d3eee7c45f7a7ce19db4a1520c3fd83e.ppt

- Количество слайдов: 23

Company presentation

Company presentation

History reference Ossam AD was created in 1980 for production of castings of spheroidal-graphite cast iron - material with a complex technology and high power consumption production. After its privatization in 1997 Ossam became a member company of Metal Technology Group Angel Balevski HOLDING AD, Sofia. Since 1985 it became the biggest and the most modern plant for production of castings of ductile cast iron on the Balkan Peninsula. Recently Ossam AD has also adopted the casting of austempered ductile cast iron (ADI). ossam. mtgbg. com 2

History reference Ossam AD was created in 1980 for production of castings of spheroidal-graphite cast iron - material with a complex technology and high power consumption production. After its privatization in 1997 Ossam became a member company of Metal Technology Group Angel Balevski HOLDING AD, Sofia. Since 1985 it became the biggest and the most modern plant for production of castings of ductile cast iron on the Balkan Peninsula. Recently Ossam AD has also adopted the casting of austempered ductile cast iron (ADI). ossam. mtgbg. com 2

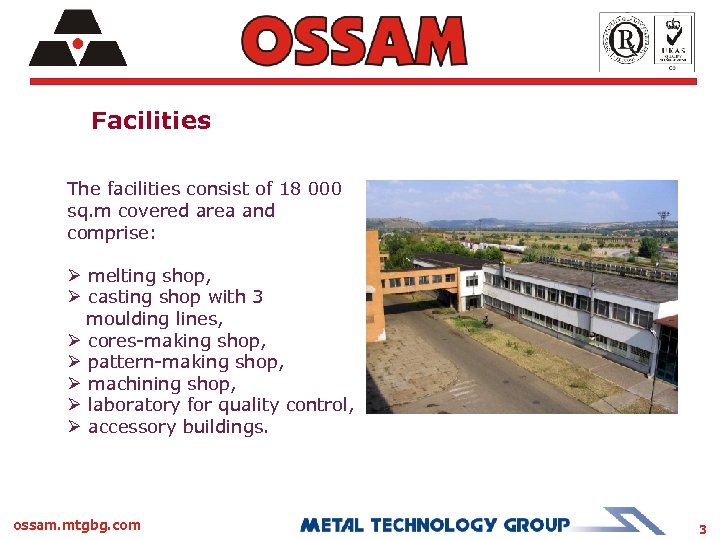

Facilities The facilities consist of 18 000 sq. m covered area and comprise: Ø melting shop, Ø casting shop with 3 moulding lines, Ø cores-making shop, Ø pattern-making shop, Ø machining shop, Ø laboratory for quality control, Ø accessory buildings. ossam. mtgbg. com 3

Facilities The facilities consist of 18 000 sq. m covered area and comprise: Ø melting shop, Ø casting shop with 3 moulding lines, Ø cores-making shop, Ø pattern-making shop, Ø machining shop, Ø laboratory for quality control, Ø accessory buildings. ossam. mtgbg. com 3

Production possibilities The company is specialized in production of castings of ductile cast iron(80 %) and grey cast iron(20 %). Ossam is also able to cast ADI (austempered ductile iron) parts. The main production method is sand casting. Presently the factory has an annual production capacity of 4 000 t. The castings have a large range of application as water- and gas-pipe fittings, parts for agricultural machinery, parts for hydraulic products, various machines etc. The single weight of the parts is from 1 kg up to 50 kg, maximum overall dimensions – 550/450/350 mm. The production of Ossam AD is in compliance with the following material standards: ossam. mtgbg. com 4

Production possibilities The company is specialized in production of castings of ductile cast iron(80 %) and grey cast iron(20 %). Ossam is also able to cast ADI (austempered ductile iron) parts. The main production method is sand casting. Presently the factory has an annual production capacity of 4 000 t. The castings have a large range of application as water- and gas-pipe fittings, parts for agricultural machinery, parts for hydraulic products, various machines etc. The single weight of the parts is from 1 kg up to 50 kg, maximum overall dimensions – 550/450/350 mm. The production of Ossam AD is in compliance with the following material standards: ossam. mtgbg. com 4

