54be9390cf53e3a3164c7ae6936349a9.ppt

- Количество слайдов: 45

© Company name - 1 3/18/2018 ABB Overview

Contents Matti Turtiainen ABB today ABB in Finland Technology leadership ABB Drives © ABB Oy 2007 - 2 - Jere Syvänne – Kenttäväylien kehitystyö Julle Ala-Lahti – RFID: n käyttö logistiikassa VAL - konsepti

ABB today ABB is a global leader in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact. ABB Group: Revenues 24 billion USD n 111 000 in around 100 countries n R&D investments around 1. 1 billion USD n © ABB Oy 2007 - 3 - n Market leader in key businesses n www. abb. com

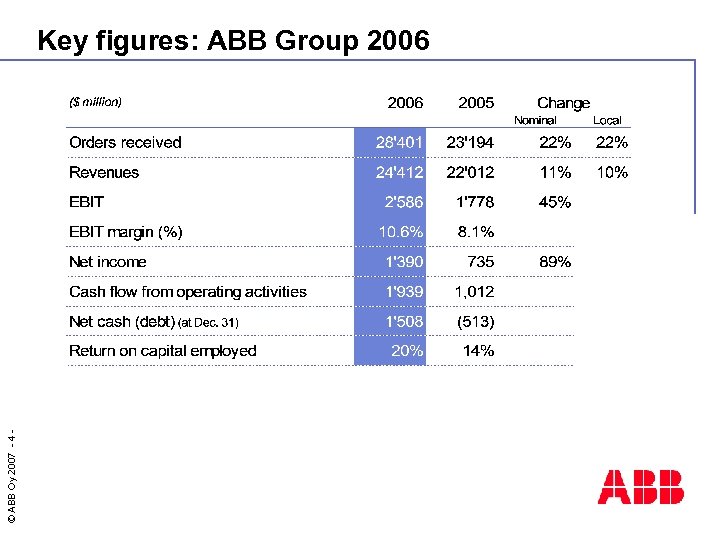

© ABB Oy 2007 - 4 - Key figures: ABB Group 2006

ABB in Finland ABB Oy: revenues 1. 7 billion EUR n more than 6000 employees on over 40 locations n R&D investments 7 % of revenues n factories in Helsinki and Vaasa n © ABB Oy 2007 - 5 - n www. abb. fi

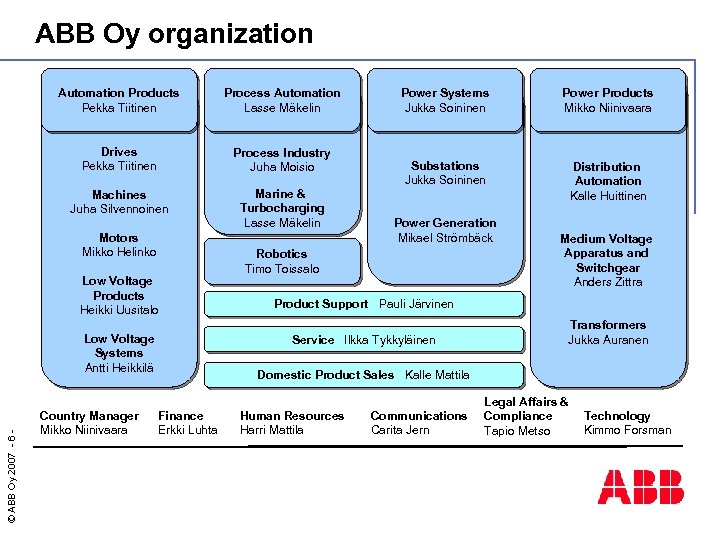

ABB Oy organization Automation Products Pekka Tiitinen Process Automation Lasse Mäkelin Drives Pekka Tiitinen Process Industry Juha Moisio Machines Juha Silvennoinen Marine & Turbocharging Lasse Mäkelin Motors Mikko Helinko Low Voltage Products Heikki Uusitalo © ABB Oy 2007 - 6 - Low Voltage Systems Antti Heikkilä Country Manager Mikko Niinivaara Power Systems Jukka Soininen Power Products Mikko Niinivaara Substations Jukka Soininen Distribution Automation Kalle Huittinen Power Generation Mikael Strömbäck Robotics Timo Toissalo Medium Voltage Apparatus and Switchgear Anders Zittra Product Support Pauli Järvinen Service Ilkka Tykkyläinen Transformers Jukka Auranen Domestic Product Sales Kalle Mattila Finance Erkki Luhta Human Resources Harri Mattila Communications Carita Jern Legal Affairs & Compliance Tapio Metso Technology Kimmo Forsman

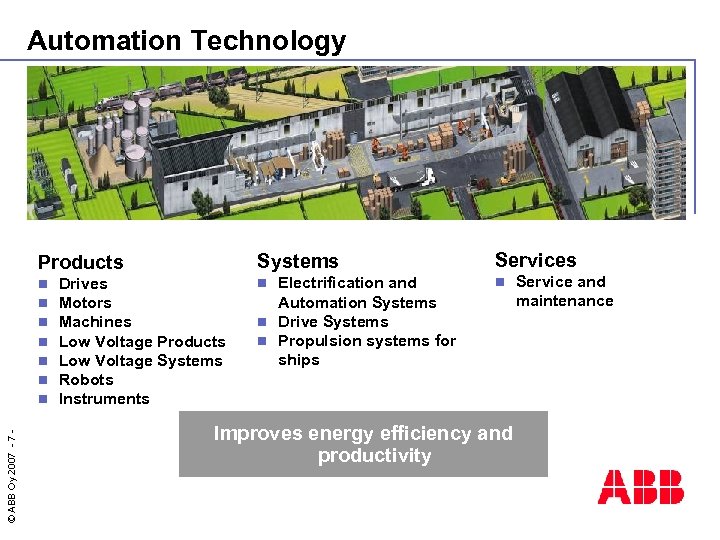

Automation Technology Systems Products © ABB Oy 2007 - n n n n Drives Motors Machines Low Voltage Products Low Voltage Systems Robots Instruments Services Electrification and Automation Systems n Drive Systems n Propulsion systems for ships n n Improves energy efficiency and productivity Service and maintenance

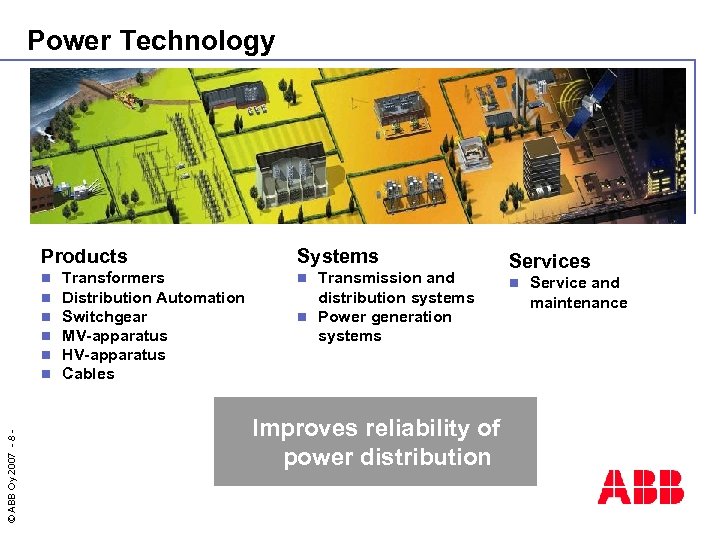

Power Technology Products © ABB Oy 2007 - 8 - n n n Transformers Distribution Automation Switchgear MV-apparatus HV-apparatus Cables Systems Transmission and distribution systems n Power generation systems n Improves reliability of power distribution Services n Service and maintenance

