82ec35f45e99c102f008b2dbe0386fc2.ppt

- Количество слайдов: 29

Collaboration across the Supply Chain through ERPS 24 September 2007

Overview of Business Support Services

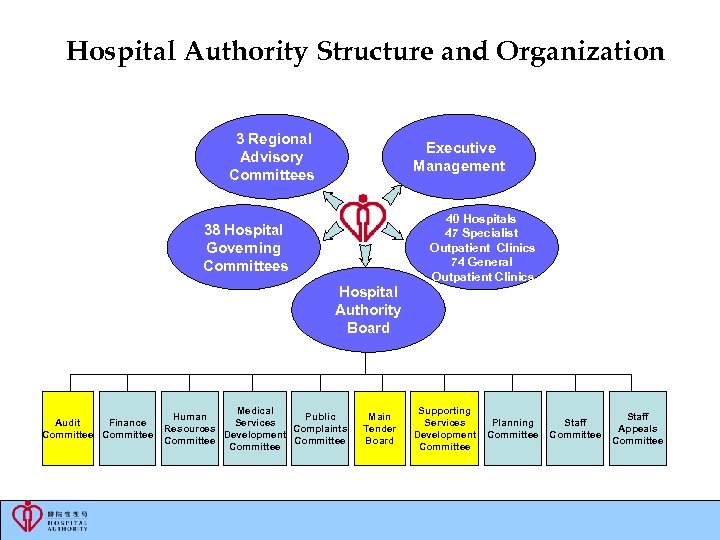

Hospital Authority Structure and Organization 3 Regional Advisory Committees Executive Management 40 Hospitals 47 Specialist Outpatient Clinics 74 General Outpatient Clinics 38 Hospital Governing Committees Hospital Authority Board Audit Finance Committee Medical Human Public Services Resources Complaints Development Committee Main Tender Board Supporting Services Development Committee Planning Committee Staff Appeals Committee

