13b5105b60f433479f1de700cf92e628.ppt

- Количество слайдов: 17

COMPANY PROFILE GARNET NAM DINH CO. , LTD.

COMPANY PROFILE GARNET NAM DINH CO. , LTD.

Overview • Skilled experiences for garment production and speed management system of order follow up keep us as one of good suppliers. • We are producing garments with customer’s mind and modern equipments to make perfect one according to order details. We are proud of ourselves put hard efforts to the valued orders, with passion for garment production. • With our qualified products, we have good reputations from Quick silver, El Corte Ingles, Burton, JC penny, Teijin Shoji (Japan) , Riachuelo (Brazil), and Korean Brands. • We are ready to collaborate with best attentions and responsibilities. Our company sprits --- create , challenge, and change – can make you better communication, understanding, qualities and deliveries. ∙ social compliance by BSCI, JC penny, Wal Mart, Mango, El Corte Ingles

Overview • Skilled experiences for garment production and speed management system of order follow up keep us as one of good suppliers. • We are producing garments with customer’s mind and modern equipments to make perfect one according to order details. We are proud of ourselves put hard efforts to the valued orders, with passion for garment production. • With our qualified products, we have good reputations from Quick silver, El Corte Ingles, Burton, JC penny, Teijin Shoji (Japan) , Riachuelo (Brazil), and Korean Brands. • We are ready to collaborate with best attentions and responsibilities. Our company sprits --- create , challenge, and change – can make you better communication, understanding, qualities and deliveries. ∙ social compliance by BSCI, JC penny, Wal Mart, Mango, El Corte Ingles

our vision • • • Becoming top 5 qualified pants and jackets manufacturer in Vietnam by year 2014. Becoming number one standard working environment factory in Nam Dinh by year 2013. Our mission : We challenge jeans and outdoor wears. We produce most qualified and competitive pants and jackets. Our Values We are true, honest, outspoken and trustful Garnet family. We make the life better, develop continuously, and lead live economically and happily.

our vision • • • Becoming top 5 qualified pants and jackets manufacturer in Vietnam by year 2014. Becoming number one standard working environment factory in Nam Dinh by year 2013. Our mission : We challenge jeans and outdoor wears. We produce most qualified and competitive pants and jackets. Our Values We are true, honest, outspoken and trustful Garnet family. We make the life better, develop continuously, and lead live economically and happily.

out target • • • Out target Sales : U$20 million per year by Year 2014 Workers : 980 workers by year 2013 Buyers : 5 major buyers from 5 countries. ( EU, Brazil, Asia, Turkey, USA) Techniques : high tech garment ( machines, materials, methods, styles) Qualities : more than AQL 2. 5 standard. Wages and incentive : better and higher according to capabilities and responsibilities. Our code of conduct We are honest , diligent and careful. We are taking responsibilities. We are saving energy, costs and recycling to protect environments. Our slogan : Change, challenge, create All of us are responsible to do best quality garments and services to the buyers By this we are responsible to support and develop our families and our societies.

out target • • • Out target Sales : U$20 million per year by Year 2014 Workers : 980 workers by year 2013 Buyers : 5 major buyers from 5 countries. ( EU, Brazil, Asia, Turkey, USA) Techniques : high tech garment ( machines, materials, methods, styles) Qualities : more than AQL 2. 5 standard. Wages and incentive : better and higher according to capabilities and responsibilities. Our code of conduct We are honest , diligent and careful. We are taking responsibilities. We are saving energy, costs and recycling to protect environments. Our slogan : Change, challenge, create All of us are responsible to do best quality garments and services to the buyers By this we are responsible to support and develop our families and our societies.

