b6ab8232dabf7e0665ef2d86edf717eb.ppt

- Количество слайдов: 58

Common Dispensing Errors Experienced in Clinical Settings Dr. CHENG Chi Man

Common Dispensing Errors Experienced in Clinical Settings Dr. CHENG Chi Man

Murphy’s Law “Things will go wrong in any given situation, if you give them a chance. ” (Steps that can go wrong will go wrong)

Murphy’s Law “Things will go wrong in any given situation, if you give them a chance. ” (Steps that can go wrong will go wrong)

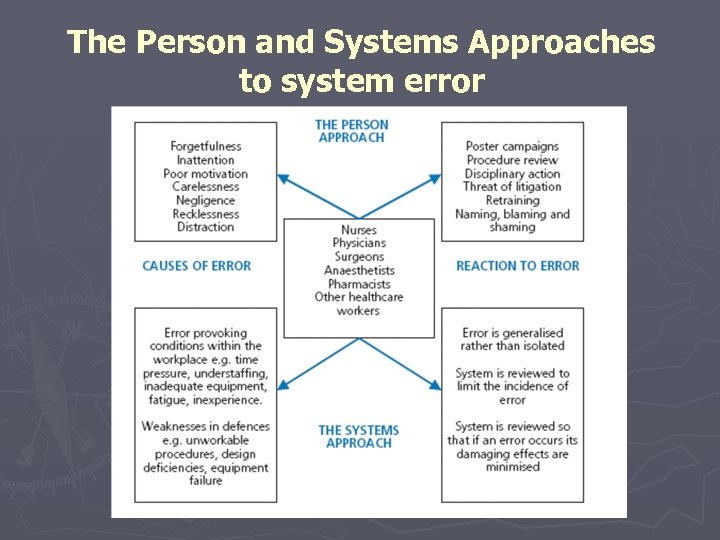

The Person and Systems Approaches to system error

The Person and Systems Approaches to system error

Reaction to error (The Person Approach) • Poster campaigns • Procedure review • Disciplinary action • Threat of litigation • Retraining • Naming, blaming and shaming

Reaction to error (The Person Approach) • Poster campaigns • Procedure review • Disciplinary action • Threat of litigation • Retraining • Naming, blaming and shaming

Reaction to error (The Systems Approach) • Error is generalized rather than isolated • System is reviewed to limit the incidence of error • System is reviewed so that if an error occurs its damaging effects are minimized

Reaction to error (The Systems Approach) • Error is generalized rather than isolated • System is reviewed to limit the incidence of error • System is reviewed so that if an error occurs its damaging effects are minimized

• Human errors cannot be eliminated totally. • Medication errors cause serious consequences.

• Human errors cannot be eliminated totally. • Medication errors cause serious consequences.

On 2/5/2007, WHO launched "Nine patient safety solutions" to help reduce the toll of health care-related harm affecting millions of patients worldwide. ► Look-alike, sound-alike medication names; ► patient identification; ► communication during patient hand-overs;

On 2/5/2007, WHO launched "Nine patient safety solutions" to help reduce the toll of health care-related harm affecting millions of patients worldwide. ► Look-alike, sound-alike medication names; ► patient identification; ► communication during patient hand-overs;

► performance of correct procedure at correct body site; ► control of concentrated electrolyte solutions; ► assuring medication accuracy at transitions in care; ► avoiding catheter and tubing misconnections; ► single use of injection devices; and ► improved hand hygiene to prevent health care-associated infection.

► performance of correct procedure at correct body site; ► control of concentrated electrolyte solutions; ► assuring medication accuracy at transitions in care; ► avoiding catheter and tubing misconnections; ► single use of injection devices; and ► improved hand hygiene to prevent health care-associated infection.

Medical Mishaps occur in all health care settings. • In the United States, it is estimated that 7, 000 deaths each year are caused by medication errors. • In Australia, hospitals show that about 1% of all admissions suffered adverse event as a result of medication error.

Medical Mishaps occur in all health care settings. • In the United States, it is estimated that 7, 000 deaths each year are caused by medication errors. • In Australia, hospitals show that about 1% of all admissions suffered adverse event as a result of medication error.

Medication errors include errors that happen during: • Prescribing • Dispensing • Administering

Medication errors include errors that happen during: • Prescribing • Dispensing • Administering

Dispensing Errors Of 1, 000 consecutive claims reported to the Medical Protection Society from 1 st July 1996, 193 (19. 3%) were associated with medication and prescribing.

