656684932f9fb9bc4057c1ba2276fbd5.ppt

- Количество слайдов: 23

Compact Integrated Receivers Using Custom and Commercial MMIC Technology Matt Morgan 9/7/2006

Compact Integrated Receivers Using Custom and Commercial MMIC Technology Matt Morgan 9/7/2006

Compact Integrated Receivers 1. critical for focal plane arrays beam spacing field of view 2. lower mass more efficient cryogenics tighter temperature control reduced mechanical load 3. fewer connectors and cables greater reliability reduced VSWR effects reduced gain slopes fewer entry points for RFI

Compact Integrated Receivers 1. critical for focal plane arrays beam spacing field of view 2. lower mass more efficient cryogenics tighter temperature control reduced mechanical load 3. fewer connectors and cables greater reliability reduced VSWR effects reduced gain slopes fewer entry points for RFI

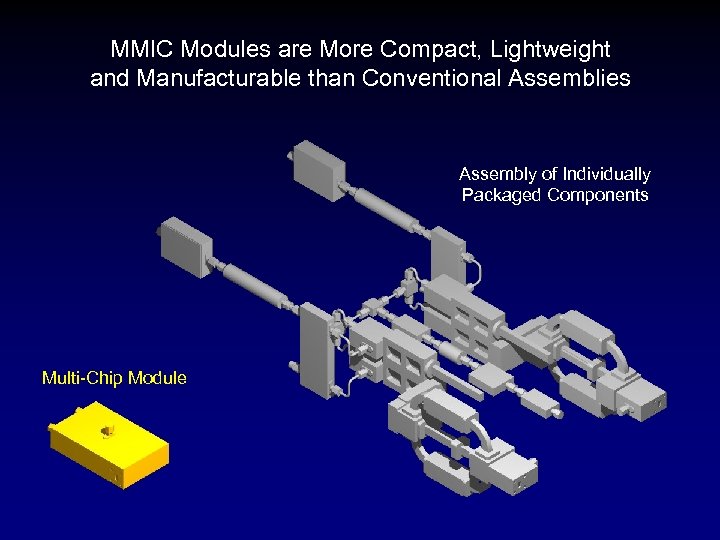

MMIC Modules are More Compact, Lightweight and Manufacturable than Conventional Assemblies Assembly of Individually Packaged Components Multi-Chip Module

MMIC Modules are More Compact, Lightweight and Manufacturable than Conventional Assemblies Assembly of Individually Packaged Components Multi-Chip Module

Many MMICs available Commercially Most things below 50 GHz are available off-the-shelf for less than $50 Exceptions include: balanced port configurations non-standard impedance some wide IF-Band mixers Some things in the 50 -100 GHz range can be found in commercial product listings, but sparse frequency coverage usually narrow-band, targeted for specific applications (communication and radar bands, etc. ) some exotic functions not supported (compound switches, etc. ) Finally, there is a large pool of proven custom designs to draw from, designed by NRAO and our collaborators (JPL, ATA, universities, foundry IRAD designs, etc. )

Many MMICs available Commercially Most things below 50 GHz are available off-the-shelf for less than $50 Exceptions include: balanced port configurations non-standard impedance some wide IF-Band mixers Some things in the 50 -100 GHz range can be found in commercial product listings, but sparse frequency coverage usually narrow-band, targeted for specific applications (communication and radar bands, etc. ) some exotic functions not supported (compound switches, etc. ) Finally, there is a large pool of proven custom designs to draw from, designed by NRAO and our collaborators (JPL, ATA, universities, foundry IRAD designs, etc. )

