382f6c8ca10370e1d7dccac13572057c.ppt

- Количество слайдов: 51

Complying with SSPC-PA 2, “Measurement of Dry Coating Thickness with Magnetic Gages” William D. Corbett KTA-Tator, Inc.

Complying with SSPC-PA 2, “Measurement of Dry Coating Thickness with Magnetic Gages” William D. Corbett KTA-Tator, Inc.

Complying with SSPC-PA 2 • Webinar Content Ø Overview and Purpose of SSPC-PA 2 Ø Definitions Ø Proper Gage Use Ø Acquisition of Measurements Ø Frequency of Measurements Ø Tolerance of Measurements Ø Measuring Coating Thickness on Steel Beams (girders) Ø Measuring Coating Thickness on Test Panels Ø Potential Changes to SSPC-PA 2 (2011/2012)

Complying with SSPC-PA 2 • Webinar Content Ø Overview and Purpose of SSPC-PA 2 Ø Definitions Ø Proper Gage Use Ø Acquisition of Measurements Ø Frequency of Measurements Ø Tolerance of Measurements Ø Measuring Coating Thickness on Steel Beams (girders) Ø Measuring Coating Thickness on Test Panels Ø Potential Changes to SSPC-PA 2 (2011/2012)

Learning Objectives/Outcomes • Completion of this webinar will enable the participant to: Ø Describe the purpose of SSPC-PA 2 Ø Describe the differences between Type 1 and Type 2 gages Ø Describe the processes associated with calibration, verification of accuracy and adjustment Ø Explain Base Metal Reading acquisition Ø Describe the differences between measurement acquisition using manual verses electronic gages Ø Describe the frequency and tolerance of measurements Ø Describe the measurement acquisition process for steel beams. laydowns and test panels

Learning Objectives/Outcomes • Completion of this webinar will enable the participant to: Ø Describe the purpose of SSPC-PA 2 Ø Describe the differences between Type 1 and Type 2 gages Ø Describe the processes associated with calibration, verification of accuracy and adjustment Ø Explain Base Metal Reading acquisition Ø Describe the differences between measurement acquisition using manual verses electronic gages Ø Describe the frequency and tolerance of measurements Ø Describe the measurement acquisition process for steel beams. laydowns and test panels

Overview and Purpose of SSPC-PA 2 • Describes the procedures to measure thickness of dry, nonmagnetic coatings applied to magnetic substrates • Measurements are acquired using commercially available gages (two “types”) • Procedures for gage adjustment & measurement acquisition are described • Procedure for determining conformance to specified thickness range over extended areas is described

Overview and Purpose of SSPC-PA 2 • Describes the procedures to measure thickness of dry, nonmagnetic coatings applied to magnetic substrates • Measurements are acquired using commercially available gages (two “types”) • Procedures for gage adjustment & measurement acquisition are described • Procedure for determining conformance to specified thickness range over extended areas is described

Definitions • • • Gage Reading Spot Measurement Calibration Verification of Accuracy Gage Adjustment Coating Thickness Standard (Test Block) Shim (Foil) Dry Film Thickness Reference Standard Accuracy Structure

Definitions • • • Gage Reading Spot Measurement Calibration Verification of Accuracy Gage Adjustment Coating Thickness Standard (Test Block) Shim (Foil) Dry Film Thickness Reference Standard Accuracy Structure

Gage Descriptions • Gage type is determined by magnetic properties employed to measure thickness (not the readout mode) Ø Type 1 – Pull-off Gages Ø Type 2 – Electronic Gages • Gages not addressed by SSPC-PA 2 Ø Measurement of coatings on non-ferrous metal surfaces Ø Measurement of coatings on non-ferrous surfaces § To qualify for use, gages must have an accuracy of +/- 5% or better (0. 1 mil or better when < 1 mil DFT)

Gage Descriptions • Gage type is determined by magnetic properties employed to measure thickness (not the readout mode) Ø Type 1 – Pull-off Gages Ø Type 2 – Electronic Gages • Gages not addressed by SSPC-PA 2 Ø Measurement of coatings on non-ferrous metal surfaces Ø Measurement of coatings on non-ferrous surfaces § To qualify for use, gages must have an accuracy of +/- 5% or better (0. 1 mil or better when < 1 mil DFT)

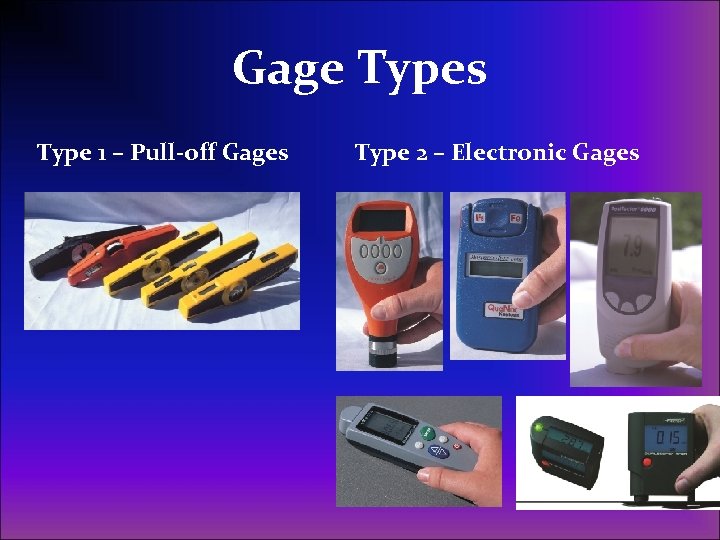

Gage Types Type 1 – Pull-off Gages Type 2 – Electronic Gages

Gage Types Type 1 – Pull-off Gages Type 2 – Electronic Gages

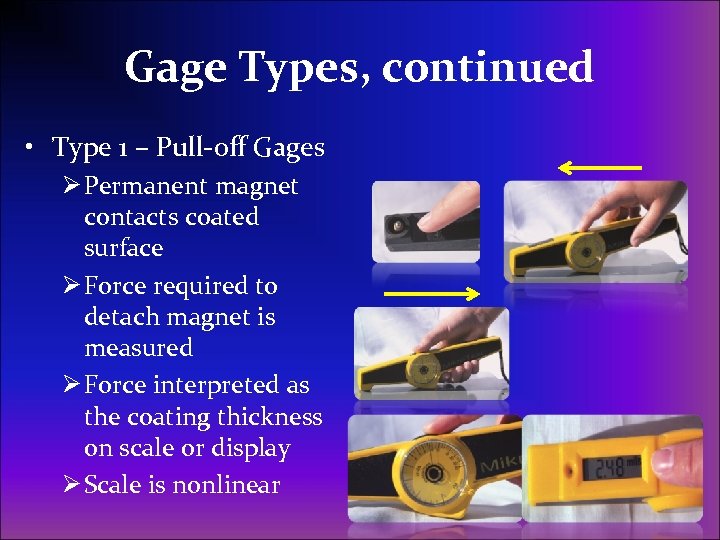

Gage Types, continued • Type 1 – Pull-off Gages Ø Permanent magnet contacts coated surface Ø Force required to detach magnet is measured Ø Force interpreted as the coating thickness on scale or display Ø Scale is nonlinear

Gage Types, continued • Type 1 – Pull-off Gages Ø Permanent magnet contacts coated surface Ø Force required to detach magnet is measured Ø Force interpreted as the coating thickness on scale or display Ø Scale is nonlinear

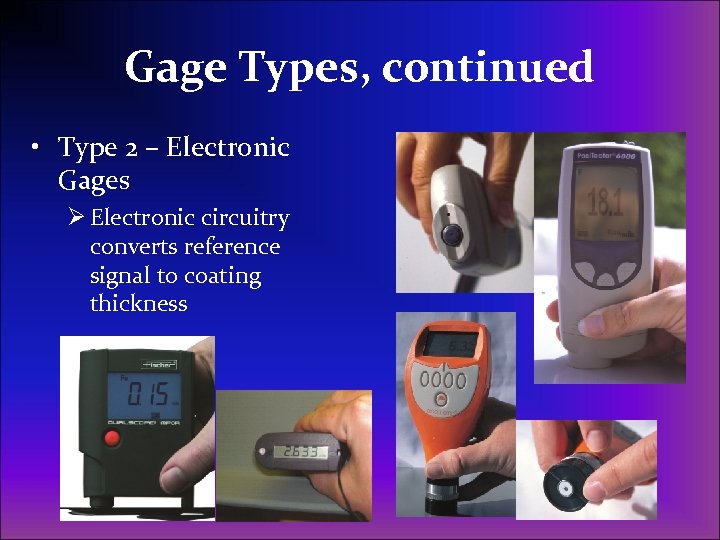

Gage Types, continued • Type 2 – Electronic Gages Ø Electronic circuitry converts reference signal to coating thickness