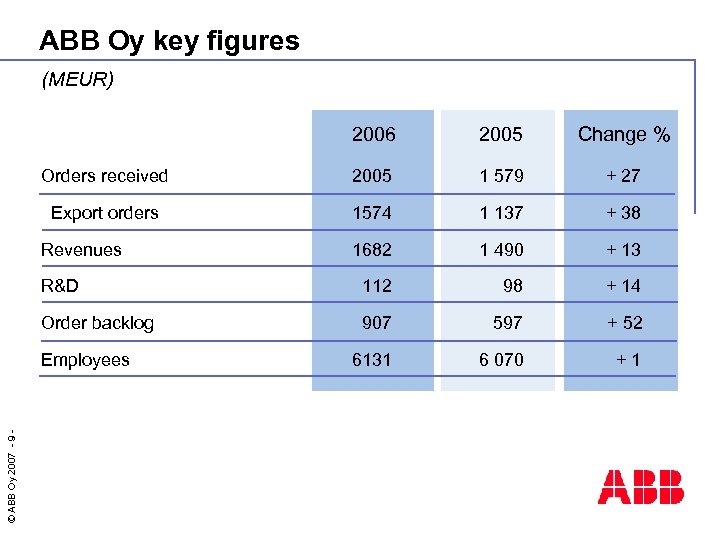

ABB Oy key figures (MEUR) 2006 2005 Change % Orders received 2005 1 579 + 27 Export orders 1574 1 137 + 38 Revenues 1682 1 490 + 13 112 98 Order backlog 907 597 + 52 Employees 6131 6 070 + 1 © ABB Oy 2007 - 9 - R&D + 14

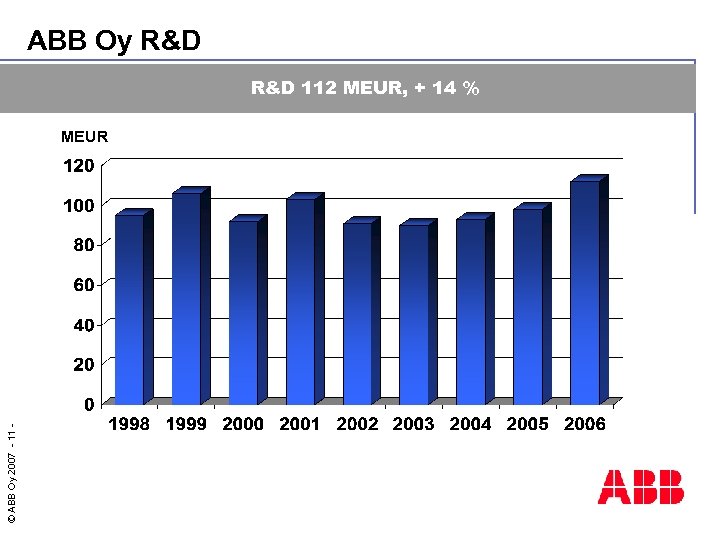

ABB Oy R&D 112 MEUR, + 14 % © ABB Oy 2007 - 11 - MEUR

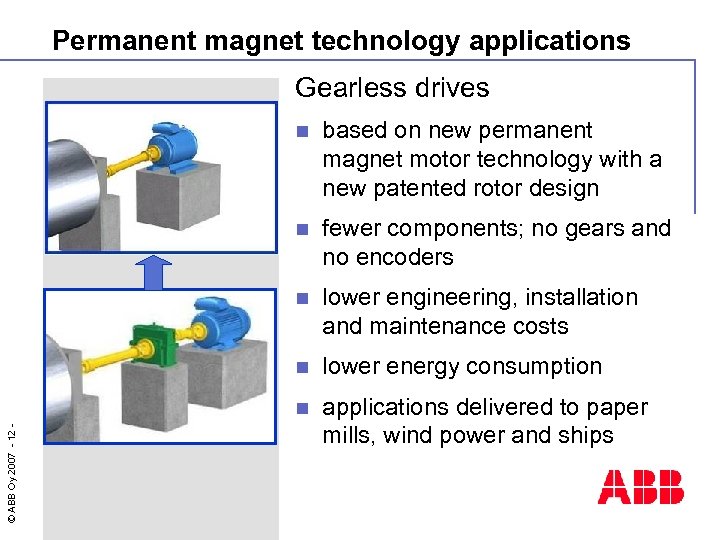

Permanent magnet technology applications Gearless drives based on new permanent magnet motor technology with a new patented rotor design n fewer components; no gears and no encoders n lower engineering, installation and maintenance costs n lower energy consumption n © ABB Oy 2007 - 12 - n applications delivered to paper mills, wind power and ships

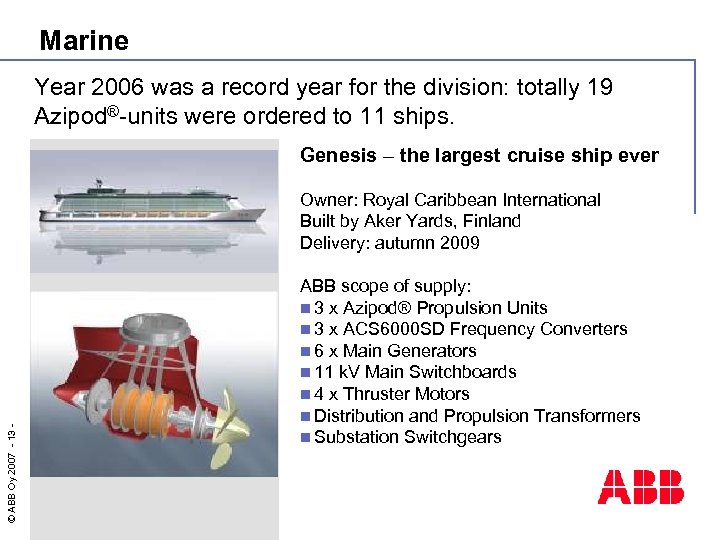

Marine Year 2006 was a record year for the division: totally 19 Azipod®-units were ordered to 11 ships. Genesis – the largest cruise ship ever © ABB Oy 2007 - 13 - Owner: Royal Caribbean International Built by Aker Yards, Finland Delivery: autumn 2009 ABB scope of supply: n 3 x Azipod® Propulsion Units n 3 x ACS 6000 SD Frequency Converters n 6 x Main Generators n 11 k. V Main Switchboards n 4 x Thruster Motors n Distribution and Propulsion Transformers n Substation Switchgears

Marine Admiralty – two Arctic shuttle tankers Customer: Sovcomflot Built at the Admiralty Shipyards in St. Petersburg, Russia Delivery: year 2009 ABB delivery: n two 8. 5 MW Azipod units (Russian ice class LU 6) n medium voltage generators n main switchboards n transformers n frequency converters © ABB Oy 2007 - 14 - The first Azipod system delivery to Russian Shipyards. In August, ABB Marine signed the contract to deliver a complete shaftline propulsion and power system for the first Superyacht to be built by Fincantieri in Italy. The 134 metre yacht will be completed in 2010 at the naval shipyard in Muggiano.