Dispensing Errors Of 1, 000 consecutive claims reported to the Medical Protection Society from 1 st July 1996, 193 (19. 3%) were associated with medication and prescribing.

Medication errors causes serious consequences to Patients (physical harm; death) • Doctors (reputation; psychological harm; liability in tort; professional misconduct; criminal liability) • The Medical Profession (trust; relationship between doctors and patients) •

Medication errors causes serious consequences to Patients (physical harm; death) • Doctors (reputation; psychological harm; liability in tort; professional misconduct; criminal liability) • The Medical Profession (trust; relationship between doctors and patients) •

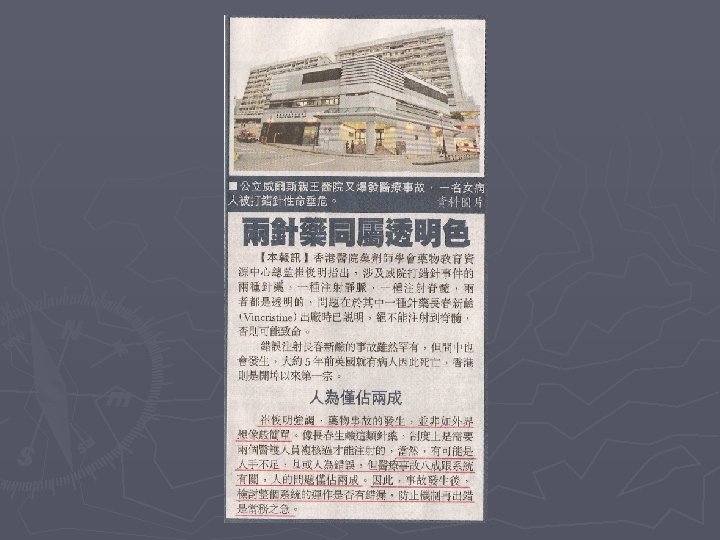

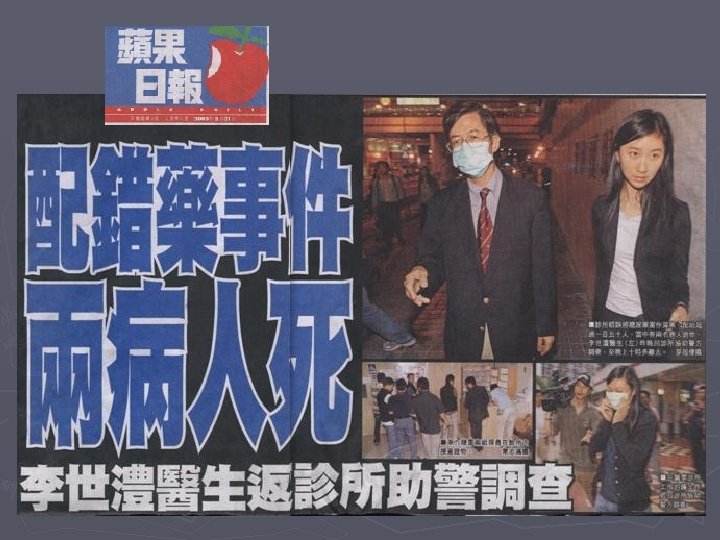

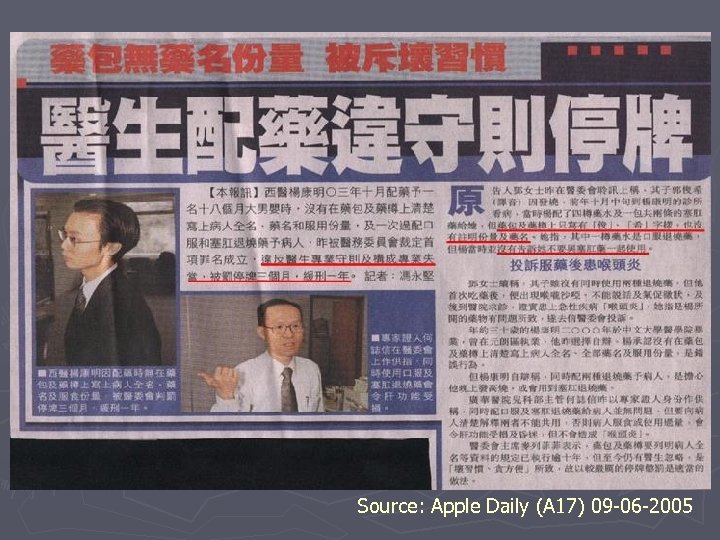

Source: Apple Daily (A 17) 09 -06 -2005

Source: Apple Daily (A 17) 09 -06 -2005

Dispensing Right In 2005, the Task Force on Separation of Prescribing from Dispensing was set up by the pharmacists. Recently, the “Separation of Prescribing from Dispensing Alliance (SPDA)” (爭取醫藥分家大聯盟) has been formed by the Pharmaceutical Society of Hong Kong (PSHK), the Practising Pharmacists Association of Hong Kong (PPAHK) and the Society of Hospital Pharmacists of Hong Kong (SHPHK)

