFR, DYM-7651 NFR, DYM-7653 NFR. Peroxide: DYM-7600 NFR, DYM-7630 NFR, DYM-8713 NFR. . Thermoplastic Jacketing ATH +etc MDH +etc DYM-8650 NFR, DYM-8651 NFR, DYM-8653 NFR. DYM-8655 NFR, DYM-8656 NFR, DYM-8657 NFR, DYM-8658 NFR, DYM-8659 NFR, DYM-8660 NFR, DYM-8661 NFR, DYM-8662 NFR. DYM-8663 NFR, DYM-8843 NFR, DYM-8844 NFR, DYM-8845 NFR, DYM-8853 NFR. DYM-8860 NFR, DYM-8861 NFR, DYM-8875 NFR, DYM-8890 NFR, DYM-8895 NFR. Insulation Silane Curing DYM-7610 NFR, DYM-7611 NFR, DYM-7615 NFR. Jacketing DYM-8610 NFR, DYM-8611 NFR. Semicon www. dymcom. co. kr DYM-500, DYM-600. Page 1

02 HFFR Compound Halogen Free Flame Retardant Compound Power Cable Sheath - DYM-8658 NFR, DYM-8663 NFR, DYM-8843 NFR Etc Communication Cable Sheath - DYM-8658 NFR, DYM-8845 NFR, DYM-8890 NFR(Optical) Etc LSHF Off-Shore Cable Sheath - DYM-8650 NFR, DYM-8653 NFR, DYM-8658 NFR - DYM-8890 NFR Etc LSHF Cross-Linkable Insulation & Sheath - INSULATION : DYM-7850 NFR, DYM-7650 NFR(Electron Beam Curing) - www. dymcom. co. kr SHEATH : DYM-8810 NFR, DYP-10704 NFR Page 2

02 DYMGrade 8650 NFR HFFR Compound Mechanical Properties General Description Application Power Cable, Offshore & Shipboard Cable, Telecom Thermomechanical properties Fire Properties Other Properties Tensile Strength (MPa) Elongation (%) Hot Pressure (80℃) Cold Impact (℃) Oxygen Index (%) HCl Content (%) Smoke Density (Ds max) Density (g/㎤) Hardness Shore D Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 LTS 1<S 3, Good mechanical and processing properties 12 170 20 -40 33 0 80 1. 43 50 8651 NFR 〃 Thermoplastic, IEC 60092 -359 SHF 1, IEC 60502, Termite repellent EVA compound 13 150 25 -38 29 0 105 1. 45 50 8653 NFR 〃 Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 LTS 1<S 3, Good processing (Improved line speed) 12 170 20 -38 31 0 120 1. 45 50 8655 NFR 〃 Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 LTS 1<S 3, Excellent Processing properties. 12 200 15 -30 33 0 90 1. 46 52 8656 NFR 〃 Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 LTS 1<S 3, Good mechanical and Excellent flame retardant 13 165 16 -38 35 0 80 1. 51 48 8658 NFR 〃 Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 LTS 1<S 3, Excellent flame retardant(IEC 60332 -3 Category-A), IEC 60502 -1 ST 8. 13. 5 225 15 -40 40 0 90 1. 48 48 8659 NFR 〃 Thermoplastic, IEC 60092 -359 SHF 1, IEC 60502, Termite repellent EVA compound 12 160 20 -38 35 0 100 1. 46 50 8660 NFR Power Cable (FR CNCO-W) Thermoplastic, ES 126 -661~ 664(KEPCO), IEC 60502 Excellent mechanical properties and low smoke 11 550 10 1) -40 33 0 802) 1. 30 46 8661 NFR Power Cable, Offshore & Shipboard Cable, Telecom Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 LTS 1<S 3, Good processing properties and Excellent Flexibility. 12 600 40 -40 35 0 100 1. 28 883) 8662 NFR Power Cable, Offshore & Shipboard Cable, Telecom Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 LTS 1<S 3, Good mechanical and Oil retardant(100℃x 24 hrs) 10 550 10 -38 36 0 100 1. 29 44 8663 NFR Power Cable, Offshore & Shipboard Cable, Telecom Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, MH 4, BS 7655 Section 6. 1 LTS 1<S 3, Flame retardant(IEC 60332 -3 Category-A), IEC 60502 -1 ST 8. 10 520 21 -40 36 0 80 1. 32 45 8843 NFR Power Cable & Telecommunication Thermoplastic, S 4002 00 01(KT), IEC 60092 -359 SHF 1. IEC 60502 -1 ST 8. Resistance to cold, Flame retardant, Flexible and good processing 12 550 4 -40 37 0 75 1. 35 46 8844 NFR Shipboard & Telecom Cable/Power Cables IEC 60092 -359 type SHF 1, Brittleness : -50℃ Flame retardant(IEC 60332 -3 Category-A), 12 550 4 -50 34 0 90 1. 32 46 8853 NFR Telecom & Optical fiber cable / Thermoplastic, S 4002 00 01(KT), IEC 60092 -359 SHF 1. Power Cables Flame retardant(IEC 60332 -3 Category-A), IEC 60502 -1 ST 8. (6/10 k. V Sheath). 13 600 3 -40 35 0 70 1. 33 48 8861 NFR Power Cable(FR CNCO-W)/ Telecom Cables 15 600 3 -40 33 0 80 1. 25 43 8890 NFR Telecom & Optical fiber cable / Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 Power Cable & Shipboard Cable LTS 1<S 3. Excellent flame retardant 11 500 30 -35 41 0 100 1. 38 46 Thermoplastic, ES 126 -661~ 664(KEPCO), IEC 60502 -1 ST 8. (6/10 KV Sheath) Excellent mechanical properties and Flame retardant(IEC 60332 -3 Category-A), Memo. Note: 1)IEC 60811 -3 -1 121℃, 2)Specimen thickness: 3㎜, 3) Shore A www. dymcom. co. kr Page 3