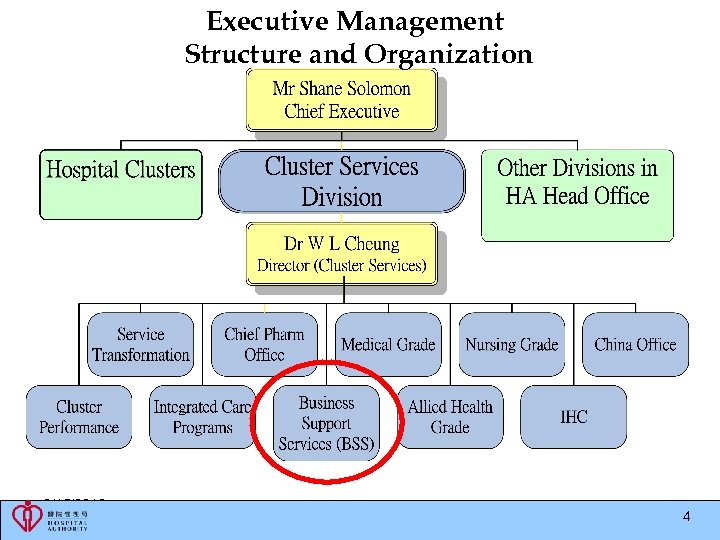

Executive Management Structure and Organization 3/15/2018 4

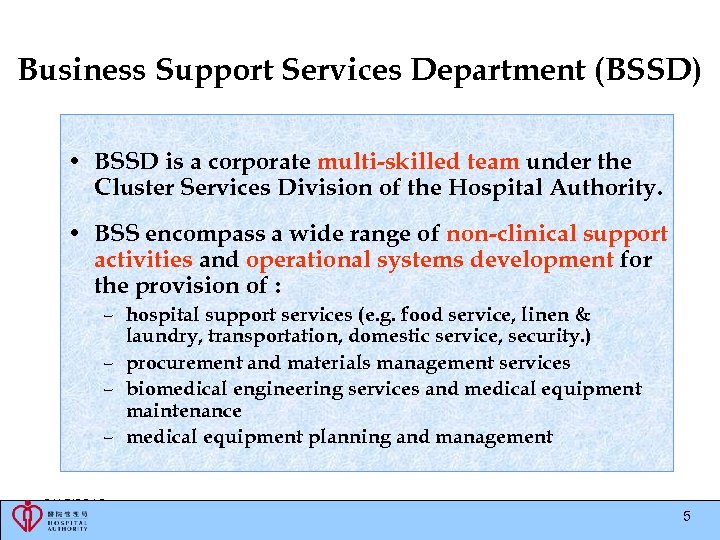

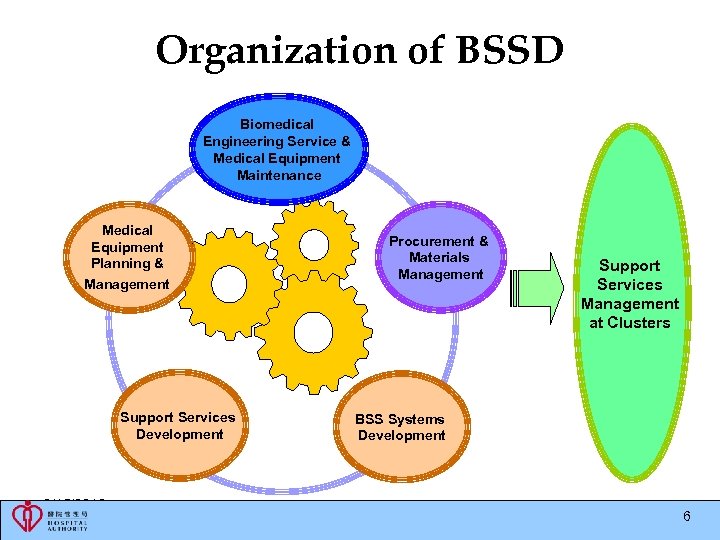

Business Support Services Department (BSSD) • BSSD is a corporate multi-skilled team under the Cluster Services Division of the Hospital Authority. • BSS encompass a wide range of non-clinical support activities and operational systems development for the provision of : – hospital support services (e. g. food service, linen & laundry, transportation, domestic service, security. ) – procurement and materials management services – biomedical engineering services and medical equipment maintenance – medical equipment planning and management 3/15/2018 5

Organization of BSSD Biomedical Engineering Service & Medical Equipment Maintenance Medical Equipment Planning & Management Support Services Development 3/15/2018 Procurement & Materials Management Support Services Management at Clusters BSS Systems Development 6

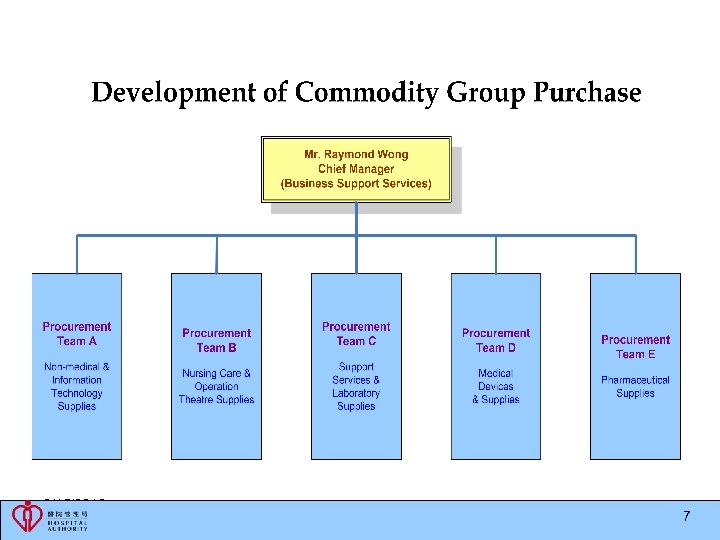

3/15/2018 7

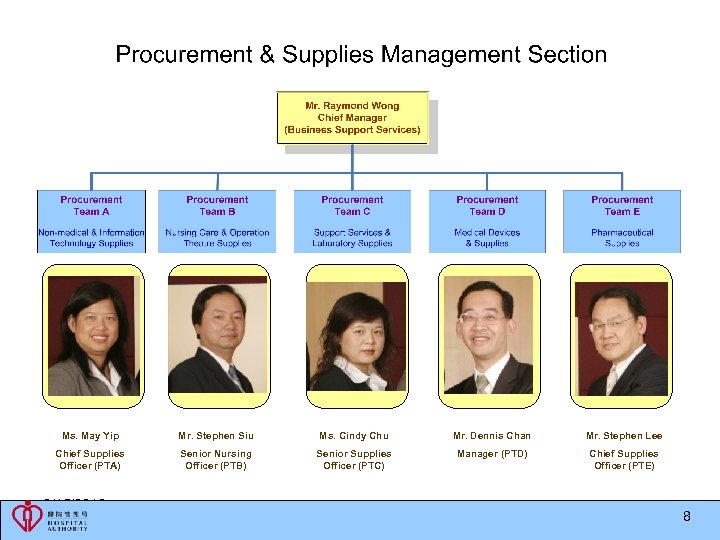

Ms. May Yip Mr. Stephen Siu Ms. Cindy Chu Mr. Dennis Chan Mr. Stephen Lee Chief Supplies Officer (PTA) Senior Nursing Officer (PTB) Senior Supplies Officer (PTC) Manager (PTD) Chief Supplies Officer (PTE) 3/15/2018 8

