0b898ae240692dbdb588f5a72da8146d.ppt

- Количество слайдов: 35

Codes & Standards

Codes & Standards

Codes and Standards Lesson Objectives When you finish this lesson you will understand: • Codes and Standards Writing Bodies • Welding Procedure Development and Qualifications Learning Activities 1. Read Handbook 412 -464 2. View Slides; 3. Read Notes, 4. Listen to lecture 5. Do on-line workbook 6. Do homework Keywords Codes, Specifications, Recommended Practices, Guides, Classifications, Methods, ANSI, ISO, Welding Procedure Specification (WPS), Procedure Qualification Record (PQR), Welder Performance Qualification

Codes and Standards Lesson Objectives When you finish this lesson you will understand: • Codes and Standards Writing Bodies • Welding Procedure Development and Qualifications Learning Activities 1. Read Handbook 412 -464 2. View Slides; 3. Read Notes, 4. Listen to lecture 5. Do on-line workbook 6. Do homework Keywords Codes, Specifications, Recommended Practices, Guides, Classifications, Methods, ANSI, ISO, Welding Procedure Specification (WPS), Procedure Qualification Record (PQR), Welder Performance Qualification

Standards that Impact Fabrication Introduction Types of Standards l l Codes are generally applicable to processes Shall/will and indicate the mandatory use of materials or actions Specifications are generally associated with Shall/will a product and indicate the mandatory use of materials or actions Should/may Recommended practices and guides are offered primarily as aids to the user Classifications and methods provide lists of established practices or categories for processes or products 0. 1. 1. 6. 0. T 1. 95. 12

Standards that Impact Fabrication Introduction Types of Standards l l Codes are generally applicable to processes Shall/will and indicate the mandatory use of materials or actions Specifications are generally associated with Shall/will a product and indicate the mandatory use of materials or actions Should/may Recommended practices and guides are offered primarily as aids to the user Classifications and methods provide lists of established practices or categories for processes or products 0. 1. 1. 6. 0. T 1. 95. 12

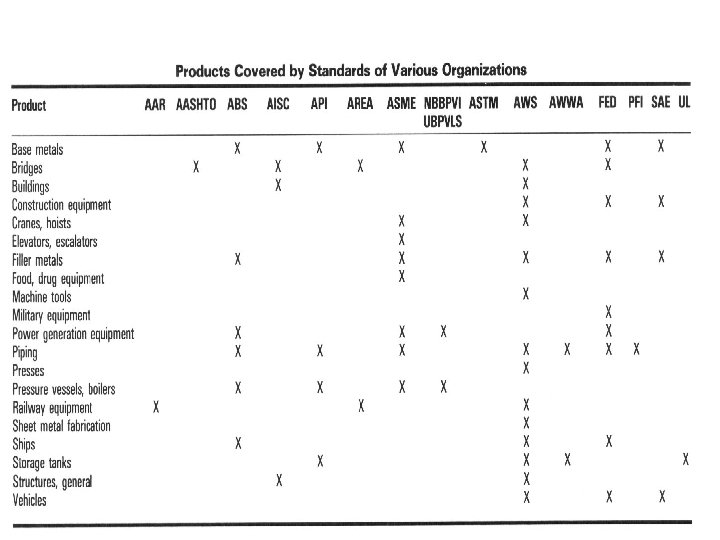

Code Writing Agencies This Table is in the Welding Handbook

Code Writing Agencies This Table is in the Welding Handbook

Standards that Impact Fabrication Introduction What is Covered by Standards l Products § Piping - American Petroleum Institute § Filler metals - American Welding Society § Ships - American Bureau of Shipping § Pressure vessels and boilers - American Society of Mechanical Engineers Bridges - American Institute of Steel Construction l l l § Health & Safety Terminology Testing Procedures 0. 1. 1. 6. 0. T 2. 95. 12

Standards that Impact Fabrication Introduction What is Covered by Standards l Products § Piping - American Petroleum Institute § Filler metals - American Welding Society § Ships - American Bureau of Shipping § Pressure vessels and boilers - American Society of Mechanical Engineers Bridges - American Institute of Steel Construction l l l § Health & Safety Terminology Testing Procedures 0. 1. 1. 6. 0. T 2. 95. 12

