86685e17d504f6aa9a0cc74ff3939fb7.ppt

- Количество слайдов: 29

Collimator Controls • Readiness of collimators control – from bottom to top • State of automated collimator positioning Extended LTC Session 6 - Readiness of Controls Friday 07 March 2008 14 h 30 2008/03/07 MJJ

Collimator Controls • Readiness of collimators control – from bottom to top • State of automated collimator positioning Extended LTC Session 6 - Readiness of Controls Friday 07 March 2008 14 h 30 2008/03/07 MJJ

Collimator Controls Primary Actors (from bottom – to top) – Alessandro Masi, Mathieu Donze, Arnaud Brielmann, Jerome Lendaro, Roberto Losito – Jacky Brahy, Enrique Blanco Vinuela – Guy Surback, Roland Chery, Nicolas Zaganidis – Stefano Redaelli, Eric Veyrunes, Delphine Jacquet Support from LSA team, AB/CO-DM, M. Lamont

Collimator Controls Primary Actors (from bottom – to top) – Alessandro Masi, Mathieu Donze, Arnaud Brielmann, Jerome Lendaro, Roberto Losito – Jacky Brahy, Enrique Blanco Vinuela – Guy Surback, Roland Chery, Nicolas Zaganidis – Stefano Redaelli, Eric Veyrunes, Delphine Jacquet Support from LSA team, AB/CO-DM, M. Lamont

Outline Installation status Architecture evolution Functional Status • Environmental Survey • Positioning & Survey • Application Layer Automatic Collimator Positioning (Beam Based Optimisation)

Outline Installation status Architecture evolution Functional Status • Environmental Survey • Positioning & Survey • Application Layer Automatic Collimator Positioning (Beam Based Optimisation)

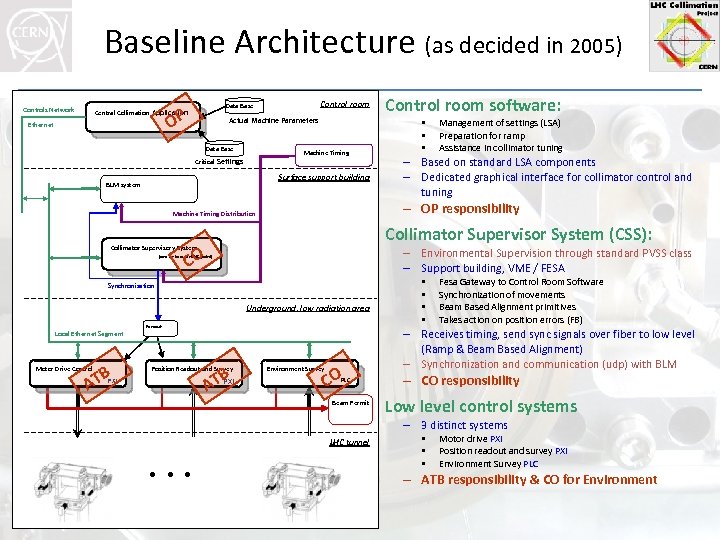

Baseline Architecture (as decided in 2005) Central Collimation Application Ethernet Control room Data Base OP Controls Network Actual Machine Parameters Data Base Machine Timing Critical Settings Surface support building BLM system CO Synchronisation Underground, low radiation area Fan out PXI TB Position Readout and Survey A PXI – Based on standard LSA components – Dedicated graphical interface for collimator control and tuning – Environmental Supervision through standard PVSS class – Support building, VME / FESA (one or two per LHC point) B AT Management of settings (LSA) Preparation for ramp Assistance in collimator tuning Collimator Supervisor System (CSS): Collimator Supervisory System Motor Drive Control • • • – OP responsibility Machine Timing Distribution Local Ethernet Segment Control room software: Environment Survey CO PLC Beam Permit • • Fesa Gateway to Control Room Software Synchronization of movements Beam Based Alignment primitives Takes action on position errors (FB) – Receives timing, send sync signals over fiber to low level (Ramp & Beam Based Alignment) – Synchronization and communication (udp) with BLM – CO responsibility Low level control systems – 3 distinct systems . . . LHC tunnel • • • Motor drive PXI Position readout and survey PXI Environment Survey PLC – ATB responsibility & CO for Environment

Baseline Architecture (as decided in 2005) Central Collimation Application Ethernet Control room Data Base OP Controls Network Actual Machine Parameters Data Base Machine Timing Critical Settings Surface support building BLM system CO Synchronisation Underground, low radiation area Fan out PXI TB Position Readout and Survey A PXI – Based on standard LSA components – Dedicated graphical interface for collimator control and tuning – Environmental Supervision through standard PVSS class – Support building, VME / FESA (one or two per LHC point) B AT Management of settings (LSA) Preparation for ramp Assistance in collimator tuning Collimator Supervisor System (CSS): Collimator Supervisory System Motor Drive Control • • • – OP responsibility Machine Timing Distribution Local Ethernet Segment Control room software: Environment Survey CO PLC Beam Permit • • Fesa Gateway to Control Room Software Synchronization of movements Beam Based Alignment primitives Takes action on position errors (FB) – Receives timing, send sync signals over fiber to low level (Ramp & Beam Based Alignment) – Synchronization and communication (udp) with BLM – CO responsibility Low level control systems – 3 distinct systems . . . LHC tunnel • • • Motor drive PXI Position readout and survey PXI Environment Survey PLC – ATB responsibility & CO for Environment

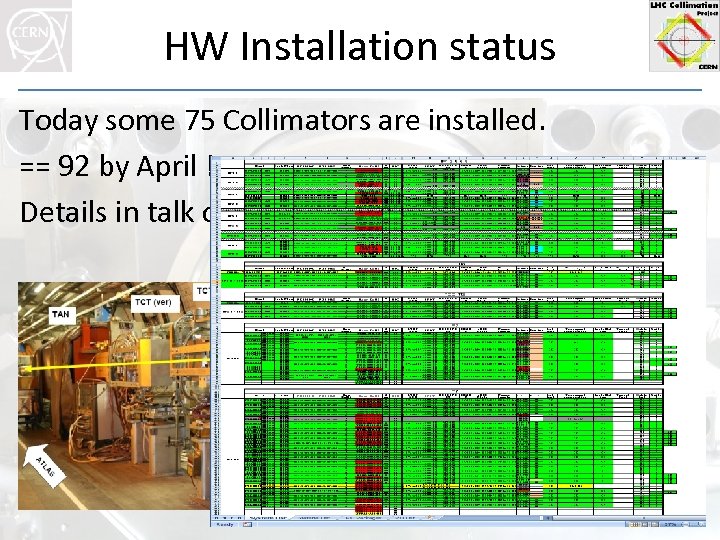

HW Installation status Today some 75 Collimators are installed. == 92 by April ! Details in talk of O. Aberle

HW Installation status Today some 75 Collimators are installed. == 92 by April ! Details in talk of O. Aberle