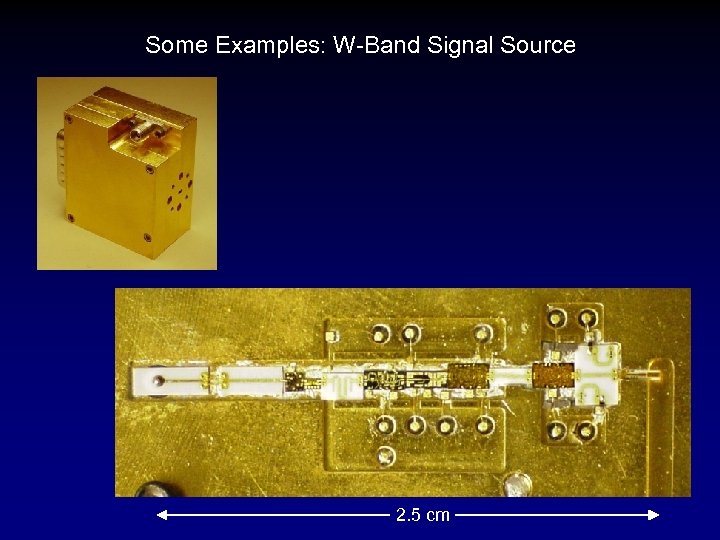

Some Examples: W-Band Signal Source 2. 5 cm

Some Examples: W-Band Signal Source 2. 5 cm

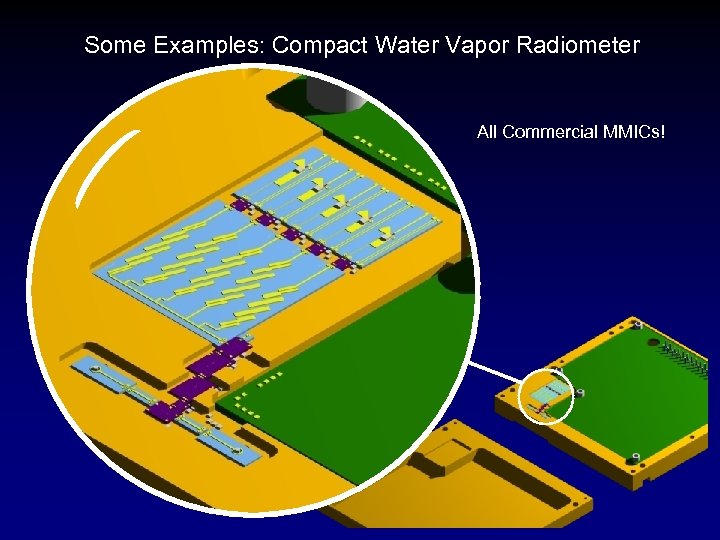

Some Examples: Compact Water Vapor Radiometer All Commercial MMICs!

Some Examples: Compact Water Vapor Radiometer All Commercial MMICs!