Standards that Impact Fabrication Introduction American National Standards Institute (ANSI) l l l Coordinating organization for the U. S. voluntary standards system There approximately 10, 000 American National Standards, which encompass nearly every field and discipline ANSI standards are developed and used voluntarily; they become mandatory when adopted or referenced by a governmental body International Organization for Standardization (ISO) • Establishment of Uniform Standards for International Trade 0. 1. 1. 6. 0. T 3. 95. 12

Standards that Impact Fabrication Introduction American National Standards Institute (ANSI) l l l Coordinating organization for the U. S. voluntary standards system There approximately 10, 000 American National Standards, which encompass nearly every field and discipline ANSI standards are developed and used voluntarily; they become mandatory when adopted or referenced by a governmental body International Organization for Standardization (ISO) • Establishment of Uniform Standards for International Trade 0. 1. 1. 6. 0. T 3. 95. 12

Standards that Impact Fabrication Professional Society Standards International Organization for Standards (ISO) l l 80 countries, 4000+ standards, ANSI is the U. S. representative ISO 9000 -9004 (ANSI/ASQC Q 90) is a series of quality management and assurance standards in manufacturing § Designed for manufacturing sector § EC has adopted ISO 9000 and prefers US suppliers § l that are ISO 9000 certified Do. D, Du. Pont, 3 M, AT&T are asking suppliers to comply with ISO 9000 ISO 3834 - Factors to be Considered When Assessing Firms Using Welding as a Prime Means of Fabrication 0. 1. 1. 6. 2. T 20. 95. 12

Standards that Impact Fabrication Professional Society Standards International Organization for Standards (ISO) l l 80 countries, 4000+ standards, ANSI is the U. S. representative ISO 9000 -9004 (ANSI/ASQC Q 90) is a series of quality management and assurance standards in manufacturing § Designed for manufacturing sector § EC has adopted ISO 9000 and prefers US suppliers § l that are ISO 9000 certified Do. D, Du. Pont, 3 M, AT&T are asking suppliers to comply with ISO 9000 ISO 3834 - Factors to be Considered When Assessing Firms Using Welding as a Prime Means of Fabrication 0. 1. 1. 6. 2. T 20. 95. 12

Standards that Impact Fabrication Health and Safety Health & Safety l l ANSI/ASC Z 49. 1 -1988 Safety in Welding and Cutting § Included in the General Industry Standards of OSHA § Specifically covers arc, oxyfuel gas, resistance welding Health and Safety in Welding and Allied Processes 4 th edition, ed. N. C. Balchin and H. R. Castner, Mc. Graw-Hill Inc. 1993 0. 1. 1. 6. 1. T 4. 95. 12

Standards that Impact Fabrication Health and Safety Health & Safety l l ANSI/ASC Z 49. 1 -1988 Safety in Welding and Cutting § Included in the General Industry Standards of OSHA § Specifically covers arc, oxyfuel gas, resistance welding Health and Safety in Welding and Allied Processes 4 th edition, ed. N. C. Balchin and H. R. Castner, Mc. Graw-Hill Inc. 1993 0. 1. 1. 6. 1. T 4. 95. 12

Standards that Impact Fabrication Professional Society Standards American Welding Society (AWS) Standards l l l Definitions and Symbols (A) Filler Metals (A 5) Qualification and Testing (B, C, and D) Welding Processes (C) Welding Applications (D) 0. 1. 1. 6. 2. T 12. 95. 12

Standards that Impact Fabrication Professional Society Standards American Welding Society (AWS) Standards l l l Definitions and Symbols (A) Filler Metals (A 5) Qualification and Testing (B, C, and D) Welding Processes (C) Welding Applications (D) 0. 1. 1. 6. 2. T 12. 95. 12

Standards that Impact Fabrication Professional Society Standards Definitions and Symbols l l ANSI/AWS A 2. 4 Symbols for Welding, Brazing, and Nondestructive Examination § Communication between designers and fabricators § Joint geometry, weld contour, surface finish ANSI/AWS A 3. 0 Standard Welding Terms and Definitions § Standard terms for use in written and oral communication § conveying materials joining information Non-standard terms 0. 1. 1. 6. 2. T 13. 95. 12

