135cb52a61c53b84982122e3d115dbbc.ppt

- Количество слайдов: 37

Combining Electric Power Generation and Water Quality Enhancement to Grow the Southwest Missouri Economy Verel W. Benson D. Todd Farrand Agriculture as a Producer and Consumer of Energy June 24 -25, 2004 Arlington, VA

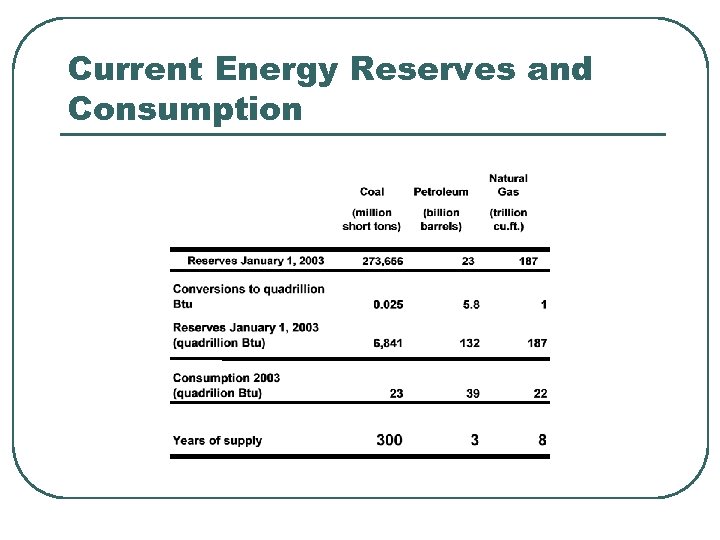

Current Energy Reserves and Consumption

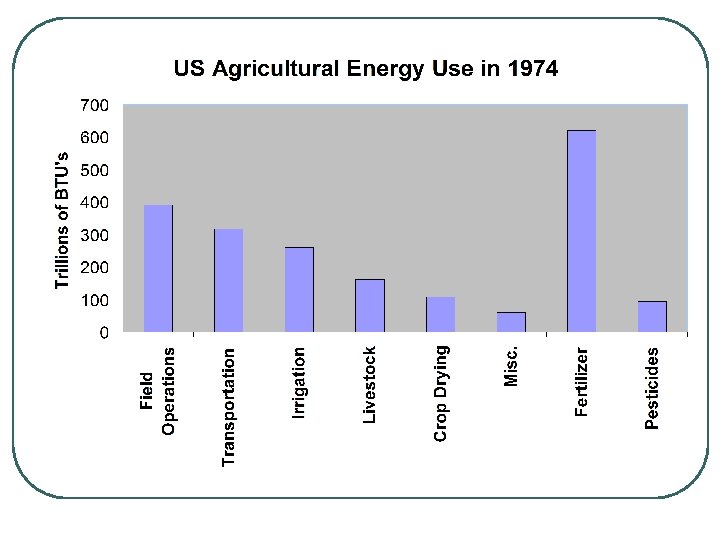

A Little Energy Use History

Objectives l estimate the poultry litter produced l estimate the amount of litter safely recycled as fertilizer l determine the feasibility of generating power from biomass l estimate the likely economic and environmental impacts

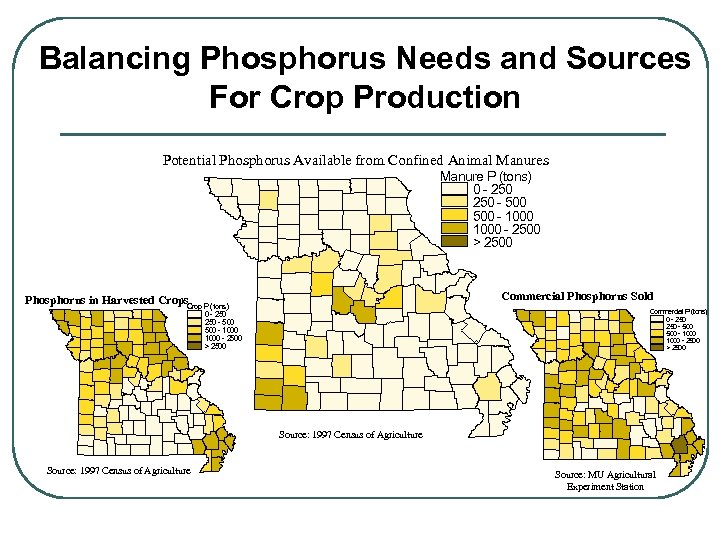

Balancing Phosphorus Needs and Sources For Crop Production Potential Phosphorus Available from Confined Animal Manures Manure P (tons) 0 - 250 - 500 - 1000 - 2500 > 2500 Commercial Phosphorus Sold Phosphorus in Harvested Crops. Crop P (tons) Commercial P (tons) 0 - 250 250 - 500 500 - 1000 - 2500 > 2500 Source: 1997 Census of Agriculture Source: MU Agricultural Experiment Station