HW Installation status Temperature readout – All PLC’s in place – All installed collimators connected – All temperature gauges tested except in IP 7 • Very few surprises • IP 7: waiting for 220 V power connections

HW Installation status Temperature readout – All PLC’s in place – All installed collimators connected – All temperature gauges tested except in IP 7 • Very few surprises • IP 7: waiting for 220 V power connections

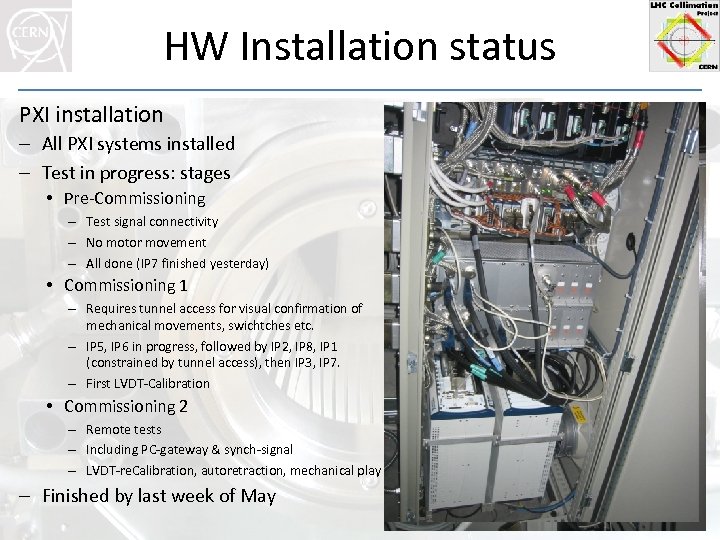

HW Installation status PXI installation – All PXI systems installed – Test in progress: stages • Pre-Commissioning – Test signal connectivity – No motor movement – All done (IP 7 finished yesterday) • Commissioning 1 – Requires tunnel access for visual confirmation of mechanical movements, swichtches etc. – IP 5, IP 6 in progress, followed by IP 2, IP 8, IP 1 (constrained by tunnel access), then IP 3, IP 7. – First LVDT-Calibration • Commissioning 2 – Remote tests – Including PC-gateway & synch-signal – LVDT-re. Calibration, autoretraction, mechanical play – Finished by last week of May

HW Installation status PXI installation – All PXI systems installed – Test in progress: stages • Pre-Commissioning – Test signal connectivity – No motor movement – All done (IP 7 finished yesterday) • Commissioning 1 – Requires tunnel access for visual confirmation of mechanical movements, swichtches etc. – IP 5, IP 6 in progress, followed by IP 2, IP 8, IP 1 (constrained by tunnel access), then IP 3, IP 7. – First LVDT-Calibration • Commissioning 2 – Remote tests – Including PC-gateway & synch-signal – LVDT-re. Calibration, autoretraction, mechanical play – Finished by last week of May

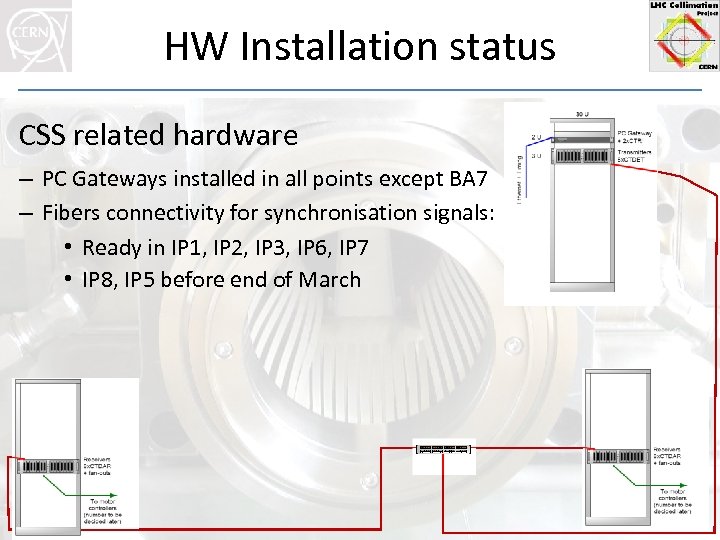

HW Installation status CSS related hardware – PC Gateways installed in all points except BA 7 – Fibers connectivity for synchronisation signals: • Ready in IP 1, IP 2, IP 3, IP 6, IP 7 • IP 8, IP 5 before end of March

HW Installation status CSS related hardware – PC Gateways installed in all points except BA 7 – Fibers connectivity for synchronisation signals: • Ready in IP 1, IP 2, IP 3, IP 6, IP 7 • IP 8, IP 5 before end of March

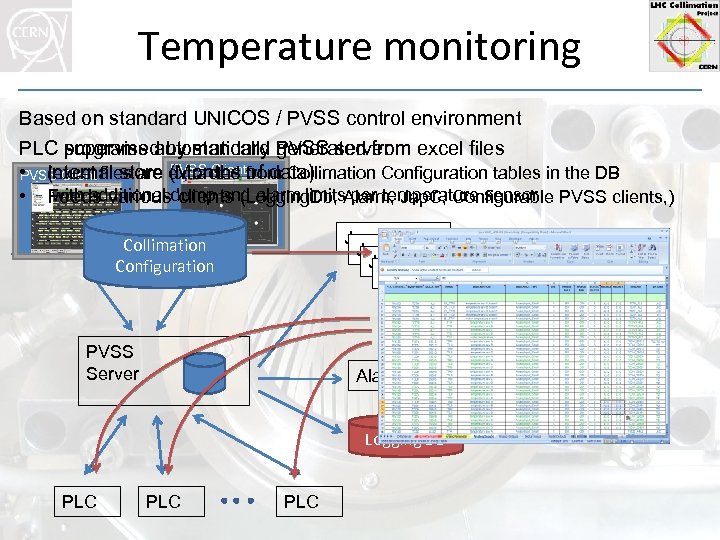

Temperature monitoring Based on standard UNICOS / PVSS control environment PLC programs automatically generated from excel files supervised by standard PVSS server PVSS Client • (excel files are extracted of data) Internal store (Months from Collimation Configuration tables in the DB PVSS Client with additional clients (Logging. Db, per temperature sensor • Feeds variousdump and alarm limits. Alarm, Jap. C, Configurable PVSS clients, ) Japc Clients Collimation Configuration PVSS Server Alarm System Logging DB PLC PLC

Temperature monitoring Based on standard UNICOS / PVSS control environment PLC programs automatically generated from excel files supervised by standard PVSS server PVSS Client • (excel files are extracted of data) Internal store (Months from Collimation Configuration tables in the DB PVSS Client with additional clients (Logging. Db, per temperature sensor • Feeds variousdump and alarm limits. Alarm, Jap. C, Configurable PVSS clients, ) Japc Clients Collimation Configuration PVSS Server Alarm System Logging DB PLC PLC