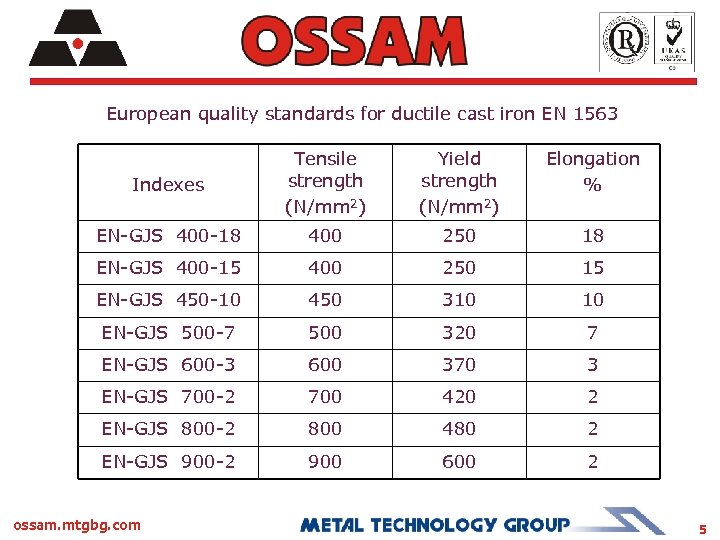

European quality standards for ductile cast iron EN 1563 Indexes Tensile strength (N/mm 2) Yield strength (N/mm 2) Elongation % EN-GJS 400 -18 400 250 18 EN-GJS 400 -15 400 250 15 EN-GJS 450 -10 450 310 10 EN-GJS 500 -7 500 320 7 EN-GJS 600 -3 600 370 3 EN-GJS 700 -2 700 420 2 EN-GJS 800 -2 800 480 2 EN-GJS 900 -2 900 600 2 ossam. mtgbg. com 5

European quality standards for ductile cast iron EN 1563 Indexes Tensile strength (N/mm 2) Yield strength (N/mm 2) Elongation % EN-GJS 400 -18 400 250 18 EN-GJS 400 -15 400 250 15 EN-GJS 450 -10 450 310 10 EN-GJS 500 -7 500 320 7 EN-GJS 600 -3 600 370 3 EN-GJS 700 -2 700 420 2 EN-GJS 800 -2 800 480 2 EN-GJS 900 -2 900 600 2 ossam. mtgbg. com 5

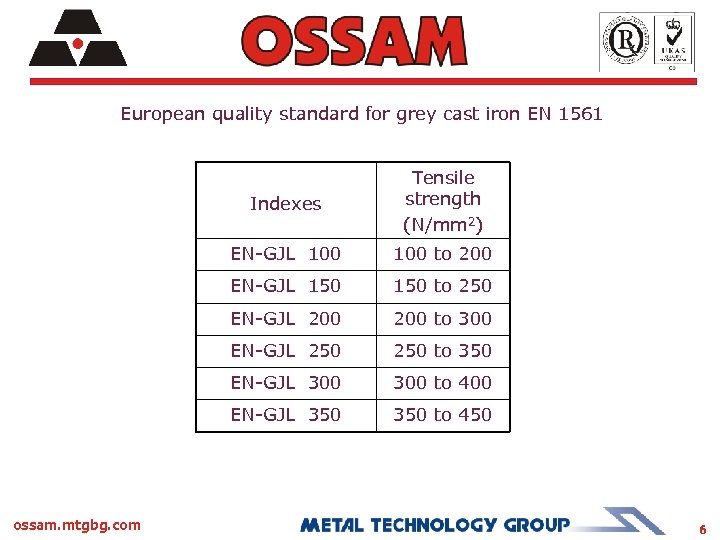

European quality standard for grey cast iron EN 1561 Indexes EN-GJL 100 to 200 EN-GJL 150 to 250 EN-GJL 200 to 300 EN-GJL 250 to 350 EN-GJL 300 to 400 EN-GJL 350 ossam. mtgbg. com Tensile strength (N/mm 2) 350 to 450 6

European quality standard for grey cast iron EN 1561 Indexes EN-GJL 100 to 200 EN-GJL 150 to 250 EN-GJL 200 to 300 EN-GJL 250 to 350 EN-GJL 300 to 400 EN-GJL 350 ossam. mtgbg. com Tensile strength (N/mm 2) 350 to 450 6

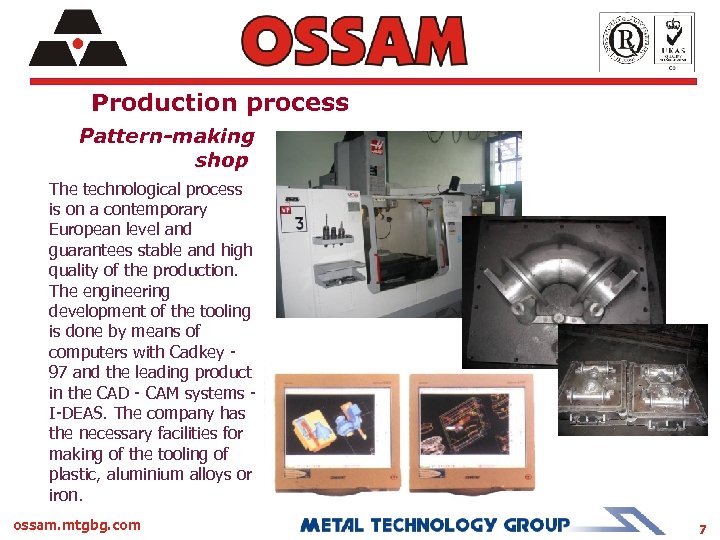

Production process Pattern-making shop The technological process is on a contemporary European level and guarantees stable and high quality of the production. The engineering development of the tooling is done by means of computers with Cadkey 97 and the leading product in the CAD - CAM systems I-DEAS. The company has the necessary facilities for making of the tooling of plastic, aluminium alloys or iron. ossam. mtgbg. com 7

