CAE-Overview_2012_July_approved_NEW.ppt

- Количество слайдов: 29

Committed to a changing world Electronic Materials by BASF Name DD/MM/2012 5/7/2012

BASF – The Chemical Company n Our chemicals are used in almost all industries n We combine economic success, social responsibility and environmental protection. n Sales 2011: € 73, 497 million n EBIT 2011: € 8, 586 million n Employees (as of December 31, 2011): 111, 141 n In 2011, BASF filed for around 1, 050 new patents worldwide n 6 Verbund sites and around 370 production sites 2

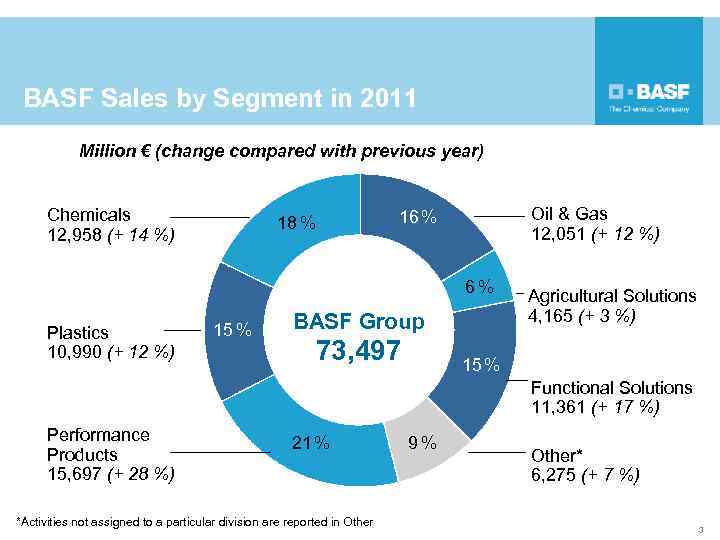

BASF Sales by Segment in 2011 Million € (change compared with previous year) Chemicals 12, 958 (+ 14 %) 18 % Oil & Gas 12, 051 (+ 12 %) 16 % 6% Plastics 10, 990 (+ 12 %) 15 % BASF Group 73, 497 Agricultural Solutions 4, 165 (+ 3 %) 15 % Functional Solutions 11, 361 (+ 17 %) Performance Products 15, 697 (+ 28 %) 21 % *Activities not assigned to a particular division are reported in Other 9% Other* 6, 275 (+ 7 %) 3

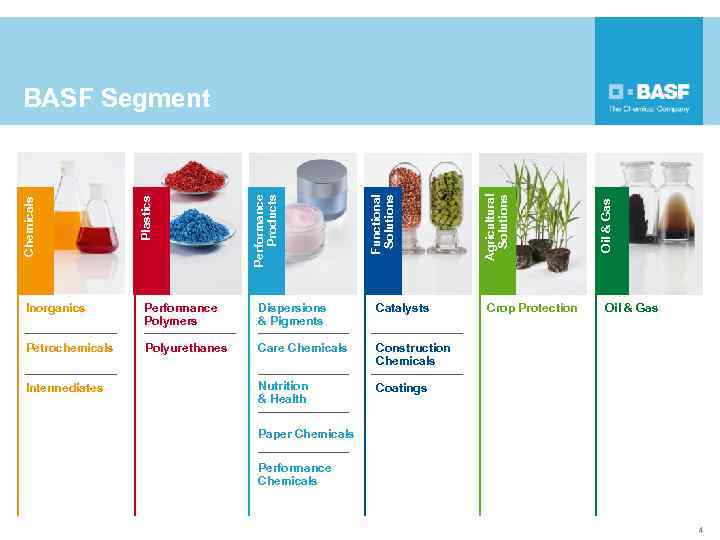

Inorganics Performance Polymers Dispersions & Pigments Catalysts Petrochemicals Polyurethanes Care Chemicals Coatings Intermediates Crop Protection Oil & Gas Construction Chemicals Nutrition & Health Agricultural Solutions Functional Solutions Performance Products Plastics Chemicals BASF Segment Oil & Gas Paper Chemicals Performance Chemicals 4

Electronic Materials by BASF At a Glance Inorganics Inorganic Chemicals Electronic Materials Glues & Impr. Resins CIP & Metal Systems BASF Fuel Cell Inorg. NA & Inorg. Life Science Chemicals Fertilizers 5