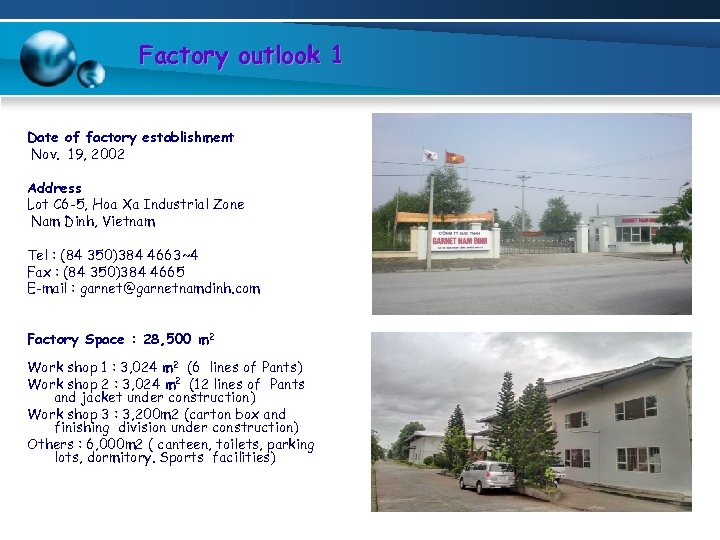

Factory outlook 1 Date of factory establishment Nov. 19, 2002 Address Lot C 6 -5, Hoa Xa Industrial Zone Nam Dinh, Vietnam Tel : (84 350)384 4663~4 Fax : (84 350)384 4665 E-mail : garnet@garnetnamdinh. com Factory Space : 28, 500 m 2 Work shop 1 : 3, 024 m 2 (6 lines of Pants) Work shop 2 : 3, 024 m 2 (12 lines of Pants and jacket under construction) Work shop 3 : 3, 200 m 2 (carton box and finishing division under construction) Others : 6, 000 m 2 ( canteen, toilets, parking lots, dormitory. Sports facilities)

Factory outlook 1 Date of factory establishment Nov. 19, 2002 Address Lot C 6 -5, Hoa Xa Industrial Zone Nam Dinh, Vietnam Tel : (84 350)384 4663~4 Fax : (84 350)384 4665 E-mail : garnet@garnetnamdinh. com Factory Space : 28, 500 m 2 Work shop 1 : 3, 024 m 2 (6 lines of Pants) Work shop 2 : 3, 024 m 2 (12 lines of Pants and jacket under construction) Work shop 3 : 3, 200 m 2 (carton box and finishing division under construction) Others : 6, 000 m 2 ( canteen, toilets, parking lots, dormitory. Sports facilities)

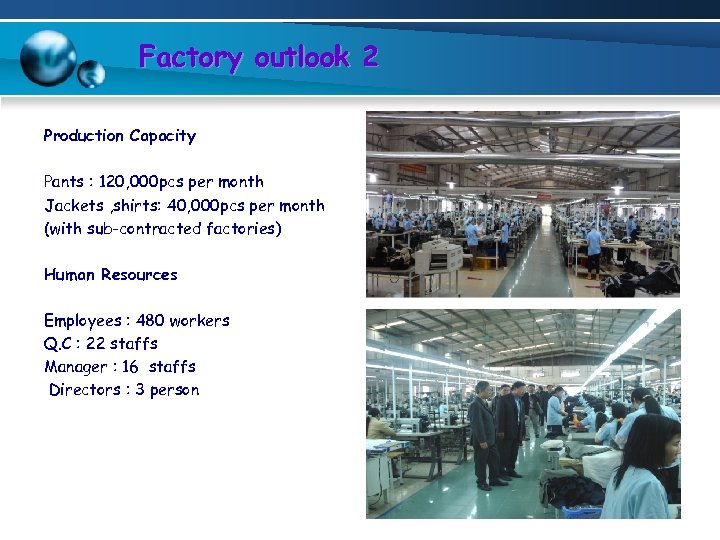

Factory outlook 2 Production Capacity Pants : 120, 000 pcs per month Jackets , shirts: 40, 000 pcs per month (with sub-contracted factories) Human Resources Employees : 480 workers Q. C : 22 staffs Manager : 16 staffs Directors : 3 person

Factory outlook 2 Production Capacity Pants : 120, 000 pcs per month Jackets , shirts: 40, 000 pcs per month (with sub-contracted factories) Human Resources Employees : 480 workers Q. C : 22 staffs Manager : 16 staffs Directors : 3 person

