c60cb5782b45daa5f72491427aeacf71.ppt

- Количество слайдов: 20

Combustion of the Butanol Isomers: Reaction Pathways at Elevated Pressures from Low-to-High Temperatures Michael R. Harper, Mary Schnoor, Shamel Merchant, William H. Green*, Kevin M. Van Geem, Bryan W. Weber, Chih-Jen Sung, Ivo Stranic, David F. Davidson, and Ronald K. Hanson MIT, U. Ghent, U. Conn. , & Stanford Primary Source of Funding: US DOE Combustion Energy Frontier Research Center

The Context & Challenge • World is running out of light sweet crude… and benefits to using biofuels instead • Dozens of alternative fuels proposed, how to assess which are worth pursuing? • Several new combustion concepts, how to assess how they work with future fuels? • Increasing regulation of emission species – need models with more chemistry

Goals/Philosophy of this Work • Improve capability to predict performance of proposed new fuels – Faster, cheaper than exptlly testing all fuels – Butanol as a test case • Can we build accurate models quickly? How? • Accuracy of predictions? How to validate models? • “Right answers for the Right Reasons”: true rate coefficients, don’t force fits

Very Big Models: Need to Think Differently • So many possible reactions and species! – Select ~350 species from ~30, 000 considered. – Select ~7, 000 reactions from ~106 considered. • No way to determine all the numbers in the model experimentally… – …and impractical to compute them all accurately. – Most experiments do not conclusively determine any number, instead constrain some combination. • Fuel performance and experiments are not sensitive to most of these numbers… – …if those numbers are right order of magnitude • Different experiments sensitive to different subsets of species and reactions.

Our Model Development Process • Computer assembles large kinetic model for particular condition(s) using rough estimates of rate coefficients. (open source RMG software) – Start from model derived for other conditions, so appending new reactions and species. – Automated identification of chemically activated product channels, and computation of k(T, P). • If sensitive to k derived from rough guess, recompute that k using quantum chemistry. – Generalize from quantum to improve rate rules. • Iterate until not sensitive to rough estimates. • Compare with experiment. – Big discrepancies? Look for bugs or typos. • Match OK? Repeat for different conditions.

Many Experimental Data on Butanol Combustion/Oxidation/Pyrolysis • Ignition Delays – Shock tube – Rapid compression machine (see poster T 40) • Flame Speeds – spherical and flat flames • Speciated Data from: – – – MS sampling in premixed and diffusion flames Flow reactors (pyrolysis & oxidation) Jet-Stirred Reactors Rapid Compression Facility Next talk: Species time profiles in shock tube We test our butanols model against all these types of experiments

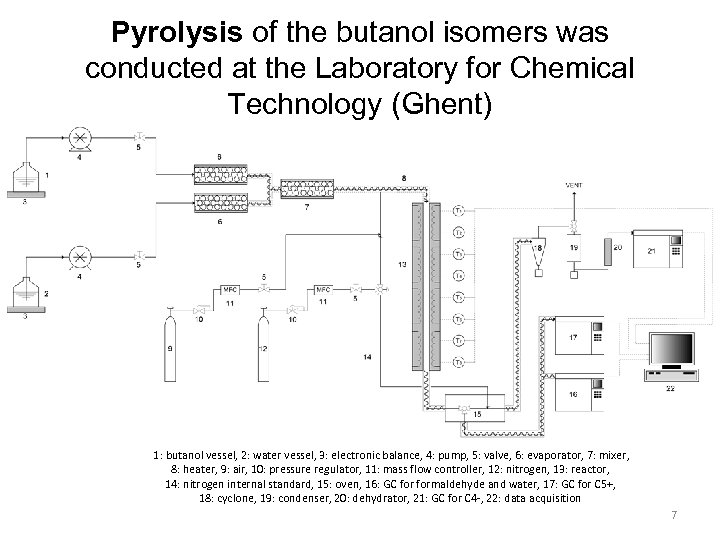

Pyrolysis of the butanol isomers was conducted at the Laboratory for Chemical Technology (Ghent) 1: butanol vessel, 2: water vessel, 3: electronic balance, 4: pump, 5: valve, 6: evaporator, 7: mixer, 8: heater, 9: air, 10: pressure regulator, 11: mass flow controller, 12: nitrogen, 13: reactor, 14: nitrogen internal standard, 15: oven, 16: GC formaldehyde and water, 17: GC for C 5+, 18: cyclone, 19: condenser, 20: dehydrator, 21: GC for C 4 -, 22: data acquisition 7

