82a454ec9c2263a94282cbdcf0a54fd7.ppt

- Количество слайдов: 15

Company Profile Tae. Seong Metal & Surface Technology Co. , Ltd. Feb. 04. 2014

Company Profile Tae. Seong Metal & Surface Technology Co. , Ltd. Feb. 04. 2014

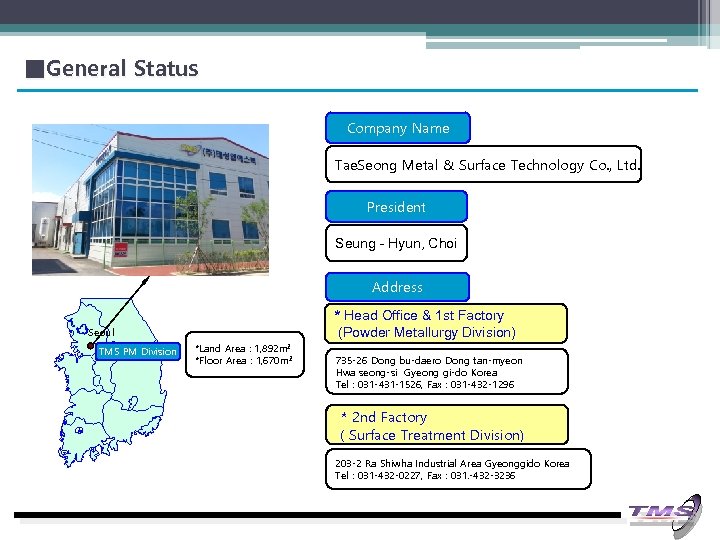

■General Status Company Name Tae. Seong Metal & Surface Technology Co. , Ltd. President Seung - Hyun, Choi Address * Head Office & 1 st Factory (Powder Metallurgy Division) Seoul TMS PM Division *Land Area : 1, 892 m 2 *Floor Area : 1, 670 m 2 735 -26 Dong bu-daero Dong tan-myeon Hwa seong-si Gyeong gi-do Korea Tel : 031 -431 -1526, Fax : 031 -432 -1296 * 2 nd Factory ( Surface Treatment Division) 203 -2 Ra Shiwha Industrial Area Gyeonggido Korea Tel : 031 -432 -0227, Fax : 031. -432 -3236

■General Status Company Name Tae. Seong Metal & Surface Technology Co. , Ltd. President Seung - Hyun, Choi Address * Head Office & 1 st Factory (Powder Metallurgy Division) Seoul TMS PM Division *Land Area : 1, 892 m 2 *Floor Area : 1, 670 m 2 735 -26 Dong bu-daero Dong tan-myeon Hwa seong-si Gyeong gi-do Korea Tel : 031 -431 -1526, Fax : 031 -432 -1296 * 2 nd Factory ( Surface Treatment Division) 203 -2 Ra Shiwha Industrial Area Gyeonggido Korea Tel : 031 -432 -0227, Fax : 031. -432 -3236

■History 2001. 10. Foundation of Taeseong Powder Metallurgy Co. , Ltd. in Si-Hwa Industrial Complex of Gyeonggi -do 2001. 12. Selected as a Business Incubator of the Ministry of Commerce, Industry and Energy(Technology providers) (Powder metallurgy products manufactured by the Warm Compaction Process) 2002. 03. Mass Production of Warm Compaction Parts for SPG Co. 2003. Obtained ISO 9002/QS-9000 Certification 2006. 12. Obtained ISO 9002/TS 16949 Certification 2007. 06. Obtained Venture Company certified (Technical evaluation assurance companies) 2007. 09. Renamed Tae Seong Metal & Surface Technology Co. , Ltd. (TMS) 2007. 10. Launched Magnesium Surface Treatment i n Si-Hwa Industrial Complex of Gyeonggi -do 2010. 08. Obtained INNO-BIZ Certification 2012. 06. Relocated to Dong-tan Industrial Complex in Hwa-Seong Si Gyeonggi -do 2013. 09. TMS R&D Center was established