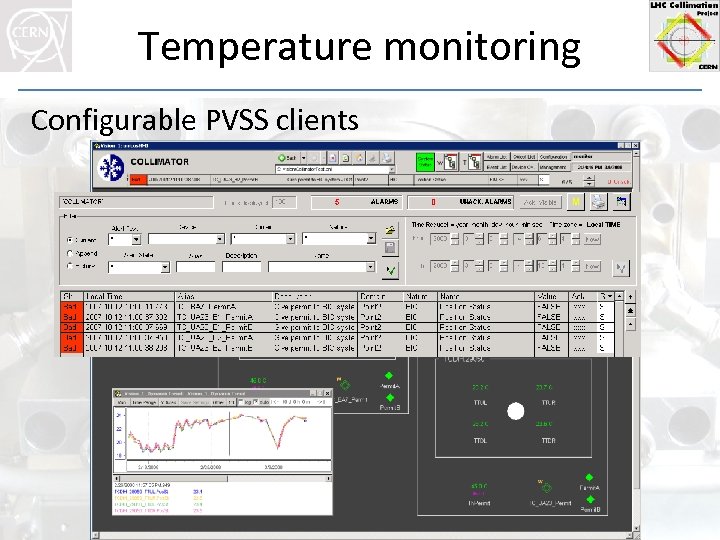

Temperature monitoring Configurable PVSS clients

Temperature monitoring Configurable PVSS clients

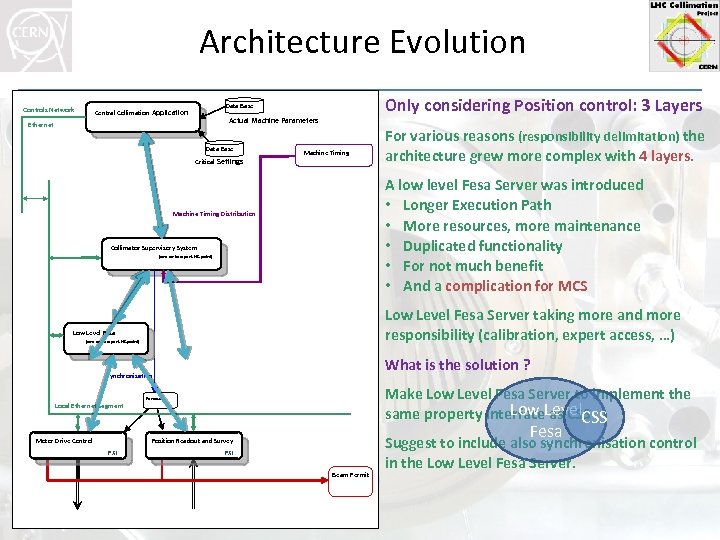

Architecture Evolution Controls Network Only considering Position control: 3 Layers Data Base Central Collimation Application Actual Machine Parameters Ethernet Data Base Critical Settings Machine Timing A low level Fesa Server was introduced • Longer Execution Path • More resources, more maintenance • Duplicated functionality • For not much benefit • And a complication for MCS Machine Timing Distribution Collimator Supervisory System (one or two per LHC point) Synchronisation Low Level Fesa Local Ethernet Segment Low Level Fesa Server taking more and more responsibility (calibration, expert access, …) Fan out (one or two per LHC point) Motor Drive Control What is the solution ? Position Readout and Survey Synchronisation PXI Local Ethernet Segment Motor Drive Control Fan out Beam Permit Make Low Level Fesa Server to implement the Low Level same property interface as CSS Fesa Position Readout and Survey PXI For various reasons (responsibility delimitation) the architecture grew more complex with 4 layers. PXI Beam Permit Suggest to include also synchronisation control in the Low Level Fesa Server.

Architecture Evolution Controls Network Only considering Position control: 3 Layers Data Base Central Collimation Application Actual Machine Parameters Ethernet Data Base Critical Settings Machine Timing A low level Fesa Server was introduced • Longer Execution Path • More resources, more maintenance • Duplicated functionality • For not much benefit • And a complication for MCS Machine Timing Distribution Collimator Supervisory System (one or two per LHC point) Synchronisation Low Level Fesa Local Ethernet Segment Low Level Fesa Server taking more and more responsibility (calibration, expert access, …) Fan out (one or two per LHC point) Motor Drive Control What is the solution ? Position Readout and Survey Synchronisation PXI Local Ethernet Segment Motor Drive Control Fan out Beam Permit Make Low Level Fesa Server to implement the Low Level same property interface as CSS Fesa Position Readout and Survey PXI For various reasons (responsibility delimitation) the architecture grew more complex with 4 layers. PXI Beam Permit Suggest to include also synchronisation control in the Low Level Fesa Server.

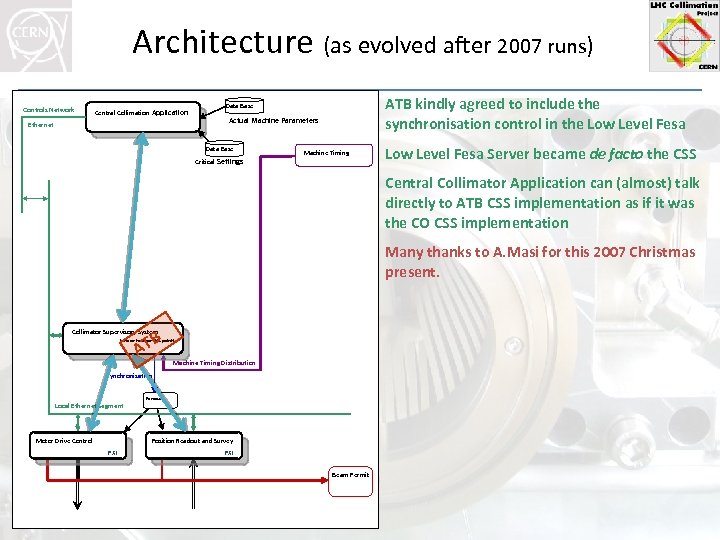

Architecture (as evolved after 2007 runs) Controls Network Central Collimation Application Ethernet ATB kindly agreed to include the synchronisation control in the Low Level Fesa Data Base Actual Machine Parameters Data Base Critical Settings Machine Timing Low Level Fesa Server became de facto the CSS Central Collimator Application can (almost) talk directly to ATB CSS implementation as if it was the CO CSS implementation Many thanks to A. Masi for this 2007 Christmas present. B Collimator Supervisory System AT (one or two per LHC point) Machine Timing Distribution Synchronisation Local Ethernet Segment Motor Drive Control Fan out Position Readout and Survey PXI Beam Permit

Architecture (as evolved after 2007 runs) Controls Network Central Collimation Application Ethernet ATB kindly agreed to include the synchronisation control in the Low Level Fesa Data Base Actual Machine Parameters Data Base Critical Settings Machine Timing Low Level Fesa Server became de facto the CSS Central Collimator Application can (almost) talk directly to ATB CSS implementation as if it was the CO CSS implementation Many thanks to A. Masi for this 2007 Christmas present. B Collimator Supervisory System AT (one or two per LHC point) Machine Timing Distribution Synchronisation Local Ethernet Segment Motor Drive Control Fan out Position Readout and Survey PXI Beam Permit