Wind Power Generators New, extended global frame agreements with the biggest wind turbine manufacturers n ABB is the world leader in Megawatt class wind power generators n Demand of generators for wind power generation was very high in 2006. A new record of orders recieved and generators delivered was made. The order backlog is very high n © ABB Oy 2007 - 15 - n First multi-megawatt permanent magnet generator specificly designed for offshore turbines was delivered

Power Systems n Gas Engine Power Plants Continuous co-operation with Wärtsilä in control system deliveries. E. g. five gas engine power plant projects to Azerbaizan including 52 engines. n Gas Turbine Power Plants Contract with Svenska Kraftnät for retrofit of Hallstavik and Lahall gas turbine power plants in Sweden, 6 x 60 MW n Hydro Power Plants Electrification and automation system to Kierikki Hydro Power Plant, ~ 2 x 20 MVA © ABB Oy 2007 - 16 - Astara, Azerbaizan Electrification and automation system to Kaltimo Hydro Power Plant, ~ 2 x 20 MVA Kaltimo Hydro Power Plant

BU LV Drives n © Company name - 17 3/18/2018 n Updated 10/2006 Introduction to ABB drives

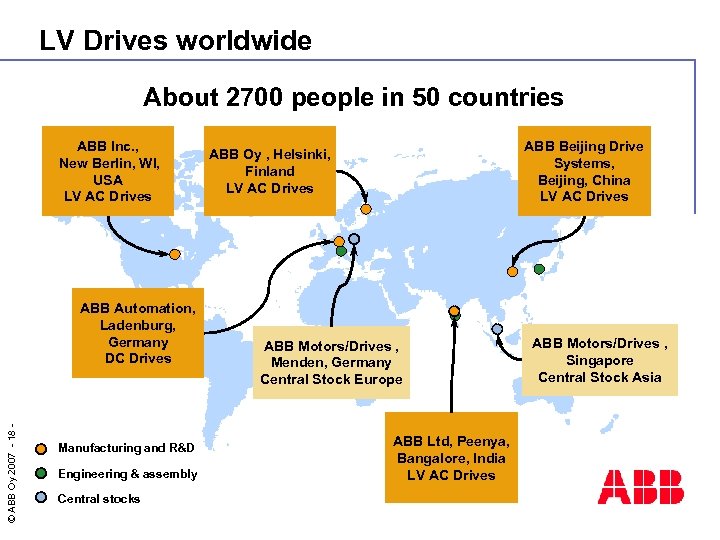

LV Drives worldwide About 2700 people in 50 countries ABB Inc. , New Berlin, WI, USA LV AC Drives © ABB Oy 2007 - 18 - ABB Automation, Ladenburg, Germany DC Drives Manufacturing and R&D Engineering & assembly Central stocks ABB Beijing Drive Systems, Beijing, China LV AC Drives ABB Oy , Helsinki, Finland LV AC Drives ABB Motors/Drives , Menden, Germany Central Stock Europe ABB Ltd, Peenya, Bangalore, India LV AC Drives ABB Motors/Drives , Singapore Central Stock Asia

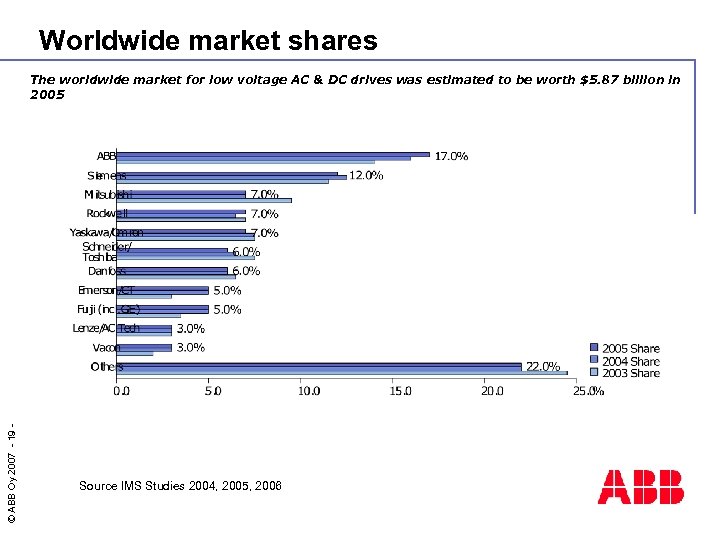

Worldwide market shares © ABB Oy 2007 - 19 - The worldwide market for low voltage AC & DC drives was estimated to be worth $5. 87 billion in 2005 Source IMS Studies 2004, 2005, 2006