■History 2001. 10. Foundation of Taeseong Powder Metallurgy Co. , Ltd. in Si-Hwa Industrial Complex of Gyeonggi -do 2001. 12. Selected as a Business Incubator of the Ministry of Commerce, Industry and Energy(Technology providers) (Powder metallurgy products manufactured by the Warm Compaction Process) 2002. 03. Mass Production of Warm Compaction Parts for SPG Co. 2003. Obtained ISO 9002/QS-9000 Certification 2006. 12. Obtained ISO 9002/TS 16949 Certification 2007. 06. Obtained Venture Company certified (Technical evaluation assurance companies) 2007. 09. Renamed Tae Seong Metal & Surface Technology Co. , Ltd. (TMS) 2007. 10. Launched Magnesium Surface Treatment i n Si-Hwa Industrial Complex of Gyeonggi -do 2010. 08. Obtained INNO-BIZ Certification 2012. 06. Relocated to Dong-tan Industrial Complex in Hwa-Seong Si Gyeonggi -do 2013. 09. TMS R&D Center was established

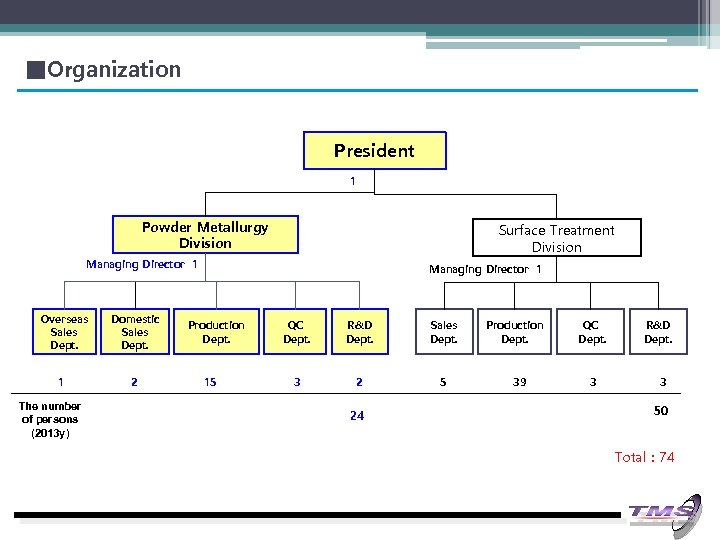

■Organization President 1 Powder Metallurgy Division Surface Treatment Division Managing Director 1 Overseas Sales Dept. 1 The number of persons (2013 y) Domestic Sales Dept. 2 Managing Director 1 Production Dept. 15 QC Dept. R&D Dept. Sales Dept. 3 2 5 24 Production Dept. 39 QC Dept. 3 R&D Dept. 3 50 Total : 74

■Organization President 1 Powder Metallurgy Division Surface Treatment Division Managing Director 1 Overseas Sales Dept. 1 The number of persons (2013 y) Domestic Sales Dept. 2 Managing Director 1 Production Dept. 15 QC Dept. R&D Dept. Sales Dept. 3 2 5 24 Production Dept. 39 QC Dept. 3 R&D Dept. 3 50 Total : 74