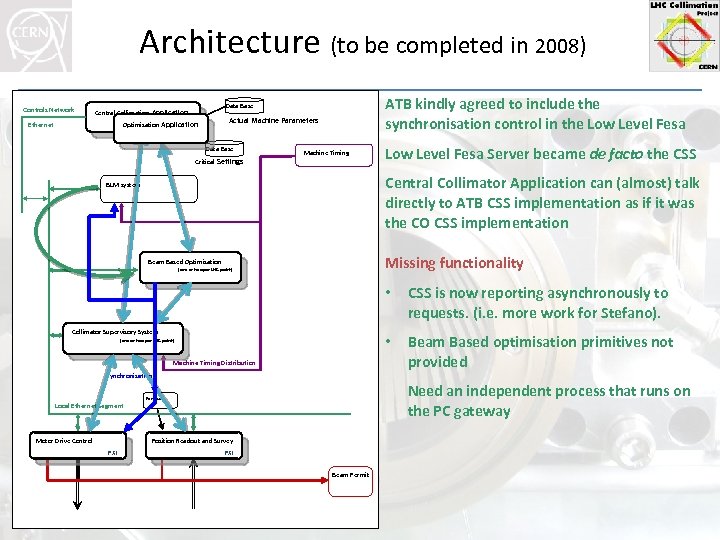

Architecture (to be completed in 2008) Controls Network Actual Machine Parameters Optimisation Application Ethernet ATB kindly agreed to include the synchronisation control in the Low Level Fesa Data Base Central Collimation Application Data Base Critical Settings Machine Timing Low Level Fesa Server became de facto the CSS Central Collimator Application can (almost) talk directly to ATB CSS implementation as if it was the CO CSS implementation BLM system Missing functionality Beam Based Optimisation (one or two per LHC point) • • Collimator Supervisory System (one or two per LHC point) Machine Timing Distribution Synchronisation Local Ethernet Segment Motor Drive Control Beam Based optimisation primitives not provided Need an independent process that runs on the PC gateway Fan out Position Readout and Survey PXI CSS is now reporting asynchronously to requests. (i. e. more work for Stefano). PXI Beam Permit

Architecture (to be completed in 2008) Controls Network Actual Machine Parameters Optimisation Application Ethernet ATB kindly agreed to include the synchronisation control in the Low Level Fesa Data Base Central Collimation Application Data Base Critical Settings Machine Timing Low Level Fesa Server became de facto the CSS Central Collimator Application can (almost) talk directly to ATB CSS implementation as if it was the CO CSS implementation BLM system Missing functionality Beam Based Optimisation (one or two per LHC point) • • Collimator Supervisory System (one or two per LHC point) Machine Timing Distribution Synchronisation Local Ethernet Segment Motor Drive Control Beam Based optimisation primitives not provided Need an independent process that runs on the PC gateway Fan out Position Readout and Survey PXI CSS is now reporting asynchronously to requests. (i. e. more work for Stefano). PXI Beam Permit

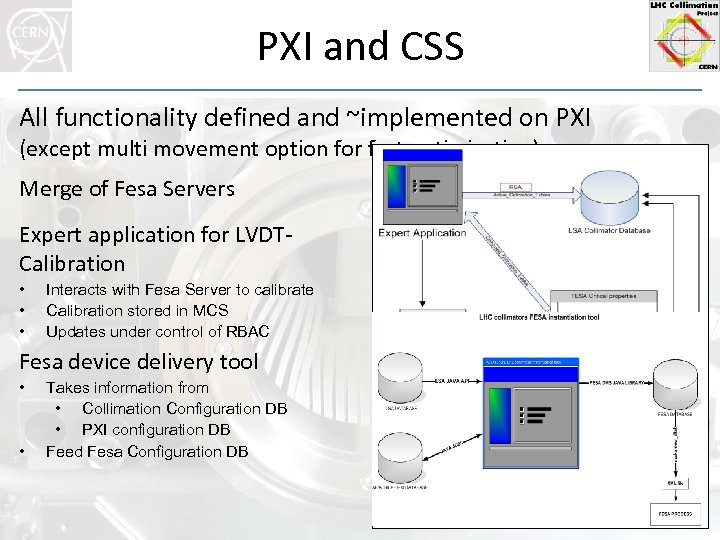

PXI and CSS All functionality defined and ~implemented on PXI (except multi movement option for fast optimisation) Merge of Fesa Servers Expert application for LVDTCalibration • • • Interacts with Fesa Server to calibrate Calibration stored in MCS Updates under control of RBAC Fesa device delivery tool • • Takes information from • Collimation Configuration DB • PXI configuration DB Feed Fesa Configuration DB

PXI and CSS All functionality defined and ~implemented on PXI (except multi movement option for fast optimisation) Merge of Fesa Servers Expert application for LVDTCalibration • • • Interacts with Fesa Server to calibrate Calibration stored in MCS Updates under control of RBAC Fesa device delivery tool • • Takes information from • Collimation Configuration DB • PXI configuration DB Feed Fesa Configuration DB

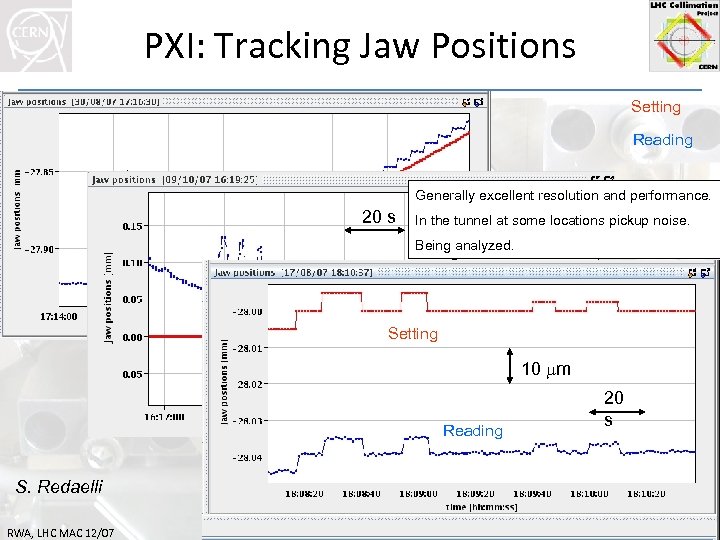

PXI: Tracking Jaw Positions Setting Reading 50 m Generally excellent resolution and performance. 20 s In the tunnel at some locations pickup noise. Being analyzed. 50 m Setting 10 m Reading 20 s S. Redaelli RWA, LHC MAC 12/07 15