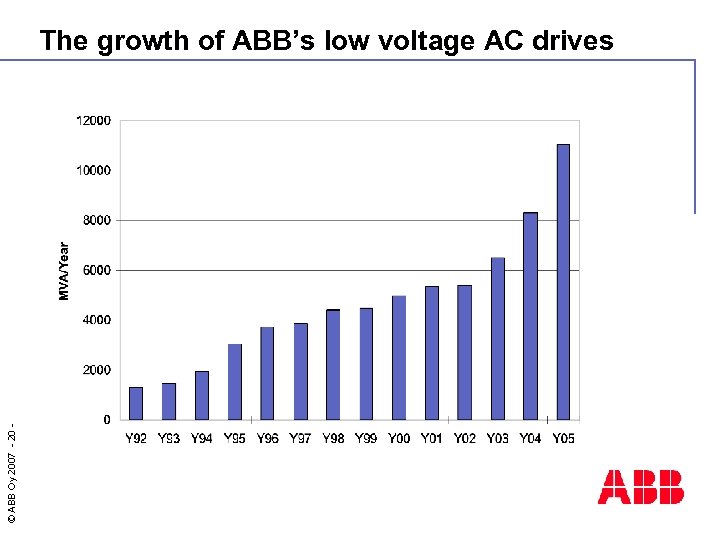

© ABB Oy 2007 - 20 - The growth of ABB’s low voltage AC drives

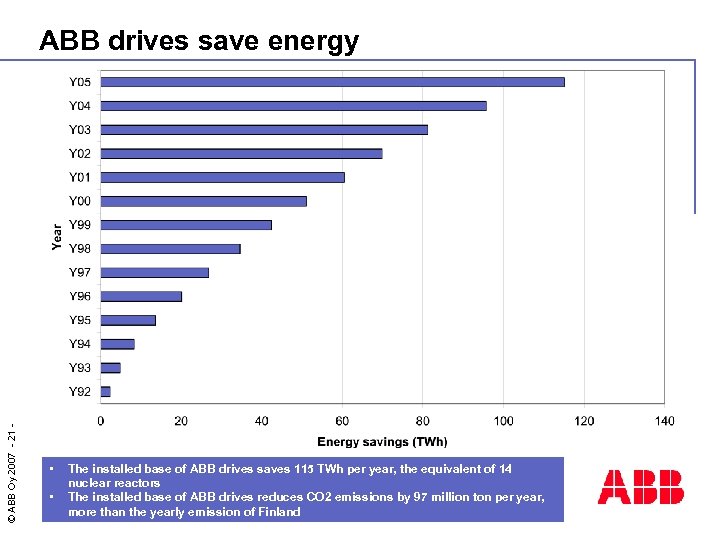

© ABB Oy 2007 - 21 - ABB drives save energy • • The installed base of ABB drives saves 115 TWh per year, the equivalent of 14 nuclear reactors The installed base of ABB drives reduces CO 2 emissions by 97 million ton per year, more than the yearly emission of Finland

© ABB Oy 2007 - 22 - Our offering

Low voltage AC drives for. . . Building automation n Industries n © ABB Oy 2007 - 23 - n Original equipment manufacturers

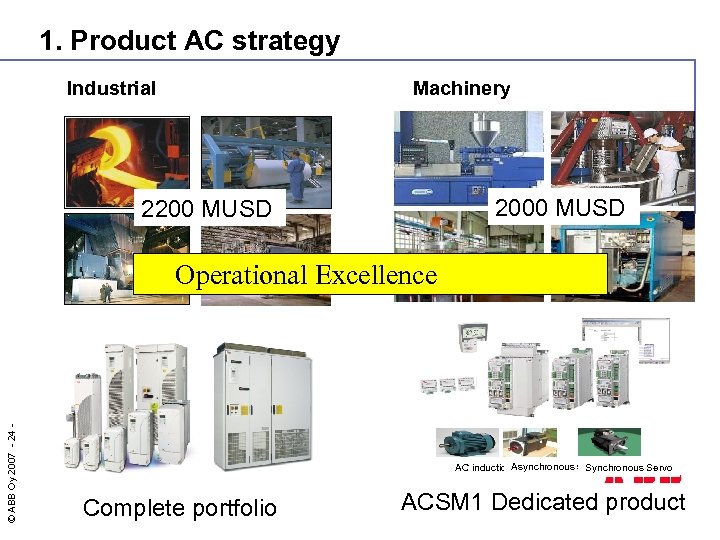

1. Product AC strategy Industrial Machinery 2000 MUSD 2200 MUSD © ABB Oy 2007 - 24 - Operational Excellence Synchronous Servo AC induction. Asynchronous servo Complete portfolio ACSM 1 Dedicated product

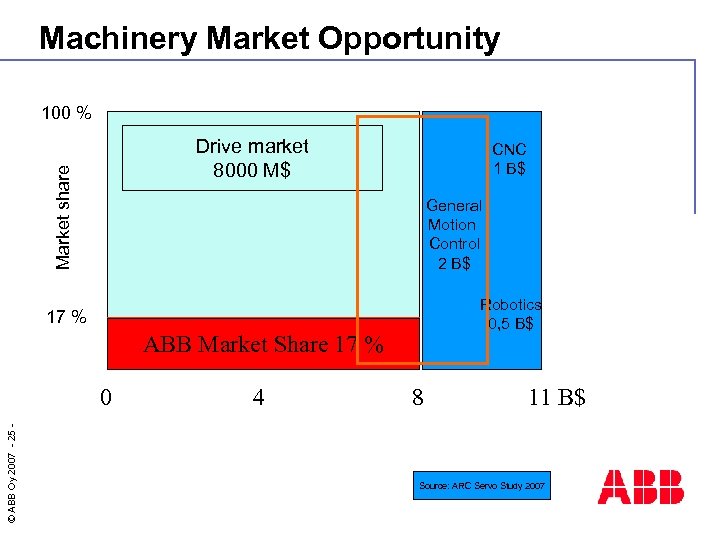

Machinery Market Opportunity 100 % Market share Drive market 8000 M$ CNC 1 B$ General Motion Control 2 B$ Robotics 0, 5 B$ 17 % ABB Market Share 17 % © ABB Oy 2007 - 25 - 0 4 8 11 B$ Source: ARC Servo Study 2007

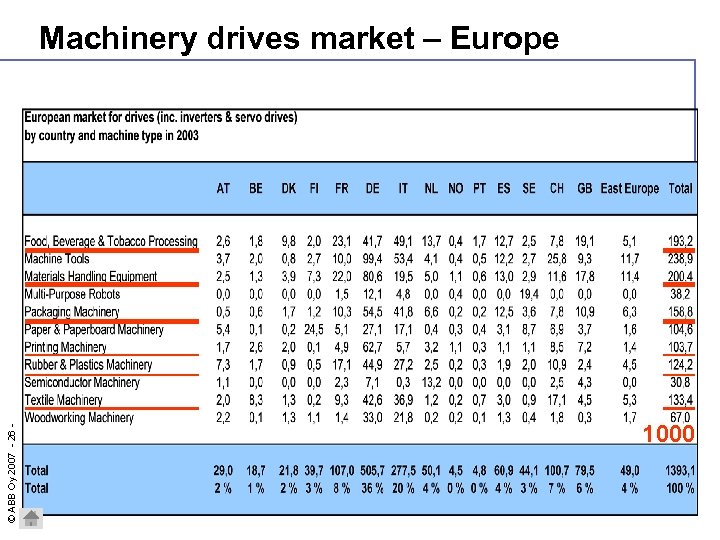

© ABB Oy 2007 - 26 - Machinery drives market – Europe 1000

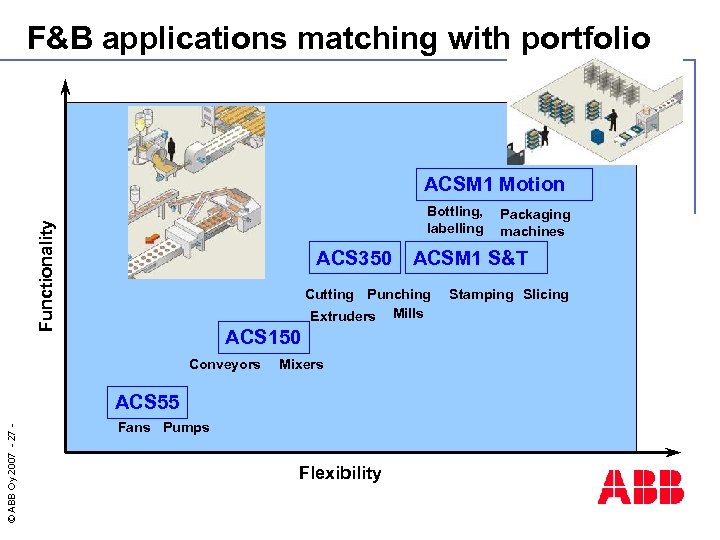

F&B applications matching with portfolio ACSM 1 Motion Functionality Bottling, labelling ACS 350 Conveyors Mixers ACS 55 © ABB Oy 2007 - 27 - ACSM 1 S&T Cutting Punching Extruders Mills ACS 150 Fans Pumps Flexibility Packaging machines Stamping Slicing