Dispensing Right In 2005, the Task Force on Separation of Prescribing from Dispensing was set up by the pharmacists. Recently, the “Separation of Prescribing from Dispensing Alliance (SPDA)” (爭取醫藥分家大聯盟) has been formed by the Pharmaceutical Society of Hong Kong (PSHK), the Practising Pharmacists Association of Hong Kong (PPAHK) and the Society of Hospital Pharmacists of Hong Kong (SHPHK)

WE CAN minimize dispensing errors. • correct attitude • knowing how • doing so • keeping it up

WE CAN minimize dispensing errors. • correct attitude • knowing how • doing so • keeping it up

Good Dispensing Practice Manual (July 2005) by the Task Force on Drug Dispensing of the Hong Kong Medical Association

Good Dispensing Practice Manual (July 2005) by the Task Force on Drug Dispensing of the Hong Kong Medical Association

The Hong Kong Medical Association CME Bulletin Oct 2006

The Hong Kong Medical Association CME Bulletin Oct 2006

Why do dispensing errors happen?

Why do dispensing errors happen?

How to prevent/minimize dispensing errors?

How to prevent/minimize dispensing errors?

Prof. David Todd • How to make a diagnosis? • First you need to think of that particular diagnosis.

Prof. David Todd • How to make a diagnosis? • First you need to think of that particular diagnosis.

Alcohol and Bricanyl

Alcohol and Bricanyl

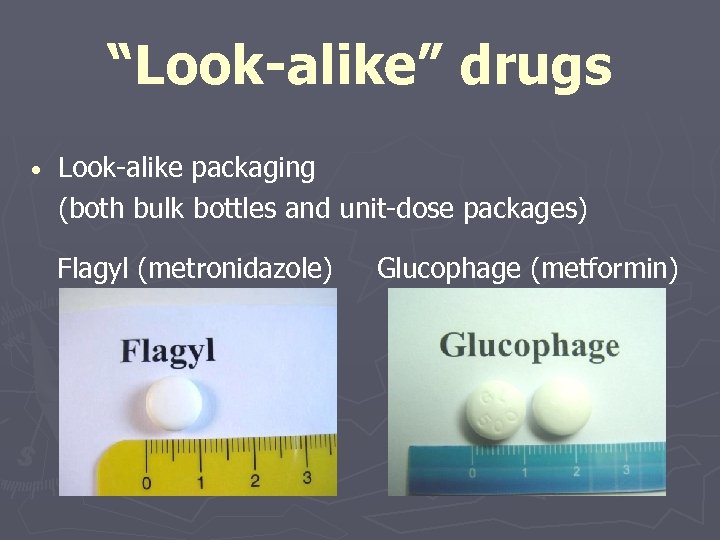

“Look-alike” drugs • Look-alike packaging (both bulk bottles and unit-dose packages) Flagyl (metronidazole) Glucophage (metformin)

“Look-alike” drugs • Look-alike packaging (both bulk bottles and unit-dose packages) Flagyl (metronidazole) Glucophage (metformin)