PXI: Tracking Jaw Positions Setting Reading 50 m Generally excellent resolution and performance. 20 s In the tunnel at some locations pickup noise. Being analyzed. 50 m Setting 10 m Reading 20 s S. Redaelli RWA, LHC MAC 12/07 15

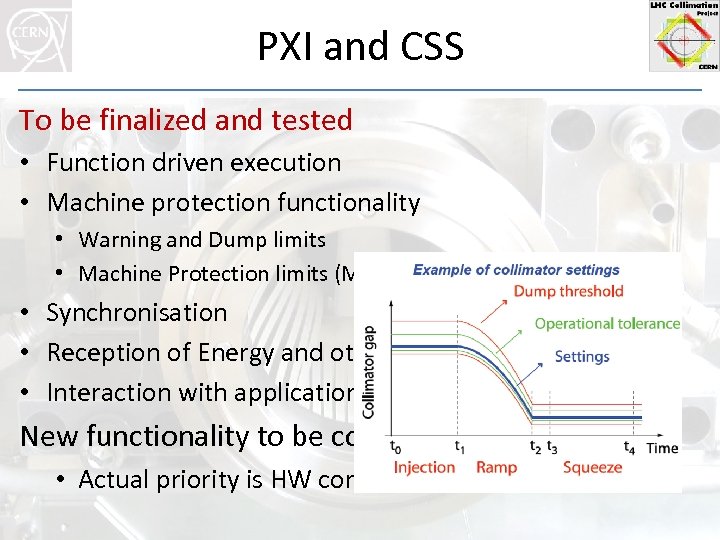

PXI and CSS To be finalized and tested • Function driven execution • Machine protection functionality • Warning and Dump limits • Machine Protection limits (MCS) depending on Energy • Synchronisation • Reception of Energy and other Machine Parameters • Interaction with applications layer (trim and Sequencer) New functionality to be commisioned in April. • Actual priority is HW commissioning in the tunnel.

PXI and CSS To be finalized and tested • Function driven execution • Machine protection functionality • Warning and Dump limits • Machine Protection limits (MCS) depending on Energy • Synchronisation • Reception of Energy and other Machine Parameters • Interaction with applications layer (trim and Sequencer) New functionality to be commisioned in April. • Actual priority is HW commissioning in the tunnel.

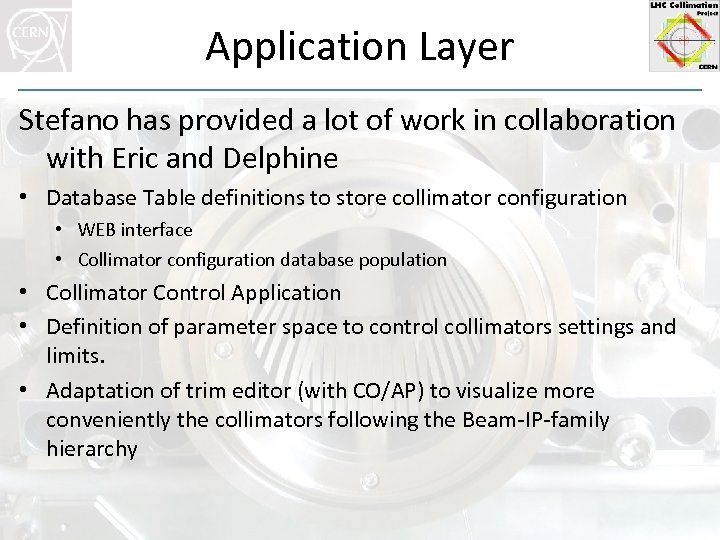

Application Layer Stefano has provided a lot of work in collaboration with Eric and Delphine • Database Table definitions to store collimator configuration • WEB interface • Collimator configuration database population • Collimator Control Application • Definition of parameter space to control collimators settings and limits. • Adaptation of trim editor (with CO/AP) to visualize more conveniently the collimators following the Beam-IP-family hierarchy

Application Layer Stefano has provided a lot of work in collaboration with Eric and Delphine • Database Table definitions to store collimator configuration • WEB interface • Collimator configuration database population • Collimator Control Application • Definition of parameter space to control collimators settings and limits. • Adaptation of trim editor (with CO/AP) to visualize more conveniently the collimators following the Beam-IP-family hierarchy