Litter Supply - Purdy

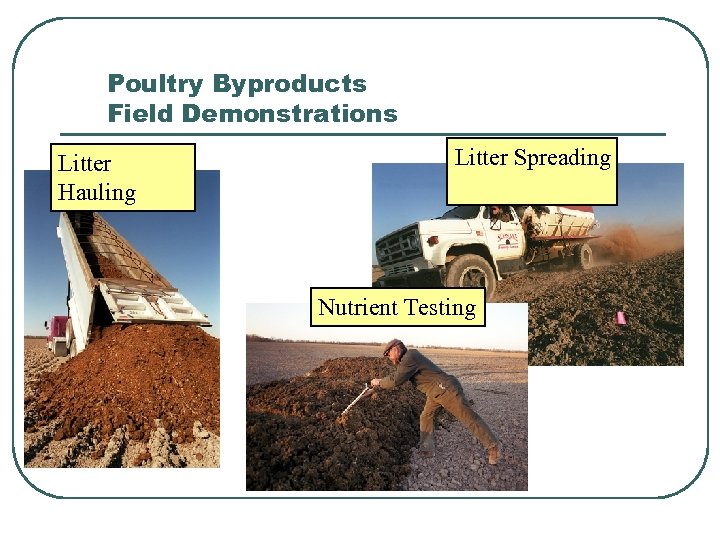

Poultry Byproducts Field Demonstrations Litter Hauling Litter Spreading Nutrient Testing

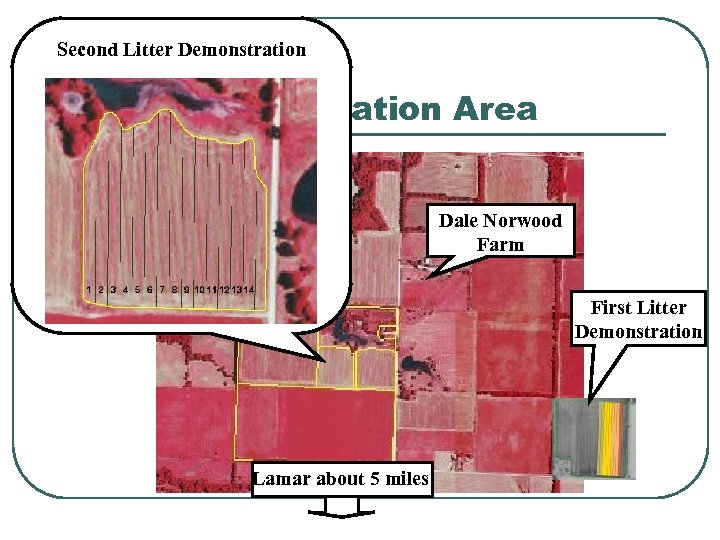

Second Litter Demonstration Area Dale Norwood Farm First Litter Demonstration Lamar about 5 miles

Demonstration Harvesting

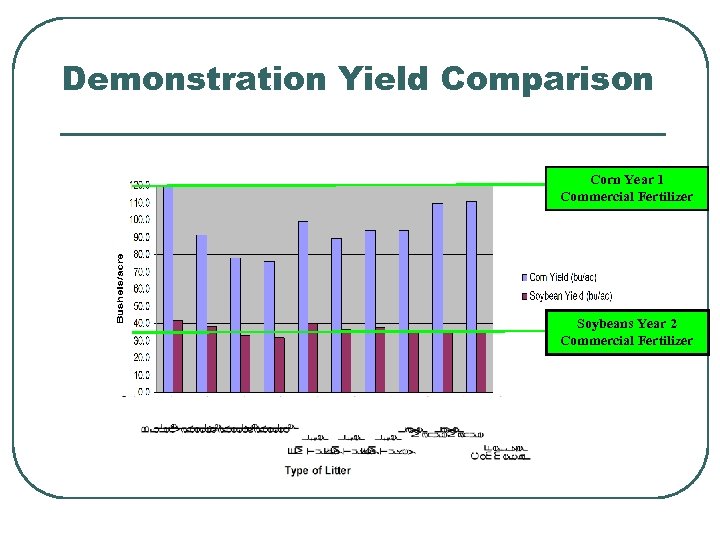

Demonstration Yield Comparison Corn Year 1 Commercial Fertilizer Poultry Litter N-P-K Applications by Strip Soybeans Year 2 Commercial Fertilizer