Standards that Impact Fabrication Professional Society Standards Definitions and Symbols l l ANSI/AWS A 2. 4 Symbols for Welding, Brazing, and Nondestructive Examination § Communication between designers and fabricators § Joint geometry, weld contour, surface finish ANSI/AWS A 3. 0 Standard Welding Terms and Definitions § Standard terms for use in written and oral communication § conveying materials joining information Non-standard terms 0. 1. 1. 6. 2. T 13. 95. 12

Standards that Impact Fabrication Professional Society Standards ANSI/AWS D 1. 1 Structural Welding Code: Steel l l Guidelines for design of welded joints as well as prequalified joint geometries § Statically loaded structures § Dynamically loaded structures § Tubular sections Details the processes used with particular joints How to qualify welding procedures and personnel Outlines quality and inspection in welded construction Filler metal recommendations 0. 1. 1. 6. 2. T 14. 95. 12

Standards that Impact Fabrication Professional Society Standards ANSI/AWS D 1. 1 Structural Welding Code: Steel l l Guidelines for design of welded joints as well as prequalified joint geometries § Statically loaded structures § Dynamically loaded structures § Tubular sections Details the processes used with particular joints How to qualify welding procedures and personnel Outlines quality and inspection in welded construction Filler metal recommendations 0. 1. 1. 6. 2. T 14. 95. 12

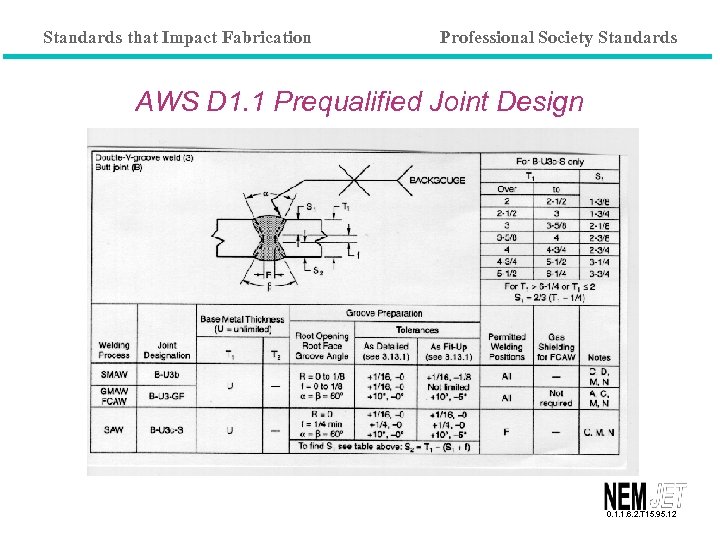

Standards that Impact Fabrication Professional Society Standards AWS D 1. 1 Prequalified Joint Design 0. 1. 1. 6. 2. T 15. 95. 12

Standards that Impact Fabrication Professional Society Standards AWS D 1. 1 Prequalified Joint Design 0. 1. 1. 6. 2. T 15. 95. 12

Standards that Impact Fabrication Professional Society Standards ASTM (American Society for Testing and Materials) l l l Specifications cover virtually all materials used in industry and commerce, but not welding consumables Annual Book of ASTM Standards, 15 sections (65 volumes) § 1 - Iron and Steel § 2 - Non-ferrous § 3 - Metal test methods and analytical procedures Specification of groups of similar steel (A) § A 36 - general construction steels § A 387 - chromium-molybdenum steel for elevated-temperature service in piping and pressure vessel systems 0. 1. 1. 6. 2. T 16. 95. 12

Standards that Impact Fabrication Professional Society Standards ASTM (American Society for Testing and Materials) l l l Specifications cover virtually all materials used in industry and commerce, but not welding consumables Annual Book of ASTM Standards, 15 sections (65 volumes) § 1 - Iron and Steel § 2 - Non-ferrous § 3 - Metal test methods and analytical procedures Specification of groups of similar steel (A) § A 36 - general construction steels § A 387 - chromium-molybdenum steel for elevated-temperature service in piping and pressure vessel systems 0. 1. 1. 6. 2. T 16. 95. 12