Electronic Materials by BASF We Enable Digital Life We offer high purity, quality process chemicals and specialized solutions for semiconductors, flat panel displays, lighting such as LED as well as photovoltaics. 6

Electronic Materials by BASF Mega Trends & Opportunities for the Electronic Industry Mega trends Impact of globalization Consumer needs Opportunities for the industry Communication Faster / Higher performance Universal connectivity Energy efficiency and new resources Smaller space / light weight Longer operating times Better light harvesting and emission Easy to use interfaces Energy efficient Consumerism Fashion 5/7/2012 Lower cost Contribution of the electronic materials Solutions towards specific challenges • Wet deposition • Chemical Mechanical Planarization • Advanced etching, cleaning and photolithography • Innovative process chemical solutions or metallization inks and pastes for solar cells Highly reliable supply of electronic grade chemicals such as: • H 2 O 2, H 2 SO 4 • NMP • NH 3, HCl 7

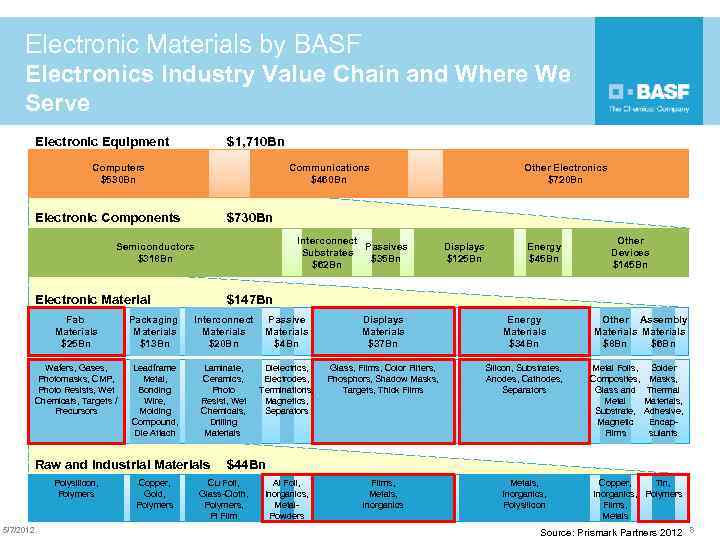

Electronic Materials by BASF Electronics Industry Value Chain and Where We Serve Electronic Equipment $1, 710 Bn Computers $530 Bn Communications $460 Bn Electronic Components Other Electronics $720 Bn $730 Bn Interconnect Passives Substrates $35 Bn $62 Bn Semiconductors $318 Bn Electronic Material Displays $125 Bn Energy $45 Bn $147 Bn Fab Materials $25 Bn Packaging Materials $13 Bn Interconnect Materials $20 Bn Passive Materials $4 Bn Displays Materials $37 Bn Energy Materials $34 Bn Wafers, Gases, Photomasks, CMP, Photo Resists, Wet Chemicals, Targets / Precursors Leadframe Metal, Bonding Wire, Molding Compound, Die Attach Laminate, Ceramics, Photo Resist, Wet Chemicals, Drilling Materials Dielectrics, Electrodes, Terminations, Magnetics, Separators Glass, Films, Color Filters, Phosphors, Shadow Masks, Targets, Thick Films Silicon, Substrates, Anodes, Cathodes, Separators Films, Metals, Inorganics, Polysilicon Raw and Industrial Materials Polysilicon, Polymers 5/7/2012 Copper, Gold, Polymers Other Devices $145 Bn Other Assembly Materials $8 Bn $6 Bn Metal Foils, Composites, Glass and Metal Substrate, Magnetic Films Solder Masks, Thermal Materials, Adhesive, Encapsulants $44 Bn Cu Foil, Glass-Cloth, Polymers, Pl Film Al Foil, Inorganics, Metal. Powders Copper, Tin, Inorganics, Polymers Films, Metals Source: Prismark Partners 2012 8