Help ABB high performance machinery drives ACSM 1 © Company name - 28 3/18/2018 n Product specification

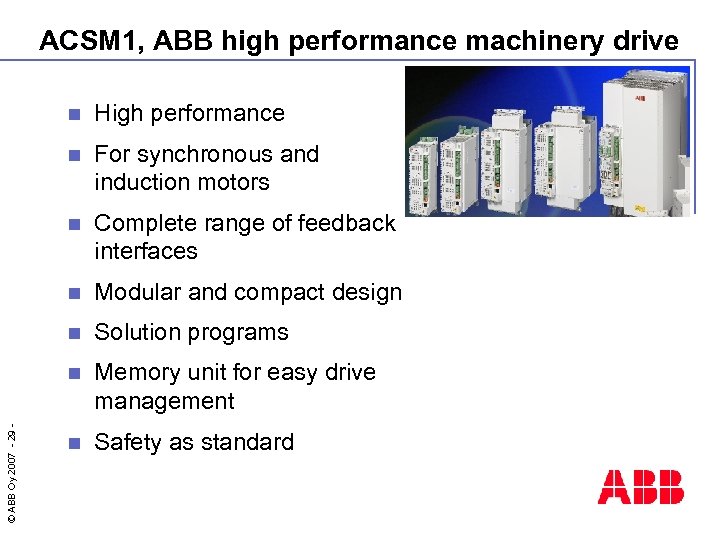

ACSM 1, ABB high performance machinery drive High performance n For synchronous and induction motors n Complete range of feedback interfaces n Modular and compact design n Solution programs n © ABB Oy 2007 - 29 - n Memory unit for easy drive management n Safety as standard

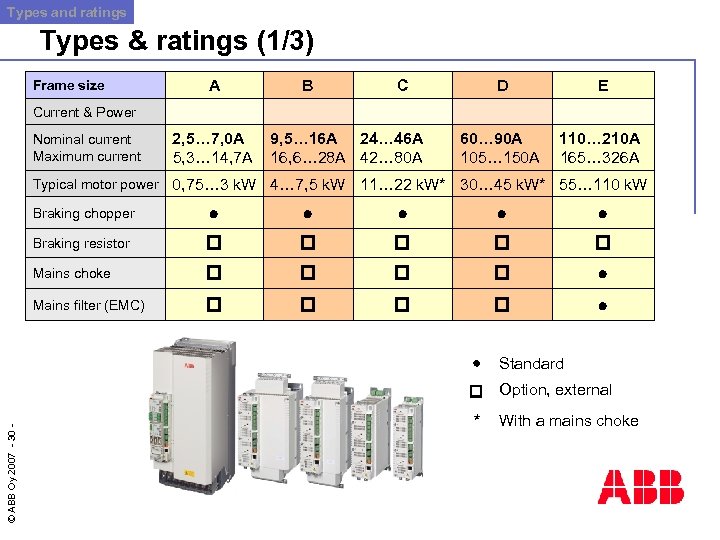

Types and ratings Types & ratings (1/3) Frame size A B C D E Current & Power Nominal current Maximum current 2, 5… 7, 0 A 5, 3… 14, 7 A 60… 90 A 105… 150 A 110… 210 A 165… 326 A Typical motor power 0, 75… 3 k. W 9, 5… 16 A 24… 46 A 16, 6… 28 A 42… 80 A 4… 7, 5 k. W 11… 22 k. W* 30… 45 k. W* 55… 110 k. W Braking chopper Braking resistor Mains choke Mains filter (EMC) Standard © ABB Oy 2007 - 30 - Option, external * With a mains choke

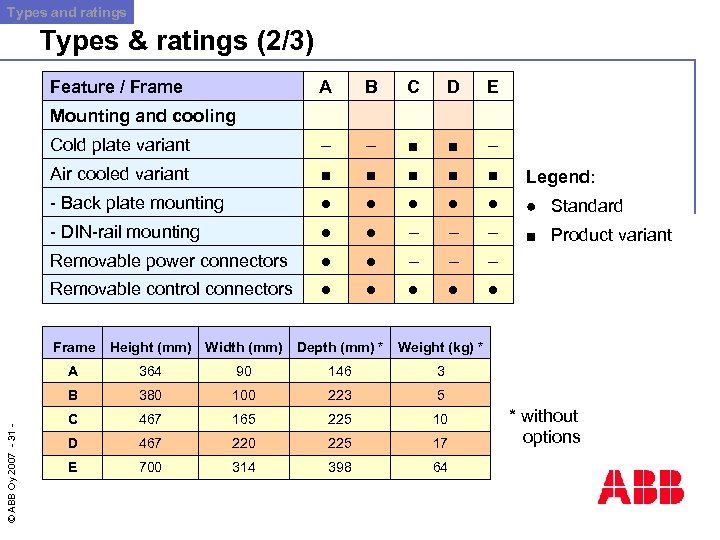

Types and ratings Types & ratings (2/3) Feature / Frame A B C D E Mounting and cooling Cold plate variant – – ■ ■ – Air cooled variant ■ ■ ■ Legend: - Back plate mounting ● ● ● Standard - DIN-rail mounting ● ● – – – ■ Product variant Removable power connectors ● ● – – – Removable control connectors ● ● ● Height (mm) Width (mm) Depth (mm) * Weight (kg) * A 364 90 146 3 B © ABB Oy 2007 - 31 - Frame 380 100 223 5 C 467 165 225 10 D 467 220 225 17 E 700 314 398 64 * without options

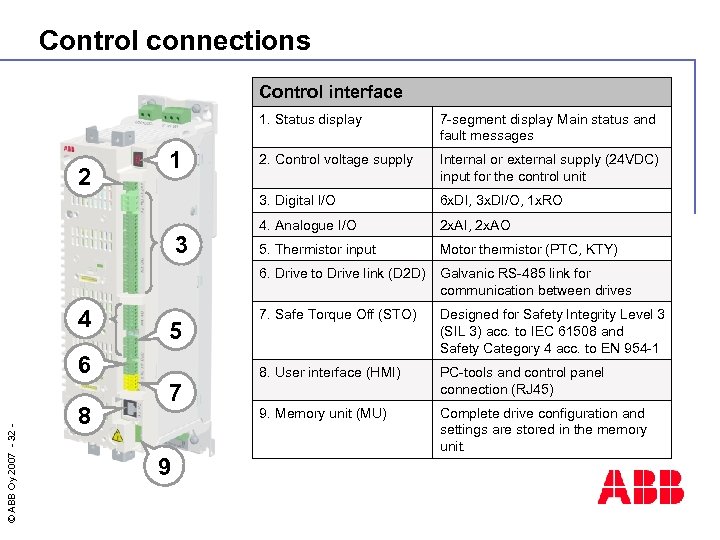

Control connections Control interface 1. Status display 4 5 © ABB Oy 2007 - 32 - 6 8 7 9 Internal or external supply (24 VDC) input for the control unit 6 x. DI, 3 x. DI/O, 1 x. RO 4. Analogue I/O 2 x. AI, 2 x. AO 5. Thermistor input Motor thermistor (PTC, KTY) 6. Drive to Drive link (D 2 D) 3 2. Control voltage supply 3. Digital I/O 2 1 7 -segment display Main status and fault messages Galvanic RS-485 link for communication between drives 7. Safe Torque Off (STO) Designed for Safety Integrity Level 3 (SIL 3) acc. to IEC 61508 and Safety Category 4 acc. to EN 954 -1 8. User interface (HMI) PC-tools and control panel connection (RJ 45) 9. Memory unit (MU) Complete drive configuration and settings are stored in the memory unit.