Standards that Impact Fabrication Professional Society Standards American Society of Mechanical Engineers (ASME) l l Boiler and Pressure Vessel Code has 11 sections and is referenced by most states, major cities in the U. S. , Canadian provinces, a number of federal agencies Before fabricating a boiler or pressure vessel, a company must have a quality control system and a manual describing it § ASME issues a Certificate of Authorization and a code symbol stamp l l Unique in that it required 3 rd party inspection independent of fabricator and user Uses same steel designations as ASTM 0. 1. 1. 6. 2. T 17. 95. 12

Standards that Impact Fabrication Professional Society Standards American Society of Mechanical Engineers (ASME) l l Boiler and Pressure Vessel Code has 11 sections and is referenced by most states, major cities in the U. S. , Canadian provinces, a number of federal agencies Before fabricating a boiler or pressure vessel, a company must have a quality control system and a manual describing it § ASME issues a Certificate of Authorization and a code symbol stamp l l Unique in that it required 3 rd party inspection independent of fabricator and user Uses same steel designations as ASTM 0. 1. 1. 6. 2. T 17. 95. 12

Standards that Impact Fabrication Professional Society Standards Boiler and Pressure Vessel Code l l l Section II- Materials Specifications for base metals, filler metals, fluxes Section V - Nondestructive Examination Section IX - Welding and Brazing Qualifications for personnel and procedures § Delineates a P number grouping of steels for the purpose of § § § welding qualification P 1 - carbon-manganese steels with a minimum UTS of 45 -90 ksi P 5 - alloy steels with 2. 25 -9% chromium, <10% total alloy All steels within a P number can be welded with the same procedure 0. 1. 1. 6. 2. T 18. 95. 12

Standards that Impact Fabrication Professional Society Standards Boiler and Pressure Vessel Code l l l Section II- Materials Specifications for base metals, filler metals, fluxes Section V - Nondestructive Examination Section IX - Welding and Brazing Qualifications for personnel and procedures § Delineates a P number grouping of steels for the purpose of § § § welding qualification P 1 - carbon-manganese steels with a minimum UTS of 45 -90 ksi P 5 - alloy steels with 2. 25 -9% chromium, <10% total alloy All steels within a P number can be welded with the same procedure 0. 1. 1. 6. 2. T 18. 95. 12

Standards that Impact Fabrication Professional Society Standards Other Standards l l American Petroleum Institute (API) Standard 1104 Welding of Pipelines and Related Facilities § Qualifications of Welding Procedures and Welders § Inspection and nondestructive testing § Repair and removal of defects Unified Numbering System (UNS) § Cross references the numbering systems from different countries § Over 3500 metals, alloys, and filler metals § Designated SAE HSJ 1086 / ASTM DS 56 0. 1. 1. 6. 2. T 19. 95. 12

Standards that Impact Fabrication Professional Society Standards Other Standards l l American Petroleum Institute (API) Standard 1104 Welding of Pipelines and Related Facilities § Qualifications of Welding Procedures and Welders § Inspection and nondestructive testing § Repair and removal of defects Unified Numbering System (UNS) § Cross references the numbering systems from different countries § Over 3500 metals, alloys, and filler metals § Designated SAE HSJ 1086 / ASTM DS 56 0. 1. 1. 6. 2. T 19. 95. 12

Turn to the person sitting next to you and discuss (1 min. ): • What does being a “third party consensus standards writing body” mean?

Turn to the person sitting next to you and discuss (1 min. ): • What does being a “third party consensus standards writing body” mean?