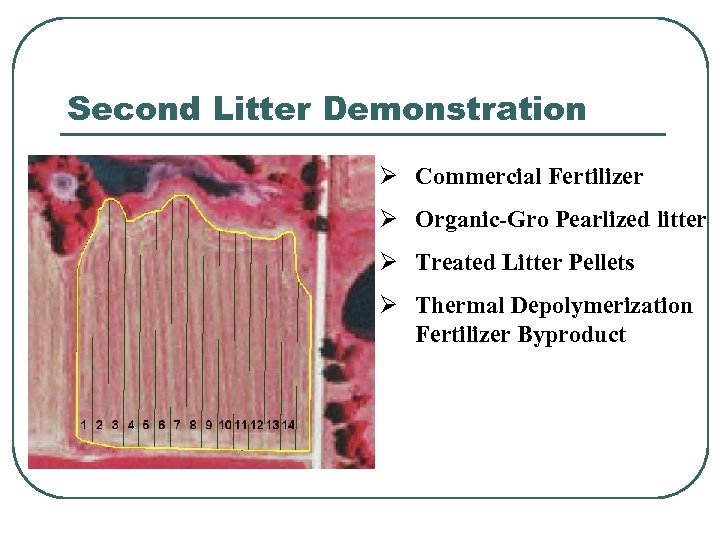

Second Litter Demonstration Ø Commercial Fertilizer Ø Organic-Gro Pearlized litter Ø Treated Litter Pellets Ø Thermal Depolymerization Fertilizer Byproduct

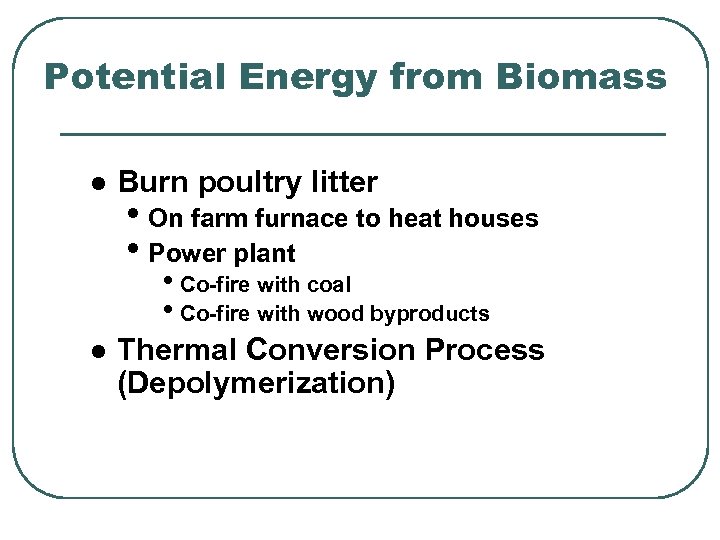

Potential Energy from Biomass l Burn poultry litter • On farm furnace to heat houses • Power plant • Co-fire with coal • Co-fire with wood byproducts l Thermal Conversion Process (Depolymerization)