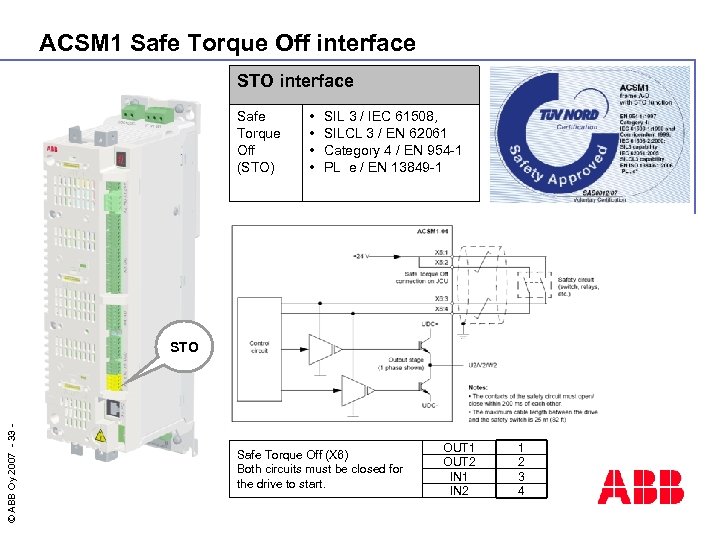

ACSM 1 Safe Torque Off interface STO interface Safe Torque Off (STO) • • SIL 3 / IEC 61508, SILCL 3 / EN 62061 Category 4 / EN 954 -1 PL e / EN 13849 -1 © ABB Oy 2007 - 33 - STO Safe Torque Off (X 6) Both circuits must be closed for the drive to start. OUT 1 OUT 2 IN 1 IN 2 1 2 3 4

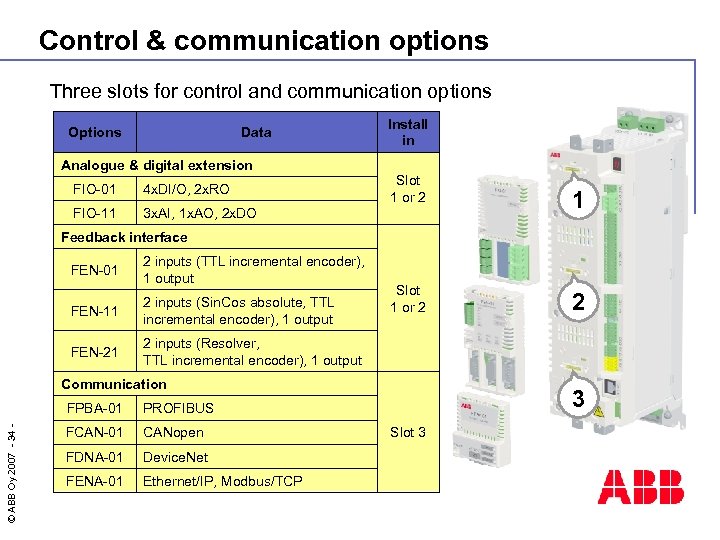

Control & communication options Three slots for control and communication options Options Data Install in Analogue & digital extension FIO-01 4 x. DI/O, 2 x. RO FIO-11 Slot 1 or 2 3 x. AI, 1 x. AO, 2 x. DO 1 Feedback interface FEN-01 2 inputs (TTL incremental encoder), 1 output FEN-11 2 inputs (Sin. Cos absolute, TTL incremental encoder), 1 output FEN-21 2 inputs (Resolver, TTL incremental encoder), 1 output Slot 1 or 2 Communication © ABB Oy 2007 - 34 - FPBA-01 CANopen FDNA-01 Device. Net FENA-01 Ethernet/IP, Modbus/TCP 3 PROFIBUS FCAN-01 2 Slot 3

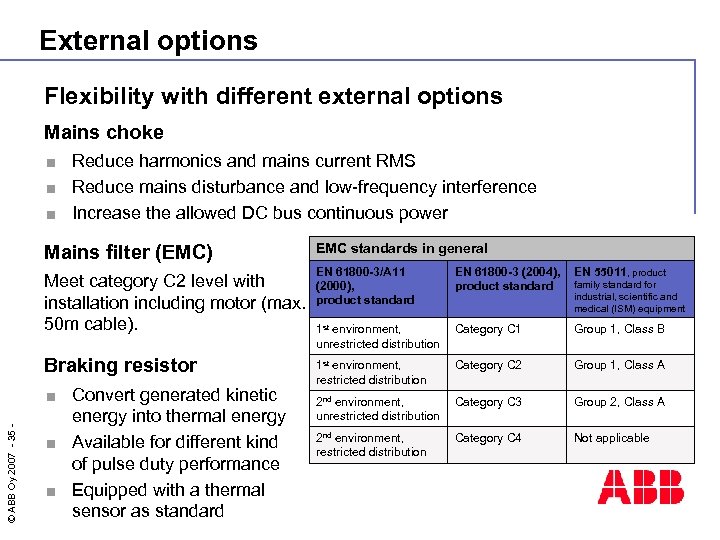

External options Flexibility with different external options Mains choke Reduce harmonics and mains current RMS < Reduce mains disturbance and low-frequency interference < Increase the allowed DC bus continuous power < Mains filter (EMC) EMC standards in general EN 61800 -3/A 11 EN 61800 -3 (2004), product standard EN 55011, product Category C 1 Group 1, Class B 1 st environment, restricted distribution Category C 2 Group 1, Class A 2 nd environment, unrestricted distribution Category C 3 Group 2, Class A 2 nd environment, restricted distribution Category C 4 Not applicable Meet category C 2 level with (2000), installation including motor (max. product standard 50 m cable). 1 st environment, family standard for industrial, scientific and medical (ISM) equipment unrestricted distribution Braking resistor Convert generated kinetic energy into thermal energy < Available for different kind of pulse duty performance < Equipped with a thermal sensor as standard © ABB Oy 2007 - 35 - <