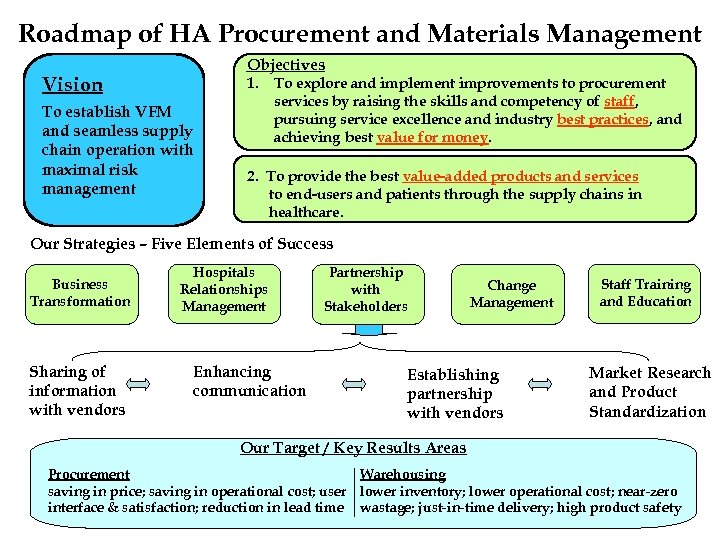

Roadmap of HA Procurement and Materials Management Objectives 1. To explore and implement improvements to procurement Vision To establish VFM and seamless supply chain operation with maximal risk management services by raising the skills and competency of staff, pursuing service excellence and industry best practices, and achieving best value for money. 2. To provide the best value-added products and services to end-users and patients through the supply chains in healthcare. Our Strategies – Five Elements of Success Business Transformation Sharing of information with vendors Hospitals Relationships Management Enhancing communication Partnership with Stakeholders Change Management Establishing partnership with vendors Staff Training and Education Market Research and Product Standardization Our Target / Key Results Areas Procurement Warehousing saving in price; saving in operational cost; user lower inventory; lower operational cost; near-zero interface & satisfaction; reduction in lead time wastage; just-in-time delivery; high product safety

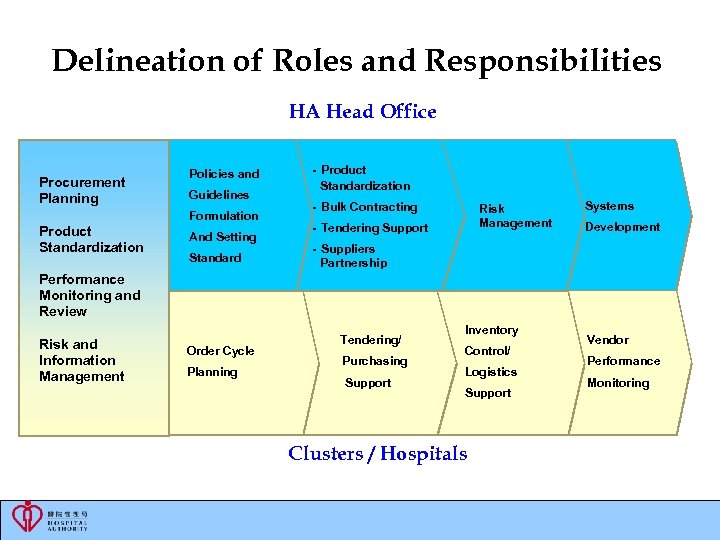

Delineation of Roles and Responsibilities HA Head Office Procurement Planning Product Standardization Policies and Guidelines Formulation And Setting Standard Performance Monitoring and Review Risk and Information Management Order Cycle Planning - Product Standardization - Bulk Contracting Risk Management - Tendering Support Systems Development - Suppliers Partnership Tendering/ Purchasing Support Inventory Control/ Logistics Support Clusters/Hospitals Clusters / Hospitals Vendor Performance Monitoring