02 HFFR Compound Mechanical Properties DYMGrade 8895 NFR General Description Application Telecom & Optical fiber cable / Thermoplastic, IEC 60092 -359 SHF 1, VDE 0207 Part 24 HM 2, BS 7655 Section 6. 1 Power Cable $ Shipboard Cable LTS 1<S 3. Good processing and Excellent flame retardant Thermomechanical properties Fire Properties Other Properties Tensile Strength (MPa) Elongation (%) Hot Pressure (80℃) Cold Impact (℃) Oxygen Index (%) HCl Content (%) Smoke Density (Ds max) Density (g/㎤) Hardness Shore A 11 550 26 -35 38 0 90 1. 34 42 7620 NFR HFFR Insulation (105℃) Thermosetting LSHF Insulation Compound ( Electric beam Cross-linking) , Flame retardant. (Ro. HS Pass) 15 400 5 -40 30 0 100 1. 35 95 7650 NFR HFFR Insulation (105℃) Thermosetting Insulation compound ( Electric beam Cross-linking) - OA Insulation Grade. Flame retardant. (VW 1 Pass. Ro. HS Pass) 12. 5 300 5 -40 45 0 130 1. 60 97 7651 NFR HFFR Insulation (105℃) Thermosetting Insulation compound ( Electric beam Cross-linking) - OA Insulation Grade. Flame retardant. (VW 1 Pass. Ro. HS Pass, Low-Halogen) 12. 5 300 5 -40 52(VW 1) 7 130 1. 60 97 7653 NFR HFFR Insulation (105/125℃) Thermosetting Insulation compound ( Electric beam Cross-linking) - OA Insulation Grade. Flame retardant. (Ro. HS Pass) 14 400 5 -40 33 0 100 1. 43 95 7660 NFR HFFR Insulation (Non-Curing, Thermoplastic LSHF Insulation Compound, Flame retardant. (Ro. HS Pass) 80℃) 13 600 20 -40 30 0 100 1. 37 95 7661 NFR HFFR Insulation (Non-Curing, Thermoplastic LSHF Insulation Compound, Excellent Flexibility. (Ro. HS Pass) 80℃) 14 600 30 -50 34 0 110 1. 32 88 7851 NFR HFFR Insulation (Non-Curing: Thermoplastic Insulation compound - OA Insulation Grade. Flame retardant (VW 1 Pass, 80℃) Ro. HS Pass, Low-Halogen). 12 280 20 -40 52(VW 1) 7 130 1. 60 95 7852 NFR HFFR Insulation (Non. Curing: 105℃ ) 14 250 5 -40 32 0 100 1. 43 95 6 50 60 -30 20 0 - 1. 80 88 6 50 60 -30 45 0 140 1. 80 88 10 180 45 -30 20 - 1. 40 91 8452 P Thermoplastic Insulation compound - OA Insulation Grade. Flame retardant (Ro. HS Pass). Normal Bedding 8452 NFR Flame retardant Bedding 8664 Memo. Semi-Conductive Bedding Note: www. dymcom. co. kr Page 4