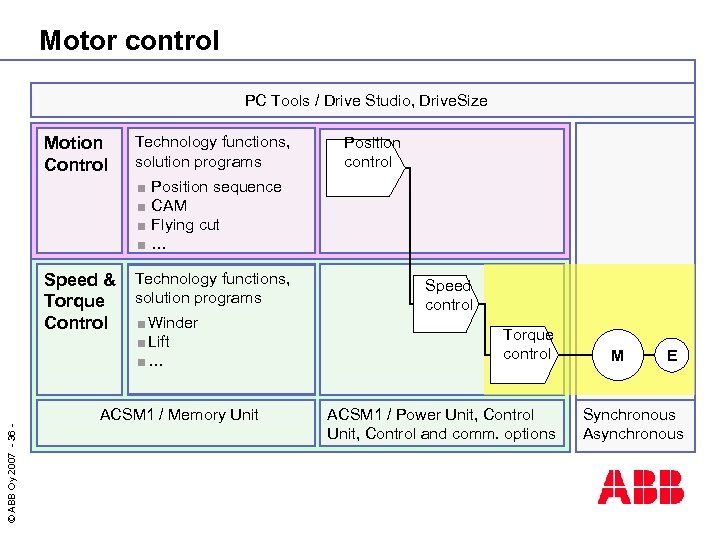

Motor control PC Tools / Drive Studio, Drive. Size Motion Control Technology functions, solution programs Position control < Position sequence < CAM < Flying cut <… Speed & Torque Control Technology functions, solution programs <Winder <Lift <… © ABB Oy 2007 - 36 - ACSM 1 / Memory Unit Speed control Torque control ACSM 1 / Power Unit, Control and comm. options M E Synchronous Asynchronous

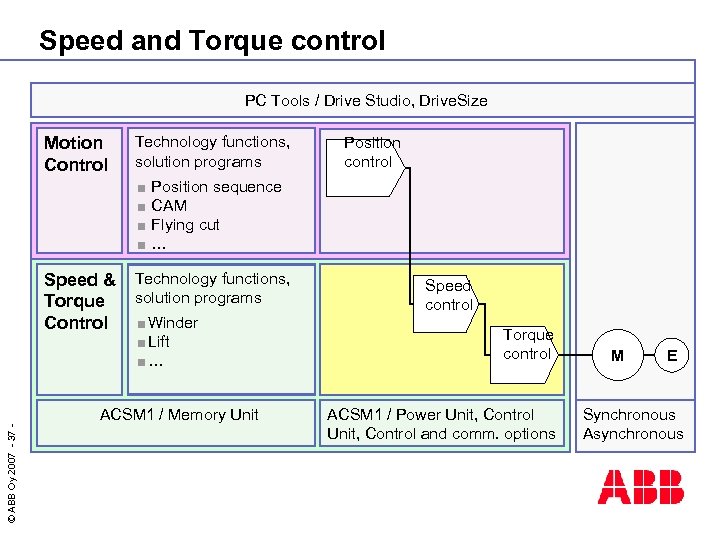

Speed and Torque control PC Tools / Drive Studio, Drive. Size Motion Control Technology functions, solution programs Position control < Position sequence < CAM < Flying cut <… Speed & Torque Control Technology functions, solution programs <Winder <Lift <… © ABB Oy 2007 - 37 - ACSM 1 / Memory Unit Speed control Torque control ACSM 1 / Power Unit, Control and comm. options M E Synchronous Asynchronous

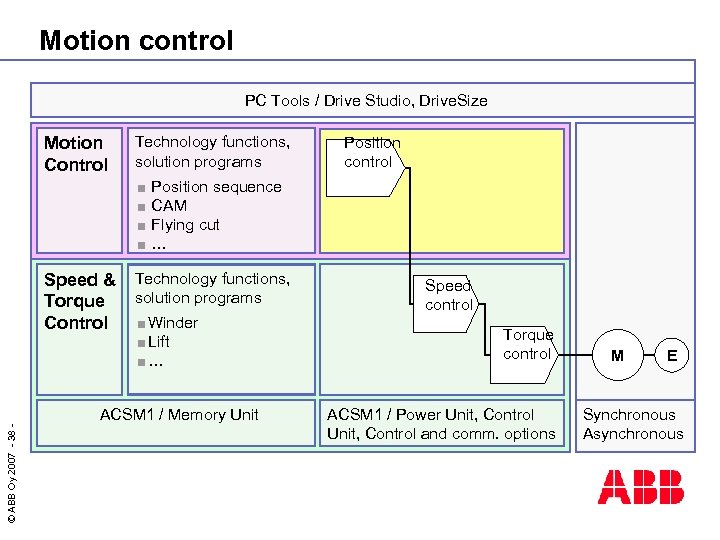

Motion control PC Tools / Drive Studio, Drive. Size Motion Control Technology functions, solution programs Position control < Position sequence < CAM < Flying cut <… Speed & Torque Control Technology functions, solution programs <Winder <Lift <… © ABB Oy 2007 - 38 - ACSM 1 / Memory Unit Speed control Torque control ACSM 1 / Power Unit, Control and comm. options M E Synchronous Asynchronous

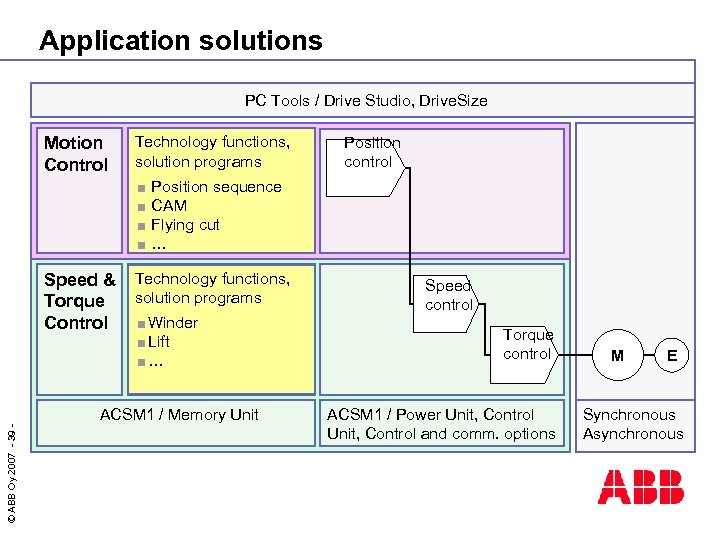

Application solutions PC Tools / Drive Studio, Drive. Size Motion Control Technology functions, solution programs Position control < Position sequence < CAM < Flying cut <… Speed & Torque Control Technology functions, solution programs <Winder <Lift <… © ABB Oy 2007 - 39 - ACSM 1 / Memory Unit Speed control Torque control ACSM 1 / Power Unit, Control and comm. options M E Synchronous Asynchronous