3/15/2018 11

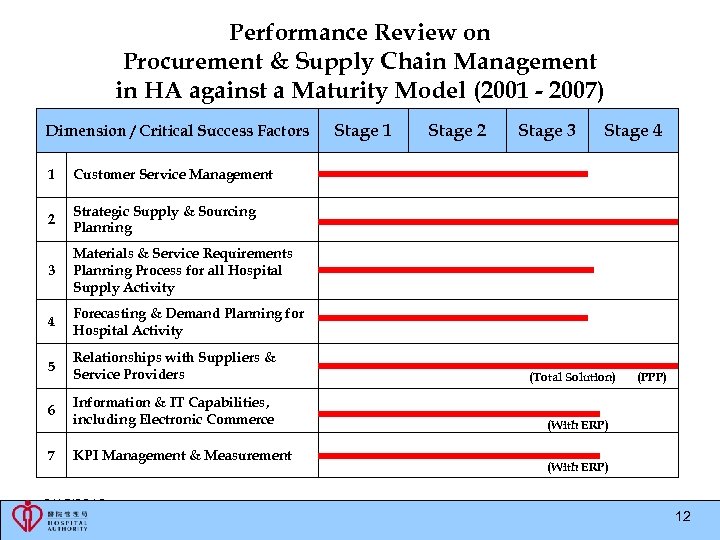

Performance Review on Procurement & Supply Chain Management in HA against a Maturity Model (2001 - 2007) Dimension / Critical Success Factors 1 Forecasting & Demand Planning for Hospital Activity 5 Relationships with Suppliers & Service Providers 6 Information & IT Capabilities, including Electronic Commerce 7 KPI Management & Measurement Stage 4 Materials & Service Requirements Planning Process for all Hospital Supply Activity 4 Stage 3 Strategic Supply & Sourcing Planning 3 Stage 2 Customer Service Management 2 Stage 1 3/15/2018 (Total Solution) (PPP) (With ERP) 12

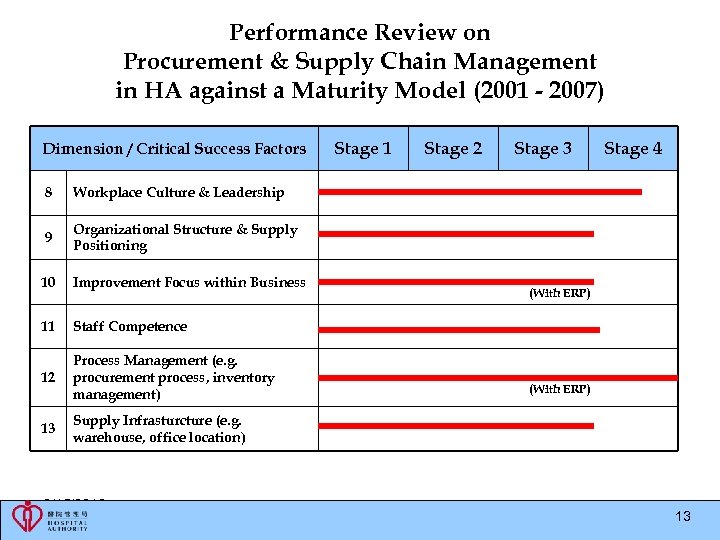

Performance Review on Procurement & Supply Chain Management in HA against a Maturity Model (2001 - 2007) Dimension / Critical Success Factors 8 Improvement Focus within Business 11 12 13 Stage 4 Staff Competence Process Management (e. g. procurement process, inventory management) Stage 3 Organizational Structure & Supply Positioning 10 Stage 2 Workplace Culture & Leadership 9 Stage 1 Supply Infrasturcture (e. g. warehouse, office location) 3/15/2018 (With ERP) 13