02 HFFR Compound Sheath Product Grade DYM-8650 NFR DYM-8653 NFR DYM-8655 NFR DYM-8656 NFR DYM-8658 NFR Description LSHF & Thermoplastic ATH type LSHF & Thermoplastic ATH type Application IEC 60092 -359 SHF 1 Power Cables, Offshore & Shipboard Cables IEC 60092 -359 SHF 1 Offshore & Shipboard Cables, Power & Telecom cables IEC 60092 -359 SHF 1 Power Cables, Offshore & Shipboard Cables Good processing & mechanical properties Good processing & Improved Line Speed Good processing & Outstanding flame retardant Good processing & Excellent flame retardant Benefits Physical Properties (Mean Values) Test Method Units Specific Gravity at 23℃ ASTM D 1505 g/㎤ 1. 43 1. 45 1. 46 1. 51 Tensile Strength IEC 60811 -1 -1 MPa > 12. 5 > 12 > 11 > 12. 5 > 13. 5 Elongation at break IEC 60811 -1 -1 % > 170 > 165 > 225 T·S IEC 60811 -1 -2 % > 95 > 90 > 95 > 92, 85(110℃) E·L IEC 60811 -1 -2 % > 90 > 88 > 90 > 92 > 90. 80(110℃) Oxygen Index ASTM D 2863 % 33 31 33 35 40 Hardness (Shore D) ASTM D 2240 - 50 50 52 48 48 Cold Impact test at -15℃ IEC 60811 -1 -4 - Pass Pass Halogen content IEC 60754 -1 % 0 0 0 Smoke Density (Flaming Mode) ASTM E 662 - 90 120 90 80 90 p. H IEC 60754 -2 - > 5. 0 > 5. 1 > 5. 0 Conductivity IEC 60754 -2 ㎲㎜ <5 < 6 < 6 After aging (Retained) (100℃, 168 hrs) Corrosivity of gases www. dymcom. co. kr Page 5

02 HFFR Compound Sheath Product Grade DYM-8663 NFR DYM-8843 NFR DYM-8853 NFR Insulation DYM-8861 NFR DYM-8890 NFR DYM-7660 NFR HFFR Insulation Description LSHF & Thermoplastic LSHF & Thermoplastic (Non-Curing, 80℃) IEC 60092 -359 SHF 1, DYM-7651 NFR Electric Beam Cross-linking Thermosetting Thermoplastic LSHF VDE 0207 Part 24 HM 2, MH 4, BS 7655 Section 6. 1 LTS 1<S 3, Flame retardant ( IEC 60332 -3 Category-A), IEC 60502 -1 ST 8. Good processing & mechanical properties Application Benefits Physical Properties (Mean Values) IEC 60502 -1 , IEC 60092 -359 SHF 1, Power Cables, Shipboard & Telecommunication Cables Good processing & Long term reliability Good processing & Excellent mechanical properties Good processing & Excellent flame retardant Good mechanical properties & Long term reliability Good mechanical properties VDE 0207 Part 24 IEC 60502 -1 , IEC 60502 -1, HM 2, MH 4, BS 7655 Insulation IEC 60092 -359 SHF 1, Section 6. 1 LTS 1<S 3, IEC 60092 -359 SHF 1, Off shore &Shipboard Compound, Flame retardant ( Communication & Optical Fiber Cables IEC 60332 -3 Category-A), Power Cables, Telecom retardant. Cables UL - HF 105℃ IEC 60502 -1 ST 8 Test Method Units Specific Gravity at 23℃ ASTM D 1505 g/㎤ 1. 36 1. 35 1. 30 1. 25 1. 38 1. 37 1. 60 Tensile Strength IEC 60811 -1 -1 MPa > 11 > 12 > 13 > 15 > 11 Ø 13 > 12. 5 Elongation at break IEC 60811 -1 -1 % Ø 420 > 550 > 600 > 500 Ø 600 > 300 T·S IEC 60811 -1 -2 % Ø 90 > 96 > 90, 85(110℃) > 90 Ø 80 > 100 E·L IEC 60811 -1 -2 % Ø 85 > 92 > 90, 80(110℃) > 85 Ø 80 > 80 Oxygen Index ASTM D 2863 % 35 37 35 33 41 30 52(VW 1 pass) Hardness (Shore D) ASTM D 2240 - 48 46 48 43 46 95(Shore A) 97(Shore A) Cold Impact test at -15℃ IEC 60811 -1 -4 - Pass Pass Halogen content IEC 60754 -1 % 0 0 0 0 Smoke Density (Flaming Mode) ASTM E 662 - 80 75 70 80 100 130 p. H IEC 60754 -2 - > 5. 0 > 5. 2 > 4. 9 > 5. 0 > 5. 2 > 5. 3 > 5. 5 Conductivity IEC 60754 -2 ㎲㎜ < 5. 5 < 6 < 5 < 5 After aging (Retained) (100℃, 168 hrs) Corrosivity of gases www. dymcom. co. kr Page 6