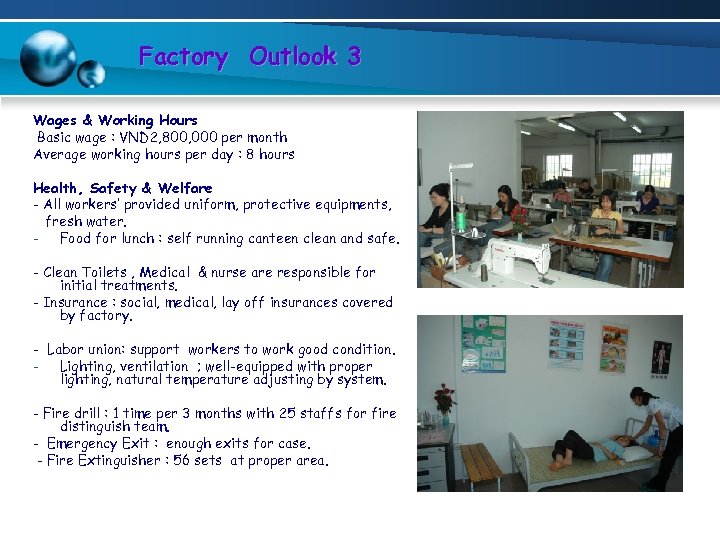

Factory Outlook 3 Wages & Working Hours Basic wage : VND 2, 800, 000 per month Average working hours per day : 8 hours Health, Safety & Welfare - All workers’ provided uniform, protective equipments, fresh water. - Food for lunch : self running canteen clean and safe. - Clean Toilets , Medical & nurse are responsible for initial treatments. - Insurance : social, medical, lay off insurances covered by factory. - Labor union: support workers to work good condition. - Lighting, ventilation ; well-equipped with proper lighting, natural temperature adjusting by system. - Fire drill : 1 time per 3 months with 25 staffs for fire distinguish team. - Emergency Exit : enough exits for case. - Fire Extinguisher : 56 sets at proper area.

Factory Outlook 3 Wages & Working Hours Basic wage : VND 2, 800, 000 per month Average working hours per day : 8 hours Health, Safety & Welfare - All workers’ provided uniform, protective equipments, fresh water. - Food for lunch : self running canteen clean and safe. - Clean Toilets , Medical & nurse are responsible for initial treatments. - Insurance : social, medical, lay off insurances covered by factory. - Labor union: support workers to work good condition. - Lighting, ventilation ; well-equipped with proper lighting, natural temperature adjusting by system. - Fire drill : 1 time per 3 months with 25 staffs for fire distinguish team. - Emergency Exit : enough exits for case. - Fire Extinguisher : 56 sets at proper area.

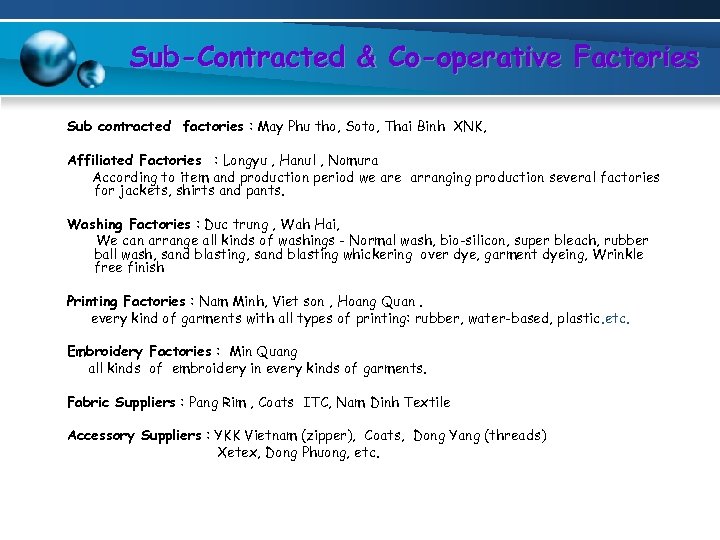

Sub-Contracted & Co-operative Factories Sub contracted factories : May Phu tho, Soto, Thai Binh XNK, Affiliated Factories : Longyu , Hanul , Nomura According to item and production period we arranging production several factories for jackets, shirts and pants. Washing Factories : Duc trung , Wah Hai, We can arrange all kinds of washings - Normal wash, bio-silicon, super bleach, rubber ball wash, sand blasting whickering over dye, garment dyeing, Wrinkle free finish Printing Factories : Nam Minh, Viet son , Hoang Quan. every kind of garments with all types of printing: rubber, water-based, plastic. etc. Embroidery Factories : Min Quang all kinds of embroidery in every kinds of garments. Fabric Suppliers : Pang Rim , Coats ITC, Nam Dinh Textile Accessory Suppliers : YKK Vietnam (zipper), Coats, Dong Yang (threads) Xetex, Dong Phuong, etc.