Gage Types, continued • Type 2 – Electronic Gages Ø Electronic circuitry converts reference signal to coating thickness

Gage Calibration • Performed by the gage manufacturer or qualified laboratory • Certificate of calibration traceable to a National Metrology Institute required • No standard calibration interval (established based on experience & work environment) • One year interval is common

Gage Calibration • Performed by the gage manufacturer or qualified laboratory • Certificate of calibration traceable to a National Metrology Institute required • No standard calibration interval (established based on experience & work environment) • One year interval is common

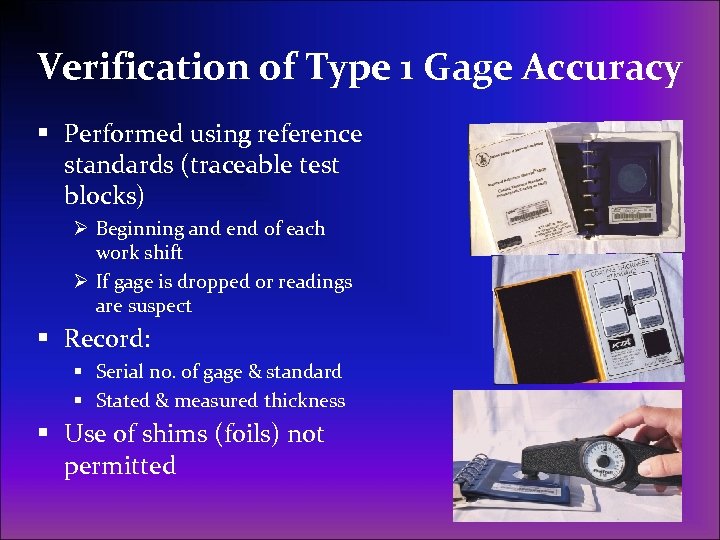

Verification of Type 1 Gage Accuracy § Performed using reference standards (traceable test blocks) Ø Beginning and end of each work shift Ø If gage is dropped or readings are suspect § Record: § Serial no. of gage & standard § Stated & measured thickness § Use of shims (foils) not permitted

Verification of Type 1 Gage Accuracy § Performed using reference standards (traceable test blocks) Ø Beginning and end of each work shift Ø If gage is dropped or readings are suspect § Record: § Serial no. of gage & standard § Stated & measured thickness § Use of shims (foils) not permitted

Verification of Type 1 Gage Accuracy • Single Point Verification ØSelect one reference test block representing the mid-range of the anticipated coating thickness ØE. g. , 4 -6 mils (100 -150 µm), select 5 mil (125 µm) reference standard • Tw 0 Point Verification ØSelect a reference test block below and above the median anticipated coating thickness ØE. g. , 5 mils (125 µm), select 3 mil (75 µm) and 7 mil (175 µm) reference standards

Verification of Type 1 Gage Accuracy • Single Point Verification ØSelect one reference test block representing the mid-range of the anticipated coating thickness ØE. g. , 4 -6 mils (100 -150 µm), select 5 mil (125 µm) reference standard • Tw 0 Point Verification ØSelect a reference test block below and above the median anticipated coating thickness ØE. g. , 5 mils (125 µm), select 3 mil (75 µm) and 7 mil (175 µm) reference standards

Verification of Type 1 Gage Accuracy • Most Type 1 gages cannot be “adjusted” • Adjustments to the helical spring may void the gage warranty • Combined tolerance of gage and reference standard determines gage accuracy ØE. g. , if gage accuracy is 5% and reference standard accuracy is 3%, combined tolerance is ~6%, calculated as: √ 52 + 32 ØOn a 10 mil reference standard, the gage reading can range from 9. 4 -10. 6 mils

Verification of Type 1 Gage Accuracy • Most Type 1 gages cannot be “adjusted” • Adjustments to the helical spring may void the gage warranty • Combined tolerance of gage and reference standard determines gage accuracy ØE. g. , if gage accuracy is 5% and reference standard accuracy is 3%, combined tolerance is ~6%, calculated as: √ 52 + 32 ØOn a 10 mil reference standard, the gage reading can range from 9. 4 -10. 6 mils

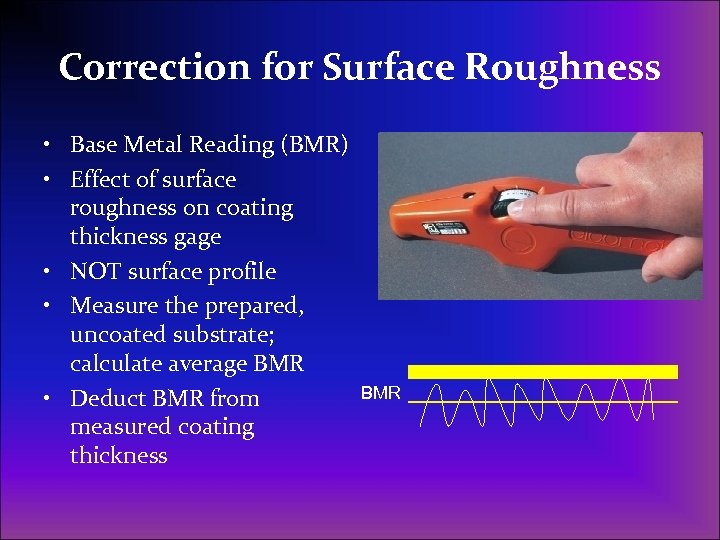

Correction for Surface Roughness • Base Metal Reading (BMR) • Effect of surface roughness on coating thickness gage • NOT surface profile • Measure the prepared, uncoated substrate; calculate average BMR • Deduct BMR from measured coating thickness BMR

Correction for Surface Roughness • Base Metal Reading (BMR) • Effect of surface roughness on coating thickness gage • NOT surface profile • Measure the prepared, uncoated substrate; calculate average BMR • Deduct BMR from measured coating thickness BMR

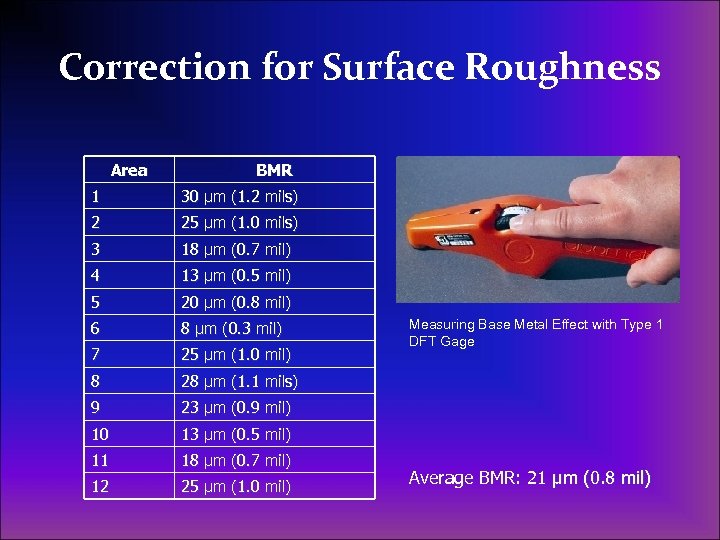

Correction for Surface Roughness Area BMR 1 30 µm (1. 2 mils) 2 25 µm (1. 0 mils) 3 18 µm (0. 7 mil) 4 13 µm (0. 5 mil) 5 20 µm (0. 8 mil) 6 8 µm (0. 3 mil) 7 25 µm (1. 0 mil) 8 28 µm (1. 1 mils) 9 23 µm (0. 9 mil) 10 13 µm (0. 5 mil) 11 18 µm (0. 7 mil) 12 25 µm (1. 0 mil) Measuring Base Metal Effect with Type 1 DFT Gage Average BMR: 21 µm (0. 8 mil)