03 Rubber Compound DYM's Rubber distribution HV & MV Insulation LV Special CR Jacketing CPE(CM) CSP(CSM) HFFR(SHF 2) HFFR-TR Insulation Bedding www. dymcom. co. kr DYP-6601 P, DYP-6602 P, DYP-6604 P(upto 69 kv), DYP-6618 P(upto 15 kv), DYP-6608 R. DYP-6608 P(HEPR/HF-HEPR), DYP-6609 R(EPR/HF-EPR) DYP-6608 R. DYP-6620 R. DYP-6628 R, DYP-6642 P, DYI-7701 R(SE 1), DYI-7703 R, DYI-7705 R, DYM-801 FR, DYM-802 FR, DYM-803 FR, DYM-805 FR, DYM-806 FR(SH) DYM-801 FR, DYM-802 FR, DYM-803 FR, DYM-805 FR, DYS-8706 R(SH), DYP-10703 FR, DYP-10704 NFR(SHF 2), DYP-10705 NFR, DYM-8810 NFR, DYP-10703 FR, DYM-8710 FR, DYM-8711 NFR, DYM-8712 NFR, DYM-8713 NFR, DYM-8410 NFR, DYM-8451, DYM-8452, DYM-8452 NFR(Bedding), Page 1

03 Rubber Compound - Insulation Product Grade DYP-6601 P DYP-6602 P Hard Grade Ethylene-Propylene Rubber Description Power Cable (Up to 69 k. V) Application Power /mining Cable (Up to 25 k. V) DYP-6604 P DYP-6618 P DYP-6609 R DYP-6608 P DYP-6642 P EPM compound EPDM & Halogen. Free compound EPDM compound Power Cable (Up to 69 kv) Medium Voltage Low Voltage Cable Down Well Pump Cable (Up to Cabl (Up to 1 kv) 15 kv) Good processing & Very suitable to use Very suitable to Good processing & mechanical properties Good processing & in high voltage in Mining & use in high voltage mechanical properties (IEC 60092 -351 power cable Industrial cable power cable properties (IEC 60502 -2 HEPR) Satisfaction) Benefits Physical Properties (Mean Values) Test Method Units (Curing Method : N 2 Gas or Steam Pressure) (Curing Method : Steam Pressure) Density at 23℃ ASTM D 1505 g/㎤ 1. 20 1. 34 1. 37 1. 35 Mooney Viscosity ML 1+4 at 125℃ ASTM D 1646 - 19. 6 17. 0 19. 2 13. 1 19. 7 21. 0 35. 4 Tensile Strength (200㎜/min) ASTM D 638 MPa > 10 > 14 > 13 > 9 > 10 > 12 Elongation ASTM D 638 % > 400 > 300 > 520 > 500 > 220 T·S ASTM D 638 % > 90 > 92 > 95 > 90 (150℃, 168 hrs) > 96 E·L ASTM D 638 % > 80 > 83 > 92 > 85 > 86 Ozone resistance (0. 025∼ 0. 030%, 30 hrs) IEC-60811 -2 -1 hrs No Crack No Crack Oxygen Index ASTM D 2863 - - - 20 - - Durometer - 88 86 94 82 72 85 85 1. 5× 1016 5. 0× 1015 4. 0× 1015 5. 0 × 1015 After aging (Retained) (168 hrs× 135℃) Hardness (Shore A) Volume Resistivity ASTM D 257 Ω·㎝ www. dymcom. co. kr Page 2