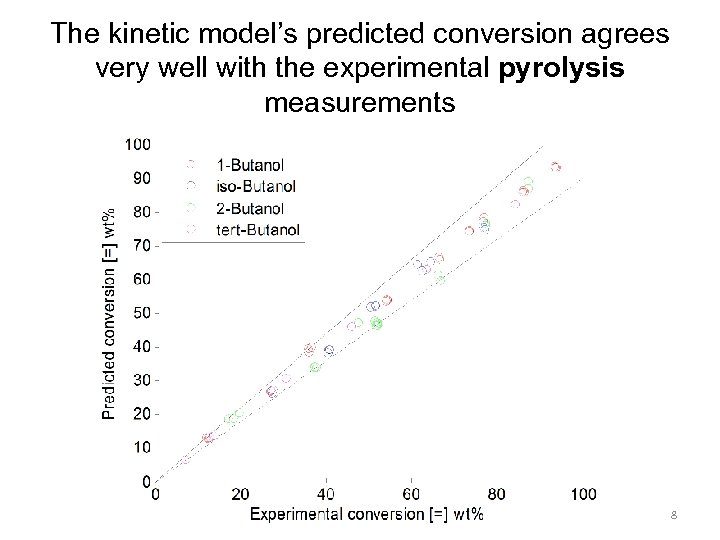

The kinetic model’s predicted conversion agrees very well with the experimental pyrolysis measurements 8

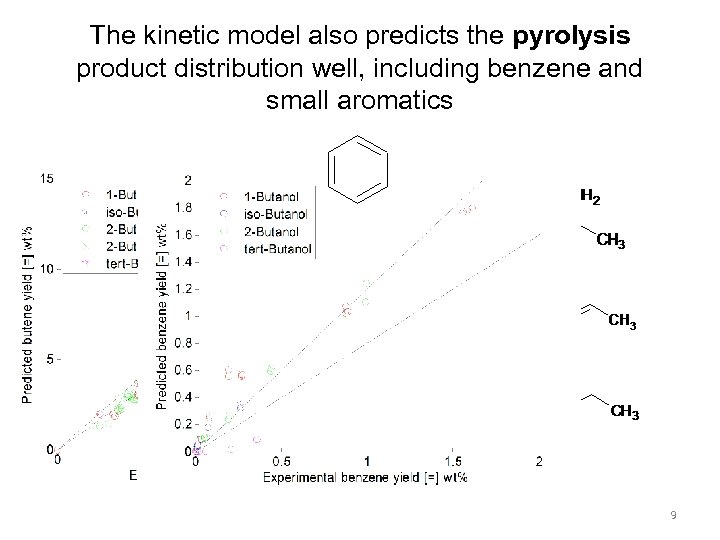

The kinetic model also predicts the pyrolysis product distribution well, including benzene and small aromatics 9

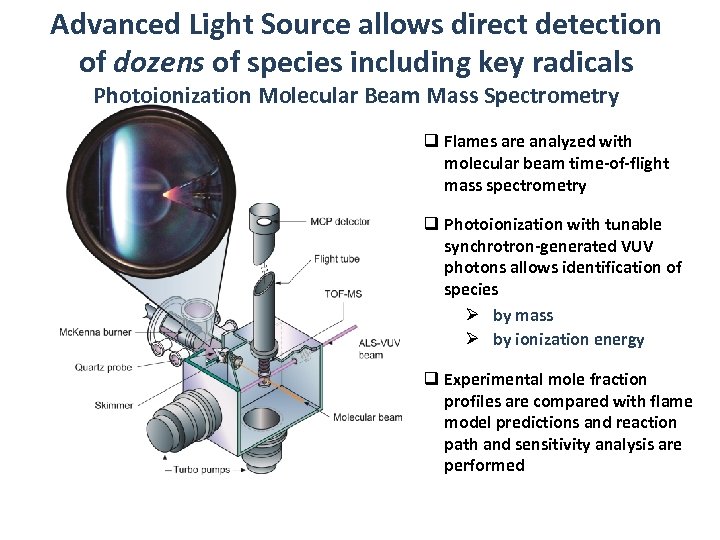

Advanced Light Source allows direct detection of dozens of species including key radicals Photoionization Molecular Beam Mass Spectrometry q Flames are analyzed with molecular beam time-of-flight mass spectrometry q Photoionization with tunable synchrotron-generated VUV photons allows identification of species Ø by mass Ø by ionization energy q Experimental mole fraction profiles are compared with flame model predictions and reaction path and sensitivity analysis are performed