Correction for Surface Roughness Area BMR 1 30 µm (1. 2 mils) 2 25 µm (1. 0 mils) 3 18 µm (0. 7 mil) 4 13 µm (0. 5 mil) 5 20 µm (0. 8 mil) 6 8 µm (0. 3 mil) 7 25 µm (1. 0 mil) 8 28 µm (1. 1 mils) 9 23 µm (0. 9 mil) 10 13 µm (0. 5 mil) 11 18 µm (0. 7 mil) 12 25 µm (1. 0 mil) Measuring Base Metal Effect with Type 1 DFT Gage Average BMR: 21 µm (0. 8 mil)

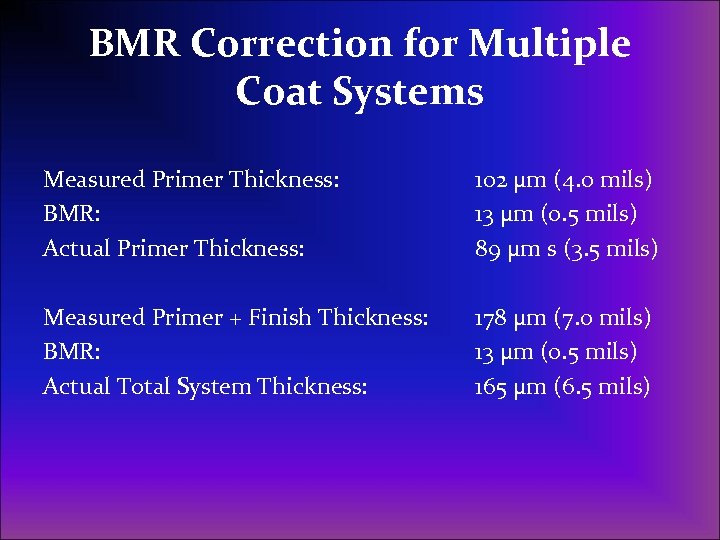

BMR Correction for Multiple Coat Systems Measured Primer Thickness: BMR: Actual Primer Thickness: 102 µm (4. 0 mils) 13 µm (0. 5 mils) 89 µm s (3. 5 mils) Measured Primer + Finish Thickness: BMR: Actual Total System Thickness: 178 µm (7. 0 mils) 13 µm (0. 5 mils) 165 µm (6. 5 mils)

BMR Correction for Multiple Coat Systems Measured Primer Thickness: BMR: Actual Primer Thickness: 102 µm (4. 0 mils) 13 µm (0. 5 mils) 89 µm s (3. 5 mils) Measured Primer + Finish Thickness: BMR: Actual Total System Thickness: 178 µm (7. 0 mils) 13 µm (0. 5 mils) 165 µm (6. 5 mils)

Correction for Surface Roughness § What if access to blast cleaned steel is not available (already coated)? § Appendix A 2. 3 addresses smooth surface adjustment § Verify gage accuracy on a smooth surface (per gage manufacturer instructions) § Deduct “assumed” approximate correction value from each gage reading (see Table A 2)

Correction for Surface Roughness § What if access to blast cleaned steel is not available (already coated)? § Appendix A 2. 3 addresses smooth surface adjustment § Verify gage accuracy on a smooth surface (per gage manufacturer instructions) § Deduct “assumed” approximate correction value from each gage reading (see Table A 2)

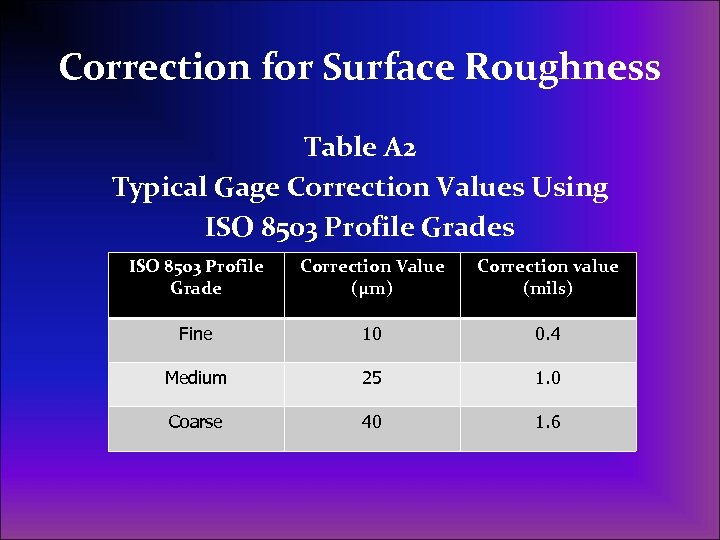

Correction for Surface Roughness Table A 2 Typical Gage Correction Values Using ISO 8503 Profile Grades ISO 8503 Profile Grade Correction Value (µm) Correction value (mils) Fine 10 0. 4 Medium 25 1. 0 Coarse 40 1. 6

Correction for Surface Roughness Table A 2 Typical Gage Correction Values Using ISO 8503 Profile Grades ISO 8503 Profile Grade Correction Value (µm) Correction value (mils) Fine 10 0. 4 Medium 25 1. 0 Coarse 40 1. 6

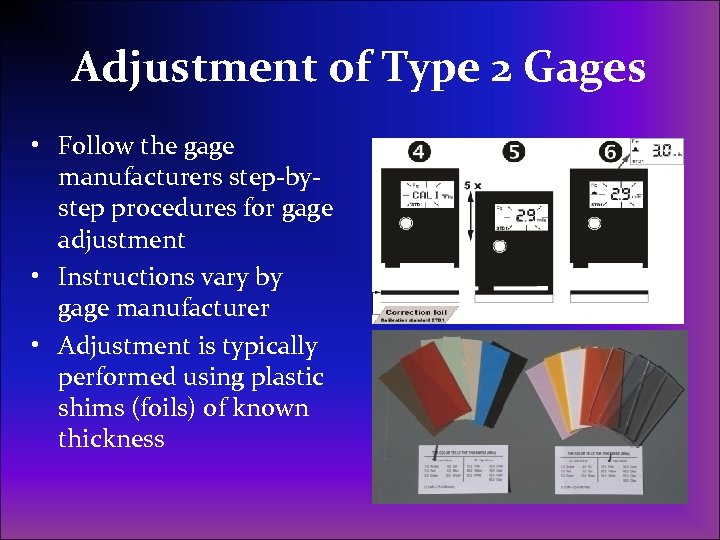

Adjustment of Type 2 Gages • Follow the gage manufacturers step-bystep procedures for gage adjustment • Instructions vary by gage manufacturer • Adjustment is typically performed using plastic shims (foils) of known thickness

Adjustment of Type 2 Gages • Follow the gage manufacturers step-bystep procedures for gage adjustment • Instructions vary by gage manufacturer • Adjustment is typically performed using plastic shims (foils) of known thickness

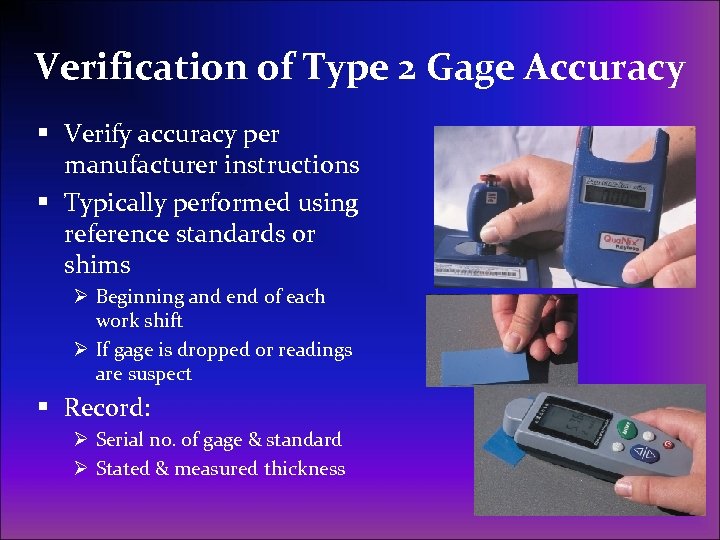

Verification of Type 2 Gage Accuracy § Verify accuracy per manufacturer instructions § Typically performed using reference standards or shims Ø Beginning and end of each work shift Ø If gage is dropped or readings are suspect § Record: Ø Serial no. of gage & standard Ø Stated & measured thickness

Verification of Type 2 Gage Accuracy § Verify accuracy per manufacturer instructions § Typically performed using reference standards or shims Ø Beginning and end of each work shift Ø If gage is dropped or readings are suspect § Record: Ø Serial no. of gage & standard Ø Stated & measured thickness