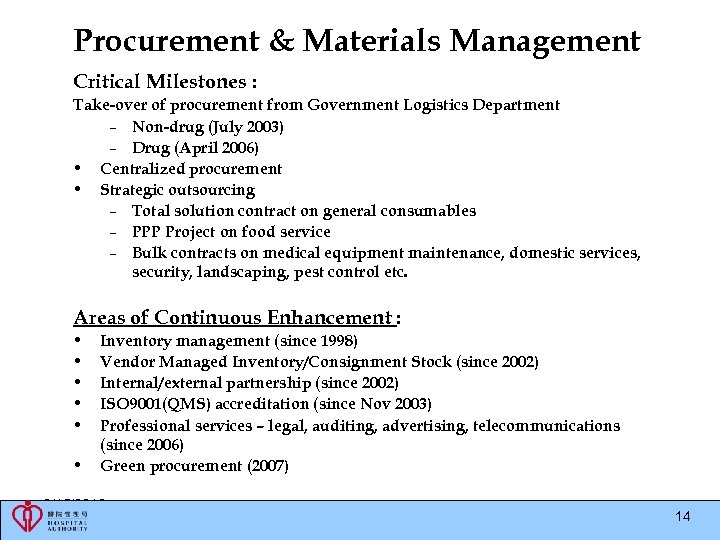

Procurement & Materials Management Critical Milestones : Take-over of procurement from Government Logistics Department – Non-drug (July 2003) – Drug (April 2006) • Centralized procurement • Strategic outsourcing – Total solution contract on general consumables – PPP Project on food service – Bulk contracts on medical equipment maintenance, domestic services, security, landscaping, pest control etc. Areas of Continuous Enhancement : • • • Inventory management (since 1998) Vendor Managed Inventory/Consignment Stock (since 2002) Internal/external partnership (since 2002) ISO 9001(QMS) accreditation (since Nov 2003) Professional services – legal, auditing, advertising, telecommunications (since 2006) Green procurement (2007) 3/15/2018 14

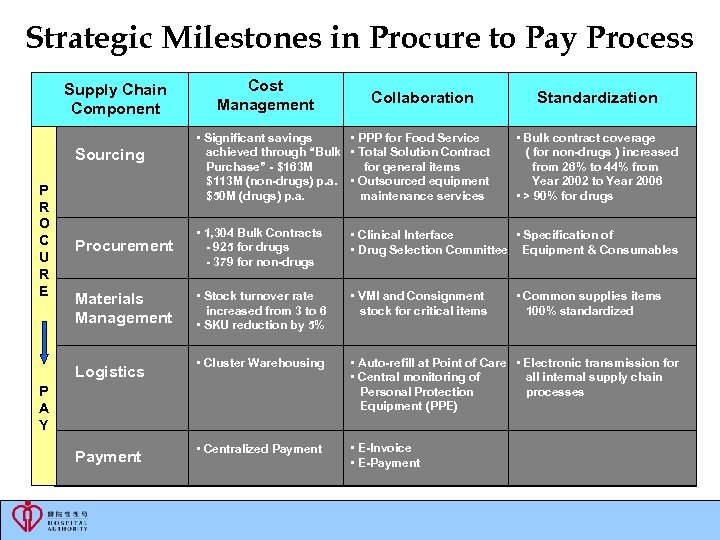

Strategic Milestones in Procure to Pay Process Supply Chain Component Sourcing P R O C U R E Cost Management Collaboration • Significant savings • PPP for Food Service achieved through “Bulk • Total Solution Contract Purchase” - $163 M for general items $113 M (non-drugs) p. a. • Outsourced equipment $50 M (drugs) p. a. maintenance services Standardization • Bulk contract coverage ( for non-drugs ) increased from 26% to 44% from Year 2002 to Year 2006 • > 90% for drugs Procurement • 1, 304 Bulk Contracts - 925 for drugs - 379 for non-drugs • Clinical Interface • Specification of • Drug Selection Committee Equipment & Consumables Materials Management • Stock turnover rate increased from 3 to 6 • SKU reduction by 5% • VMI and Consignment stock for critical items • Cluster Warehousing • Auto-refill at Point of Care • Electronic transmission for • Central monitoring of all internal supply chain Personal Protection processes Equipment (PPE) • Centralized Payment • E-Invoice • E-Payment Logistics P A Y Payment • Common supplies items 100% standardized