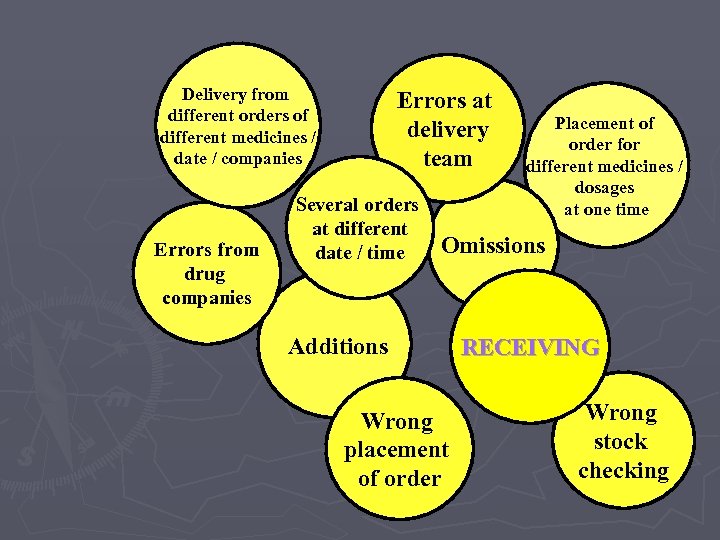

Delivery from different orders of different medicines / date / companies Errors from drug companies Errors at delivery team Several orders at different date / time Placement of order for different medicines / dosages at one time Omissions Additions Wrong placement of order RECEIVING Wrong stock checking

Delivery from different orders of different medicines / date / companies Errors from drug companies Errors at delivery team Several orders at different date / time Placement of order for different medicines / dosages at one time Omissions Additions Wrong placement of order RECEIVING Wrong stock checking

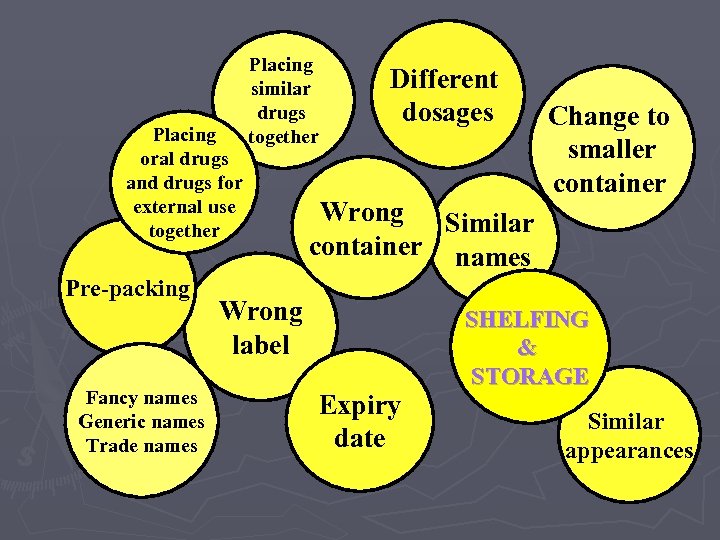

Placing oral drugs and drugs for external use together Pre-packing Fancy names Generic names Trade names Placing similar drugs together Different dosages Wrong Similar container names Wrong label Expiry date Change to smaller container SHELFING & STORAGE Similar appearances

Placing oral drugs and drugs for external use together Pre-packing Fancy names Generic names Trade names Placing similar drugs together Different dosages Wrong Similar container names Wrong label Expiry date Change to smaller container SHELFING & STORAGE Similar appearances

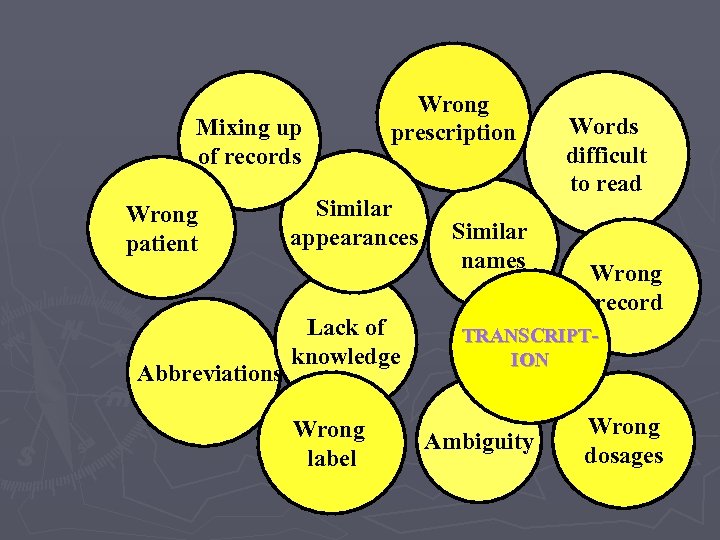

Mixing up of records Wrong patient Abbreviations Wrong prescription Similar appearances Lack of knowledge Wrong label Similar names Words difficult to read Wrong record TRANSCRIPTION Ambiguity Wrong dosages