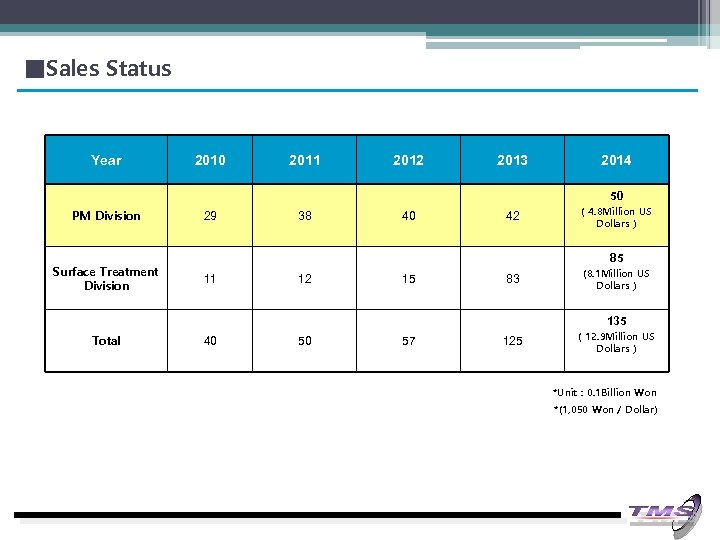

■Sales Status Year 2010 2011 2012 2013 2014 50 PM Division Surface Treatment Division 29 38 40 42 ( 4. 8 Million US Dollars ) 85 11 12 15 83 (8. 1 Million US Dollars ) 125 ( 12. 9 Million US Dollars ) 135 Total 단위: 억 40 50 57 *Unit : 0. 1 Billion Won *(1, 050 Won / Dollar)

■Sales Status Year 2010 2011 2012 2013 2014 50 PM Division Surface Treatment Division 29 38 40 42 ( 4. 8 Million US Dollars ) 85 11 12 15 83 (8. 1 Million US Dollars ) 125 ( 12. 9 Million US Dollars ) 135 Total 단위: 억 40 50 57 *Unit : 0. 1 Billion Won *(1, 050 Won / Dollar)

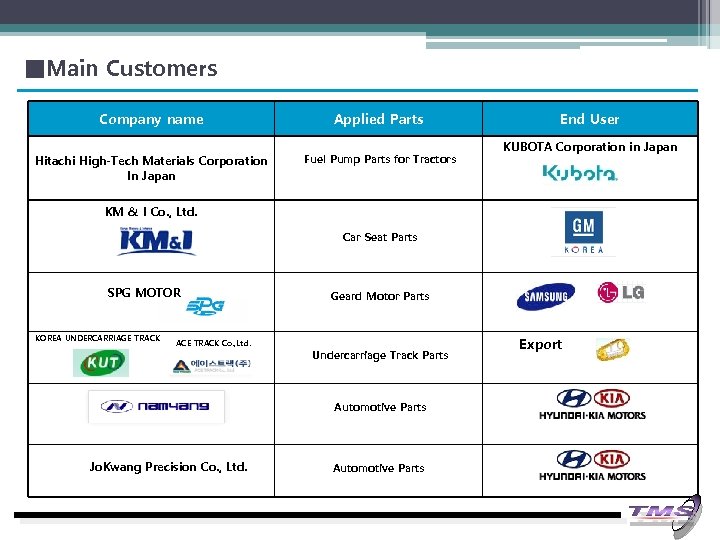

■Main Customers Company name Applied Parts Hitachi High-Tech Materials Corporation In Japan Fuel Pump Parts for Tractors End User KUBOTA Corporation in Japan KM & I Co. , Ltd. Car Seat Parts SPG MOTOR KOREA UNDERCARRIAGE TRACK ACE TRACK Co. , Ltd. Geard Motor Parts Undercarriage Track Parts Automotive Parts Jo. Kwang Precision Co. , Ltd. Automotive Parts Export

■Main Customers Company name Applied Parts Hitachi High-Tech Materials Corporation In Japan Fuel Pump Parts for Tractors End User KUBOTA Corporation in Japan KM & I Co. , Ltd. Car Seat Parts SPG MOTOR KOREA UNDERCARRIAGE TRACK ACE TRACK Co. , Ltd. Geard Motor Parts Undercarriage Track Parts Automotive Parts Jo. Kwang Precision Co. , Ltd. Automotive Parts Export