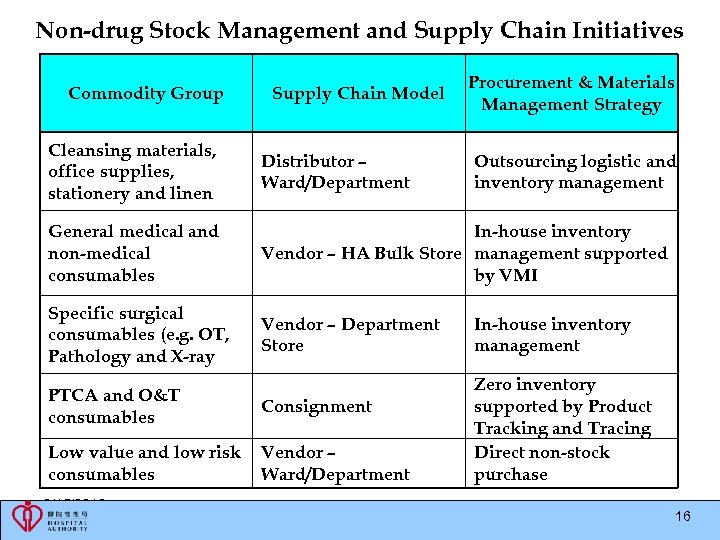

Non-drug Stock Management and Supply Chain Initiatives Commodity Group Supply Chain Model Procurement & Materials Management Strategy Cleansing materials, office supplies, stationery and linen Distributor – Ward/Department General medical and non-medical consumables In-house inventory Vendor – HA Bulk Store management supported by VMI Specific surgical consumables (e. g. OT, Pathology and X-ray Vendor – Department Store PTCA and O&T consumables Consignment Low value and low risk consumables Vendor – Ward/Department 3/15/2018 Outsourcing logistic and inventory management In-house inventory management Zero inventory supported by Product Tracking and Tracing Direct non-stock purchase 16

Implementation Progress of Enterprise Resource Planning System (ERPS)

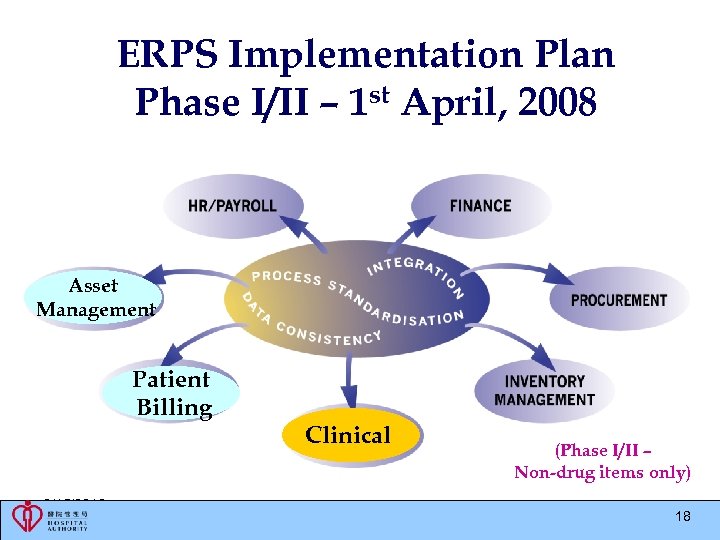

ERPS Implementation Plan Phase I/II – 1 st April, 2008 Asset Management Patient Billing 3/15/2018 Clinical (Phase I/II – Non-drug items only) 18

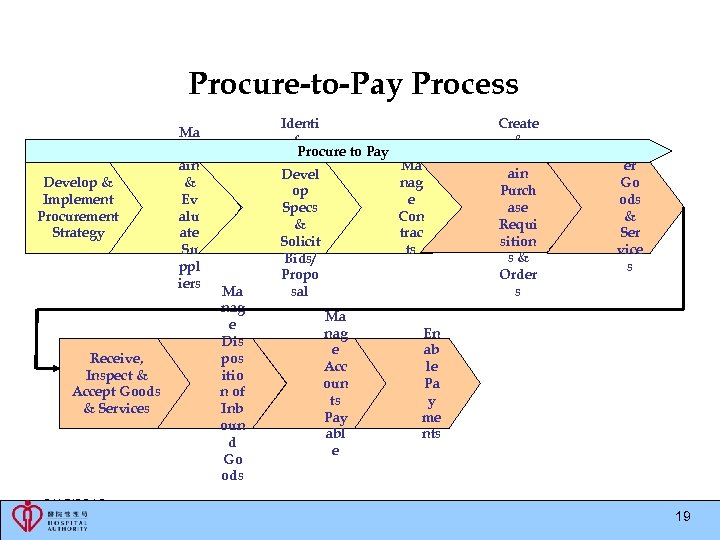

Procure-to-Pay Process Develop & Implement Procurement Strategy Receive, Inspect & Accept Goods & Services 3/15/2018 Ma int ain & Ev alu ate Su ppl iers Ma nag e Dis pos itio n of Inb oun d Go ods Identi fy Procure to Pay Need Devel op Specs & Solicit Bids/ Propo sal Ma nag e Acc oun ts Pay abl e Ma nag e Con trac ts Create & Maint ain Purch ase Requi sition s& Order s Ord er Go ods & Ser vice s En ab le Pa y me nts 19