Mixing up of records Wrong patient Abbreviations Wrong prescription Similar appearances Lack of knowledge Wrong label Similar names Words difficult to read Wrong record TRANSCRIPTION Ambiguity Wrong dosages

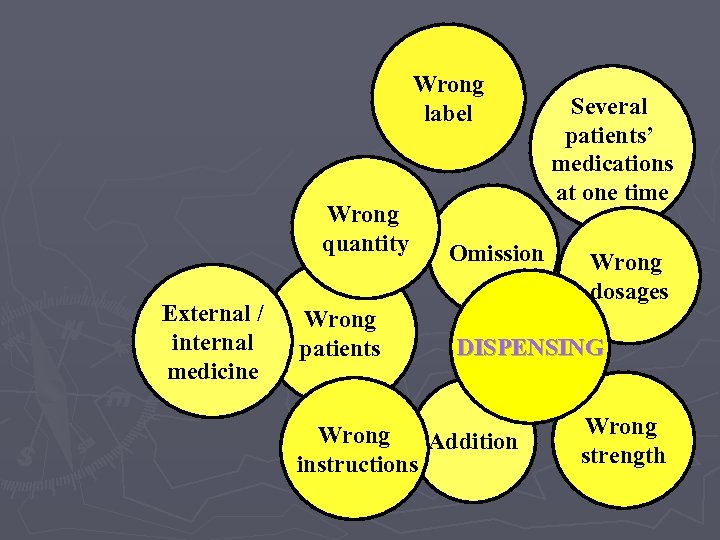

Wrong label Wrong quantity External / internal medicine Wrong patients Omission Several patients’ medications at one time Wrong dosages DISPENSING Wrong Addition instructions Wrong strength

Wrong label Wrong quantity External / internal medicine Wrong patients Omission Several patients’ medications at one time Wrong dosages DISPENSING Wrong Addition instructions Wrong strength

We have the responsibility to ensure patient safety.

We have the responsibility to ensure patient safety.

How to prevent dispensing errors? • Removing the hazard • Alerting staff to imminent error • Preventing completion of hazardous action • Minimizing the consequences of error

How to prevent dispensing errors? • Removing the hazard • Alerting staff to imminent error • Preventing completion of hazardous action • Minimizing the consequences of error

Removing the hazard (1) • Check medication by doctor after receiving from drug company • Supervise and check by another person when changing from large container to smaller container • Write the name of the medication clearly on all containers

Removing the hazard (1) • Check medication by doctor after receiving from drug company • Supervise and check by another person when changing from large container to smaller container • Write the name of the medication clearly on all containers

Removing the hazard (2) • Make sure that the labels / lids / covers of the containers will not be mixed up, and check this regularly • Do not give fancy names or similar names to medication • Make sure assistants know both the generic and brand name of each medication, and provide a list where they can confirm

Removing the hazard (2) • Make sure that the labels / lids / covers of the containers will not be mixed up, and check this regularly • Do not give fancy names or similar names to medication • Make sure assistants know both the generic and brand name of each medication, and provide a list where they can confirm

Removing the hazard (3) • Do not order medications which look too similar • Do not put medications which look similar together • Use more individually packed medications

Removing the hazard (3) • Do not order medications which look too similar • Do not put medications which look similar together • Use more individually packed medications

Removing the hazard (4) • Before pre-packing, have another person to check the medication from the large container, make sure that each pack is clearly and correctly labelled. Containers of pre-packed medications should be labelled clearly • Shelf long term medications (esp. dangerous ones: DM, HT, psychotrophic, NSAID) separate with short term medications

Removing the hazard (4) • Before pre-packing, have another person to check the medication from the large container, make sure that each pack is clearly and correctly labelled. Containers of pre-packed medications should be labelled clearly • Shelf long term medications (esp. dangerous ones: DM, HT, psychotrophic, NSAID) separate with short term medications