Sub-Contracted & Co-operative Factories Sub contracted factories : May Phu tho, Soto, Thai Binh XNK, Affiliated Factories : Longyu , Hanul , Nomura According to item and production period we arranging production several factories for jackets, shirts and pants. Washing Factories : Duc trung , Wah Hai, We can arrange all kinds of washings - Normal wash, bio-silicon, super bleach, rubber ball wash, sand blasting whickering over dye, garment dyeing, Wrinkle free finish Printing Factories : Nam Minh, Viet son , Hoang Quan. every kind of garments with all types of printing: rubber, water-based, plastic. etc. Embroidery Factories : Min Quang all kinds of embroidery in every kinds of garments. Fabric Suppliers : Pang Rim , Coats ITC, Nam Dinh Textile Accessory Suppliers : YKK Vietnam (zipper), Coats, Dong Yang (threads) Xetex, Dong Phuong, etc.

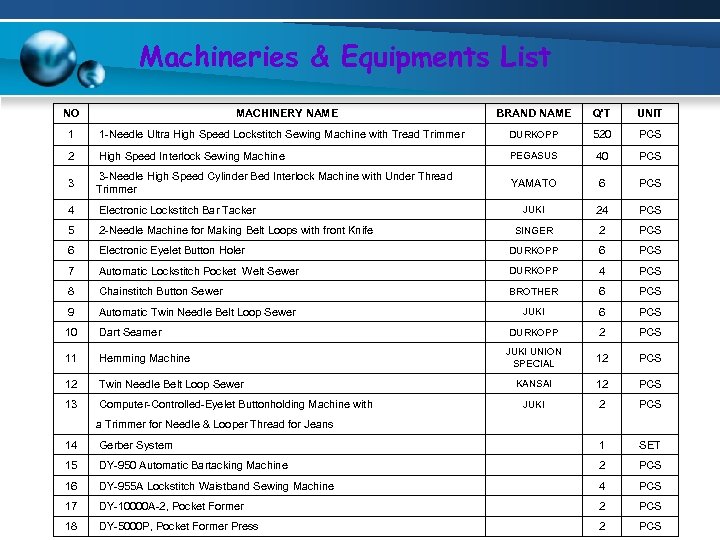

Machineries & Equipments List NO MACHINERY NAME BRAND NAME Q'T UNIT 1 1 -Needle Ultra High Speed Lockstitch Sewing Machine with Tread Trimmer DURKOPP 520 PCS 2 High Speed Interlock Sewing Machine PEGASUS 40 PCS 3 3 -Needle High Speed Cylinder Bed Interlock Machine with Under Thread Trimmer YAMATO 6 PCS 4 Electronic Lockstitch Bar Tacker JUKI 24 PCS 5 2 -Needle Machine for Making Belt Loops with front Knife SINGER 2 PCS 6 Electronic Eyelet Button Holer DURKOPP 6 PCS 7 Automatic Lockstitch Pocket Welt Sewer DURKOPP 4 PCS 8 Chainstitch Button Sewer BROTHER 6 PCS 9 Automatic Twin Needle Belt Loop Sewer JUKI 6 PCS 10 Dart Seamer DURKOPP 2 PCS 11 Hemming Machine JUKI UNION SPECIAL 12 PCS 12 Twin Needle Belt Loop Sewer KANSAI 12 PCS 13 Computer-Controlled-Eyelet Buttonholding Machine with JUKI 2 PCS a Trimmer for Needle & Looper Thread for Jeans 14 Gerber System 1 SET 15 DY-950 Automatic Bartacking Machine 2 PCS 16 DY-955 A Lockstitch Waistband Sewing Machine 4 PCS 17 DY-10000 A-2, Pocket Former 2 PCS 18 DY-5000 P, Pocket Former Press 2 PCS