Production process Pattern-making shop The technological process is on a contemporary European level and guarantees stable and high quality of the production. The engineering development of the tooling is done by means of computers with Cadkey 97 and the leading product in the CAD - CAM systems I-DEAS. The company has the necessary facilities for making of the tooling of plastic, aluminium alloys or iron. ossam. mtgbg. com 7

Melting area The melting shop is equipped with 4 indiction furnaces with capacity of 10 tons each and 1 induction furnace with capacity of 5 tons. ossam. mtgbg. com 8

Melting area The melting shop is equipped with 4 indiction furnaces with capacity of 10 tons each and 1 induction furnace with capacity of 5 tons. ossam. mtgbg. com 8

Sand cores-making shop The cores are made on automatic machines using both the HOT BOX and the COLD BOX processes. ossam. mtgbg. com 9

Sand cores-making shop The cores are made on automatic machines using both the HOT BOX and the COLD BOX processes. ossam. mtgbg. com 9

Moulding and casting area Three moulding lines are available in the factory: Ø 2 semi-automatic moulding lines with dimensions of the boxes: - 750 x 630 x 250/320 mm - 750 x 630 x 250/250 mm Capacity: 60 boxes per hour Ø 1 automatic moulding line with dimensions of the boxes: - 630 x 500 x 160/160 mm Capacity: 100 boxes per hour Maximal dimensions of the castings: 550 x 450 x 350 mm ossam. mtgbg. com 10

Moulding and casting area Three moulding lines are available in the factory: Ø 2 semi-automatic moulding lines with dimensions of the boxes: - 750 x 630 x 250/320 mm - 750 x 630 x 250/250 mm Capacity: 60 boxes per hour Ø 1 automatic moulding line with dimensions of the boxes: - 630 x 500 x 160/160 mm Capacity: 100 boxes per hour Maximal dimensions of the castings: 550 x 450 x 350 mm ossam. mtgbg. com 10

Machining shop The available equipment installed in the new machining shop consists of lathes, milling machines, horizontal and vertical centers – all with CNC control. ossam. mtgbg. com 11

Machining shop The available equipment installed in the new machining shop consists of lathes, milling machines, horizontal and vertical centers – all with CNC control. ossam. mtgbg. com 11

Quality control The high quality of the products is guaranteed by mechanical and chemical tests performed in: Ø Spectral laboratory Ø Laboratory for analysis of the moulding and sand moulding mixtures Ø Mechanical laboratory Ø Metallographic laboratory ossam. mtgbg. com 12

Quality control The high quality of the products is guaranteed by mechanical and chemical tests performed in: Ø Spectral laboratory Ø Laboratory for analysis of the moulding and sand moulding mixtures Ø Mechanical laboratory Ø Metallographic laboratory ossam. mtgbg. com 12

Production range Fittings for gas- and water-pipe industry valves distributors hydrants ossam. mtgbg. com 13

Production range Fittings for gas- and water-pipe industry valves distributors hydrants ossam. mtgbg. com 13

Transport and agricultural machinery housings camshafts brake system parts ossam. mtgbg. com power transmission suspension parts 14

Transport and agricultural machinery housings camshafts brake system parts ossam. mtgbg. com power transmission suspension parts 14

Other applications ring body bearing cover body ossam. mtgbg. com 15

Other applications ring body bearing cover body ossam. mtgbg. com 15

Quality The implemented quality system is certified according to ISO 9001: 2000. Certifying body – Lloyd’s Register Quality Assurance. Certificate No: 368016 ossam. mtgbg. com 16

Quality The implemented quality system is certified according to ISO 9001: 2000. Certifying body – Lloyd’s Register Quality Assurance. Certificate No: 368016 ossam. mtgbg. com 16

Human resources For all the technological processes Ossam AD relies on its experienced and well trained staff. The company invests in training programs, education of the employees and better working conditions in the factory. A close collaboration is established with The Institute of Metal Sciences – Bulgarian Academy of Sciences and this allows the company to apply the latest achievements in the foundry industry. The total number of employees is 265. ossam. mtgbg. com 17