Heating with Poultry Litter

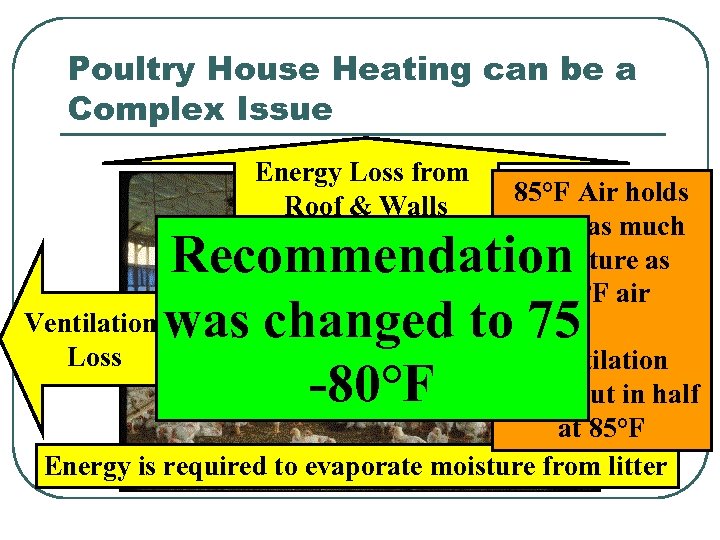

Poultry House Heating can be a Complex Issue Energy Loss from Roof & Walls 85°F Air holds twice as much moisture as 65°F air Early 1970’s the Recommendation recommended Ventilation was house temperature broiler changed to 75 Loss Ventilation was 65°F -80°F needs cut in half at 85°F Energy is required to evaporate moisture from litter

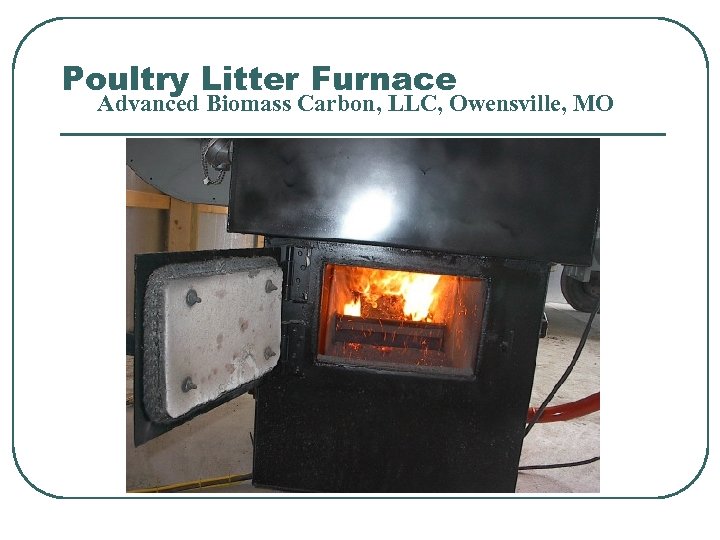

Poultry Litter Furnace Advanced Biomass Carbon, LLC, Owensville, MO

Considerations for On-farm Litter Burning §Heating demands are seasonal §Heating demands concentrated in the first two weeks of growth

Producing Energy from Poultry & Forestry Byproducts

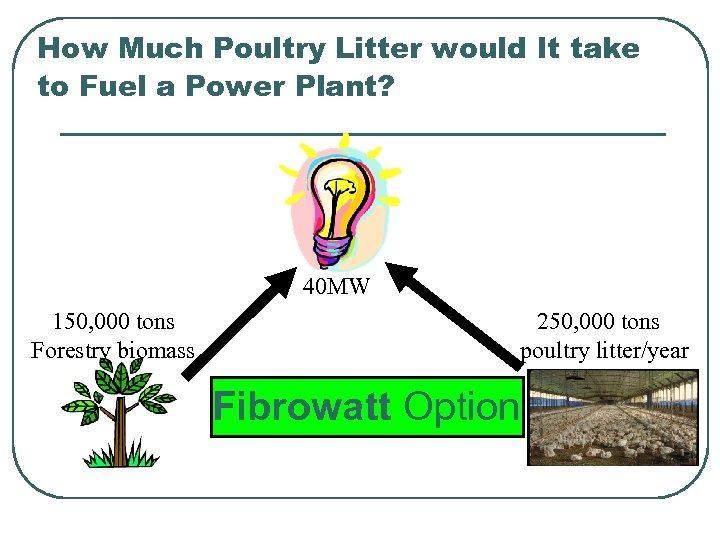

How Much Poultry Litter would It take to Fuel a Power Plant? 40 MW 150, 000 tons Forestry biomass 250, 000 tons poultry litter/year Fibrowatt Option