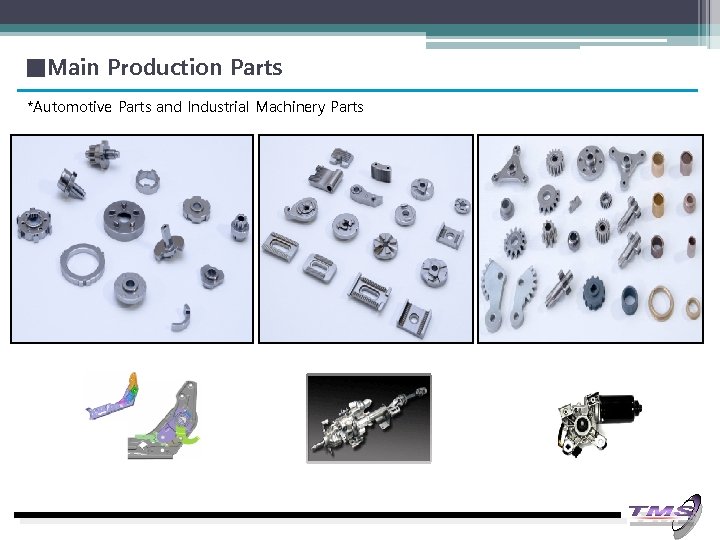

■Main Production Parts *Automotive Parts and Industrial Machinery Parts

■Main Production Parts *Automotive Parts and Industrial Machinery Parts

■Main Production Parts *Fuel Pump Parts for Agricultural Tractor motor

■Main Production Parts *Fuel Pump Parts for Agricultural Tractor motor

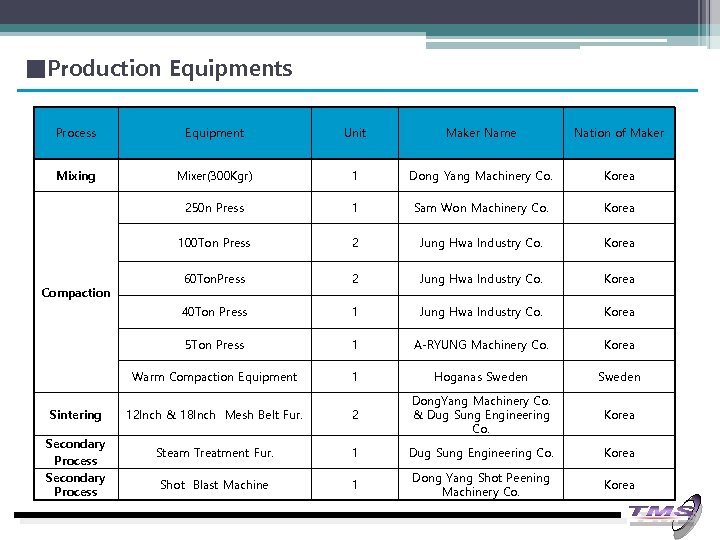

■Production Equipments Process Equipment Unit Maker Name Nation of Maker Mixing Mixer(300 Kgr) 1 Dong Yang Machinery Co. Korea 250 n Press 1 Sam Won Machinery Co. Korea 100 Ton Press 2 Jung Hwa Industry Co. Korea 60 Ton. Press 2 Jung Hwa Industry Co. Korea 40 Ton Press 1 Jung Hwa Industry Co. Korea 5 Ton Press 1 A-RYUNG Machinery Co. Korea Warm Compaction Equipment 1 Hoganas Sweden 12 Inch & 18 Inch Mesh Belt Fur. 2 Dong. Yang Machinery Co. & Dug Sung Engineering Co. Korea Steam Treatment Fur. 1 Dug Sung Engineering Co. Korea Shot Blast Machine 1 Dong Yang Shot Peening Machinery Co. Korea Compaction Sintering Secondary Process