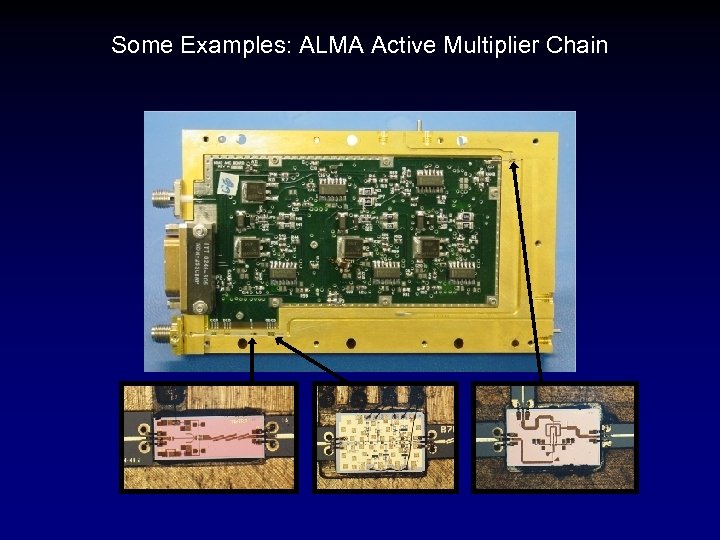

Some Examples: ALMA Active Multiplier Chain

Some Examples: ALMA Active Multiplier Chain

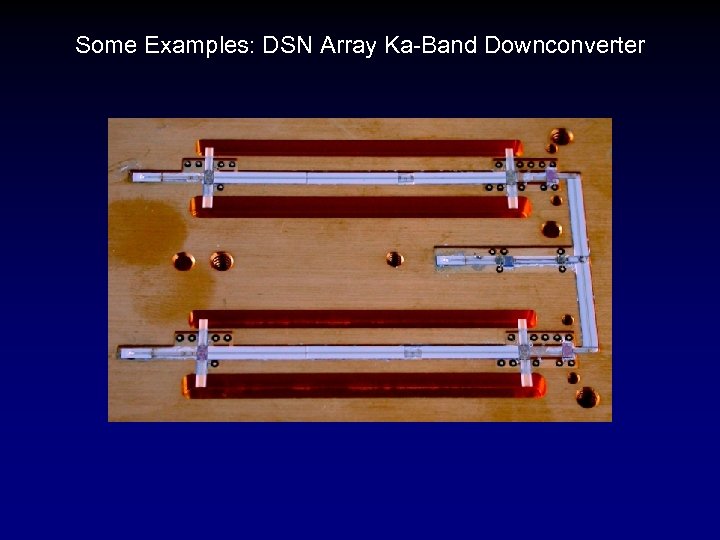

Some Examples: DSN Array Ka-Band Downconverter

Some Examples: DSN Array Ka-Band Downconverter

Working Toward an All-MMIC Receiver 1. 2. Once a design is set, MMIC components and assemblies can be massproduced with exceptional repeatability especially in the cm-wave range, where most MMICs are commercially available – chips are screened by the manufacturer and their specs guaranteed. module assembly is insensitive to small variations – bondwires are used for 50 interconnects, not for tuning! Repairs are relatively easy to diagnose and repair because of the inherent uniformity in performance, device failure is usually apparent from the DC bias alone. when it isn't, the chips are cheap enough to simply replace them o at a time until the culprit is found. It is therefore reasonable to think about implementing even very sophisticated front-ends in a single module using all MMIC technology. no internal connectors! no internal cables! only 1 block to machine small, lightweight, manufacturable

Working Toward an All-MMIC Receiver 1. 2. Once a design is set, MMIC components and assemblies can be massproduced with exceptional repeatability especially in the cm-wave range, where most MMICs are commercially available – chips are screened by the manufacturer and their specs guaranteed. module assembly is insensitive to small variations – bondwires are used for 50 interconnects, not for tuning! Repairs are relatively easy to diagnose and repair because of the inherent uniformity in performance, device failure is usually apparent from the DC bias alone. when it isn't, the chips are cheap enough to simply replace them o at a time until the culprit is found. It is therefore reasonable to think about implementing even very sophisticated front-ends in a single module using all MMIC technology. no internal connectors! no internal cables! only 1 block to machine small, lightweight, manufacturable

Shall we take integration a step further: Receiver-on-a-Chip? I would say no. . . LNAs, mixers, and multipliers have all been demonstrated on comm semiconductor technologies, but with compromised performance – to pick the right MMIC process for the right chip even if it works, the yield is too low on III-V semiconductors for large integration a lot of expensive wafer real estate is wasted on passives can no longer take advantage of commercial components – have to it all from scratch no opportunity for chip reuse Microwave substrates are thin! A large, floppy chip would be too ha handle and mount without damaging it.

Shall we take integration a step further: Receiver-on-a-Chip? I would say no. . . LNAs, mixers, and multipliers have all been demonstrated on comm semiconductor technologies, but with compromised performance – to pick the right MMIC process for the right chip even if it works, the yield is too low on III-V semiconductors for large integration a lot of expensive wafer real estate is wasted on passives can no longer take advantage of commercial components – have to it all from scratch no opportunity for chip reuse Microwave substrates are thin! A large, floppy chip would be too ha handle and mount without damaging it.

Could We Put the Whole Receiver in One Module and Cool Everything? Not if it is a heterodyne receiver, because LO generation dissipates too much power for cryogenics IF components are usually Silicon, which will not function col However, special-purpose direct detection receivers could occupy a single cold module even more compact better sensitivity better temperature stability better component lifetime

Could We Put the Whole Receiver in One Module and Cool Everything? Not if it is a heterodyne receiver, because LO generation dissipates too much power for cryogenics IF components are usually Silicon, which will not function col However, special-purpose direct detection receivers could occupy a single cold module even more compact better sensitivity better temperature stability better component lifetime