SW Missouri Growers produce 250, 000 tons of litter per year

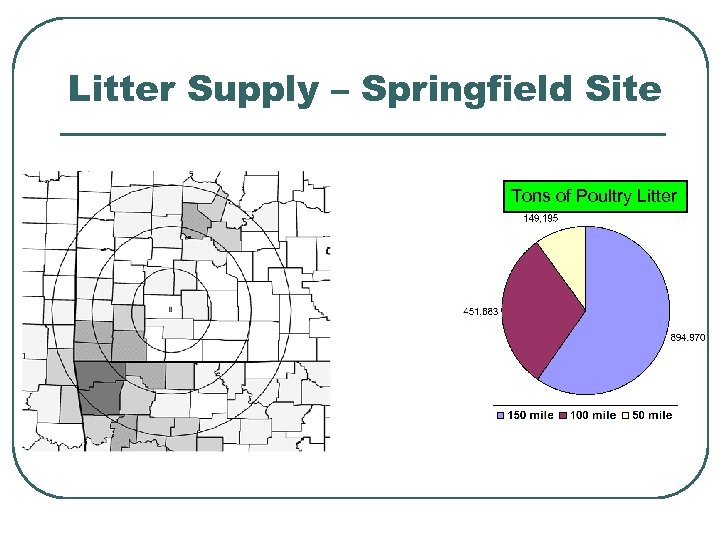

Litter Supply – Springfield Site Tons of Poultry Litter

Arkansas and Virginia Studies Estimate litter hauling costs to be 10 to 12 cents per ton/mile

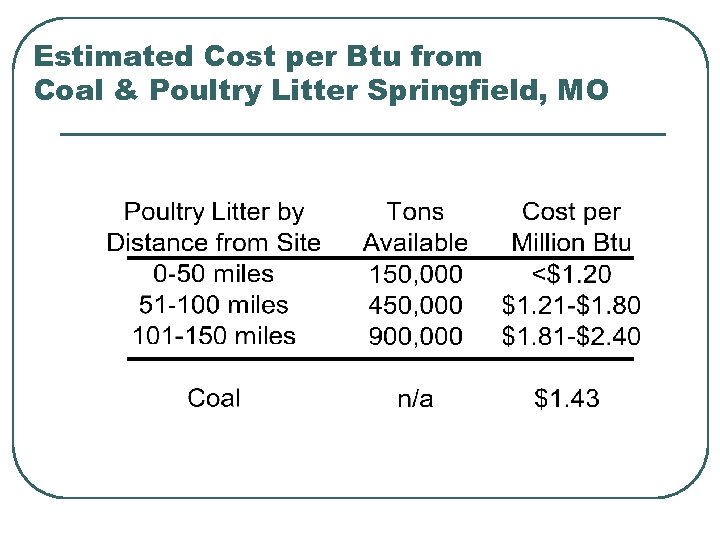

Estimated Cost per Btu from Coal & Poultry Litter Springfield, MO

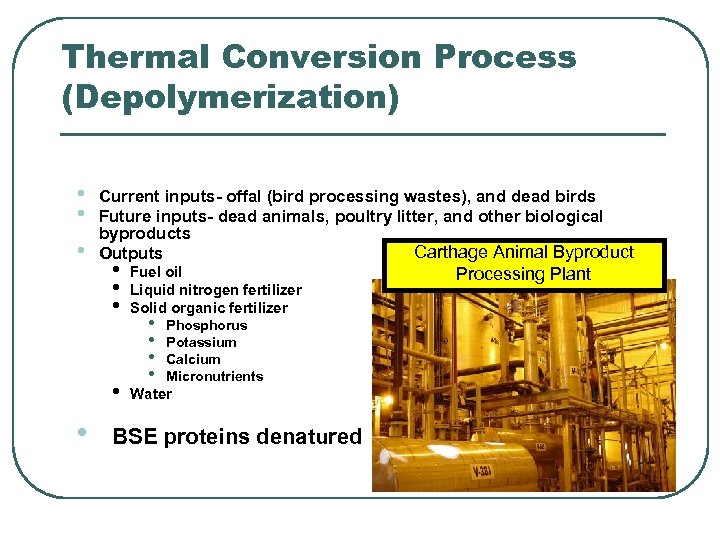

Thermal Conversion Process (Depolymerization) • • • Current inputs- offal (bird processing wastes), and dead birds Future inputs- dead animals, poultry litter, and other biological byproducts Carthage Animal Byproduct Outputs Fuel oil Liquid nitrogen fertilizer Solid organic fertilizer • • • Water • • Phosphorus Potassium Calcium Micronutrients BSE proteins denatured Processing Plant

Economic and Impacts Environmental l Consumer impacts l Farm impacts l Watershed impacts l Regional impacts