■Production Equipments Process Equipment Unit Maker Name Nation of Maker Mixing Mixer(300 Kgr) 1 Dong Yang Machinery Co. Korea 250 n Press 1 Sam Won Machinery Co. Korea 100 Ton Press 2 Jung Hwa Industry Co. Korea 60 Ton. Press 2 Jung Hwa Industry Co. Korea 40 Ton Press 1 Jung Hwa Industry Co. Korea 5 Ton Press 1 A-RYUNG Machinery Co. Korea Warm Compaction Equipment 1 Hoganas Sweden 12 Inch & 18 Inch Mesh Belt Fur. 2 Dong. Yang Machinery Co. & Dug Sung Engineering Co. Korea Steam Treatment Fur. 1 Dug Sung Engineering Co. Korea Shot Blast Machine 1 Dong Yang Shot Peening Machinery Co. Korea Compaction Sintering Secondary Process

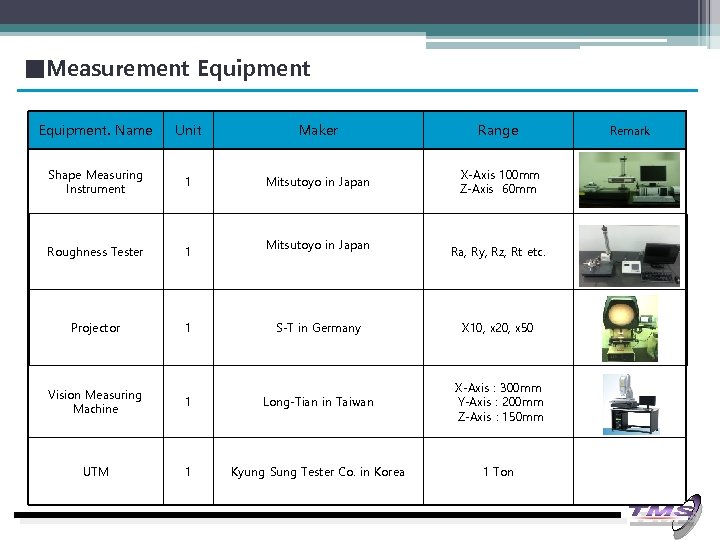

■Measurement Equipment. Name Unit Maker Range Shape Measuring Instrument 1 Mitsutoyo in Japan X-Axis 100 mm Z-Axis 60 mm Roughness Tester 1 Projector 1 Mitsutoyo in Japan Ra, Ry, Rz, Rt etc. S-T in Germany X 10, x 20, x 50 Vision Measuring Machine 1 Long-Tian in Taiwan X-Axis : 300 mm Y-Axis : 200 mm Z-Axis : 150 mm UTM 1 Kyung Sung Tester Co. in Korea 1 Ton Remark

■Measurement Equipment. Name Unit Maker Range Shape Measuring Instrument 1 Mitsutoyo in Japan X-Axis 100 mm Z-Axis 60 mm Roughness Tester 1 Projector 1 Mitsutoyo in Japan Ra, Ry, Rz, Rt etc. S-T in Germany X 10, x 20, x 50 Vision Measuring Machine 1 Long-Tian in Taiwan X-Axis : 300 mm Y-Axis : 200 mm Z-Axis : 150 mm UTM 1 Kyung Sung Tester Co. in Korea 1 Ton Remark