Verification of Type 2 Gage Accuracy • Single Point Verification ØSame as described for Type 1 gages ØCan use reference blocks or shims (per gage manufacturer) • Tw 0 Point Verification ØSame as described for Type 1 gages ØCan use reference blocks or shims (per gage manufacturer)

Verification of Type 2 Gage Accuracy • Single Point Verification ØSame as described for Type 1 gages ØCan use reference blocks or shims (per gage manufacturer) • Tw 0 Point Verification ØSame as described for Type 1 gages ØCan use reference blocks or shims (per gage manufacturer)

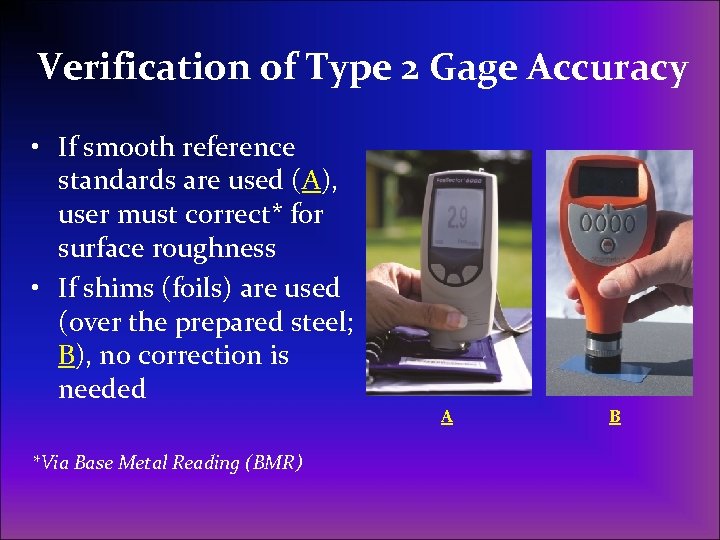

Verification of Type 2 Gage Accuracy • If smooth reference standards are used (A), user must correct* for surface roughness • If shims (foils) are used (over the prepared steel; B), no correction is needed A *Via Base Metal Reading (BMR) B

Verification of Type 2 Gage Accuracy • If smooth reference standards are used (A), user must correct* for surface roughness • If shims (foils) are used (over the prepared steel; B), no correction is needed A *Via Base Metal Reading (BMR) B

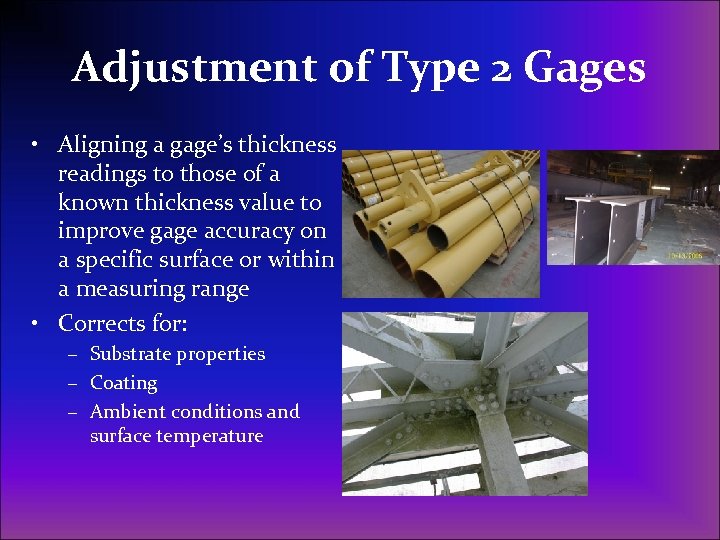

Adjustment of Type 2 Gages • Aligning a gage’s thickness readings to those of a known thickness value to improve gage accuracy on a specific surface or within a measuring range • Corrects for: – Substrate properties – Coating – Ambient conditions and surface temperature

Adjustment of Type 2 Gages • Aligning a gage’s thickness readings to those of a known thickness value to improve gage accuracy on a specific surface or within a measuring range • Corrects for: – Substrate properties – Coating – Ambient conditions and surface temperature

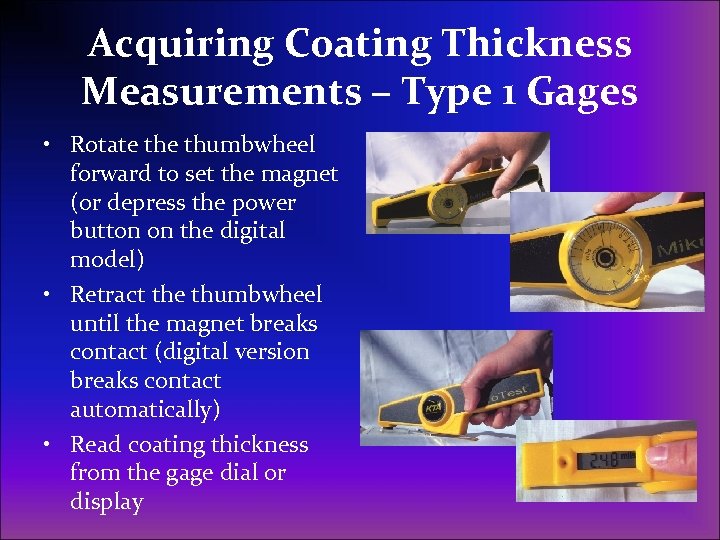

Acquiring Coating Thickness Measurements – Type 1 Gages • Rotate thumbwheel forward to set the magnet (or depress the power button on the digital model) • Retract the thumbwheel until the magnet breaks contact (digital version breaks contact automatically) • Read coating thickness from the gage dial or display

Acquiring Coating Thickness Measurements – Type 1 Gages • Rotate thumbwheel forward to set the magnet (or depress the power button on the digital model) • Retract the thumbwheel until the magnet breaks contact (digital version breaks contact automatically) • Read coating thickness from the gage dial or display

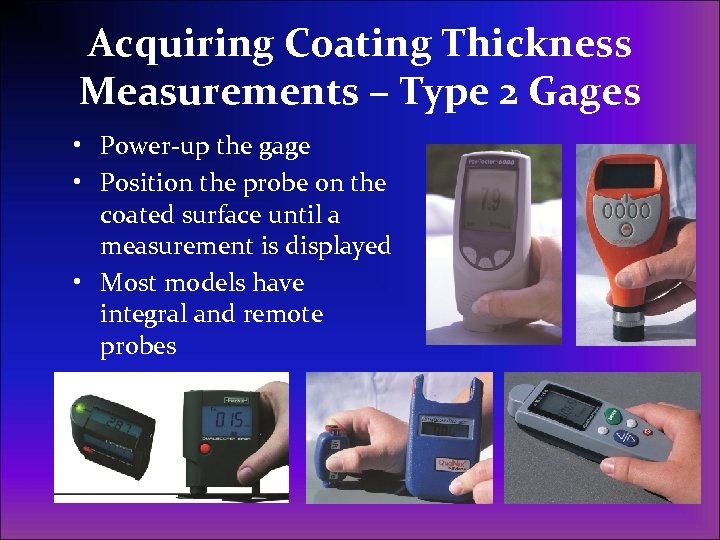

Acquiring Coating Thickness Measurements – Type 2 Gages • Power-up the gage • Position the probe on the coated surface until a measurement is displayed • Most models have integral and remote probes

Acquiring Coating Thickness Measurements – Type 2 Gages • Power-up the gage • Position the probe on the coated surface until a measurement is displayed • Most models have integral and remote probes

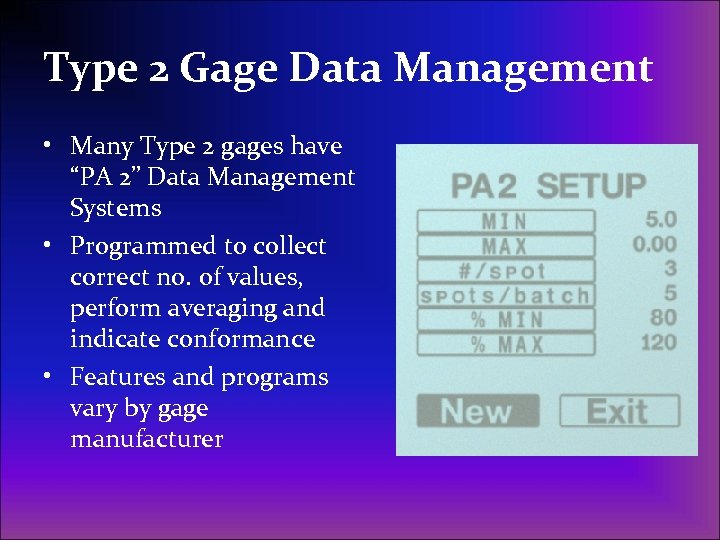

Type 2 Gage Data Management • Many Type 2 gages have “PA 2” Data Management Systems • Programmed to collect correct no. of values, perform averaging and indicate conformance • Features and programs vary by gage manufacturer