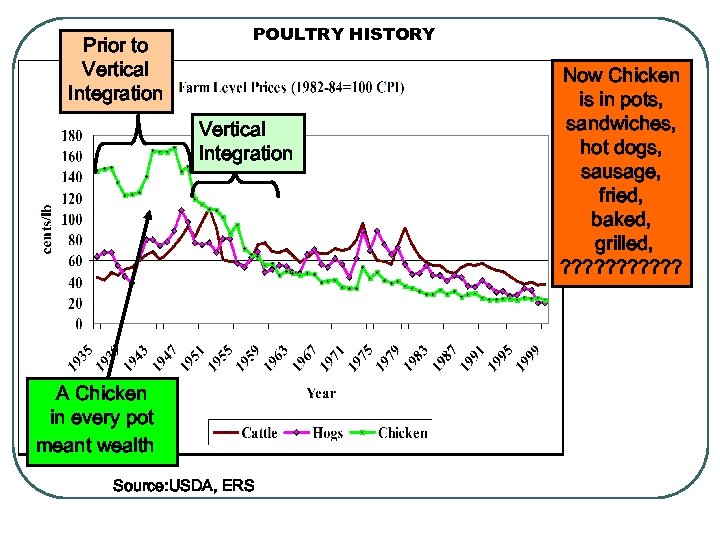

Prior to Vertical Integration POULTRY HISTORY Vertical Integration A Chicken in every pot meant wealth Source: USDA, ERS Now Chicken is in pots, sandwiches, hot dogs, sausage, fried, baked, grilled, ? ? ?

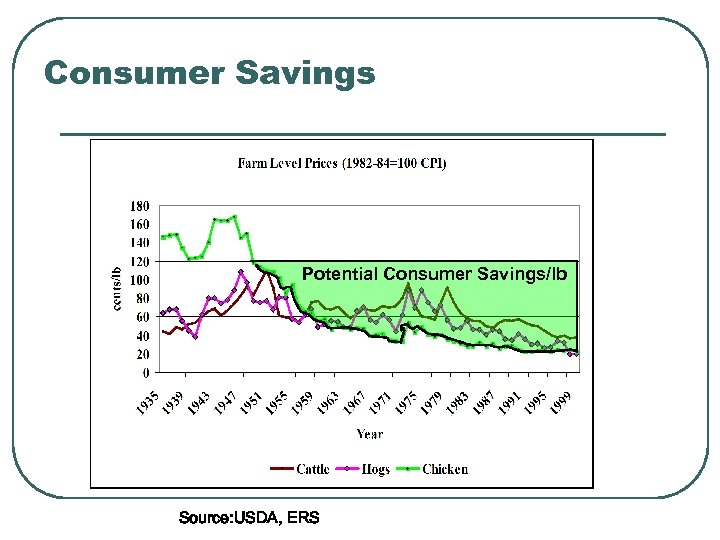

Consumer Savings Potential Consumer Savings/lb Source: USDA, ERS

Farm Impacts Poultry production impacts nearby grain producers Nearby grain producers have greatest potential to recycle poultry litter fertilizer byproducts

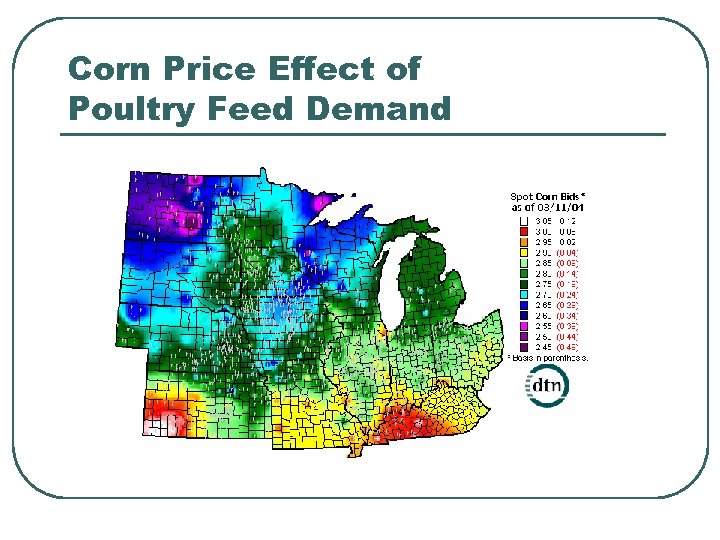

Corn Price Effect of Poultry Feed Demand

Watershed Impacts l Reduce fecal Coliform load l Reduce phosphorus load l Biomass production