Machineries & Equipments List NO MACHINERY NAME BRAND NAME Q'T UNIT 1 1 -Needle Ultra High Speed Lockstitch Sewing Machine with Tread Trimmer DURKOPP 520 PCS 2 High Speed Interlock Sewing Machine PEGASUS 40 PCS 3 3 -Needle High Speed Cylinder Bed Interlock Machine with Under Thread Trimmer YAMATO 6 PCS 4 Electronic Lockstitch Bar Tacker JUKI 24 PCS 5 2 -Needle Machine for Making Belt Loops with front Knife SINGER 2 PCS 6 Electronic Eyelet Button Holer DURKOPP 6 PCS 7 Automatic Lockstitch Pocket Welt Sewer DURKOPP 4 PCS 8 Chainstitch Button Sewer BROTHER 6 PCS 9 Automatic Twin Needle Belt Loop Sewer JUKI 6 PCS 10 Dart Seamer DURKOPP 2 PCS 11 Hemming Machine JUKI UNION SPECIAL 12 PCS 12 Twin Needle Belt Loop Sewer KANSAI 12 PCS 13 Computer-Controlled-Eyelet Buttonholding Machine with JUKI 2 PCS a Trimmer for Needle & Looper Thread for Jeans 14 Gerber System 1 SET 15 DY-950 Automatic Bartacking Machine 2 PCS 16 DY-955 A Lockstitch Waistband Sewing Machine 4 PCS 17 DY-10000 A-2, Pocket Former 2 PCS 18 DY-5000 P, Pocket Former Press 2 PCS

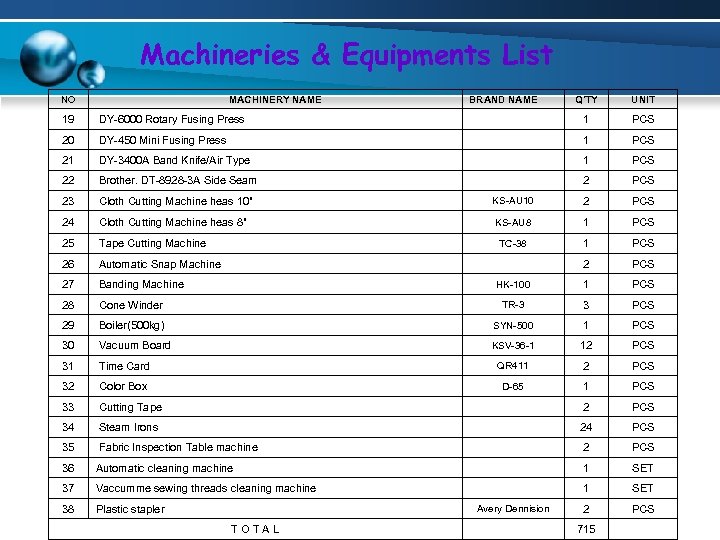

Machineries & Equipments List NO MACHINERY NAME BRAND NAME Q'TY UNIT 19 DY-6000 Rotary Fusing Press 1 PCS 20 DY-450 Mini Fusing Press 1 PCS 21 DY-3400 A Band Knife/Air Type 1 PCS 22 Brother. DT-8928 -3 A Side Seam 2 PCS 23 Cloth Cutting Machine heas 10" KS-AU 10 2 PCS 24 Cloth Cutting Machine heas 8" KS-AU 8 1 PCS 25 Tape Cutting Machine TC-38 1 PCS 26 Automatic Snap Machine 2 PCS 27 Banding Machine HK-100 1 PCS 28 Cone Winder TR-3 3 PCS 29 Boiler(500 kg) SYN-500 1 PCS 30 Vacuum Board KSV-36 -1 12 PCS 31 Time Card QR 411 2 PCS 32 Color Box D-65 1 PCS 33 Cutting Tape 2 PCS 34 Steam Irons 24 PCS 35 Fabric Inspection Table machine 2 PCS 36 Automatic cleaning machine 1 SET 37 Vaccumme sewing threads cleaning machine 1 SET 38 Plastic stapler 2 PCS Avery Dennision TOTAL 715

Machineries & Equipments List NO MACHINERY NAME BRAND NAME Q'TY UNIT 19 DY-6000 Rotary Fusing Press 1 PCS 20 DY-450 Mini Fusing Press 1 PCS 21 DY-3400 A Band Knife/Air Type 1 PCS 22 Brother. DT-8928 -3 A Side Seam 2 PCS 23 Cloth Cutting Machine heas 10" KS-AU 10 2 PCS 24 Cloth Cutting Machine heas 8" KS-AU 8 1 PCS 25 Tape Cutting Machine TC-38 1 PCS 26 Automatic Snap Machine 2 PCS 27 Banding Machine HK-100 1 PCS 28 Cone Winder TR-3 3 PCS 29 Boiler(500 kg) SYN-500 1 PCS 30 Vacuum Board KSV-36 -1 12 PCS 31 Time Card QR 411 2 PCS 32 Color Box D-65 1 PCS 33 Cutting Tape 2 PCS 34 Steam Irons 24 PCS 35 Fabric Inspection Table machine 2 PCS 36 Automatic cleaning machine 1 SET 37 Vaccumme sewing threads cleaning machine 1 SET 38 Plastic stapler 2 PCS Avery Dennision TOTAL 715