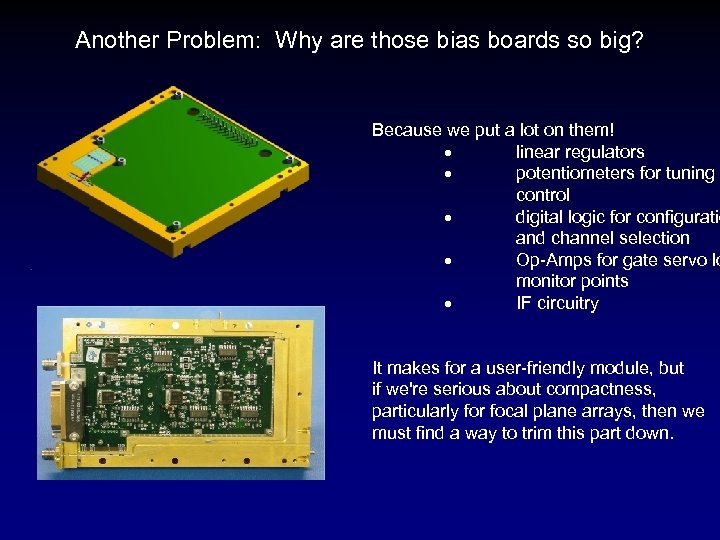

Another Problem: Why are those bias boards so big? Because we put a lot on them! linear regulators potentiometers for tuning a control digital logic for configuratio and channel selection Op-Amps for gate servo lo monitor points IF circuitry It makes for a user-friendly module, but if we're serious about compactness, particularly for focal plane arrays, then we must find a way to trim this part down.

Another Problem: Why are those bias boards so big? Because we put a lot on them! linear regulators potentiometers for tuning a control digital logic for configuratio and channel selection Op-Amps for gate servo lo monitor points IF circuitry It makes for a user-friendly module, but if we're serious about compactness, particularly for focal plane arrays, then we must find a way to trim this part down.

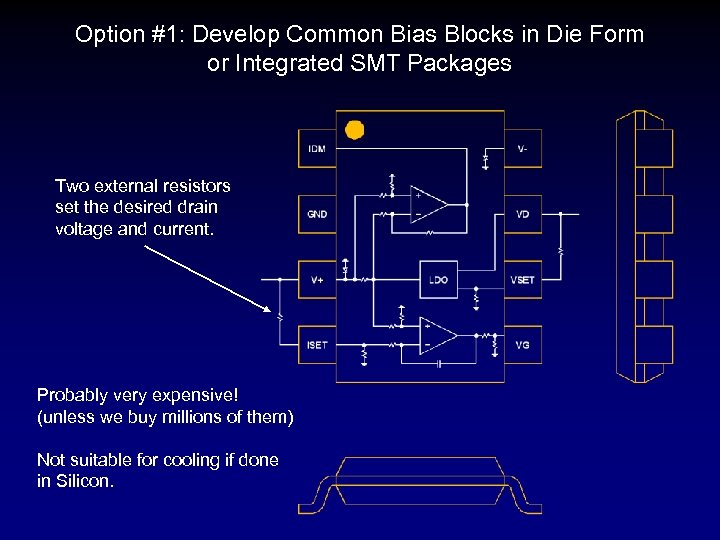

Option #1: Develop Common Bias Blocks in Die Form or Integrated SMT Packages Two external resistors set the desired drain voltage and current. Probably very expensive! (unless we buy millions of them) Not suitable for cooling if done in Silicon.

Option #1: Develop Common Bias Blocks in Die Form or Integrated SMT Packages Two external resistors set the desired drain voltage and current. Probably very expensive! (unless we buy millions of them) Not suitable for cooling if done in Silicon.

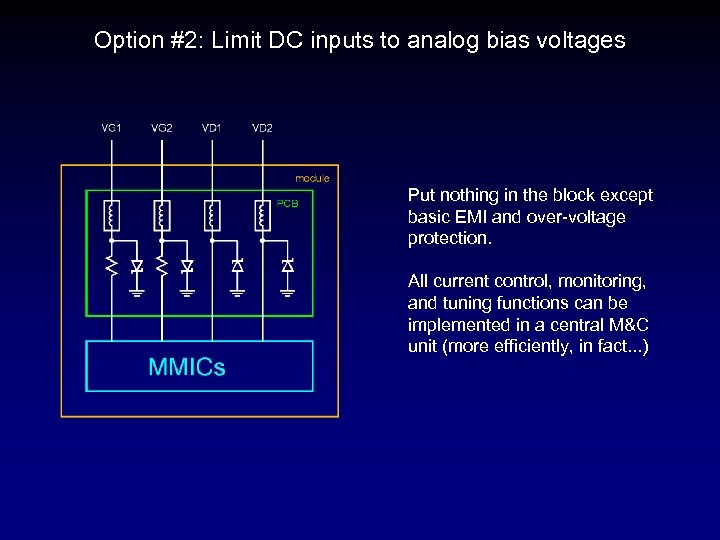

Option #2: Limit DC inputs to analog bias voltages Put nothing in the block except basic EMI and over-voltage protection. All current control, monitoring, and tuning functions can be implemented in a central M&C unit (more efficiently, in fact. . . )