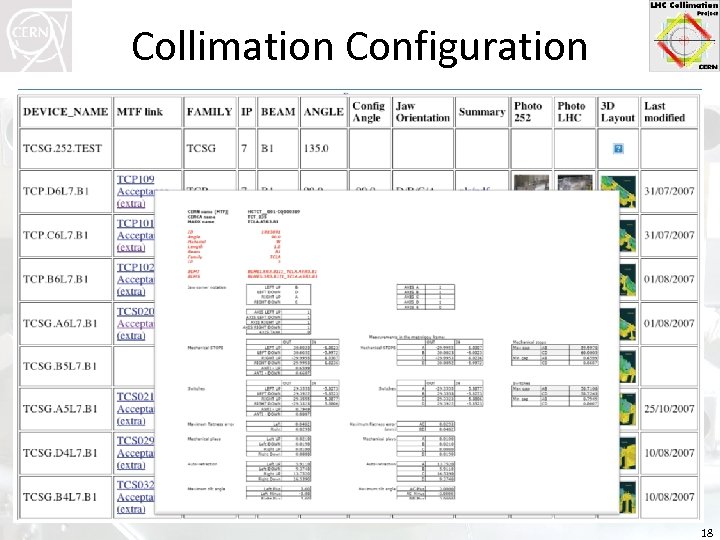

Collimation Configuration 18

Collimation Configuration 18

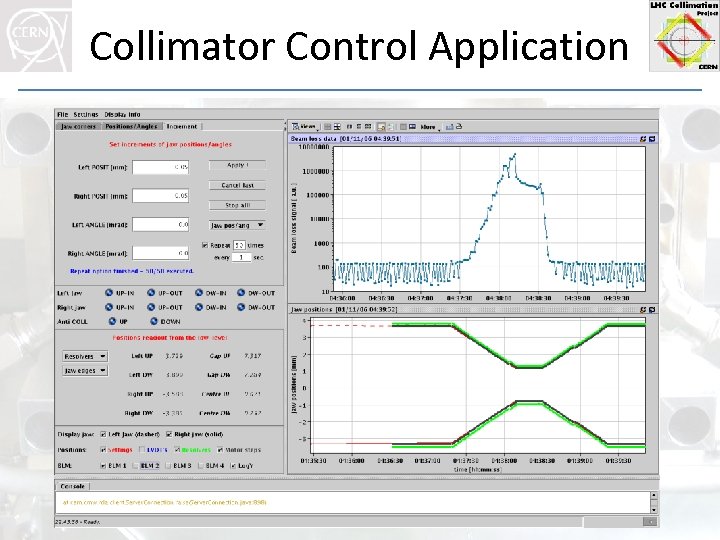

Collimator Control Application

Collimator Control Application

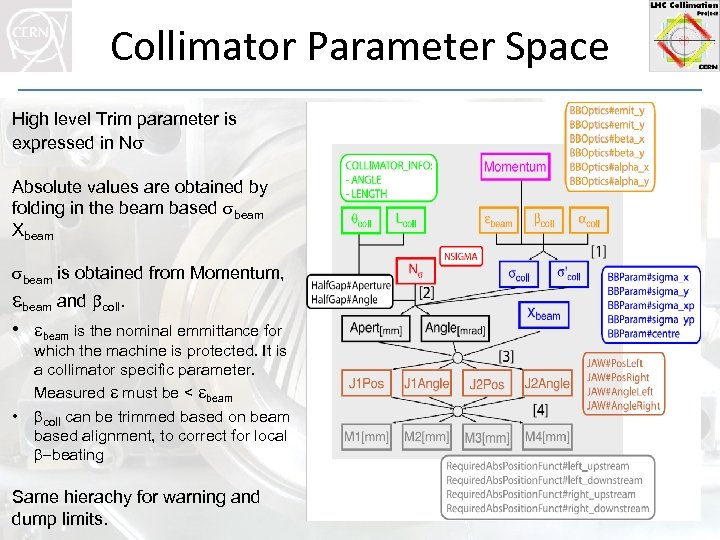

Collimator Parameter Space High level Trim parameter is expressed in N Absolute values are obtained by folding in the beam based beam Xbeam is obtained from Momentum, ebeam and bcoll. • ebeam is the nominal emmittance for • which the machine is protected. It is a collimator specific parameter. Measured e must be < ebeam bcoll can be trimmed based on beam based alignment, to correct for local b-beating Same hierachy for warning and dump limits.

Collimator Parameter Space High level Trim parameter is expressed in N Absolute values are obtained by folding in the beam based beam Xbeam is obtained from Momentum, ebeam and bcoll. • ebeam is the nominal emmittance for • which the machine is protected. It is a collimator specific parameter. Measured e must be < ebeam bcoll can be trimmed based on beam based alignment, to correct for local b-beating Same hierachy for warning and dump limits.

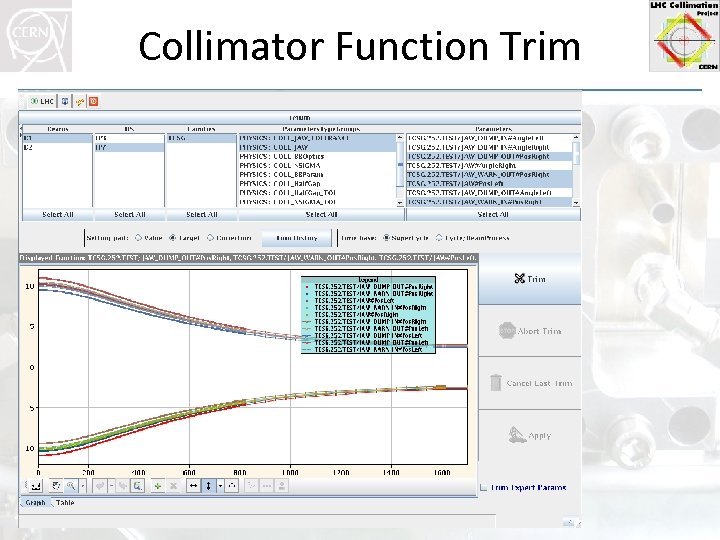

Collimator Function Trim

Collimator Function Trim

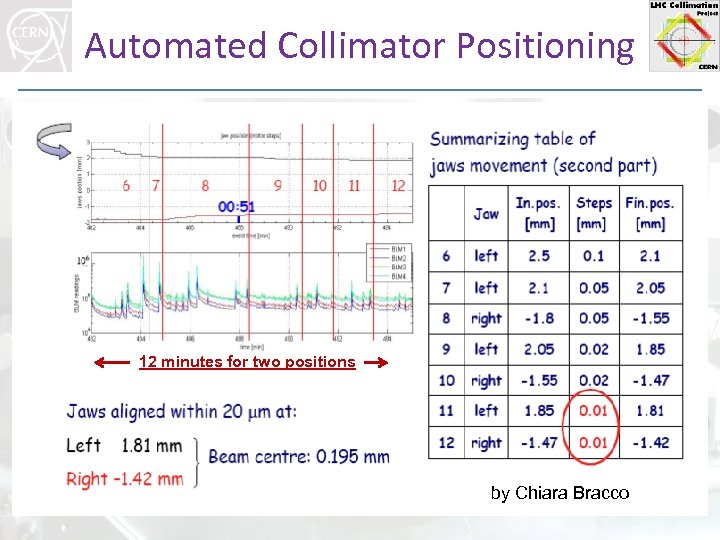

Automated Collimator Positioning 94 (up to 160 in final upgrade) collimators, to protect against machine damage and magnet quenches. The collimation process is a multi-staged process that require precise (0. 1 beam) setting of the jaws with respect to the beam envelope. Goal for positioning accuracy is 20 m (0. 1 beam at 7 Te. V). Actual beam envelope (position and size) may change (from fill to fill ? , by how much? ) Adapt to changing beam parameters to guarantee machine protection and to keep good cleaning efficiency There are 376 degrees of freedom (4 motors per collimator) (188 if not considering the angle 12 minutes for two positions of the jaws) 30 seconds per degree of freedom (a very efficient operator) still requires about 3 hours. We need automated tools and procedures by Chiara Bracco

Automated Collimator Positioning 94 (up to 160 in final upgrade) collimators, to protect against machine damage and magnet quenches. The collimation process is a multi-staged process that require precise (0. 1 beam) setting of the jaws with respect to the beam envelope. Goal for positioning accuracy is 20 m (0. 1 beam at 7 Te. V). Actual beam envelope (position and size) may change (from fill to fill ? , by how much? ) Adapt to changing beam parameters to guarantee machine protection and to keep good cleaning efficiency There are 376 degrees of freedom (4 motors per collimator) (188 if not considering the angle 12 minutes for two positions of the jaws) 30 seconds per degree of freedom (a very efficient operator) still requires about 3 hours. We need automated tools and procedures by Chiara Bracco