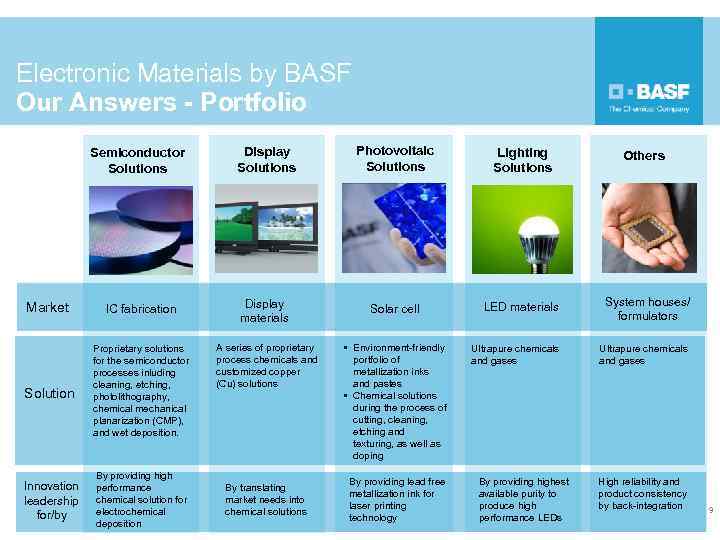

Electronic Materials by BASF Our Answers - Portfolio Semiconductor Solutions Market IC fabrication Solution Proprietary solutions for the semiconductor processes inluding cleaning, etching, photolithography, chemical mechanical planarization (CMP), and wet deposition. Innovation leadership for/by By providing high performance chemical solution for electrochemical deposition Display Solutions Photovoltaic Solutions Lighting Solutions Display materials Solar cell LED materials System houses/ formulators Ultrapure chemicals and gases A series of proprietary process chemicals and customized copper (Cu) solutions By translating market needs into chemical solutions • Environment-friendly portfolio of metallization inks and pastes • Chemical solutions during the process of cutting, cleaning, etching and texturing, as well as doping By providing lead free metallization ink for laser printing technology By providing highest available purity to produce high performance LEDs Others High reliability and product consistency by back-integration 9

Electronic Materials by BASF Key to Our Success Production • Reliable and consistent high quality product • State-of-the-art production facility • Excellent container technology to keep chemicals at the best possible purity levels Analytics • Analytical expertise and quality management to ensure quality consistency • Ultra-modern laboratories in Asia and Europe Logistics Research • Just-in-time delivery • Dedicated R&D team • 100% reliable supply • BASF’s globally integrated R&D network and broad chemical expertise • Collaboration with research institutes, tool suppliers and customers • Fast response time We are active in three major markets of U. S. Europe and Asia Pacific! 10

Electronic Materials by BASF Worldwide Presence – Sales by Region Europe Asia Pacific North America Net sales 3 rd party 2011 11

Electronic Materials by BASF Worldwide Presence North America Germany Korea Japan China Production and Sales & Marketing Global Headquarters, R&D, Production, Sales & Marketing Production, Service Center Sales & Marketing Malaysia Singapore Hong Kong Taiwan Service Center Sales & Marketing Production, Sales & Marketing Regional Headquarters Production, Development, Sales & Marketing 12

Electronic Materials by BASF R&D to Meet Customer Needs n State-of-the-art R&D and application facilities in Europe and Asia n Approx. 100 employees dedicated to the development activities in Electronic Materials n A component of approx. 9, 300 employees of BASF’s R&D and technology community n Some of our R&D projects: § Advanced BEOL and FEOL cleaning solutions § Copper electroplating § New CMP slurries n Collaborations with academic organizations, leading research institutes, tool suppliers and customers. 13

Electronic Materials by BASF Quality Management n Quality management is an integral part of our daily business. To generate customer satisfaction, we pay strict adherence to a customer-oriented process optimization and strive for continuous improvement. n We have a worldwide network of quality management and combine with a Safety & Environment system to ensure reliable and sustainable development products. § § § Our certifications include: OHSAS 18001 ISO 14001 ISO 17025 ISO TS 16949 ISO 9001 14

Electronic Materials by BASF Quality Control n We ensure our products stand for the high purity and quality required for processes and applications our customers in the next generation need n We are the first and only company to receive an ISO-17025 trace analysis certificate for our testing laboratory from Taiwan. We apply the most advanced techniques in quality control, including: § § § § Assay Anion impurity analysis Trace metal impurity analysis Liquids particle measurement General physical/chemical properties measurement Tailor-made services for customers Trouble-shooting clarification 15