Alerting staff to imminent error • Hazard warnings and signs, e. g. Attach tags to containers of medications which are used in daily or BD dosage instead of more frequent dosing • Warning messages in electronic prescribing systems • Warning labels on potentially hazardous drugs, e. g. diabetic medications, potassium, penicillins

Alerting staff to imminent error • Hazard warnings and signs, e. g. Attach tags to containers of medications which are used in daily or BD dosage instead of more frequent dosing • Warning messages in electronic prescribing systems • Warning labels on potentially hazardous drugs, e. g. diabetic medications, potassium, penicillins

We need to pay attention to special patient groups where medication errors can occur more easily • Patients with drug allergy • Patients with chronic illness • Repeat prescription • Children

We need to pay attention to special patient groups where medication errors can occur more easily • Patients with drug allergy • Patients with chronic illness • Repeat prescription • Children

We need to pay attention to special groups of medicine where medication errors can cause more serious consequences • Medicine with narrow margin of safety • Long term medication • Medications which need dilution or compounding • Medicine for external use only

We need to pay attention to special groups of medicine where medication errors can cause more serious consequences • Medicine with narrow margin of safety • Long term medication • Medications which need dilution or compounding • Medicine for external use only

Education & Training Certificate Course for Clinic Nurses $960 Federation of Medical (6 Sessions) Societies of Hong Kong Understanding Drug $6 000 Therapy and (35 hours) Management $200 護理人員醫藥基礎認識 (16 hours) $190 診所醫護人員配藥技巧 (15 hours) Open University of Hong Kong & Hong Kong Doctors Union Skills Upgrading Scheme, Education and Manpower Bureau

Education & Training Certificate Course for Clinic Nurses $960 Federation of Medical (6 Sessions) Societies of Hong Kong Understanding Drug $6 000 Therapy and (35 hours) Management $200 護理人員醫藥基礎認識 (16 hours) $190 診所醫護人員配藥技巧 (15 hours) Open University of Hong Kong & Hong Kong Doctors Union Skills Upgrading Scheme, Education and Manpower Bureau

Preventing completion of hazardous action Checking and Double Checking

Preventing completion of hazardous action Checking and Double Checking

A study of more than 1 million dispensed items in British hospital identified 178 errors (0. 018%). The error rate was 0. 01% when the dispensing of pharmacists and technicians was double-checked, compared with 0. 035% when there was no double-check. Spencer MG. A multicentre study of dispensing errors in British Hospital. Int. J. Pharm Pract 1993; 2: 142 -146

A study of more than 1 million dispensed items in British hospital identified 178 errors (0. 018%). The error rate was 0. 01% when the dispensing of pharmacists and technicians was double-checked, compared with 0. 035% when there was no double-check. Spencer MG. A multicentre study of dispensing errors in British Hospital. Int. J. Pharm Pract 1993; 2: 142 -146

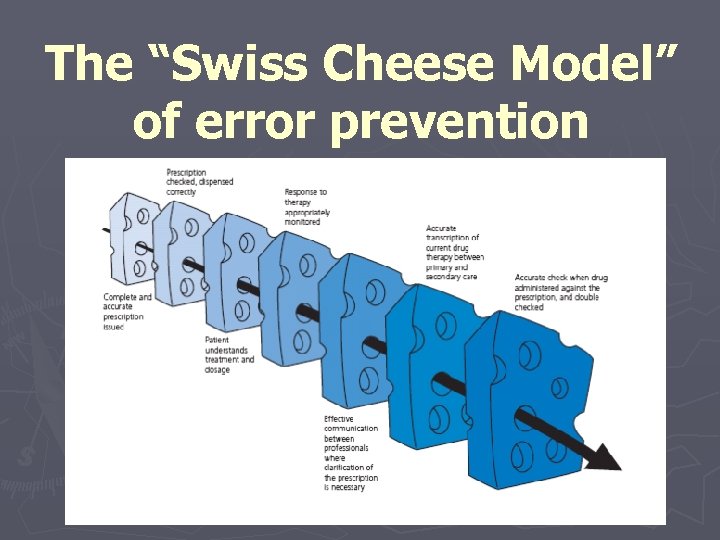

The “Swiss Cheese Model” of error prevention

The “Swiss Cheese Model” of error prevention

The “Swiss Cheese Model” of error prevention The more layers of defence there and the lower the likelihood of holes in those defences opening up, the lower the risk of a damaging error or accident occurring.