Option #2: Limit DC inputs to analog bias voltages Put nothing in the block except basic EMI and over-voltage protection. All current control, monitoring, and tuning functions can be implemented in a central M&C unit (more efficiently, in fact. . . )

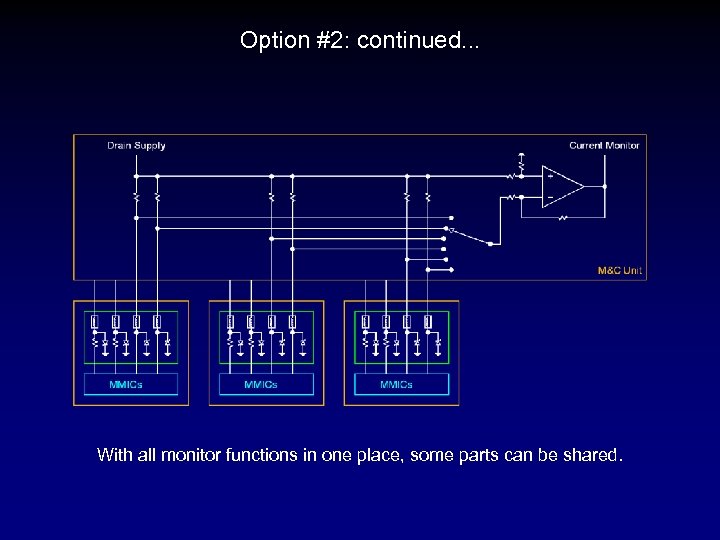

Option #2: continued. . . With all monitor functions in one place, some parts can be shared.

Option #2: continued. . . With all monitor functions in one place, some parts can be shared.

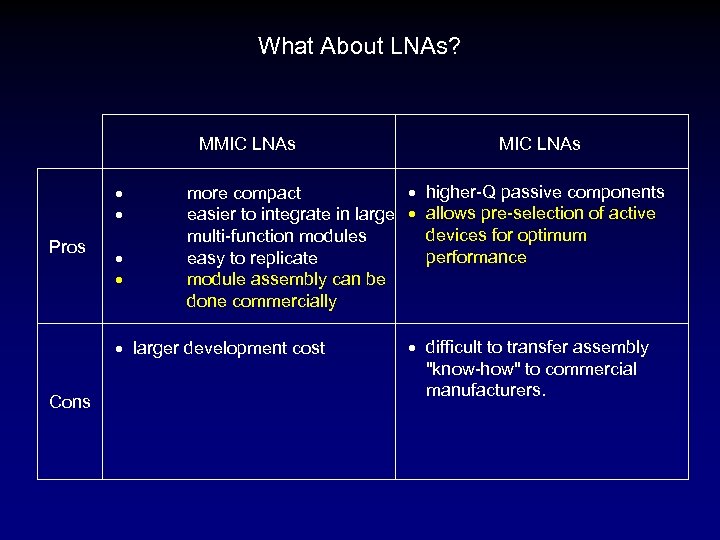

What About LNAs? MMIC LNAs Pros higher-Q passive components more compact easier to integrate in large allows pre-selection of active devices for optimum multi-function modules performance easy to replicate module assembly can be done commercially larger development cost Cons MIC LNAs difficult to transfer assembly "know-how" to commercial manufacturers.

What About LNAs? MMIC LNAs Pros higher-Q passive components more compact easier to integrate in large allows pre-selection of active devices for optimum multi-function modules performance easy to replicate module assembly can be done commercially larger development cost Cons MIC LNAs difficult to transfer assembly "know-how" to commercial manufacturers.