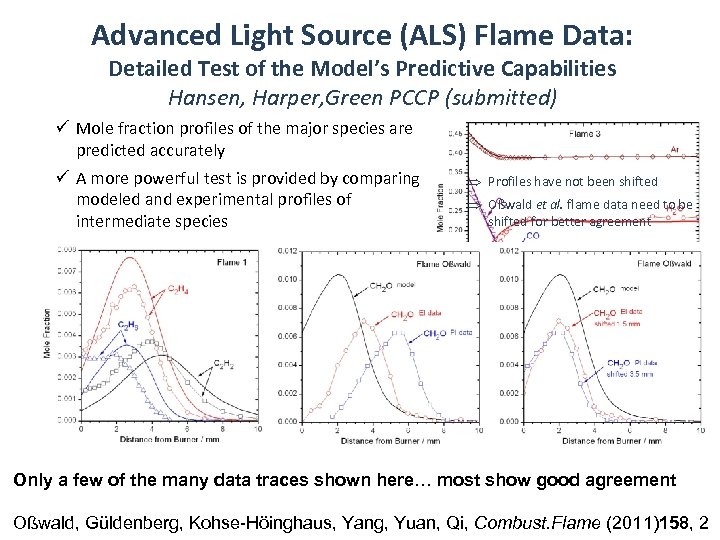

Advanced Light Source (ALS) Flame Data: Detailed Test of the Model’s Predictive Capabilities Hansen, Harper, Green PCCP (submitted) ü Mole fraction profiles of the major species are predicted accurately ü A more powerful test is provided by comparing modeled and experimental profiles of intermediate species Þ Profiles have not been shifted Þ Oßwald et al. flame data need to be shifted for better agreement Only a few of the many data traces shown here… most show good agreement Oßwald, Güldenberg, Kohse-Höinghaus, Yang, Yuan, Qi, Combust. Flame (2011)158, 2

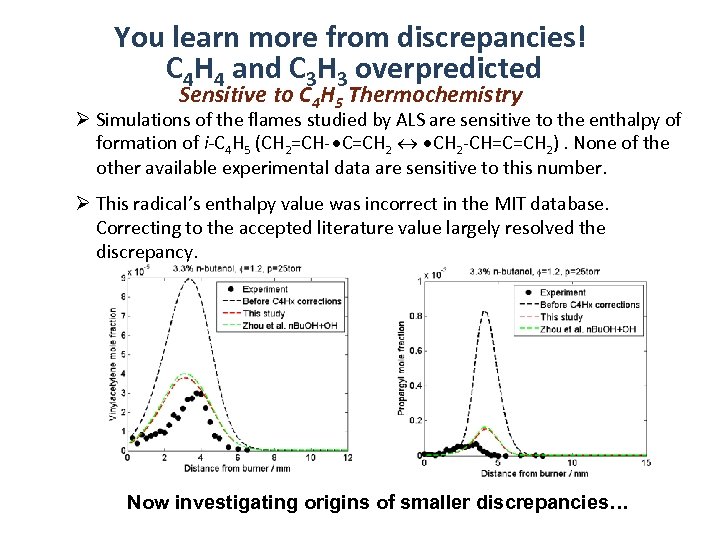

You learn more from discrepancies! C 4 H 4 and C 3 H 3 overpredicted Sensitive to C 4 H 5 Thermochemistry Ø Simulations of the flames studied by ALS are sensitive to the enthalpy of formation of i-C 4 H 5 (CH 2=CH-∙C=CH 2 ∙CH 2 -CH=C=CH 2). None of the other available experimental data are sensitive to this number. Ø This radical’s enthalpy value was incorrect in the MIT database. Correcting to the accepted literature value largely resolved the discrepancy. Now investigating origins of smaller discrepancies…

Focus on what is important! Most important fuel performance property: ignition delay • Gasoline “Octane Number” • Diesel “Cetane Number” • Small changes in fuel make big changes in ignition: sensitive to molecular structure! • New engines under development are even more sensitive to ignition – Potential for big gains… but only if the fuel ignition delay time matches engine requirements