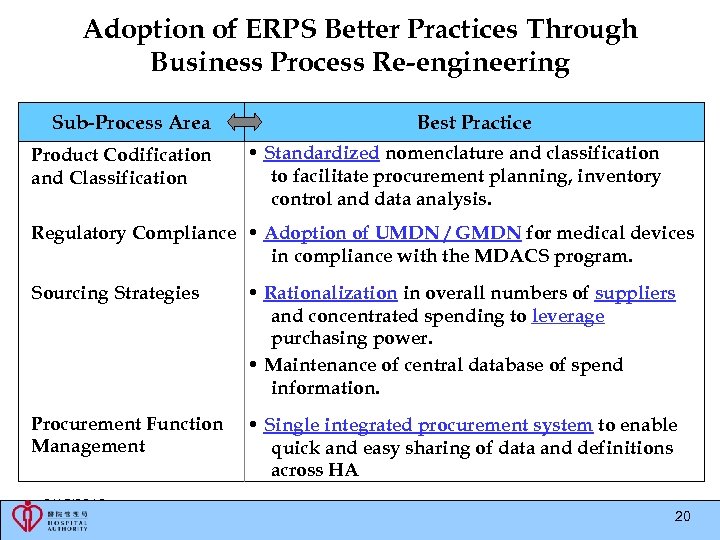

Adoption of ERPS Better Practices Through Business Process Re-engineering Sub-Process Area Product Codification and Classification Best Practice • Standardized nomenclature and classification to facilitate procurement planning, inventory control and data analysis. Regulatory Compliance • Adoption of UMDN / GMDN for medical devices in compliance with the MDACS program. Sourcing Strategies • Rationalization in overall numbers of suppliers and concentrated spending to leverage purchasing power. • Maintenance of central database of spend information. Procurement Function Management • Single integrated procurement system to enable quick and easy sharing of data and definitions across HA 3/15/2018 20

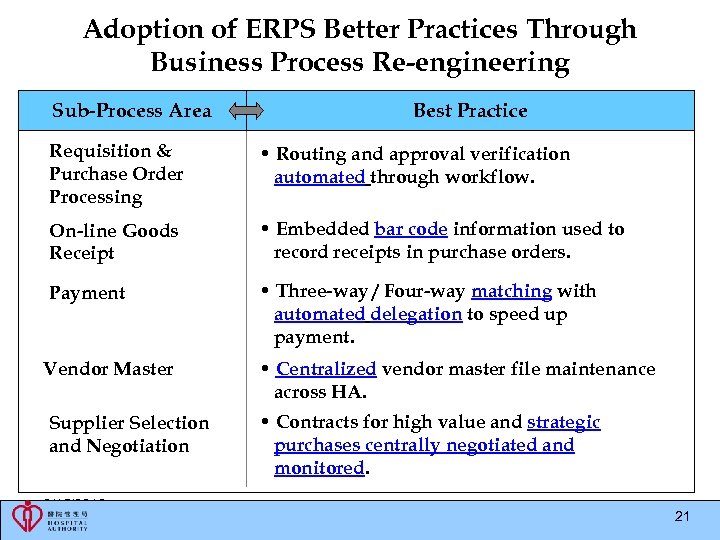

Adoption of ERPS Better Practices Through Business Process Re-engineering Sub-Process Area Best Practice Requisition & Purchase Order Processing • Routing and approval verification automated through workflow. On-line Goods Receipt • Embedded bar code information used to record receipts in purchase orders. Payment • Three-way / Four-way matching with automated delegation to speed up payment. Vendor Master • Centralized vendor master file maintenance across HA. Supplier Selection and Negotiation • Contracts for high value and strategic purchases centrally negotiated and monitored. 3/15/2018 21