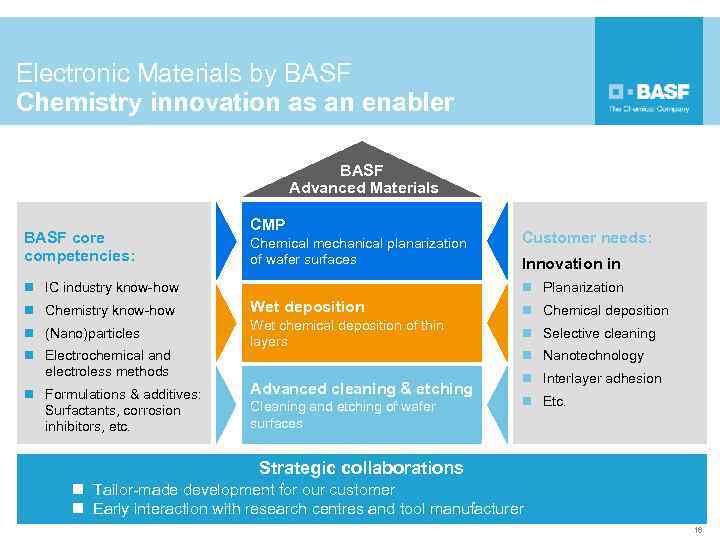

Electronic Materials by BASF Chemistry innovation as an enabler BASF Advanced Materials BASF core competencies: CMP Chemical mechanical planarization of wafer surfaces n IC industry know-how n Chemistry know-how n (Nano)particles n Electrochemical and electroless methods n Formulations & additives: Surfactants, corrosion inhibitors, etc. Customer needs: Innovation in n Planarization Wet deposition Wet chemical deposition of thin layers Advanced cleaning & etching Cleaning and etching of wafer surfaces n Chemical deposition n Selective cleaning n Nanotechnology n Interlayer adhesion n Etc. Strategic collaborations n Tailor-made development for our customer n Early interaction with research centres and tool manufacturer 16

Electronic Materials by BASF Our Key Products Semiconductor Solutions Market IC fabrication Display Solutions Photovoltaic Solutions Lighting Solutions Others Display materials Solar cell LED materials System houses / formulators Inorganic acids PLANAPUR® Solution SELECTIPUR® FOTOPUR® SELURIS® Textur® Cypo. Sol® CUPUR® ? SELECTIPUR® NH 3 7. 0 Organic solvents Hydrogen chloride gas Hydroxylamine free base 17

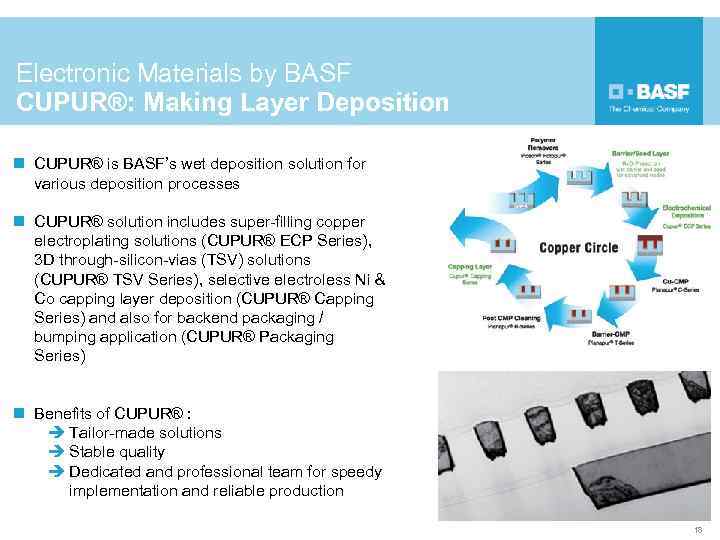

Electronic Materials by BASF CUPUR®: Making Layer Deposition n CUPUR® is BASF’s wet deposition solution for various deposition processes n CUPUR® solution includes super-filling copper electroplating solutions (CUPUR® ECP Series), 3 D through-silicon-vias (TSV) solutions (CUPUR® TSV Series), selective electroless Ni & Co capping layer deposition (CUPUR® Capping Series) and also for backend packaging / bumping application (CUPUR® Packaging Series) n Benefits of CUPUR® : è Tailor-made solutions è Stable quality è Dedicated and professional team for speedy implementation and reliable production 18