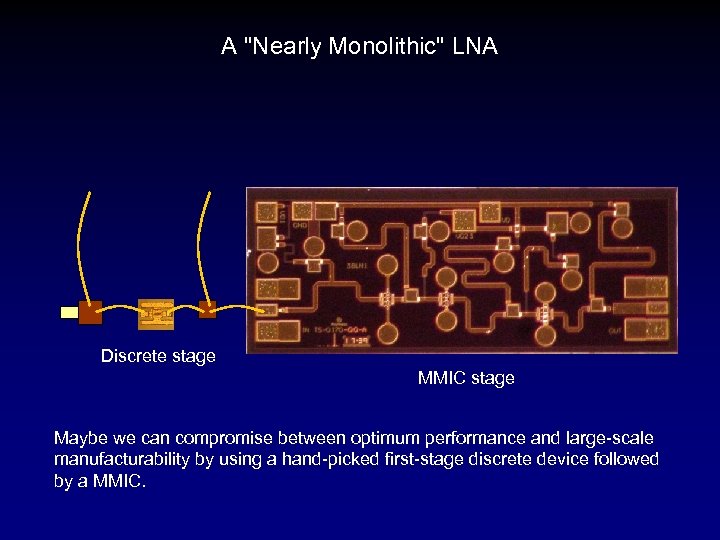

A "Nearly Monolithic" LNA Discrete stage MMIC stage Maybe we can compromise between optimum performance and large-scale manufacturability by using a hand-picked first-stage discrete device followed by a MMIC.

A "Nearly Monolithic" LNA Discrete stage MMIC stage Maybe we can compromise between optimum performance and large-scale manufacturability by using a hand-picked first-stage discrete device followed by a MMIC.

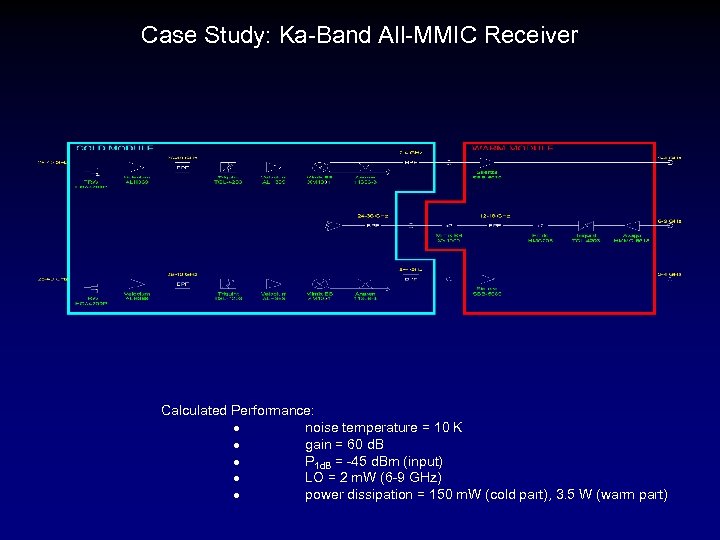

Case Study: Ka-Band All-MMIC Receiver Calculated Performance: noise temperature = 10 K gain = 60 d. B P 1 d. B = -45 d. Bm (input) LO = 2 m. W (6 -9 GHz) power dissipation = 150 m. W (cold part), 3. 5 W (warm part)

Case Study: Ka-Band All-MMIC Receiver Calculated Performance: noise temperature = 10 K gain = 60 d. B P 1 d. B = -45 d. Bm (input) LO = 2 m. W (6 -9 GHz) power dissipation = 150 m. W (cold part), 3. 5 W (warm part)

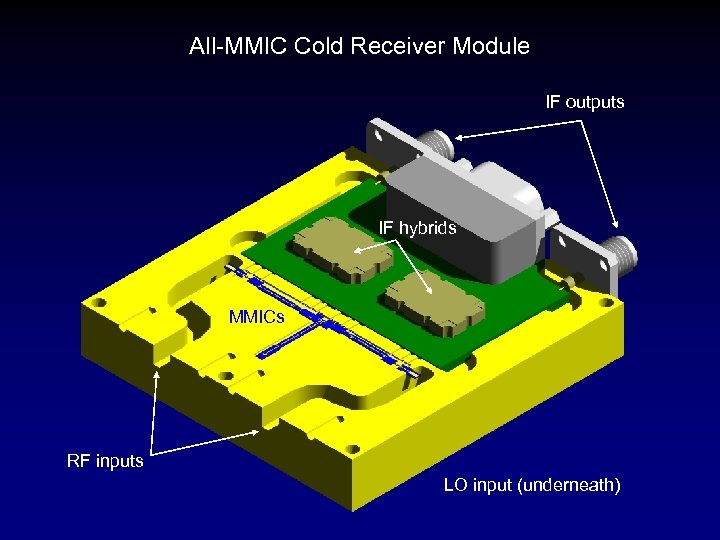

All-MMIC Cold Receiver Module IF outputs IF hybrids MMICs RF inputs LO input (underneath)