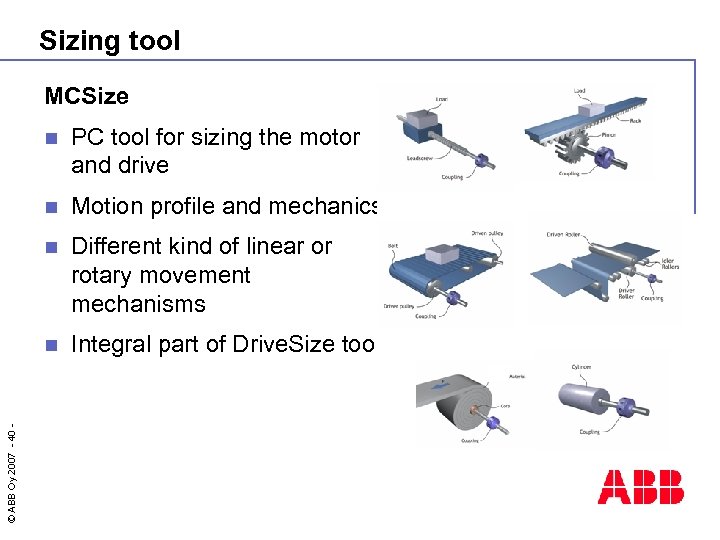

Sizing tool MCSize PC tool for sizing the motor and drive n Motion profile and mechanics n Different kind of linear or rotary movement mechanisms n © ABB Oy 2007 - 40 - n Integral part of Drive. Size tool

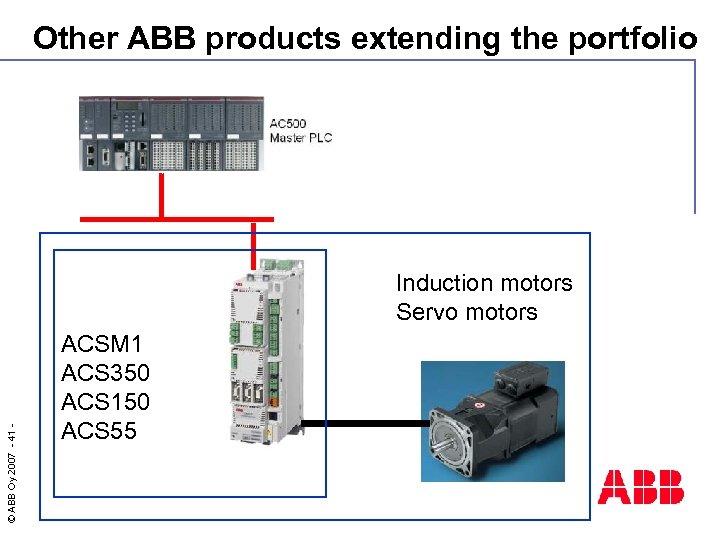

Other ABB products extending the portfolio © ABB Oy 2007 - 41 - Induction motors Servo motors ACSM 1 ACS 350 ACS 150 ACS 55

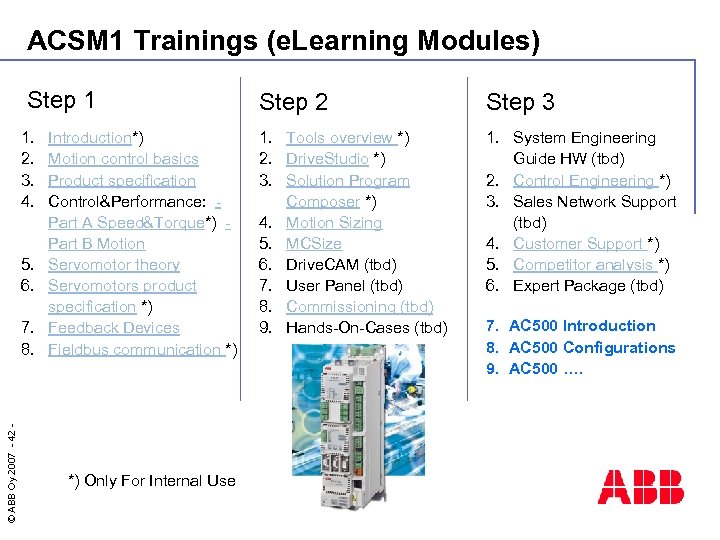

ACSM 1 Trainings (e. Learning Modules) Step 1 1. 2. 3. 4. 5. 6. © ABB Oy 2007 - 42 - 7. 8. Introduction*) Motion control basics Product specification Control&Performance: Part A Speed&Torque*) Part B Motion Servomotor theory Servomotors product specification *) Feedback Devices Fieldbus communication *) *) Only For Internal Use Step 2 Step 3 1. Tools overview *) 2. Drive. Studio *) 3. Solution Program Composer *) 4. Motion Sizing 5. MCSize 6. Drive. CAM (tbd) 7. User Panel (tbd) 8. Commissioning (tbd) 9. Hands-On-Cases (tbd) 1. System Engineering Guide HW (tbd) 2. Control Engineering *) 3. Sales Network Support (tbd) 4. Customer Support *) 5. Competitor analysis *) 6. Expert Package (tbd) 7. AC 500 Introduction 8. AC 500 Configurations 9. AC 500 ….

© ABB Oy 2007 - 43 - ABB Machinery Drives Portfolio is Ready It is time to work for growth in the machinery business!

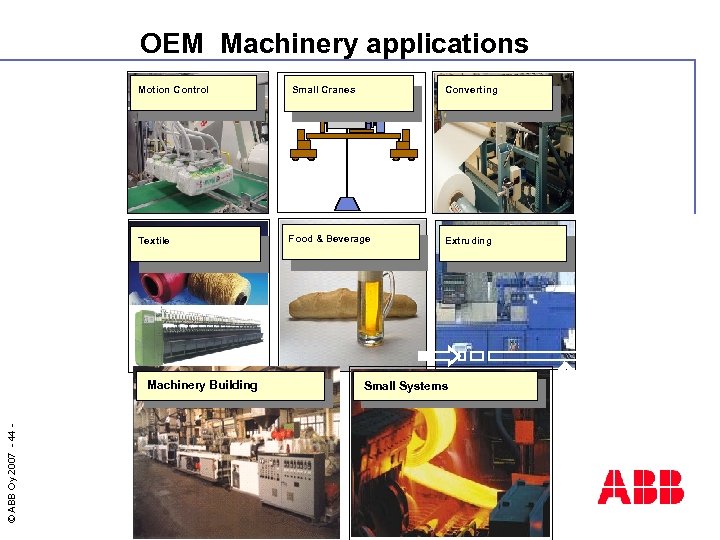

OEM Machinery applications Motion Control Liikkeen ohjaus Textile Tekstiili © ABB Oy 2007 - 44 - Machinery Building Koneen rakennus Small Cranes Pienet nosturit Food & Beverage Elintarvikkeet Converting P ää llystys Extruding Ruiskupuristus Small Systems Pienet J ä rjestelm ät

Some ACSM 1 Cases © ABB Oy 2007 - 45 - Stove pipe grabber in Germany Ship ramp winch in Sweden Lathe application in Spain Lifting the curtain in Vienna Opera Tube pending in Switzerland Elevator position control in Italy

© ABB Oy 2007 - 46 -

54be9390cf53e3a3164c7ae6936349a9.ppt