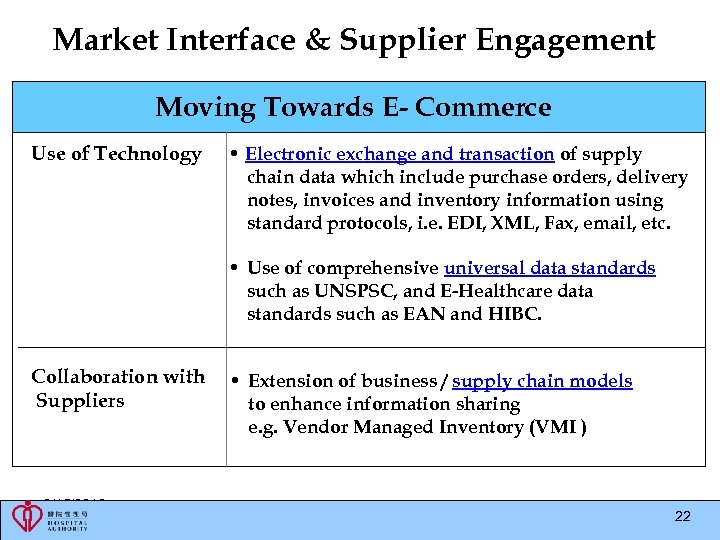

Market Interface & Supplier Engagement Moving Towards E- Commerce Use of Technology • Electronic exchange and transaction of supply chain data which include purchase orders, delivery notes, invoices and inventory information using standard protocols, i. e. EDI, XML, Fax, email, etc. • Use of comprehensive universal data standards such as UNSPSC, and E-Healthcare data standards such as EAN and HIBC. Collaboration with Suppliers 3/15/2018 • Extension of business / supply chain models to enhance information sharing e. g. Vendor Managed Inventory (VMI ) 22

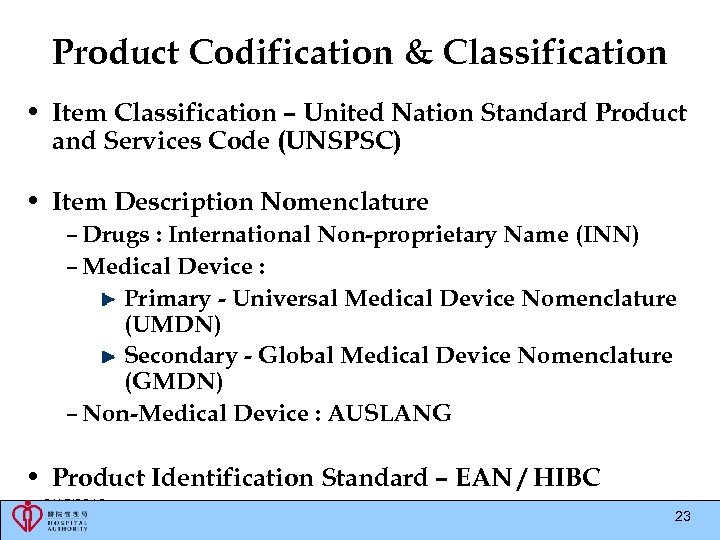

Product Codification & Classification • Item Classification – United Nation Standard Product and Services Code (UNSPSC) • Item Description Nomenclature – Drugs : International Non-proprietary Name (INN) – Medical Device : Primary - Universal Medical Device Nomenclature (UMDN) Secondary - Global Medical Device Nomenclature (GMDN) – Non-Medical Device : AUSLANG • Product Identification Standard – EAN / HIBC 3/15/2018 23

Vendor Master Maintenance • Central vendor creation and maintenance by Procurement and Materials Management Section in Head Office with effective 1 September, 2007 • Designated multiple currency bank account to receive remittance from HA • Vendors to provide update information, if any before October, 2007 3/15/2018 24

e-Transmission of Purchase Order Ø E-mail Ø Fax Ø EDI/XML 3/15/2018 25

ERPS Rollout Plan • 1 st Rollout (1 st April, 2008) – Kowloon East Cluster – Hong Kong East Cluster – Hospital Authority Head Office • 2 nd Rollout (1 st July, 2008) • 3 rd Rollout (1 st October, 2008) 3/15/2018 26

Payment Documentation Requirement effective 1 st April, 2008 • Suppliers to send invoices direct to Head Office/Cluster Finance Offices Ø PO number must be specified Ø Name of the staff, name of his/her department, and hospital (for direct invoices without PO) be provided • Payment will be settled in the specified currency in the PO (local and foreign currencies) • For purchase with Trade-in, suppliers to split invoice lines into Ø Gross amount for the new purchase equipment Ø Trade-in amount for the old equipment 3/15/2018 27

Medical Device Administrative Control (MDACS) • Regulatory compliance with the MDACS requirement on purchase of medical device • Requirement to register with Department of Health under consideration in HA 3/15/2018 28

Q&A

82ec35f45e99c102f008b2dbe0386fc2.ppt