03 Rubber Compound – Sheath Product Grade Low Halogen Sheath DYI-7701 R DYI-7703 R DYM-806 FR DYM-805 FR DYS-8706 R DYP-10704 NFR Description CR Compound CPE Compound (Jacketing) CSP Compound HFFR thermosetting EVM Compound Application CR Cabtyre cable jackets Welding cable IEC 60245, CENELEC HD 22 EM 2, EM 5, EM 7 HD 22. 1 S 3 EM 2, EM 7 Shipboard cable & Off shore cable Good processing & mechanical properties (PCP: IEC 60092 -359 SE 1) Good processing Benefits Physical Properties (Mean Values) Good heat resistance Excellent mechanical & flame retardant Good heat resistance & properties & satisfy the properties. spec. IEC flame retardant properties spec. IEC 60092 -359(SH) Excellent mechanical properties & satisfy the spec. IEC 60092 -359(SHF 2) (Curing Method : Steam Pressure) Test Method Units Density at 23℃ ASTM D 1505 g/㎤ 1. 54 1. 45 1. 38 1. 50 Tensile Strength (200㎜/min) ASTM D 638 MPa > 14. 5 > 13 > 12 Ø 16 > 11 > 10 Elongation ASTM D 638 % > 360 > 400 > 350 > 400 > 440 > 350 T·S ASTM D 638 % > 98 (48 hrs× 100℃) (42 hrs× 127℃× 5. 7 kgf/㎟ ) > 82 > 90 (240 hrs× 120℃) > 97 (96 hrs× 150℃) > 93 (168 hrs× 135℃) > 96 (168 hrs× 135℃) E·L ASTM D 638 % > 85 (48 hrs× 100℃) (42 hrs× 127℃× 5. 7 kgf/㎟ ) > 76 > 80 (240 hrs× 120℃) > 89 (96 hrs× 150℃) > 86 (168 hrs× 135℃) > 95 (168 hrs× 135℃) ASTM D 2863 - 30 28 34 30 Durometer - 75 72 85 75 90 90 - - After aging (Retained) Oxygen Index Hardness (Shore A) Volume Resistivity ASTM D 257 Ω·㎝ - - - 1. 8× 1014 ML 1+4100℃/180℃ t 90 ASTM D 1646 - - - 55 / t 90 -3’ 00” 36 / t 90 -3’ 00” - 0 ASTM E 662 % 280 - 200 - 150 Max 110 T·S ASTM D 638 % > 81 > 94 (After 18 Hrs at 120℃) (After 24 Hrs at 100℃) > 80 (24 hrs× 100℃) > 70 (24 hrs× 100℃) > 85 (24 hrs× 100℃) > 83 (24 hrs× 100℃) E·L ASTM D 638 % > 82 > 85 (After 18 Hrs at 120℃) (After 24 Hrs at 100℃) > 75 (24 hrs× 100℃) > 70 (24 hrs× 100℃) > 86 (24 hrs× 100℃) Smoke Density Oil resistance (ASTM #2 Oil) www. dymcom. co. kr Page 3

03 Rubber Compound - Sheath Halogen Free Flame Retardant Sheath Product Grade DYP-10705 NFR DYM-8810 NFR Description HFFR thermosetting MUD Retardant Compound HFFR Thermosetting Compound Application Shipboard cable & Off shore cable Excellent mechanical properties & satisfy the spec. NEK 606, SHF 2(IEC) spec. IEC 60092 -359(SHF 2) Benefits Physical Properties (Mean Values) HFFR Insulation DYM-8410 NFR DYM-8712 NFR Thermosetting inorganic filler HFFR Insulation Compound Bedding Satisfy the spec. IEC 60092, 60502. Electric train and Railway DYM-8713 NFR HFFR Insulation Compound Electric train and marine cable Excellent mechanical properties & Flame Retardant (UL-VW 1 Pass) (Curing Method : Steam Pressure) Test Method Units Density at 23℃ ASTM D 1505 g/㎤ 1. 50 1. 41 1. 53 1. 34 1. 38 Tensile Strength (200㎜/min) ASTM D 638 MPa > 12 > 6 > 12 > 11 Elongation ASTM D 638 % > 195 > 550 > 500 > 350 T·S ASTM D 638 % 〉90 (168 hrs× 135℃) 〉90 (168 hrs× 120℃) - 〉90 (96 hrs× 150℃) 〉90 (168 hrs× 135℃) E·L ASTM D 638 % 〉85 (168 hrs× 135℃) 〉80 (168 hrs× 120℃) - 〉90 (96 hrs× 150℃) 〉90 (168 hrs× 135℃) ASTM D 2863 - 35 31 31 32 40 (VW 1 Pass) Durometer - 90 83 85 80 83 2. 8× 1014 After aging (Retained) Oxygen Index Hardness (Shore A) Volume Resistivity ASTM D 257 Ω·㎝ - - - 7. 7× 1015 Halogen content IEC 60754 -1 % 〈 0. 1 Smoke Density ASTM E 662 % 120(t=0. 5 mm) 90(t=0. 5 mm) 150(t=0. 5 mm) Max 120(NF) Max 110(NF) T·S IEC 60811 -2 -1 % 〉80 (After 24 Hrs at 100℃) 〉80 (After 18 Hrs at 120℃) - 〉80 (24 hrs× 100℃) E·L IEC 60811 -2 -1 % 〉80 (After 24 Hrs at 100℃) 〉70 (After 18 Hrs at 120℃) - 〉70 (24 hrs× 100℃) 〉80 (24 hrs× 100℃) Oil resistance (ASTM #2 Oil) www. dymcom. co. kr Page 4