Quality Control System WAREHOUSE § § § Fabric quality checkshrinkage, skew, color fastness, fabric listing, streaky Accessory quality checkstring, label, snap, button, rivet, sewing thread Color matching chart : check colors, qualities, missing accessories CUTTING DEPT § § § All one way cutting Each cutting panel inspect fabrics & replacing Numbering PREPARING PRODUCTION § § Marking sewing point Folding fabrics with mold Ironing waist band for sewing Pre production meeting

Quality Control System WAREHOUSE § § § Fabric quality checkshrinkage, skew, color fastness, fabric listing, streaky Accessory quality checkstring, label, snap, button, rivet, sewing thread Color matching chart : check colors, qualities, missing accessories CUTTING DEPT § § § All one way cutting Each cutting panel inspect fabrics & replacing Numbering PREPARING PRODUCTION § § Marking sewing point Folding fabrics with mold Ironing waist band for sewing Pre production meeting

Quality Control System SEWING DEPT FINISHING DEPT § § § All machine sewing stitch adjust In line inspection by line inspector After sewing inspection by line inspector Stain inspection before washing § § § After washing inspectionwashing touch, washing quality, washing effect, washing defects Before ironing inspection Before poly-bag inspection Customer inspection

Quality Control System SEWING DEPT FINISHING DEPT § § § All machine sewing stitch adjust In line inspection by line inspector After sewing inspection by line inspector Stain inspection before washing § § § After washing inspectionwashing touch, washing quality, washing effect, washing defects Before ironing inspection Before poly-bag inspection Customer inspection

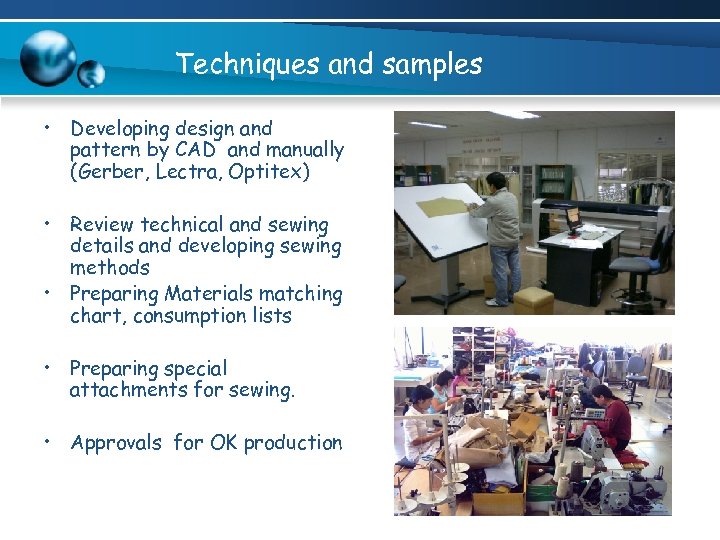

Techniques and samples • Developing design and pattern by CAD and manually (Gerber, Lectra, Optitex) • Review technical and sewing details and developing sewing methods • Preparing Materials matching chart, consumption lists • Preparing special attachments for sewing. • Approvals for OK production

Techniques and samples • Developing design and pattern by CAD and manually (Gerber, Lectra, Optitex) • Review technical and sewing details and developing sewing methods • Preparing Materials matching chart, consumption lists • Preparing special attachments for sewing. • Approvals for OK production

Merchandising • Communicate with customers, following up orders • Purchasing materials developing fabrics, designs, washing methods. manage sub-contract factories Developing samples • Suggest samples of design and sewing problems

Merchandising • Communicate with customers, following up orders • Purchasing materials developing fabrics, designs, washing methods. manage sub-contract factories Developing samples • Suggest samples of design and sewing problems