Human resources For all the technological processes Ossam AD relies on its experienced and well trained staff. The company invests in training programs, education of the employees and better working conditions in the factory. A close collaboration is established with The Institute of Metal Sciences – Bulgarian Academy of Sciences and this allows the company to apply the latest achievements in the foundry industry. The total number of employees is 265. ossam. mtgbg. com 17

Key advantages Ø long-time experience in production of ductile cast iron Ø contemporary Quality Management System Ø closed production cycle Ø investments in new equipment Ø advanced technologies Ø experienced and skilled staff Ø flexibility and customer orientation ossam. mtgbg. com 18

Key advantages Ø long-time experience in production of ductile cast iron Ø contemporary Quality Management System Ø closed production cycle Ø investments in new equipment Ø advanced technologies Ø experienced and skilled staff Ø flexibility and customer orientation ossam. mtgbg. com 18

Financial figures Ø Turnover in 2008: Euro 6 371 000 Ø Investments in 2008: Euro 176 000 Ø Export share in 2008: 87% ossam. mtgbg. com 19

Financial figures Ø Turnover in 2008: Euro 6 371 000 Ø Investments in 2008: Euro 176 000 Ø Export share in 2008: 87% ossam. mtgbg. com 19

Markets Austria Germany References Hawle Armaturenwerke, Austria Krammer Armaturen, Austria Henke Guß- und Metallgeselschaft Gmb. H, Germany Hungary Faiveley Transport Amiens, France Faiveley Transport, Sweden Richter Formteile Gmb. H, Germany Greece Rinner KG, Austria Poland Harenia Bros S. A. , Greece LTW – Tiefbauvertriebs Gmb. H, Germany ossam. mtgbg. com 20

Markets Austria Germany References Hawle Armaturenwerke, Austria Krammer Armaturen, Austria Henke Guß- und Metallgeselschaft Gmb. H, Germany Hungary Faiveley Transport Amiens, France Faiveley Transport, Sweden Richter Formteile Gmb. H, Germany Greece Rinner KG, Austria Poland Harenia Bros S. A. , Greece LTW – Tiefbauvertriebs Gmb. H, Germany ossam. mtgbg. com 20

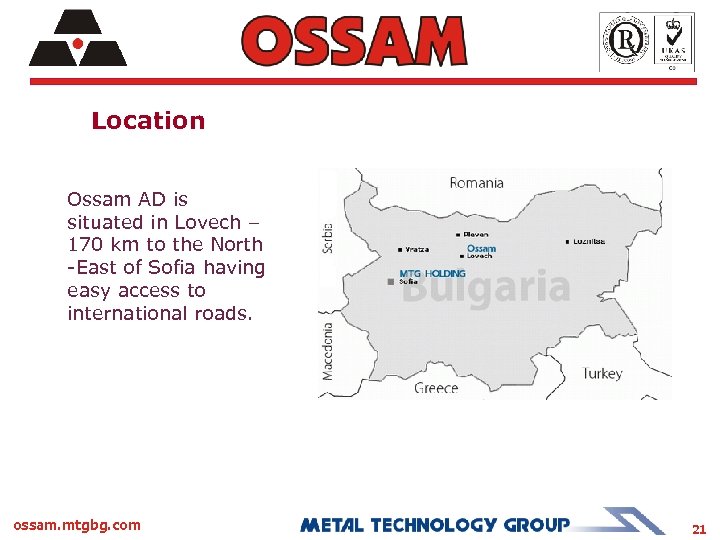

Location Ossam AD is situated in Lovech – 170 km to the North -East of Sofia having easy access to international roads. ossam. mtgbg. com 21

Location Ossam AD is situated in Lovech – 170 km to the North -East of Sofia having easy access to international roads. ossam. mtgbg. com 21

Contacts METAL TECHNOLOGY GROUP OSSAM AD Bulgaria Blvd. , 18 Bokar, 1404 Sofia, BULGARIA Tel: + 359 2 8185918 Fax: + 359 2 8185949 E-mail: mtg@mtgbg. com Web: www. mtgbg. com 5500 Lovech Bulgaria North Industrial Zone Tel: +359 68 601 176; 601 178 Fax: +359 68 601 174 E-mail: ossam_marketing@mail. bg Web: http: //ossam. mtgbg. com 22

Contacts METAL TECHNOLOGY GROUP OSSAM AD Bulgaria Blvd. , 18 Bokar, 1404 Sofia, BULGARIA Tel: + 359 2 8185918 Fax: + 359 2 8185949 E-mail: mtg@mtgbg. com Web: www. mtgbg. com 5500 Lovech Bulgaria North Industrial Zone Tel: +359 68 601 176; 601 178 Fax: +359 68 601 174 E-mail: ossam_marketing@mail. bg Web: http: //ossam. mtgbg. com 22

Thank you for your attention ! Ossam ossam. mtgbg. com 23

Thank you for your attention ! Ossam ossam. mtgbg. com 23