03 Rubber Compound RUBBER COMPOUND Filling Compound Power / Industrial / Shipboard Etc. INSULATION Power Electric Cables Shipboard Cables Off-Shore Cables Industrial Cables DYM-8452 Etc DYP-6609 R(LV) DYP-6602 P(25 kv) DYP-6601 P(35 kv) SHEATHING CR Jacketing CSM Jacketing EVM Jacketing CPE Jacketing www. dymcom. co. kr Ø DYI-7701 R(UL-62 Class 15), DYI-7704 R(mining cable/ICEA S 19 -18) Ø DYS-8603 R(105℃), DYS-8701 R(Heavy Duty) Ø Halogen Free Compound , DYP-10703 FR, DYP-10704 NFR Ø DYM-801 FR(Train Cables). DYM-8710 FR(Halogen Free) Page 5

03 Filling Compound : DYM-8452 NFR Test Items Test Method Units DYM-8452 NFR Specific Gravity ASTM D 792 - 1. 80 ML 1+4 100℃ ASTM D 1646 - 27. 1 Hardness (Shore A) ASTM D 2240 - 88 Tensile Strength ASTM D 638 Mpa 0. 7 Elongation ASTM D 638 % 25 • Press Sheet Conditions : 170℃. 5 min, 200 kg/㎠ • Data should not be used for specification work. www. dymcom. co. kr Page 6

03 Filling Compound 1 State before DYM-8452 NFR extrusion. (Cabling) 2 EXTRUSION WORK 4 Jacketing Extrusion Work On DYM-8452 NFR 5 Examination After Product 3 DYM-8452 NFR www. dymcom. co. kr Page 7

04 Silane Cross Linkable Compound DYM's Silane Curing Compound distribution EPR DYM-7610 NFR. Insulation HF-XLPE DYM-7611 NFR, DYM-7615 NFR. SHF 1 DYM-8611 NFR. SFH 2 DYM-8610 NFR. Jacketing Semi. Conductive www. dymcom. co. kr Conductor Screen Insulation Screen DYM-500. DYM-600. Page 1

04 Silane Cross Linkable Compound Mechanical Properties DYMGrade 7610 NFR EPR Insulation 7611 NFR 8611 NFR Power Cable & Shipboard Cable Jacketing Hot Pressure (80℃) Cold Impact (℃) Oxygen Index (%) HCl Content (%) Smoke Density (Ds max) Density (g/㎤) Hardness Shore D 8 290 5 -40 18 0. 1 180 1. 28 833) 15 250 5 -40 30 0. 1 90 1. 30 913) Thermosetting Insulation compound ( Silane Cross-linking) - OA Insulation Grade. Flame retardant (VW 1 Pass, Ro. HS Pass) 13 240 5 -40 30 2. 0 120 1. 25 953) Thermosetting Jacketing compound (Silane cross-linking Jacketing), IEC 60092 -359 SHF 2 11 250 5 -40 40 0. 1 90 1. 45 973 Thermosetting Jacketing compound (Silane cross-linking Jacketing), Excellent Flexibility. 12 250 5 -40 35 0. 1 100 1. 45 953 Density (g/㎤) Hardness Shore A Moisture Content (Karl Fischer) Thermosetting Insulation compound (Silane cross-linking Insulation) IEC 60092 -351 TYPE , JIS C 3410(1999’) EPDM, Application 500 Semi-Conductive Compound 600 Semi-Conductive Compound Memo. Other Properties Elongation (%) Mechanical Properties DYMGrade Fire Properties Tensile Strength (MPa) Power Cable &Shipboard Cable Thermosetting Insulation compound (Silane cross-linking Insulation), Flame retardant. Insulation((105/125℃) IEC 60092 -351 TYPE HF XLPE, BS 6724 7615 NFR HFFR Insulation 8610 NFR General Description Application Thermo mechanical properties General Description Tensile Strength (MPa) Elongation (%) Bonded Conductor Screen for Medium Voltage. (Up to 25 k. V) 13. 5 180 Strippable Insulation Screen for Medium Voltage. (Up to 25 k. V) 13. 5 200 After Aging (variation) (121℃, 165 hrs) Tensile Strength (MPa) Elongation (%) Volume Resistivity 23℃ 90℃ 〈10% 〈15% 〈100 〈500 1. 16 97 〈500 〈10% 〈15% 〈100 〈500 1. 16 95 〈500 Note: 1)IEC 60811 -3 -1 121℃, 2)Specimen thickness: 3㎜ , 3) Shore A www. dymcom. co. kr Page 2