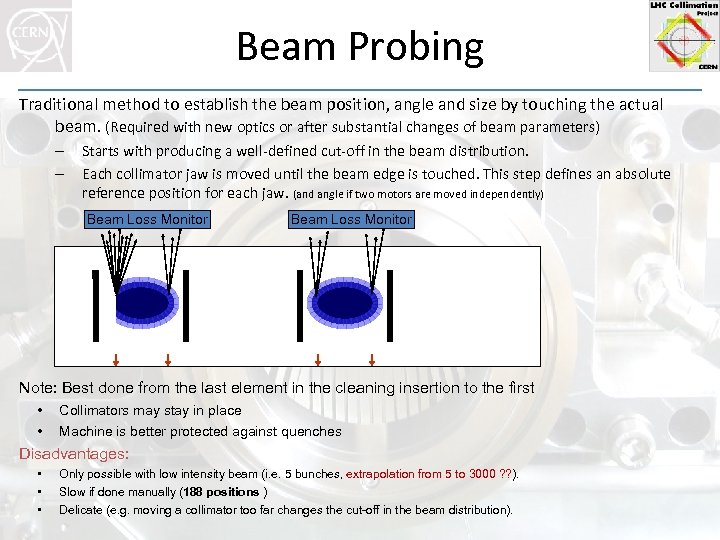

Beam Probing Traditional method to establish the beam position, angle and size by touching the actual beam. (Required with new optics or after substantial changes of beam parameters) – – Starts with producing a well-defined cut-off in the beam distribution. Each collimator jaw is moved until the beam edge is touched. This step defines an absolute reference position for each jaw. (and angle if two motors are moved independently) Beam Loss Monitor Note: Best done from the last element in the cleaning insertion to the first • • Collimators may stay in place Machine is better protected against quenches Disadvantages: • • • Only possible with low intensity beam (i. e. 5 bunches, extrapolation from 5 to 3000 ? ? ). Slow if done manually (188 positions ) Delicate (e. g. moving a collimator too far changes the cut-off in the beam distribution).

Beam Probing Traditional method to establish the beam position, angle and size by touching the actual beam. (Required with new optics or after substantial changes of beam parameters) – – Starts with producing a well-defined cut-off in the beam distribution. Each collimator jaw is moved until the beam edge is touched. This step defines an absolute reference position for each jaw. (and angle if two motors are moved independently) Beam Loss Monitor Note: Best done from the last element in the cleaning insertion to the first • • Collimators may stay in place Machine is better protected against quenches Disadvantages: • • • Only possible with low intensity beam (i. e. 5 bunches, extrapolation from 5 to 3000 ? ? ). Slow if done manually (188 positions ) Delicate (e. g. moving a collimator too far changes the cut-off in the beam distribution).

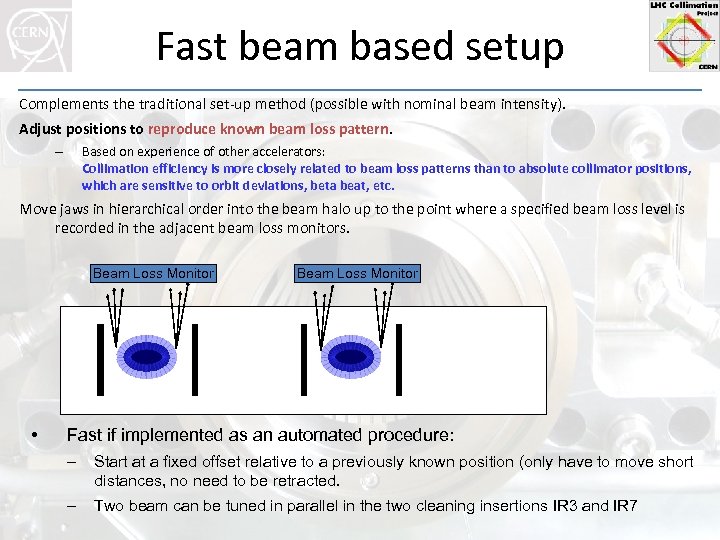

Fast beam based setup Complements the traditional set-up method (possible with nominal beam intensity). Adjust positions to reproduce known beam loss pattern. Based on experience of other accelerators: Collimation efficiency is more closely related to beam loss patterns than to absolute collimator positions, which are sensitive to orbit deviations, beta beat, etc. – Move jaws in hierarchical order into the beam halo up to the point where a specified beam loss level is recorded in the adjacent beam loss monitors. Beam Loss Monitor • Beam Loss Monitor Fast if implemented as an automated procedure: – Start at a fixed offset relative to a previously known position (only have to move short distances, no need to be retracted. – Two beam can be tuned in parallel in the two cleaning insertions IR 3 and IR 7

Fast beam based setup Complements the traditional set-up method (possible with nominal beam intensity). Adjust positions to reproduce known beam loss pattern. Based on experience of other accelerators: Collimation efficiency is more closely related to beam loss patterns than to absolute collimator positions, which are sensitive to orbit deviations, beta beat, etc. – Move jaws in hierarchical order into the beam halo up to the point where a specified beam loss level is recorded in the adjacent beam loss monitors. Beam Loss Monitor • Beam Loss Monitor Fast if implemented as an automated procedure: – Start at a fixed offset relative to a previously known position (only have to move short distances, no need to be retracted. – Two beam can be tuned in parallel in the two cleaning insertions IR 3 and IR 7

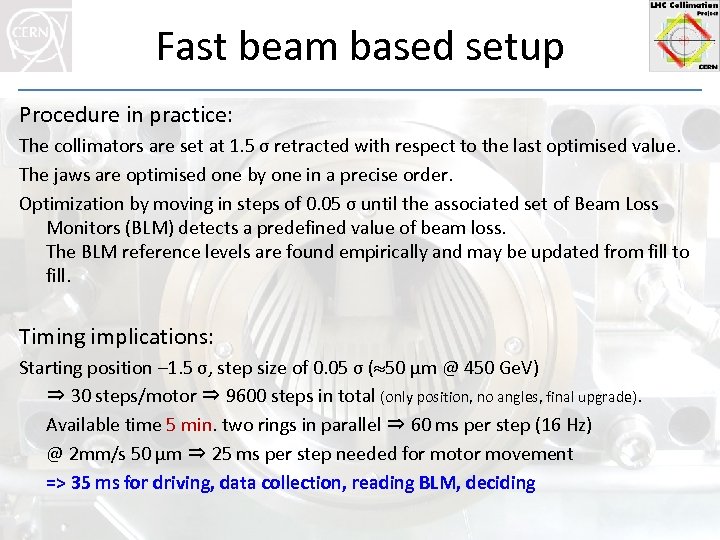

Fast beam based setup Procedure in practice: The collimators are set at 1. 5 σ retracted with respect to the last optimised value. The jaws are optimised one by one in a precise order. Optimization by moving in steps of 0. 05 σ until the associated set of Beam Loss Monitors (BLM) detects a predefined value of beam loss. The BLM reference levels are found empirically and may be updated from fill to fill. Timing implications: Starting position – 1. 5 σ, step size of 0. 05 σ ( 50 μm @ 450 Ge. V) ⇒ 30 steps/motor ⇒ 9600 steps in total (only position, no angles, final upgrade). Available time 5 min. two rings in parallel ⇒ 60 ms per step (16 Hz) @ 2 mm/s 50 μm ⇒ 25 ms per step needed for motor movement => 35 ms for driving, data collection, reading BLM, deciding