Type 2 Gage Data Management • Many Type 2 gages have “PA 2” Data Management Systems • Programmed to collect correct no. of values, perform averaging and indicate conformance • Features and programs vary by gage manufacturer

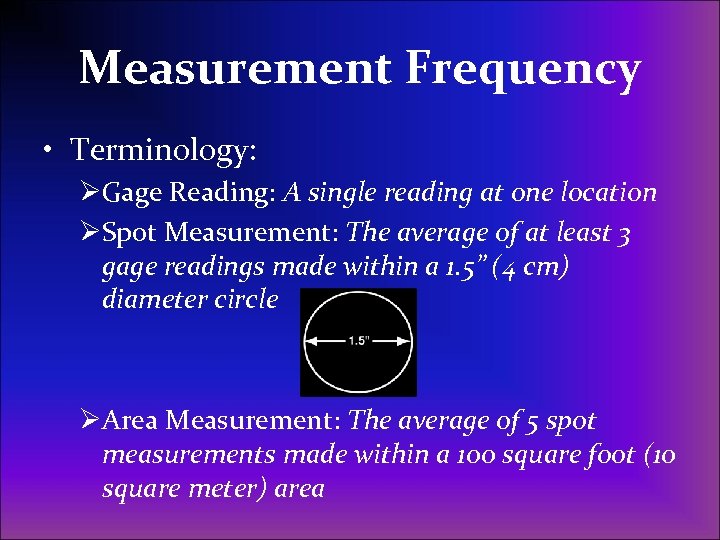

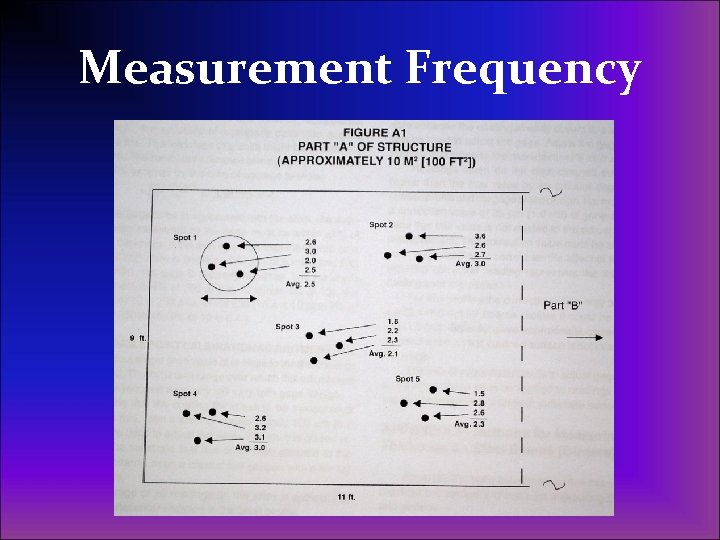

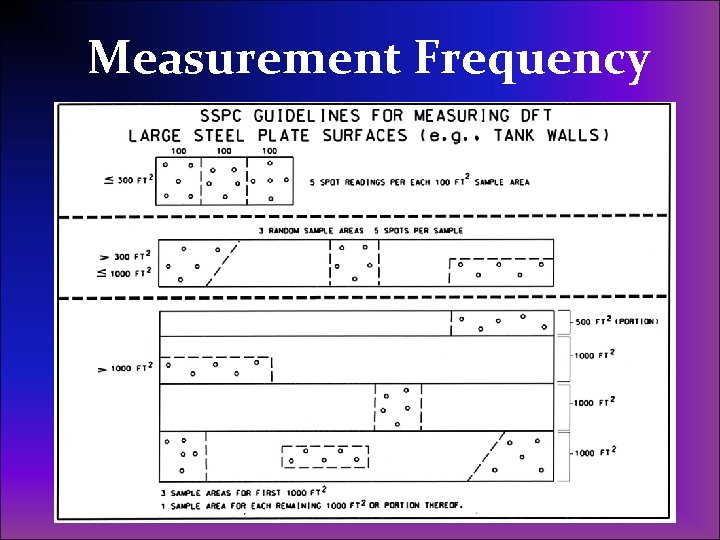

Measurement Frequency • Terminology: ØGage Reading: A single reading at one location ØSpot Measurement: The average of at least 3 gage readings made within a 1. 5” (4 cm) diameter circle ØArea Measurement: The average of 5 spot measurements made within a 100 square foot (10 square meter) area

Measurement Frequency • Terminology: ØGage Reading: A single reading at one location ØSpot Measurement: The average of at least 3 gage readings made within a 1. 5” (4 cm) diameter circle ØArea Measurement: The average of 5 spot measurements made within a 100 square foot (10 square meter) area

Measurement Frequency

Measurement Frequency

Measurement Frequency § If the structure is less than 300 square feet, (~28 square meters) each 100 square feet (~10 square meters) is measured § If the structure is between 300 and 1000 square feet (~28 and 100 square meters), arbitrarily select 3 random 100 square foot (~10 square meter) test areas and measure

Measurement Frequency § If the structure is less than 300 square feet, (~28 square meters) each 100 square feet (~10 square meters) is measured § If the structure is between 300 and 1000 square feet (~28 and 100 square meters), arbitrarily select 3 random 100 square foot (~10 square meter) test areas and measure

Measurement Frequency § For structures exceeding 1000 square feet (~100 square meters), arbitrarily select 3 random 100 square feet (~10 square meter) testing areas for the first 1000 square feet (~100 square meters), and 1 random 100 square foot(~10 square meter) testing area for each additional 1000 square feet (100 square meters)

Measurement Frequency § For structures exceeding 1000 square feet (~100 square meters), arbitrarily select 3 random 100 square feet (~10 square meter) testing areas for the first 1000 square feet (~100 square meters), and 1 random 100 square foot(~10 square meter) testing area for each additional 1000 square feet (100 square meters)

Measurement Frequency

Measurement Frequency

Measurement Frequency Example 1 (US Standard) Structure Size: 900 square feet No. of Areas: No. of Spots: 3 areas 3 Areas x 5 Spots/Area = 15 Spots Minimum No. of Gage Readings: 15 Spots x 3 Readings/Spot = 45 Gage Readings

Measurement Frequency Example 1 (US Standard) Structure Size: 900 square feet No. of Areas: No. of Spots: 3 areas 3 Areas x 5 Spots/Area = 15 Spots Minimum No. of Gage Readings: 15 Spots x 3 Readings/Spot = 45 Gage Readings

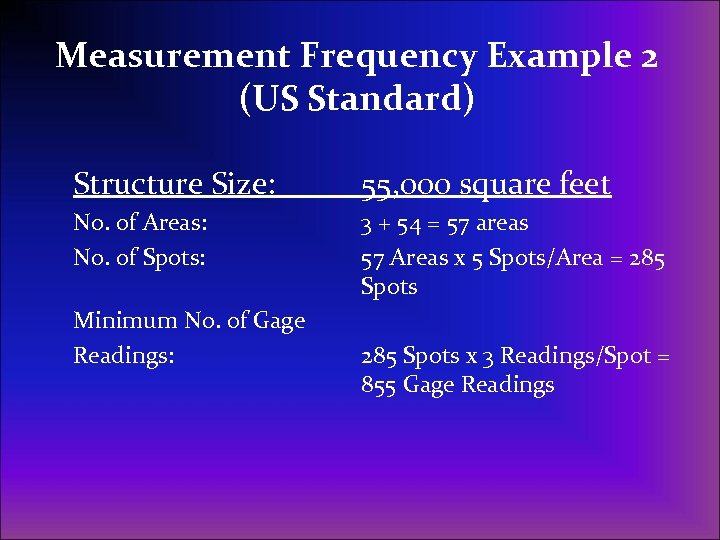

Measurement Frequency Example 2 (US Standard) Structure Size: 55, 000 square feet No. of Areas: No. of Spots: 3 + 54 = 57 areas 57 Areas x 5 Spots/Area = 285 Spots Minimum No. of Gage Readings: 285 Spots x 3 Readings/Spot = 855 Gage Readings