Electronic Materials by BASF FOTOPUR®: Chemical for Photolithography n FOTOPUR® are surfactants, chelating and anti-corrosion agents used for photolithography, a crucial step in electronics manufacturing. n BEOL and FEOL application n FOTOPUR® C Series for defect reduction rinse solution n FOTOPUR® R Series for post etch/post ash/post implant residue removers n Bumping and 3 D TSV application n FOTOPUR® D Series for photoresist/polyimide developer n FOTOPUR® S Series for photoresist/polyimide stripper n Benefits of FOTOPUR® : è Tailor-made solutions and Stable quality 19

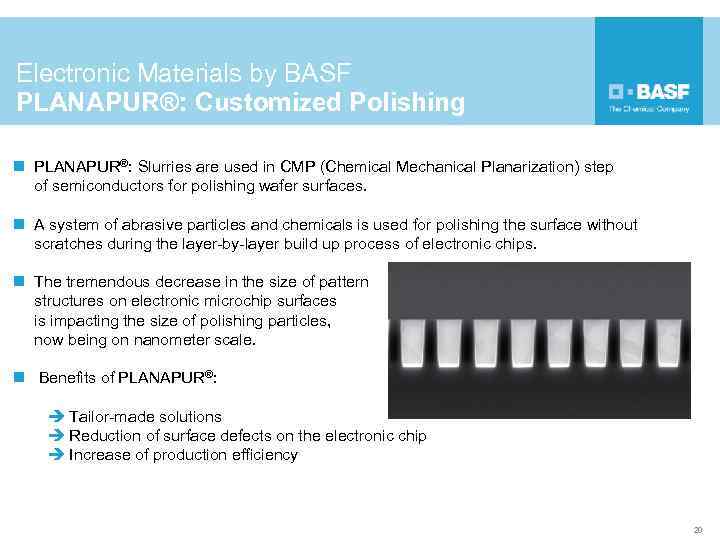

Electronic Materials by BASF PLANAPUR®: Customized Polishing n PLANAPUR®: Slurries are used in CMP (Chemical Mechanical Planarization) step of semiconductors for polishing wafer surfaces. n A system of abrasive particles and chemicals is used for polishing the surface without scratches during the layer-by-layer build up process of electronic chips. n The tremendous decrease in the size of pattern structures on electronic microchip surfaces is impacting the size of polishing particles, now being on nanometer scale. n Benefits of PLANAPUR®: è Tailor-made solutions è Reduction of surface defects on the electronic chip è Increase of production efficiency 20

Electronic Materials by BASF SELECTIPUR®: Best Cleaning and Etching n SELECTIPUR® is high-purity chemicals for cleaning and etching step in IC manufacturing, including bumping and 3 D TSV application. n As integrated circuits (ICs) have consistently migrated to smaller feature sizes, the cleaning process involved is more important than ever. BASF cleaning product includes: H 2 O 2, IPA, NH 4 OH, H 2 SO 4, HCI, HNO 3, CH 3 COOH, and HF. n The efficient wet etching process relies heavily on chemicals with precise recipe control. BASF provide high quality and tailor-made SELECTIPUR® based on customers’ requirement from diversified developing electronic manufacturing industry n Benefits of SELECTIPUR® è Tailor-made solutions è Constant quality 21

Electronic Materials by BASF Cypo. Sol®: For Better Metallization n Cypo. Sol® is metallization ink and paste used for metallization of front and back side of solar cell wafers n Product range comprises metallization inks for both the screen printing process and the new laser transfer printing (LTP) technology n Reduce cracking rate in ultra-thin solar cell production, boost performance and simplify handling n Benefits of Cypo. Sol®: è high performance and efficiency è simplify handling è Eco-friendly 22

Electronic Materials by BASF SELURIS® Clean: Easy Way to Clean n Cleaning solution for use in the production of solar cell wafers n SELURIS® Clean is used twice in the process: before and after phosphoric acid doping n After doping, SELURIS® Clean removes any disruptive residual phosphorus remaining on the surface n Benefits of SELURIS® Clean: è Enhanced cell efficiency, i. e. higher performance è Environmentally sound è Unwanted electric errors are eliminated 23

Electronic Materials by BASF Our Competencies at a Glance Leading We are one of the global market leaders in electronic materials 30 years We have been serving the electronic industry for over 30 years Over 150 patents 100 We have applied over 150 patents within the last 5 years Approximately 100 employees dedicated to R&D activities in Electronic Materials, fully integrated into BASF’s R&D and technology community with approx. 9, 300 employees 24