The “Swiss Cheese Model” of error prevention The more layers of defence there and the lower the likelihood of holes in those defences opening up, the lower the risk of a damaging error or accident occurring.

Preventing completion of hazardous action (1) Checking and double checking: • Checked by the one who prepared the medications, then by the doctor, and then by the one who give the medications to the patient

Preventing completion of hazardous action (1) Checking and double checking: • Checked by the one who prepared the medications, then by the doctor, and then by the one who give the medications to the patient

Preventing completion of hazardous action (2) Checking and double checking: • Date • Name of patient • Number of types of medication • Type (make sure all parties can recognise each medication. If in doubt, open a new bottle for confirmation, or contact the drug company)

Preventing completion of hazardous action (2) Checking and double checking: • Date • Name of patient • Number of types of medication • Type (make sure all parties can recognise each medication. If in doubt, open a new bottle for confirmation, or contact the drug company)

Preventing completion of hazardous action (3) • Dosage (how many tabs each time? How much syrup each time? ) • Frequency of dosing • Number of tablets/volume of syrup in each pack • Route of adminstration • Container • Drug allergy

Preventing completion of hazardous action (3) • Dosage (how many tabs each time? How much syrup each time? ) • Frequency of dosing • Number of tablets/volume of syrup in each pack • Route of adminstration • Container • Drug allergy

Preventing completion of hazardous action (4) The use of Information Technology • e. g. electronic systems which prevent prescribing of a penicillin to a patient with known allergy

Preventing completion of hazardous action (4) The use of Information Technology • e. g. electronic systems which prevent prescribing of a penicillin to a patient with known allergy

Minimizing the consequences of error • Encourage staff to report immediately if anything goes wrong • Communicate with patients and allow channels for enquiry and complaint

Minimizing the consequences of error • Encourage staff to report immediately if anything goes wrong • Communicate with patients and allow channels for enquiry and complaint

Vanilla ice-cream = Car problems?

Vanilla ice-cream = Car problems?

Even insane looking problems are sometimes real General Motors received a complaint. A man could not restart his car engine everytime after he bought a vanilla icecream, but not other favors. An engineer looked into the matter and found that this was really the case.

Even insane looking problems are sometimes real General Motors received a complaint. A man could not restart his car engine everytime after he bought a vanilla icecream, but not other favors. An engineer looked into the matter and found that this was really the case.

It took less time to buy a vanilla ice-cream than other favors. Eventually it was found out that the vapor lock of the model had some defects. So, it might be worth spending some time on seemingly insane complaints !

It took less time to buy a vanilla ice-cream than other favors. Eventually it was found out that the vapor lock of the model had some defects. So, it might be worth spending some time on seemingly insane complaints !

My Own Story A patient called after seeing me for URTI. He complaint of nausea and headache after taking medication for one time. I reviewed the record and found nothing wrong with the medications.

My Own Story A patient called after seeing me for URTI. He complaint of nausea and headache after taking medication for one time. I reviewed the record and found nothing wrong with the medications.

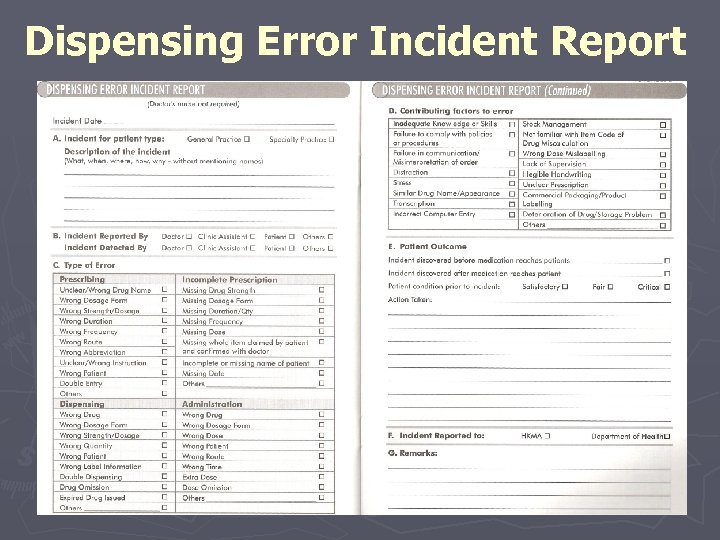

Dispensing Error Incident Report

Dispensing Error Incident Report