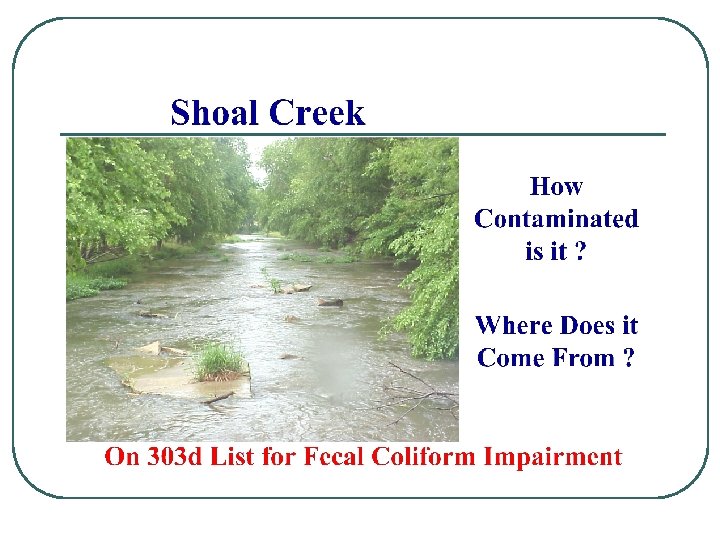

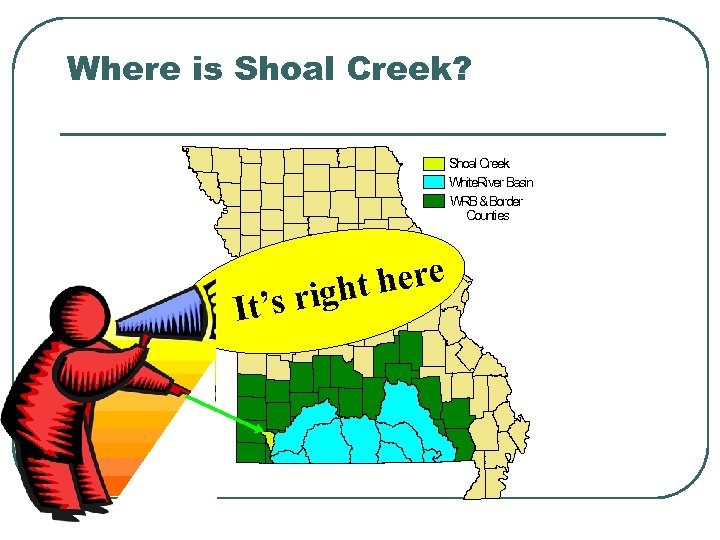

Where is Shoal Creek? Shoal Creek White. River Basin WRB & Border Counties N W E S here right It’s

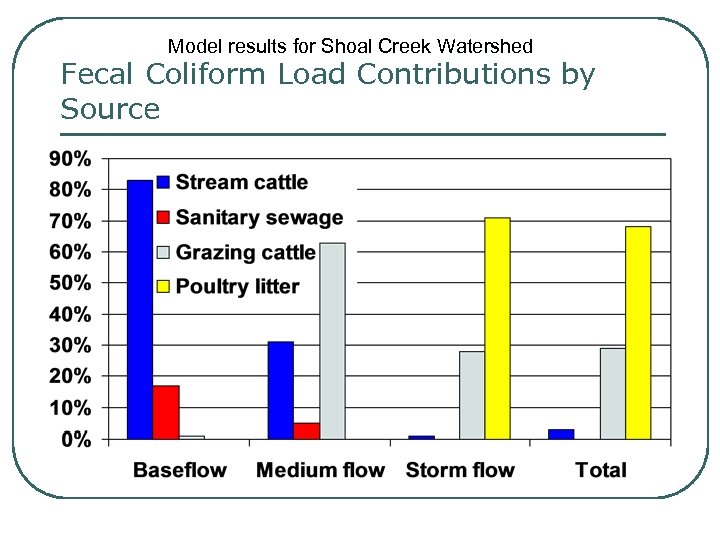

Model results for Shoal Creek Watershed Fecal Coliform Load Contributions by Source