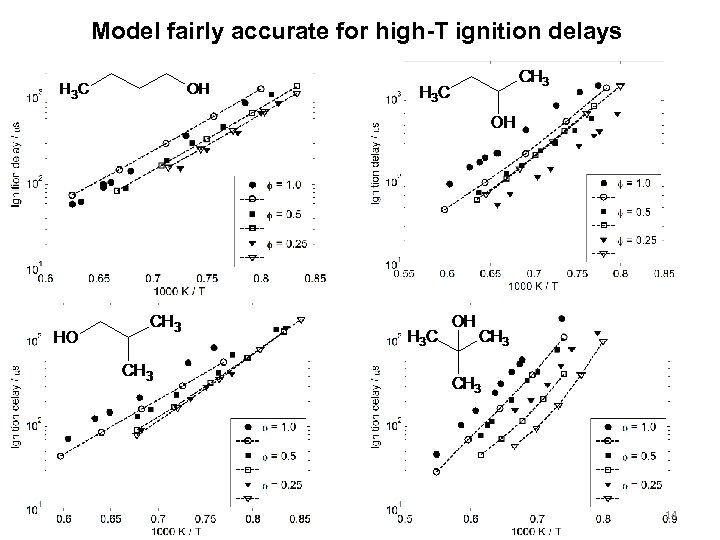

Model fairly accurate for high-T ignition delays 14

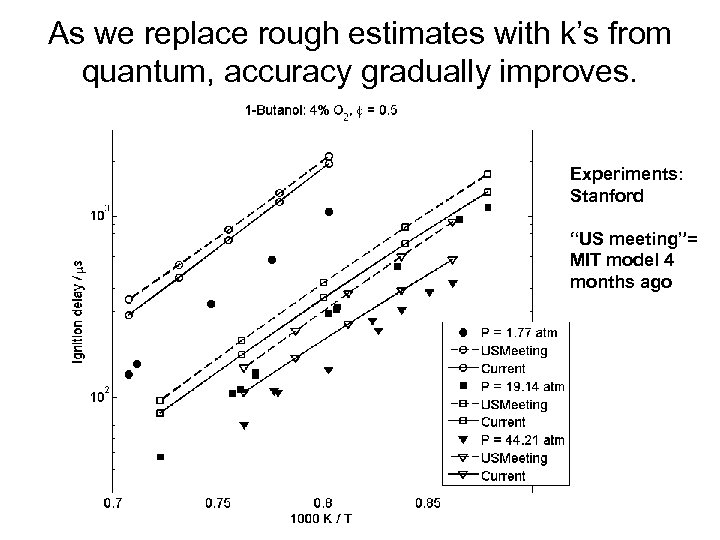

As we replace rough estimates with k’s from quantum, accuracy gradually improves. Experiments: Stanford “US meeting”= MIT model 4 months ago