Electronic Materials by BASF Future of Electronics enabled by Electronic Materials We are committed to a changing world! 5/7/2012 25

5/7/2012 26

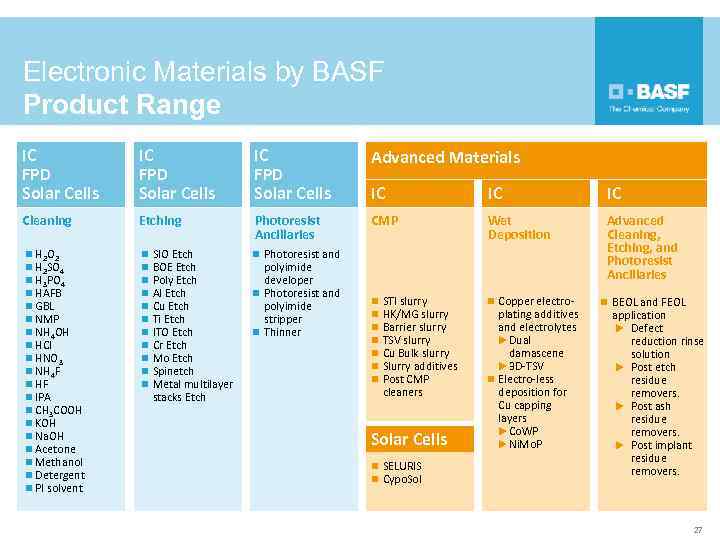

Electronic Materials by BASF Product Range IC FPD Solar Cells Advanced Materials IC IC IC Cleaning Etching Photoresist Ancillaries CMP Wet Deposition n H 2 O 2 n H 2 SO 4 n H 3 PO 4 n HAFB n GBL n NMP n NH 4 OH n HCl n HNO 3 n NH 4 F n HF n IPA n CH 3 COOH n KOH n Na. OH n Acetone n Methanol n Detergent n PI solvent n n n Advanced Cleaning, Etching, and Photoresist Ancillaries SIO Etch BOE Etch Poly Etch Al Etch Cu Etch Ti Etch ITO Etch Cr Etch Mo Etch Spinetch Metal multilayer stacks Etch n Photoresist and polyimide developer n Photoresist and polyimide stripper n Thinner n n n n STI slurry HK/MG slurry Barrier slurry TSV slurry Cu Bulk slurry Slurry additives Post CMP cleaners Solar Cells n SELURIS n Cypo. Sol n Copper electro- plating additives and electrolytes u Dual damascene u 3 D-TSV n Electro-less deposition for Cu capping layers u Co. WP u Ni. Mo. P n BEOL and FEOL application u Defect reduction rinse solution u Post etch residue removers. u Post ash residue removers. u Post implant residue removers. 27

Electronic Materials by BASF Smaller and higher performance device 1943 1998 2010 IBM ASCC Apple i. Mac Apple i. Phone Size 250 cm H, 1500 cm W 38 cm H, 38 cm W 11 cm H, 5 cm W Wight 4500 Kg 15800 g 137 g Wire 80 um 250 nm 45 nm Speed Less than 2. 25 MHz 500 MHz 1 GHz IC Industry pursues “High Performance”, “Low Cost” and “Small Space” 28

Electronic Materials by BASF Semiconductor process development 10 um (1971) e. g. Intel 8008 3 um (1975) e. g. Intel 8088 3 um 1. 5 um (1982) e. g. Intel 80286 1 um (1985) e. g. Intel 80386 1 um 800 nm 800 nm (1989) e. g. P 5 Pentium 600 nm 600 nm (1994) e. g. Motorola Power. PC 601 350 nm (1995) e. g. Pentium II Klamath i. Mac 350 nm 250 nm (1998) e. g. AMD K 6 -2 & Intel Core i 5 250 nm 180 nm (1999) e. g. Coppermine E 180 nm 130 nm (2000) e. g. Power PC 7447 130 nm 90 nm (2002) e. g. IBM Xenon 65 nm 65 nm (2006) e. g. Core Duo Apple Power. Book G 4 45 nm 45 nm (2008) e. g. Core 2 32 nm 32 nm (2010) Core i 3 XBOX 360 22 nm 1970 1980 1990 22 nm (2011) i. Pad / i. Phone 2000 2010 29

CAE-Overview_2012_July_approved_NEW.ppt