Measurement Frequency Example 2 (US Standard) Structure Size: 55, 000 square feet No. of Areas: No. of Spots: 3 + 54 = 57 areas 57 Areas x 5 Spots/Area = 285 Spots Minimum No. of Gage Readings: 285 Spots x 3 Readings/Spot = 855 Gage Readings

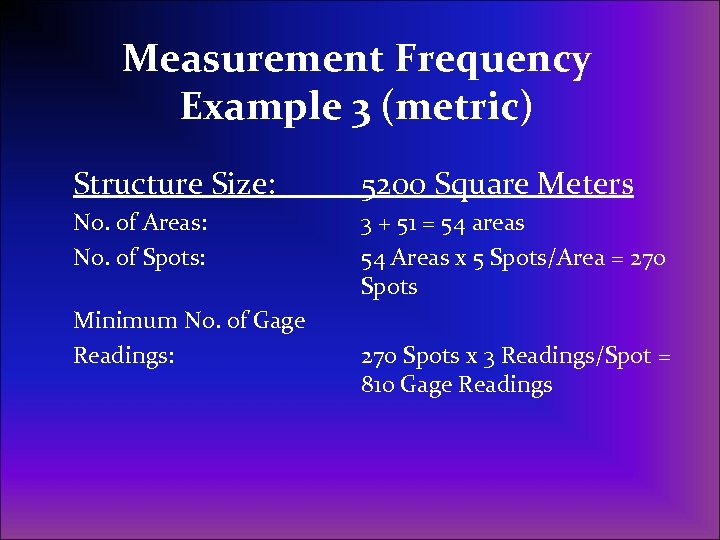

Measurement Frequency Example 3 (metric) Structure Size: 5200 Square Meters No. of Areas: No. of Spots: 3 + 51 = 54 areas 54 Areas x 5 Spots/Area = 270 Spots Minimum No. of Gage Readings: 270 Spots x 3 Readings/Spot = 810 Gage Readings

Measurement Frequency Example 3 (metric) Structure Size: 5200 Square Meters No. of Areas: No. of Spots: 3 + 51 = 54 areas 54 Areas x 5 Spots/Area = 270 Spots Minimum No. of Gage Readings: 270 Spots x 3 Readings/Spot = 810 Gage Readings

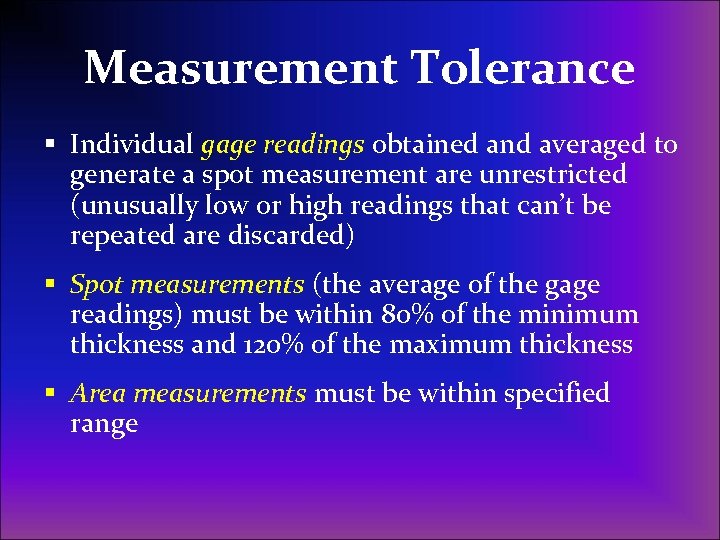

Measurement Tolerance § Individual gage readings obtained and averaged to generate a spot measurement are unrestricted (unusually low or high readings that can’t be repeated are discarded) § Spot measurements (the average of the gage readings) must be within 80% of the minimum thickness and 120% of the maximum thickness § Area measurements must be within specified range

Measurement Tolerance § Individual gage readings obtained and averaged to generate a spot measurement are unrestricted (unusually low or high readings that can’t be repeated are discarded) § Spot measurements (the average of the gage readings) must be within 80% of the minimum thickness and 120% of the maximum thickness § Area measurements must be within specified range

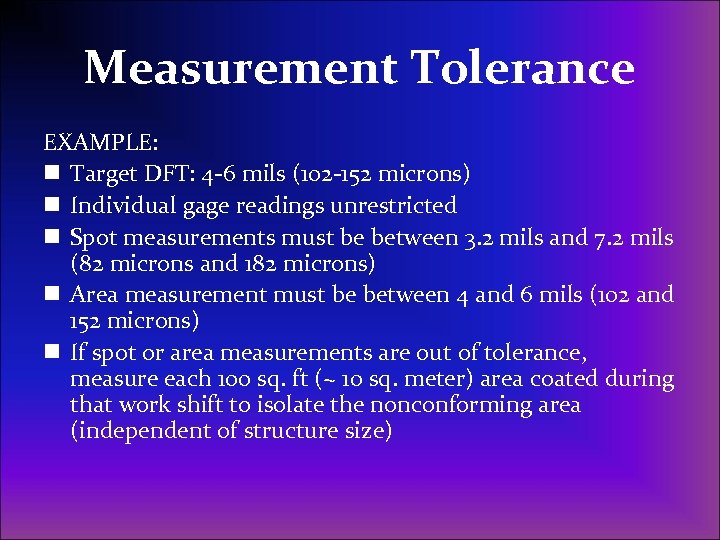

Measurement Tolerance EXAMPLE: n Target DFT: 4 -6 mils (102 -152 microns) n Individual gage readings unrestricted n Spot measurements must be between 3. 2 mils and 7. 2 mils (82 microns and 182 microns) n Area measurement must be between 4 and 6 mils (102 and 152 microns) n If spot or area measurements are out of tolerance, measure each 100 sq. ft (~ 10 sq. meter) area coated during that work shift to isolate the nonconforming area (independent of structure size)

Measurement Tolerance EXAMPLE: n Target DFT: 4 -6 mils (102 -152 microns) n Individual gage readings unrestricted n Spot measurements must be between 3. 2 mils and 7. 2 mils (82 microns and 182 microns) n Area measurement must be between 4 and 6 mils (102 and 152 microns) n If spot or area measurements are out of tolerance, measure each 100 sq. ft (~ 10 sq. meter) area coated during that work shift to isolate the nonconforming area (independent of structure size)

Specifying Coating Thickness n Specifications should indicate the range of coating thickness (e. g. , 5 -7 mils or 127 -178 microns), not as a single value (e. g. , 5 mils or 127 microns) n Nearly impossible for an applicator to achieve a single thickness value n The Quality Control and Quality Assurance inspectors should not have to assume a range

Specifying Coating Thickness n Specifications should indicate the range of coating thickness (e. g. , 5 -7 mils or 127 -178 microns), not as a single value (e. g. , 5 mils or 127 microns) n Nearly impossible for an applicator to achieve a single thickness value n The Quality Control and Quality Assurance inspectors should not have to assume a range

Cumulative Thickness Measurements § Nondestructive coating thickness gages: Ø Most cannot distinguish coating layers Ø Measure the total cumulative thickness

Cumulative Thickness Measurements § Nondestructive coating thickness gages: Ø Most cannot distinguish coating layers Ø Measure the total cumulative thickness

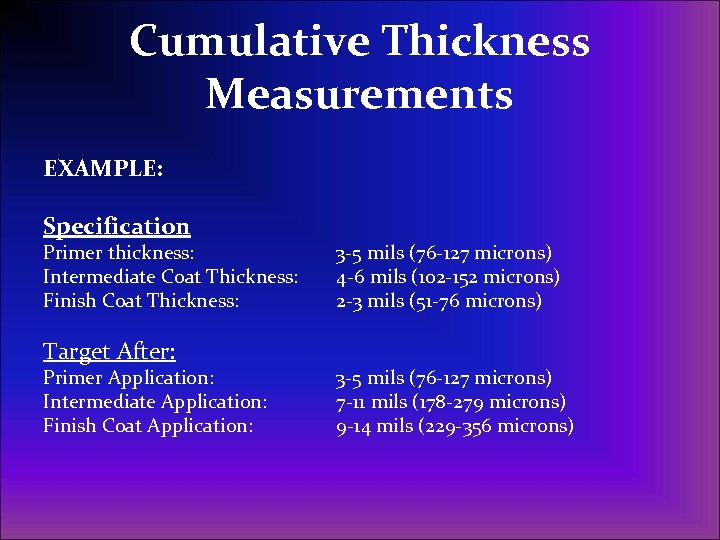

Cumulative Thickness Measurements EXAMPLE: Specification Primer thickness: Intermediate Coat Thickness: Finish Coat Thickness: Target After: Primer Application: Intermediate Application: Finish Coat Application: 3 -5 mils (76 -127 microns) 4 -6 mils (102 -152 microns) 2 -3 mils (51 -76 microns) 3 -5 mils (76 -127 microns) 7 -11 mils (178 -279 microns) 9 -14 mils (229 -356 microns)