All-MMIC Cold Receiver Module IF outputs IF hybrids MMICs RF inputs LO input (underneath)

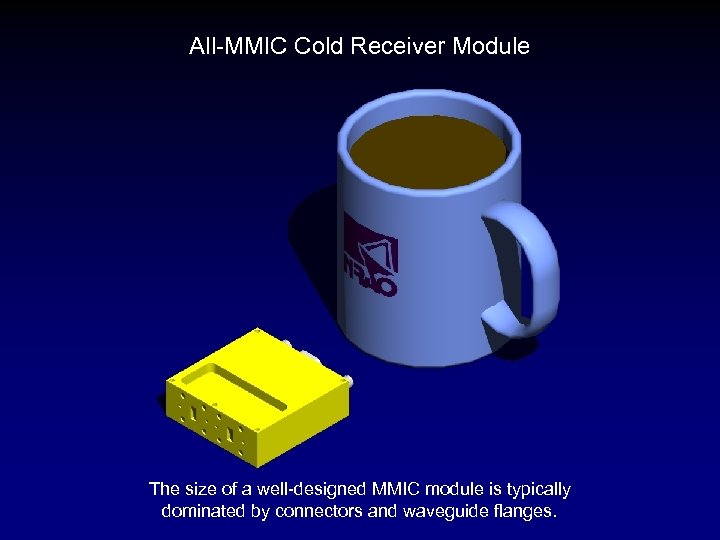

All-MMIC Cold Receiver Module The size of a well-designed MMIC module is typically dominated by connectors and waveguide flanges.

All-MMIC Cold Receiver Module The size of a well-designed MMIC module is typically dominated by connectors and waveguide flanges.

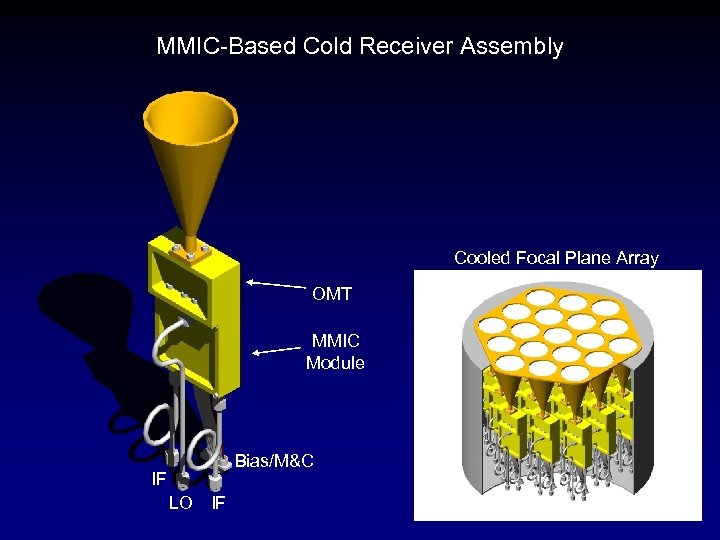

MMIC-Based Cold Receiver Assembly Cooled Focal Plane Array OMT MMIC Module Bias/M&C IF LO IF

MMIC-Based Cold Receiver Assembly Cooled Focal Plane Array OMT MMIC Module Bias/M&C IF LO IF

Backup slides follow

Backup slides follow

If the entire receiver is cooled anyway, should we consider using superconducting passive elements (couplers, filters, etc)? I don't think so excellent LNA performance can be achieved at ~20 K, but a go microwave superconductor would force you to much lower temperatures (~5 K) not really a commercial process – your passive elements could be more expensive than the MMICs! you lose the ability to test it at room temperature not much to gain anyway? – superconductors are not lossless at high frequency, and cooled copper may be competitive if it i reasonably pure

If the entire receiver is cooled anyway, should we consider using superconducting passive elements (couplers, filters, etc)? I don't think so excellent LNA performance can be achieved at ~20 K, but a go microwave superconductor would force you to much lower temperatures (~5 K) not really a commercial process – your passive elements could be more expensive than the MMICs! you lose the ability to test it at room temperature not much to gain anyway? – superconductors are not lossless at high frequency, and cooled copper may be competitive if it i reasonably pure