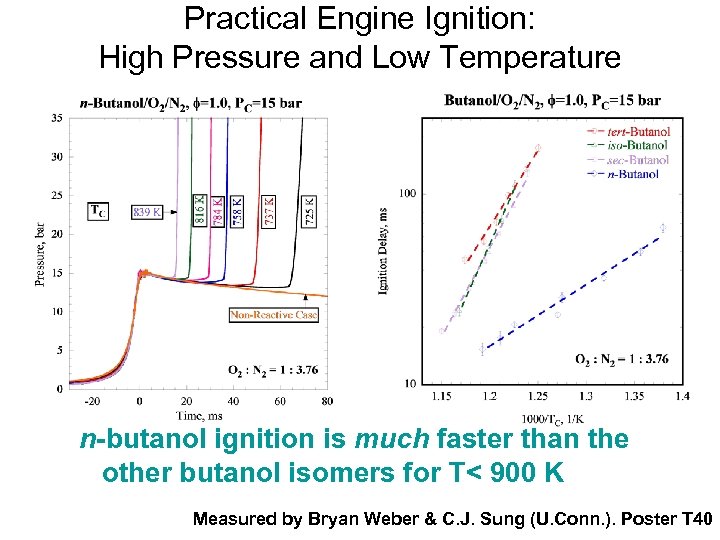

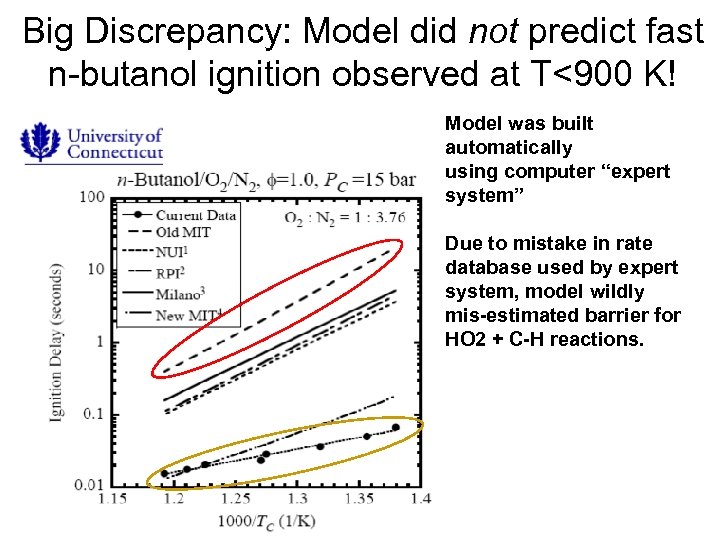

Practical Engine Ignition: High Pressure and Low Temperature n-butanol ignition is much faster than the other butanol isomers for T< 900 K Measured by Bryan Weber & C. J. Sung (U. Conn. ). Poster T 40

Big Discrepancy: Model did not predict fast n-butanol ignition observed at T<900 K! Model was built automatically using computer “expert system” Due to mistake in rate database used by expert system, model wildly mis-estimated barrier for HO 2 + C-H reactions.

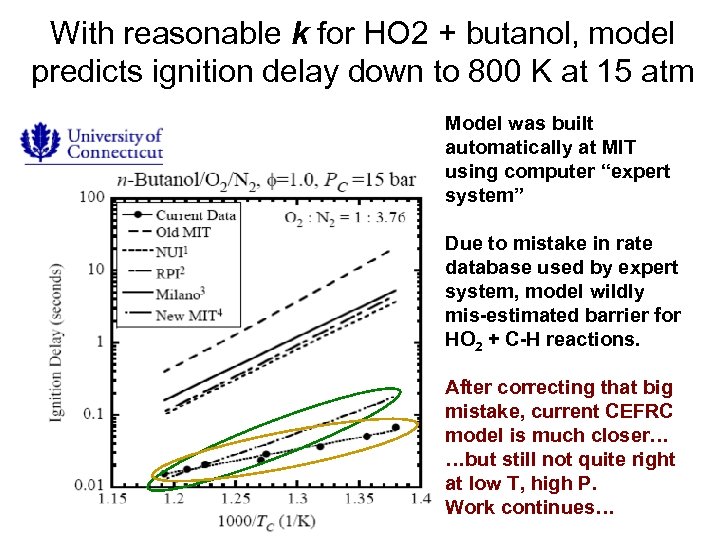

With reasonable k for HO 2 + butanol, model predicts ignition delay down to 800 K at 15 atm Model was built automatically at MIT using computer “expert system” Due to mistake in rate database used by expert system, model wildly mis-estimated barrier for HO 2 + C-H reactions. After correcting that big mistake, current CEFRC model is much closer… …but still not quite right at low T, high P. Work continues…

![Model not capturing dependence on [O 2] below 800 K: probably missing or misestimating Model not capturing dependence on [O 2] below 800 K: probably missing or misestimating](https://present5.com/presentation/c60cb5782b45daa5f72491427aeacf71/image-19.jpg)

Model not capturing dependence on [O 2] below 800 K: probably missing or misestimating some peroxyl chemistry Exptl Data: U. Conn. MIT model Predictions Sensitive to chemically-activated R+O 2 = QOOH: g-C 4 H 8 OH + O 2 (+M) = CH 3 CH(OOH)CH 2 CHOH

Summary • Kinetic models based on quantum chemistry + rate estimates can be predictive for huge range of combustion/oxidation/pyrolysis experiments. – Big models can be built and refined pretty quickly. – Experimentalists + Modelers team very effective. – Useful for assessing proposed new fuels • Big errors usually due to bugs, typos, holes in database. Experiments and team-mates great for catching them! • P-dependence and chemical activation important for high -T, but also in peroxyl chemistry. More than 50% of k’s in model are significantly P-dependent. • Starting to reach expected “factor of 2” small errors due to inaccuracies in rate coefficients and thermo. – May be difficult to significantly improve accuracy…but calculations can be great guide for experiments to more precisely determine key parameters. • Kinetics is starting to become a predictive science, possible to use in predictive design of new processes.

c60cb5782b45daa5f72491427aeacf71.ppt