Riparian Buffers trap Sediment Phosphorus Fecal coliform Buffers Produce Biomass

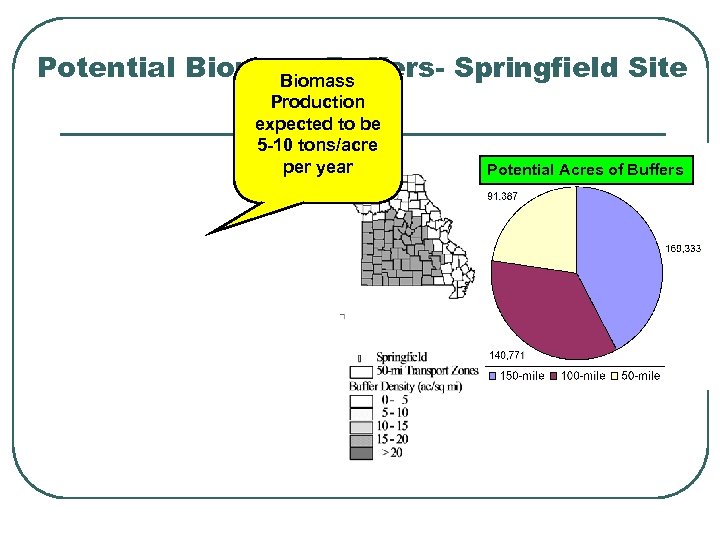

Potential Biomass Buffers- Springfield Site Biomass Production expected to be 5 -10 tons/acre per year Potential Acres of Buffers

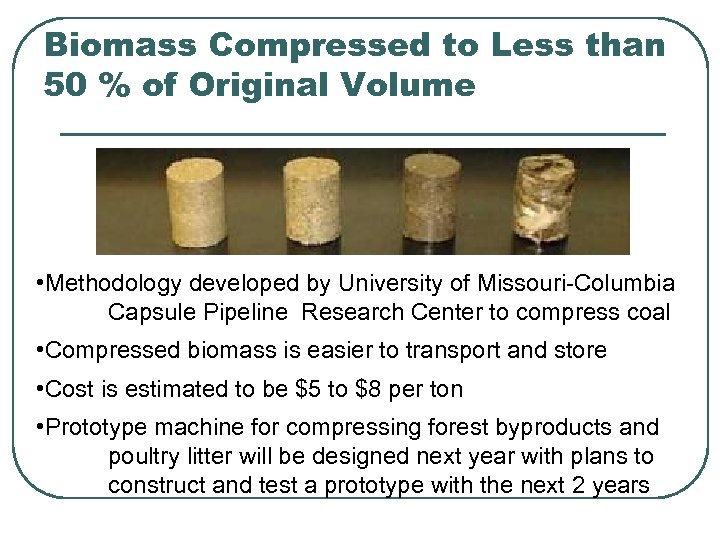

Biomass Compressed to Less than 50 % of Original Volume • Methodology developed by University of Missouri-Columbia Capsule Pipeline Research Center to compress coal • Compressed biomass is easier to transport and store • Cost is estimated to be $5 to $8 per ton • Prototype machine for compressing forest byproducts and poultry litter will be designed next year with plans to construct and test a prototype with the next 2 years

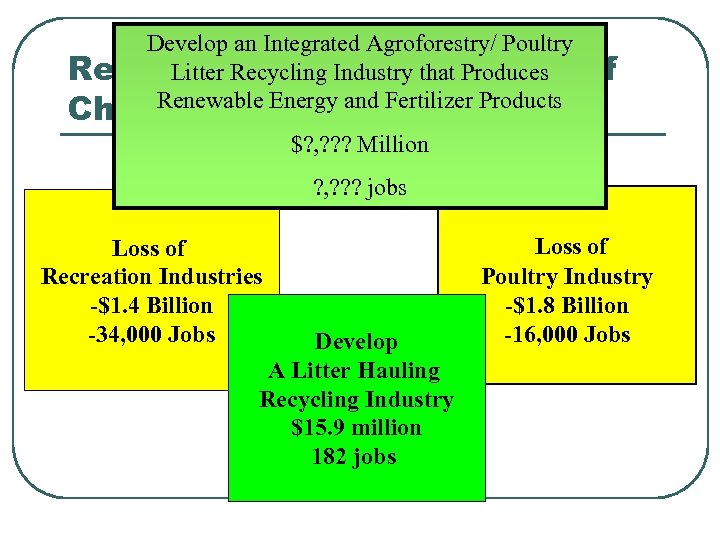

Develop an Integrated Agroforestry/ Poultry Litter Economic Impacts Regional Recycling Industry that Produces Renewable Energy and Fertilizer Products Choices of $? , ? ? ? Million ? , ? ? ? jobs Loss of Recreation Industries -$1. 4 Billion -34, 000 Jobs Develop A Litter Hauling Recycling Industry $15. 9 million 182 jobs Loss of Poultry Industry -$1. 8 Billion -16, 000 Jobs

Thank You Questio ns?

135cb52a61c53b84982122e3d115dbbc.ppt