Fast beam based setup Procedure in practice: The collimators are set at 1. 5 σ retracted with respect to the last optimised value. The jaws are optimised one by one in a precise order. Optimization by moving in steps of 0. 05 σ until the associated set of Beam Loss Monitors (BLM) detects a predefined value of beam loss. The BLM reference levels are found empirically and may be updated from fill to fill. Timing implications: Starting position – 1. 5 σ, step size of 0. 05 σ ( 50 μm @ 450 Ge. V) ⇒ 30 steps/motor ⇒ 9600 steps in total (only position, no angles, final upgrade). Available time 5 min. two rings in parallel ⇒ 60 ms per step (16 Hz) @ 2 mm/s 50 μm ⇒ 25 ms per step needed for motor movement => 35 ms for driving, data collection, reading BLM, deciding

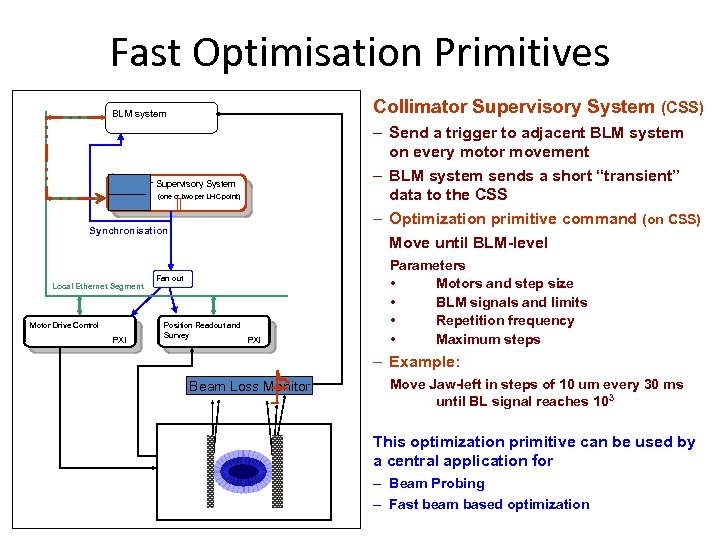

Fast Optimisation Primitives Collimator Supervisory System (CSS) BLM system – Send a trigger to adjacent BLM system on every motor movement – BLM system sends a short “transient” data to the CSS – Optimization primitive command (on CSS) Move until BLM-level Collimator Supervisory System (one or two per LHC point) Synchronisation Local Ethernet Segment Motor Drive Control PXI Fan out Position Readout and Survey PXI Parameters • Motors and step size • BLM signals and limits • Repetition frequency • Maximum steps – Example: Beam Loss Monitor Move Jaw-left in steps of 10 um every 30 ms until BL signal reaches 103 This optimization primitive can be used by a central application for – Beam Probing – Fast beam based optimization

Fast Optimisation Primitives Collimator Supervisory System (CSS) BLM system – Send a trigger to adjacent BLM system on every motor movement – BLM system sends a short “transient” data to the CSS – Optimization primitive command (on CSS) Move until BLM-level Collimator Supervisory System (one or two per LHC point) Synchronisation Local Ethernet Segment Motor Drive Control PXI Fan out Position Readout and Survey PXI Parameters • Motors and step size • BLM signals and limits • Repetition frequency • Maximum steps – Example: Beam Loss Monitor Move Jaw-left in steps of 10 um every 30 ms until BL signal reaches 103 This optimization primitive can be used by a central application for – Beam Probing – Fast beam based optimization

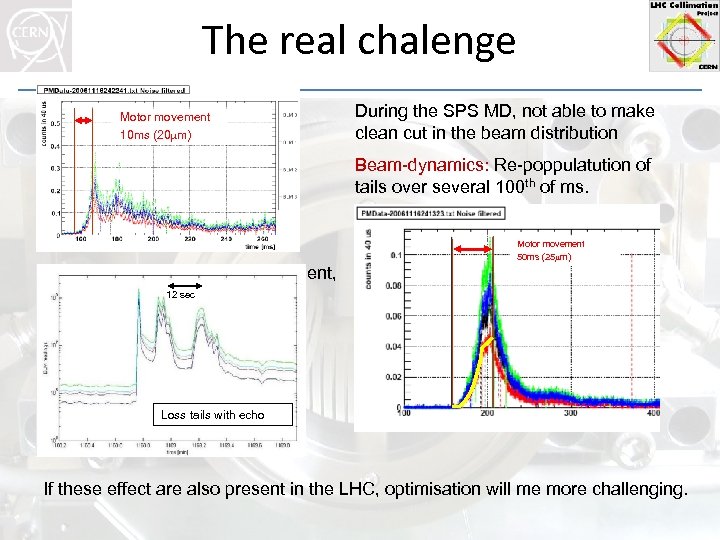

The real chalenge Motor movement 10 ms (20 m) During the SPS MD, not able to make clean cut in the beam distribution Beam-dynamics: Re-poppulatution of tails over several 100 th of ms. Motor movement 50 ms (25 m) Long tails after collimator movement, (70 Hz) sec 12 Large noise components 50, 150, 300, 450 & 600 Hz noise Loss tails with echo If these effect are also present in the LHC, optimisation will me more challenging.

The real chalenge Motor movement 10 ms (20 m) During the SPS MD, not able to make clean cut in the beam distribution Beam-dynamics: Re-poppulatution of tails over several 100 th of ms. Motor movement 50 ms (25 m) Long tails after collimator movement, (70 Hz) sec 12 Large noise components 50, 150, 300, 450 & 600 Hz noise Loss tails with echo If these effect are also present in the LHC, optimisation will me more challenging.

Fast Optimisation Implementation To be developed this year. • • Implement Multi-Step movements at Low Level Development of Optimiser Process − − • Beam Based Optimisation Primitive Already useful for operator assisted collimator setup. Development of Central Optimisation Control Process − − Sequencing the optimisation of the individual jaw positions Driven by a DB configuration, able to react intelligently if there is unexpected behaviour. − Initially simple, improve by learning. Doctoral student ? The challenges • • Convince BI/SW that transfer of 600 bytes @ 30 Hz is sustainable (when used occasionally for a single BLM crate at the time). Understanding the beam loss response

Fast Optimisation Implementation To be developed this year. • • Implement Multi-Step movements at Low Level Development of Optimiser Process − − • Beam Based Optimisation Primitive Already useful for operator assisted collimator setup. Development of Central Optimisation Control Process − − Sequencing the optimisation of the individual jaw positions Driven by a DB configuration, able to react intelligently if there is unexpected behaviour. − Initially simple, improve by learning. Doctoral student ? The challenges • • Convince BI/SW that transfer of 600 bytes @ 30 Hz is sustainable (when used occasionally for a single BLM crate at the time). Understanding the beam loss response

Conclusions Collimation controls is ready to set the collimators for the first beam. Still to be demonstrated • Function driven control. • Machine protection functionality still to be tested. Collimation position setup will be challenging. • Development of tools and applications required

Conclusions Collimation controls is ready to set the collimators for the first beam. Still to be demonstrated • Function driven control. • Machine protection functionality still to be tested. Collimation position setup will be challenging. • Development of tools and applications required