04 Silane Cross Linkable Compound Insulation Product Grade Jacketing DYM-7610 NFR DYM-7611 NFR DYM-7615 NFR DYM – 8610 NFR DYM – 8611 NFR Description EPR Insulation HF-XLPE Insulation IEC 60092 SHF 2 HF- Flame retardant Application Thermosetting Insulation EPR Compound. IEC 60092351 EPR, JISC 3410(1999’) Benefits Good processing & mechanical properties Good processing & flame retardant Physical Properties (Mean Values) Thermosetting Insulation Compound. Thermosetting Jacketing Insulation Compound. Ro. Hs Pass and UL 94 compound (Silane cross. IEC 60092 -351 HFlinking Jacketing), XLPE, IEC 60092 -359 SHF 2 IEC 60502, BS 6724 VW 1 Pass Thermosetting Jacketing compound (Silane crosslinking Jacketing), Excellent Flexibility. Test Method Units Specific Gravity at 23℃ ASTM D 1505 g/㎤ 1. 28 1. 30 1. 25 1. . 45 1. 45 Tensile Strength IEC 60811 -1 -1 MPa > 10 > 15 > 13 > 11 > 12 Elongation at break IEC 60811 -1 -1 % > 290 > 250 > 240 > 250 T·S IEC 60811 -1 -2 % > 95 > 90 > 85 > 90 E·L IEC 60811 -1 -2 % > 85 > 90 > 85 Oxygen Index ASTM D 2863 % 18 30 30 40 35 Hardness (Shore A) ASTM D 2240 - 83 91 95 97 95 Moisture Content Karl Fischer ppm < 500 < 500 Halogen content IEC 60754 -1 % 0. 1 2 0. 1 Smoke Density (Flaming Mode) ASTM E 662 - < 180 < 90 < 130 < 90 < 100 ASTM D 257 / ICEA S-66 -524 ΩㆍM > 1. 4 x 1016 Ωㆍ㎝ > 1. 0 x 1015 Ωㆍ㎝ > 1. 0 x 1014 Ωㆍ㎝ After aging (Retained) (121, 135℃, 168 hrs) Volume Resistivity 23℃ www. dymcom. co. kr Page 3

04 Silane Cross Linkable Compound Semi- Conductive Product Grade DYM- 500 Conductor Screen Description DYM- 600 Insulation Screen Silane Crosslinkable semiconductive conductor shielding Compound. Application Silane Crosslinkable semiconductive Insulation shielding Compound. Good processing & mechanical properties Benefits Physical Properties (Mean Values) Good processing & Easy Strip Type Test Method Units Specific Gravity at 23℃ ASTM D 1505 g/㎤ 1. 15 1. 20 Tensile Strength IEC 60811 -1 -1 MPa > 14 > 13 Elongation at break IEC 60811 -1 -1 % > 200 T·S IEC 60811 -1 -2 % > 90 E·L IEC 60811 -1 -2 % > 85 Stripping Force for XLPE(180) ASTM D 903 kgf/12. 7 m m - 3 Gel Content ASTM D 2765 % 60 60 Karl Fischer ppm < 500 E. S. C. R 100% "IGEPAL"F 20 ASTM D 1693 hrs > 200 Brittleness Temperature ASTM D 746 ℃ -50 23℃ ICEA S-94 -649 ΩㆍM < 50 90℃ ICEA S -94 -649 ΩㆍM < 300 After aging (Retained) (121, 135℃, 168 hrs) Moisture Content Volume Resistivity www. dymcom. co. kr Page 4