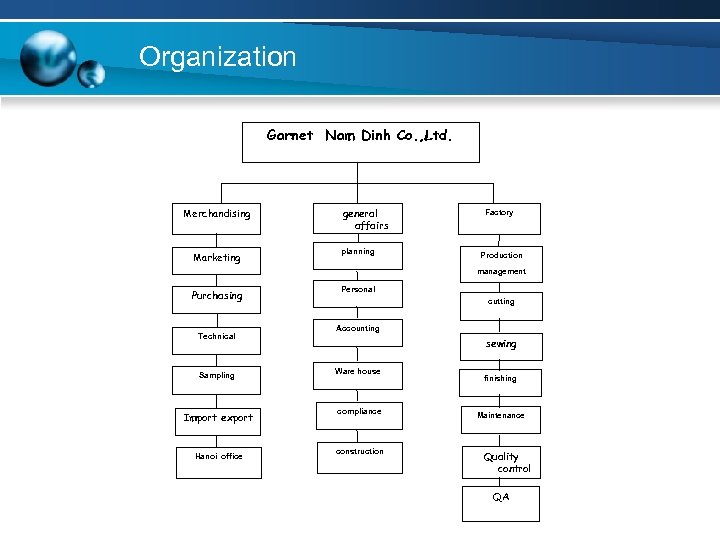

Organization Garnet Nam Dinh Co. , Ltd. Merchandising Marketing general affairs planning Factory Production management Purchasing Technical Sampling Import export Hanoi office Personal cutting Accounting sewing Ware house compliance construction finishing Maintenance Quality control QA

Organization Garnet Nam Dinh Co. , Ltd. Merchandising Marketing general affairs planning Factory Production management Purchasing Technical Sampling Import export Hanoi office Personal cutting Accounting sewing Ware house compliance construction finishing Maintenance Quality control QA

Contacts HANOI OFFICE NO 8. Dinh thon road, My Dinh Hanoi, Vietnam Tel : (84 4) 3787 5890 Fax : (84 4) 3787 -5891 E-mail : garnet@garnetnamdinh. com Mobile (84) 93 231 1488 Skype ID: garnet. namdinh CEO: Mr. Peter Hong Contact Person : Ms. Linh NAM DINH FACTORY Lot C 6 -5 Hoa Xa Industrial Zone, Nam Dinh, Vietnam Tel: (84 350)384 4663~4 Fax: (84 350)384 4665 Email : garnet@garnetnamdinh. com Contact person : Ms. Yen; Mr. Tuan

Contacts HANOI OFFICE NO 8. Dinh thon road, My Dinh Hanoi, Vietnam Tel : (84 4) 3787 5890 Fax : (84 4) 3787 -5891 E-mail : garnet@garnetnamdinh. com Mobile (84) 93 231 1488 Skype ID: garnet. namdinh CEO: Mr. Peter Hong Contact Person : Ms. Linh NAM DINH FACTORY Lot C 6 -5 Hoa Xa Industrial Zone, Nam Dinh, Vietnam Tel: (84 350)384 4663~4 Fax: (84 350)384 4665 Email : garnet@garnetnamdinh. com Contact person : Ms. Yen; Mr. Tuan

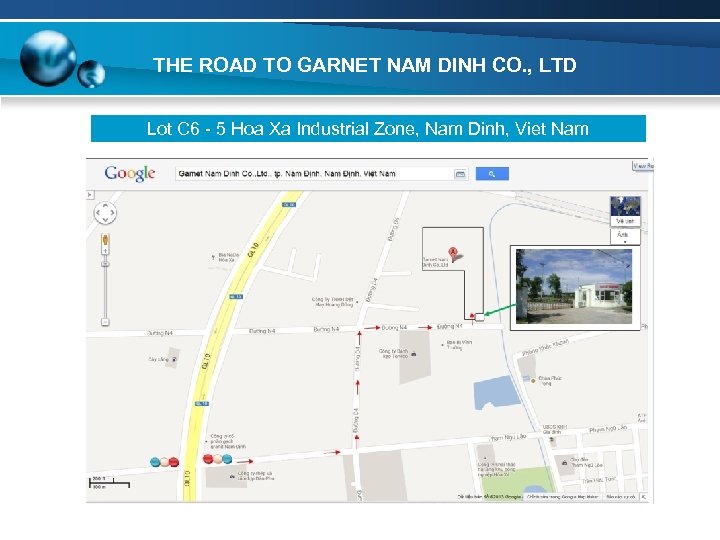

THE ROAD TO GARNET NAM DINH CO. , LTD Lot C 6 - 5 Hoa Xa Industrial Zone, Nam Dinh, Viet Nam

THE ROAD TO GARNET NAM DINH CO. , LTD Lot C 6 - 5 Hoa Xa Industrial Zone, Nam Dinh, Viet Nam