Cumulative Thickness Measurements EXAMPLE: Specification Primer thickness: Intermediate Coat Thickness: Finish Coat Thickness: Target After: Primer Application: Intermediate Application: Finish Coat Application: 3 -5 mils (76 -127 microns) 4 -6 mils (102 -152 microns) 2 -3 mils (51 -76 microns) 3 -5 mils (76 -127 microns) 7 -11 mils (178 -279 microns) 9 -14 mils (229 -356 microns)

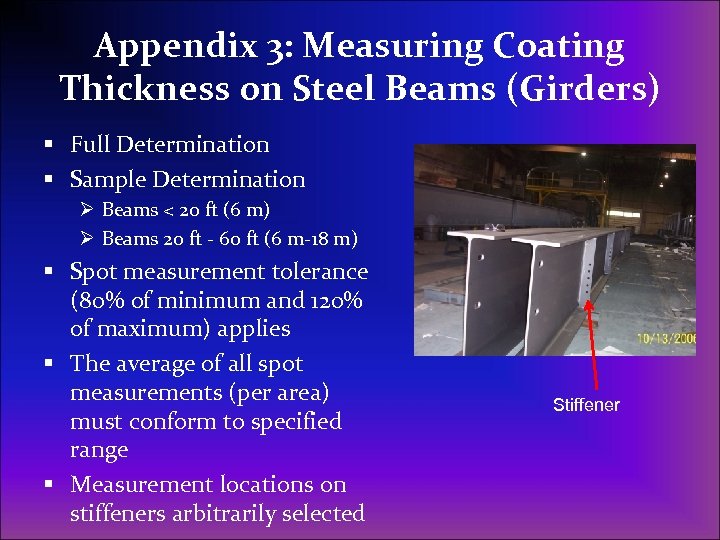

Appendix 3: Measuring Coating Thickness on Steel Beams (Girders) § Full Determination § Sample Determination Ø Beams < 20 ft (6 m) Ø Beams 20 ft - 60 ft (6 m-18 m) § Spot measurement tolerance (80% of minimum and 120% of maximum) applies § The average of all spot measurements (per area) must conform to specified range § Measurement locations on stiffeners arbitrarily selected Stiffener

Appendix 3: Measuring Coating Thickness on Steel Beams (Girders) § Full Determination § Sample Determination Ø Beams < 20 ft (6 m) Ø Beams 20 ft - 60 ft (6 m-18 m) § Spot measurement tolerance (80% of minimum and 120% of maximum) applies § The average of all spot measurements (per area) must conform to specified range § Measurement locations on stiffeners arbitrarily selected Stiffener

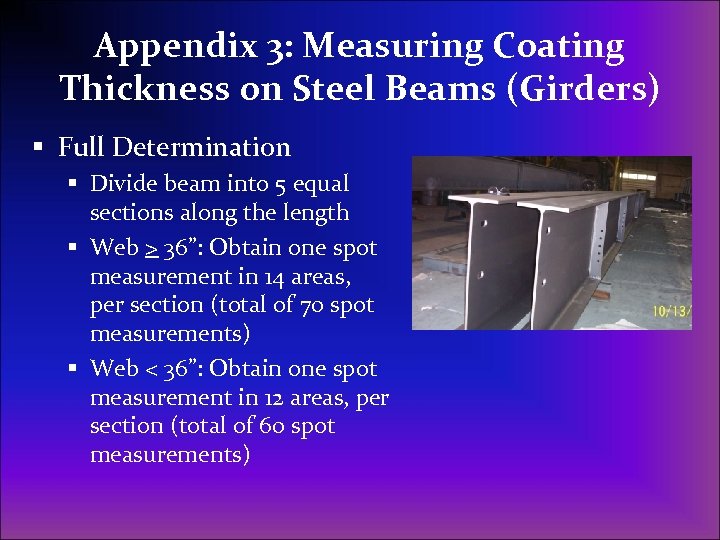

Appendix 3: Measuring Coating Thickness on Steel Beams (Girders) § Full Determination § Divide beam into 5 equal sections along the length § Web > 36”: Obtain one spot measurement in 14 areas, per section (total of 70 spot measurements) § Web < 36”: Obtain one spot measurement in 12 areas, per section (total of 60 spot measurements)

Appendix 3: Measuring Coating Thickness on Steel Beams (Girders) § Full Determination § Divide beam into 5 equal sections along the length § Web > 36”: Obtain one spot measurement in 14 areas, per section (total of 70 spot measurements) § Web < 36”: Obtain one spot measurement in 12 areas, per section (total of 60 spot measurements)

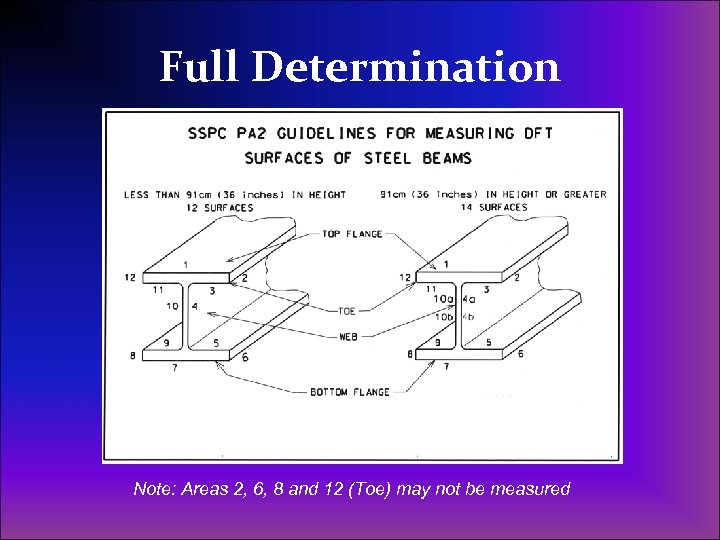

Full Determination Note: Areas 2, 6, 8 and 12 (Toe) may not be measured

Full Determination Note: Areas 2, 6, 8 and 12 (Toe) may not be measured

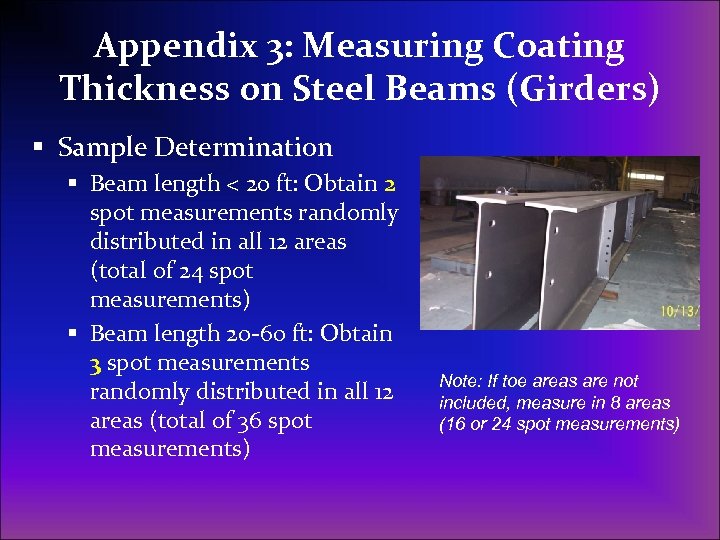

Appendix 3: Measuring Coating Thickness on Steel Beams (Girders) § Sample Determination § Beam length < 20 ft: Obtain 2 spot measurements randomly distributed in all 12 areas (total of 24 spot measurements) § Beam length 20 -60 ft: Obtain 3 spot measurements randomly distributed in all 12 areas (total of 36 spot measurements) Note: If toe areas are not included, measure in 8 areas (16 or 24 spot measurements)