05 Black Color Master Batch v DYM-880 BK v DYM-810 BK Jacketing compound for Outdoor Cables - Black Color M/B for Pigment Property Test Method Unit Grade DYM-880 BK DYM-810 BK Density at 23℃ ASTM D 1505 g/cm 3 0. 99 1. 06 Tensile Strength (25 mm/min) IEC 60811 -1 -1 Mpa 15 14 Elongation IEC 60811 -1 -1 % 250 230 Carbon Black Content IEC 60811 -4 -1 % 6. 6 25. 4 Melting Point ASTM D 2117 ℃ 105 100 Description : DYM-880 BK & 810 BK is a carbon black master batch compound for the coloring of Power and Communication cables, based on Polyethylene. This is very effective in UV absorption and has a excellent carbon black dispersion, good extrusion process ability and good heat resistance. www. dymcom. co. kr Page 1

Toward the successful future Thanks for your kind attention!

Contents Introduce The Company Products Quality Control System Chapter 1 Chapter 2 Chapter 3

01 Quality Assurance The quality guarantee system ISO 9001 ; 2008 + ISO 14001 ; 2004 + OHSAS 18001 ; 2007 + Customer’s Quality Requirement + International Specifications DYM’s Quality Assurance www. dymcom. co. kr Page 1

02 Quality Inspection - Smoothness (Products) Smoothness Silo Gate ON/OFF Surface Smoothness tester 싸이 클론 / 호퍼로더 (용량 : 약 1 kg) 10~300배율 카메라 ☞ Test Extruder Guide 권치기 부착 Take-Up Tape 검사용 시료 채취 부위: 반제품 자동 이송 600 kg/1 hr을 기준하여 중간 부분 500㎛ Surface Smoothness Test 1. Purpose : Checking the level of smoothness and protrusions Examination of the extruded tape(20~40 times) Protrusion size and number 2. Method : To take the compound sample from each lot, then continually extrude and making the tape. www. dymcom. co. kr Page 2

02 Quality Inspection Item : Tensile Tester & Mooney Viscometer (Products) Tensile Test u Check Point - Tensile Strength (Mpa) - Elongation(%) www. dymcom. co. kr Mooney Viscosity Mooney Scorch Page 3

02 Quality Inspection Item : Rheometer & Densimeter (Products) O. D. R < Check Point > (Torque and tc 90) Tmax / Tmin / ts 1 / tc 90 www. dymcom. co. kr Densimeter < Check Point > - Density Page 4

02 Quality Inspection Item : Oven Tester & Volume Resistivity (Products) V A DC VR at high temp. Oven Tester < Check Point > - DC VR at 90℃ - HOT CREEP TEST www. dymcom. co. kr Volume Resistivity (Wheatstone bridge Method) Page 5

02 Quality Inspection Item : Ageing Tester & Curing Rate (Products) v Ageing Tester < Check Point > -Variation after ageing www. dymcom. co. kr v Curing Rate < Check Point > - Gel content(%) Page 6

02 Quality Inspection Item : Moisture Content -Karl Fischer Method (Products) ⑬ Moisture content (Karl Fischer Method) Item Moisture Content (Karl Fischer) MV compound 425. 8 PPm HV compound 211. 1 PPm Remark Vial (specimen) input <Moisture content Result> www. dymcom. co. kr Page 7

02 Quality Inspection Item : Pressure test at high Temperature & MI Tester Pressure test at high temperature § § MI Tester < Check Point > - Hot deformation - Melt Index < Method > - IEC 60811 -3 -1 www. dymcom. co. kr Page 8

03 Managements of Cable Compounds 1 Storage 2 Unpacking & Hopper Loading 3 Extrusion Processing www. dymcom. co. kr ① Temperature of compound is controlled over 18~48℃ ② Humid of controlled 40~60% ③ Products must be stored in clean space and in closed warehouse ① Box & Pallet must be controlled clearly before hopper loading ② The air in Clean Room must be controlled clearly ③ Clean Room’s Class is 1, 000~10, 000 ① Clean the extruder & Screw, using Cleaning Compounds ② Protect the amber on connection of the Cross-Head ③ Use the clean Screw Mesh. Page 9

Toward the successful future Thanks for your kind attention!