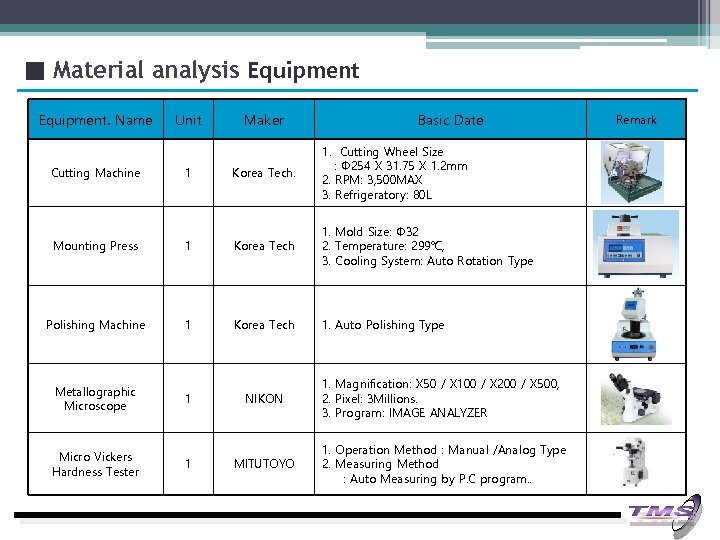

■ Material analysis Equipment. Name Cutting Machine Unit 1 Maker Basic Date Korea Tech. 1. Cutting Wheel Size : Φ 254 X 31. 75 X 1. 2 mm 2. RPM: 3, 500 MAX 3. Refrigeratory: 80 L Mounting Press 1 Korea Tech 1. Mold Size: Φ 32 2. Temperature: 299℃, 3. Cooling System: Auto Rotation Type Polishing Machine 1 Korea Tech 1. Auto Polishing Type Metallographic Microscope 1 NIKON 1. Magnification: X 50 / X 100 / X 200 / X 500, 2. Pixel: 3 Millions. 3. Program: IMAGE ANALYZER MITUTOYO 1. Operation Method : Manual /Analog Type 2. Measuring Method : Auto Measuring by P. C program. . Micro Vickers Hardness Tester 1 Remark

■ Material analysis Equipment. Name Cutting Machine Unit 1 Maker Basic Date Korea Tech. 1. Cutting Wheel Size : Φ 254 X 31. 75 X 1. 2 mm 2. RPM: 3, 500 MAX 3. Refrigeratory: 80 L Mounting Press 1 Korea Tech 1. Mold Size: Φ 32 2. Temperature: 299℃, 3. Cooling System: Auto Rotation Type Polishing Machine 1 Korea Tech 1. Auto Polishing Type Metallographic Microscope 1 NIKON 1. Magnification: X 50 / X 100 / X 200 / X 500, 2. Pixel: 3 Millions. 3. Program: IMAGE ANALYZER MITUTOYO 1. Operation Method : Manual /Analog Type 2. Measuring Method : Auto Measuring by P. C program. . Micro Vickers Hardness Tester 1 Remark

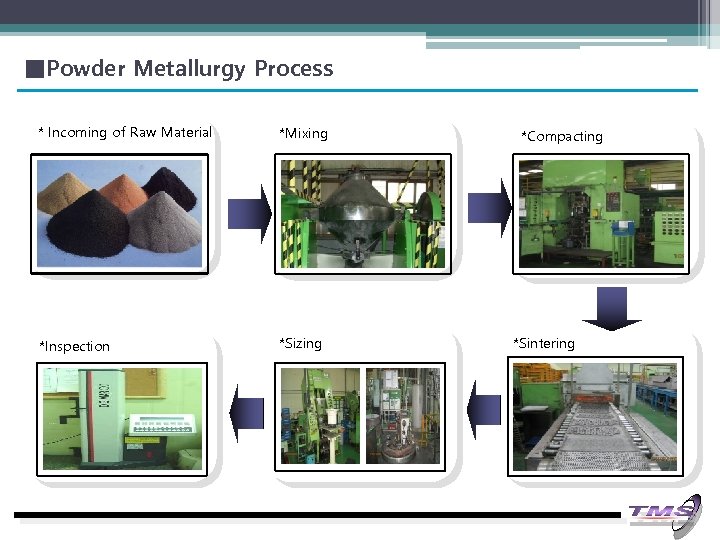

■Powder Metallurgy Process * Incoming of Raw Material *Mixing *Inspection *Sizing *Compacting *Sintering

■Powder Metallurgy Process * Incoming of Raw Material *Mixing *Inspection *Sizing *Compacting *Sintering