Appendix 3: Measuring Coating Thickness on Steel Beams (Girders) § Sample Determination § Beam length < 20 ft: Obtain 2 spot measurements randomly distributed in all 12 areas (total of 24 spot measurements) § Beam length 20 -60 ft: Obtain 3 spot measurements randomly distributed in all 12 areas (total of 36 spot measurements) Note: If toe areas are not included, measure in 8 areas (16 or 24 spot measurements)

Appendix 4: Measuring Coating Thickness on Laydowns § Laydown: Group of steel members laid down to be painted in one shift by one applicator § Full DFT Determination Ø Beams (girders) Ø Miscellaneous parts § Sample DFT Determination Ø Beams < 20 ft (6 m) Ø Beams 20 ft - 60 ft (6 m-18 m)

Appendix 4: Measuring Coating Thickness on Laydowns § Laydown: Group of steel members laid down to be painted in one shift by one applicator § Full DFT Determination Ø Beams (girders) Ø Miscellaneous parts § Sample DFT Determination Ø Beams < 20 ft (6 m) Ø Beams 20 ft - 60 ft (6 m-18 m)

Appendix 4: Measuring Coating Thickness on Laydowns § Full DFT Determination § Beams: Same procedure described earlier § Miscellaneous parts: 1 spot measurement per “surface” (minimum of 5 spots) § Spot measurement tolerance (80% of minimum and 120% of maximum) applies § The average of all spot measurements (per area) must conform to specified range

Appendix 4: Measuring Coating Thickness on Laydowns § Full DFT Determination § Beams: Same procedure described earlier § Miscellaneous parts: 1 spot measurement per “surface” (minimum of 5 spots) § Spot measurement tolerance (80% of minimum and 120% of maximum) applies § The average of all spot measurements (per area) must conform to specified range

Appendix 4: Measuring Coating Thickness on Laydowns § Sample DFT Determination § Beams: Same procedure described earlier § Miscellaneous parts: 3 spot measurements per part § Spot measurement tolerance (80% of minimum and 120% of maximum) applies § The average of all spot measurements (per area) must conform to specified range

Appendix 4: Measuring Coating Thickness on Laydowns § Sample DFT Determination § Beams: Same procedure described earlier § Miscellaneous parts: 3 spot measurements per part § Spot measurement tolerance (80% of minimum and 120% of maximum) applies § The average of all spot measurements (per area) must conform to specified range

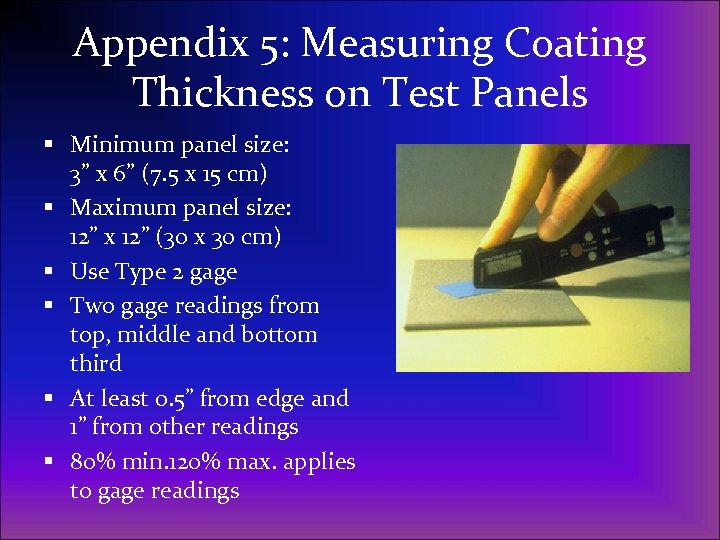

Appendix 5: Measuring Coating Thickness on Test Panels § Minimum panel size: 3” x 6” (7. 5 x 15 cm) § Maximum panel size: 12” x 12” (30 x 30 cm) § Use Type 2 gage § Two gage readings from top, middle and bottom third § At least 0. 5” from edge and 1” from other readings § 80% min. 120% max. applies to gage readings

Appendix 5: Measuring Coating Thickness on Test Panels § Minimum panel size: 3” x 6” (7. 5 x 15 cm) § Maximum panel size: 12” x 12” (30 x 30 cm) § Use Type 2 gage § Two gage readings from top, middle and bottom third § At least 0. 5” from edge and 1” from other readings § 80% min. 120% max. applies to gage readings

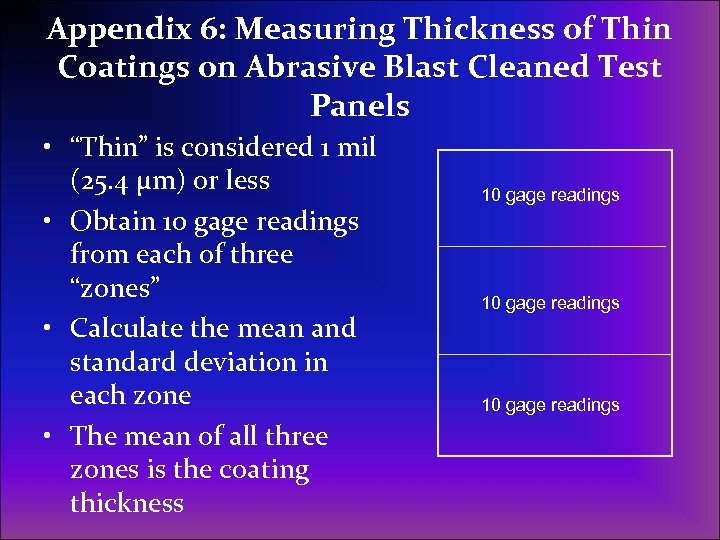

Appendix 6: Measuring Thickness of Thin Coatings on Abrasive Blast Cleaned Test Panels • “Thin” is considered 1 mil (25. 4 µm) or less • Obtain 10 gage readings from each of three “zones” • Calculate the mean and standard deviation in each zone • The mean of all three zones is the coating thickness 10 gage readings

Appendix 6: Measuring Thickness of Thin Coatings on Abrasive Blast Cleaned Test Panels • “Thin” is considered 1 mil (25. 4 µm) or less • Obtain 10 gage readings from each of three “zones” • Calculate the mean and standard deviation in each zone • The mean of all three zones is the coating thickness 10 gage readings

Potential Changes to SSPC PA 2 • Most recent revision is May 2004 (editorial changes to Appendix 6 made in 2009) • Document revisions and updating in progress • Changes may include: Ø Re-title, “Procedure for Determining Conformance to Dry Coating Thickness Requirements” Ø Use in concert with ASTM D 7091* Ø Measurement of coatings on ferrous and non-ferrous metal surfaces Ø Information on calibration and verification of accuracy removed (already in ASTM D 7091) Ø *Primarily focus on frequency and tolerance of measurements (instead of gage use)

Potential Changes to SSPC PA 2 • Most recent revision is May 2004 (editorial changes to Appendix 6 made in 2009) • Document revisions and updating in progress • Changes may include: Ø Re-title, “Procedure for Determining Conformance to Dry Coating Thickness Requirements” Ø Use in concert with ASTM D 7091* Ø Measurement of coatings on ferrous and non-ferrous metal surfaces Ø Information on calibration and verification of accuracy removed (already in ASTM D 7091) Ø *Primarily focus on frequency and tolerance of measurements (instead of gage use)

Summary • During this webinar, we have: Ø Described the purpose of SSPC-PA 2 Ø Described the differences between Type 1 and Type 2 gages Ø Described the processes associated with calibration, verification of accuracy and adjustment Ø Explained Base Metal Reading acquisition Ø Described the differences between measurement acquisition using manual verses electronic gages Ø Described the frequency and tolerance of measurements Ø Described the measurement acquisition process for steel beams, laydowns and test panels

Summary • During this webinar, we have: Ø Described the purpose of SSPC-PA 2 Ø Described the differences between Type 1 and Type 2 gages Ø Described the processes associated with calibration, verification of accuracy and adjustment Ø Explained Base Metal Reading acquisition Ø Described the differences between measurement acquisition using manual verses electronic gages Ø Described the frequency and tolerance of measurements Ø Described the measurement acquisition process for steel beams, laydowns and test panels

Complying with SSPC-PA 2, “Measurement of Dry Coating Thickness with Magnetic Gages” THE END

Complying with SSPC-PA 2, “Measurement of Dry Coating Thickness with Magnetic Gages” THE END