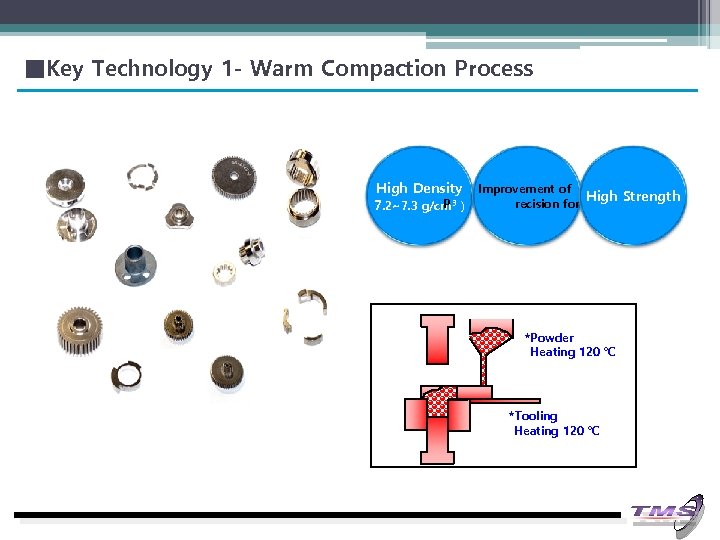

■Key Technology 1 - Warm Compaction Process High Density Improvement of High Strength P recision for Gear 7. 2~7. 3 g/cm 3 ) *Powder Heating 120 ℃ *Tooling Heating 120 ℃

■Key Technology 1 - Warm Compaction Process High Density Improvement of High Strength P recision for Gear 7. 2~7. 3 g/cm 3 ) *Powder Heating 120 ℃ *Tooling Heating 120 ℃

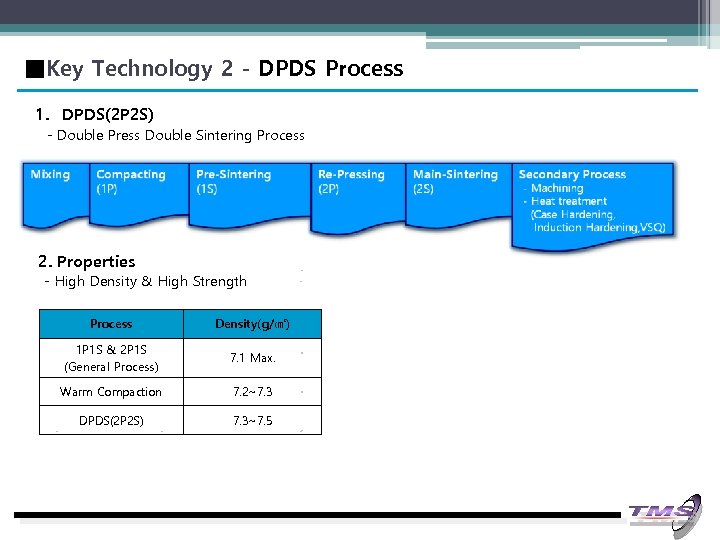

■Key Technology 2 - DPDS Process 1. DPDS(2 P 2 S) - Double Press Double Sintering Process 2. Properties - High Density & High Strength Process Density(g/㎤) 1 P 1 S & 2 P 1 S (General Process) 7. 1 Max. Warm Compaction 7. 2~7. 3 DPDS(2 P 2 S) 7. 3~7. 5

■Key Technology 2 - DPDS Process 1. DPDS(2 P 2 S) - Double Press Double Sintering Process 2. Properties - High Density & High Strength Process Density(g/㎤) 1 P 1 S & 2 P 1 S (General Process) 7. 1 Max. Warm Compaction 7. 2~7. 3 DPDS(2 P 2 S) 7. 3~7. 5

■Certificate ü ISO / TS – 9001: 2000 ü ISO / TS – 16949: 2002 ü INO-BIZ (2013. 08)

■Certificate ü ISO / TS – 9001: 2000 ü ISO / TS – 16949: 2002 ü INO-BIZ (2013. 08)