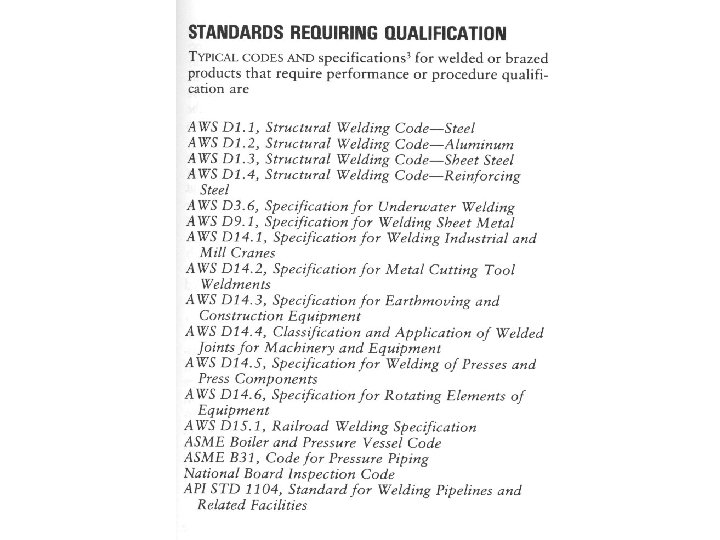

Qualification & Certification

Qualification & Certification

Welding Procedure Specification (WPS) A document that provides in detail required welding conditions for a specific application. Procedure Qualification Record (PQR) A record of actual welding conditions used to produce an acceptable test joint and the results of the qualification tests. Welder Performance Qualification-Certification A record of a welder’s or welding operator’s ability to produce welded joints that meet prescribed standards

Welding Procedure Specification (WPS) A document that provides in detail required welding conditions for a specific application. Procedure Qualification Record (PQR) A record of actual welding conditions used to produce an acceptable test joint and the results of the qualification tests. Welder Performance Qualification-Certification A record of a welder’s or welding operator’s ability to produce welded joints that meet prescribed standards

Pre-Qualified Procedures (Some Codes Permit - Example AWS D 1. 1 Code) Based on the reliability of certain proven procedures spelled out by the applicable code or specification • Use Written Procedures From Code • All Essential Variable Specified • Weld Qualification Tests Not Required • Employer Accepts Responsibility for Use • Deviations Negate Prequalified Status

Pre-Qualified Procedures (Some Codes Permit - Example AWS D 1. 1 Code) Based on the reliability of certain proven procedures spelled out by the applicable code or specification • Use Written Procedures From Code • All Essential Variable Specified • Weld Qualification Tests Not Required • Employer Accepts Responsibility for Use • Deviations Negate Prequalified Status

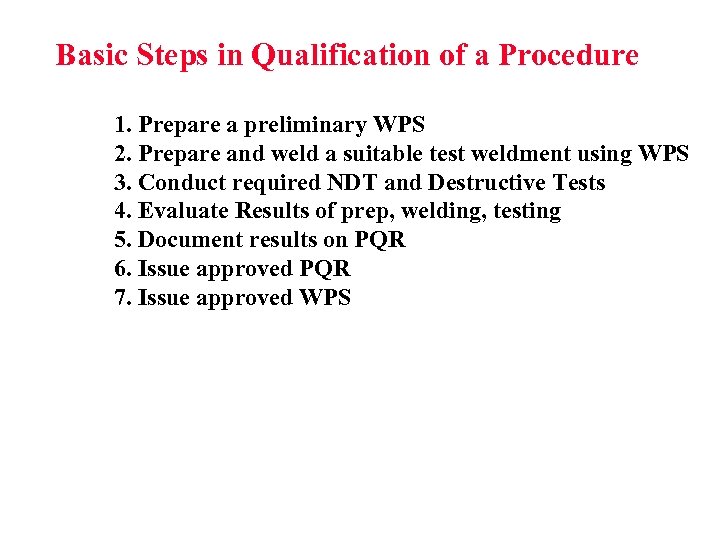

Basic Steps in Qualification of a Procedure 1. Prepare a preliminary WPS 2. Prepare and weld a suitable test weldment using WPS 3. Conduct required NDT and Destructive Tests 4. Evaluate Results of prep, welding, testing 5. Document results on PQR 6. Issue approved PQR 7. Issue approved WPS

Basic Steps in Qualification of a Procedure 1. Prepare a preliminary WPS 2. Prepare and weld a suitable test weldment using WPS 3. Conduct required NDT and Destructive Tests 4. Evaluate Results of prep, welding, testing 5. Document results on PQR 6. Issue approved PQR 7. Issue approved WPS

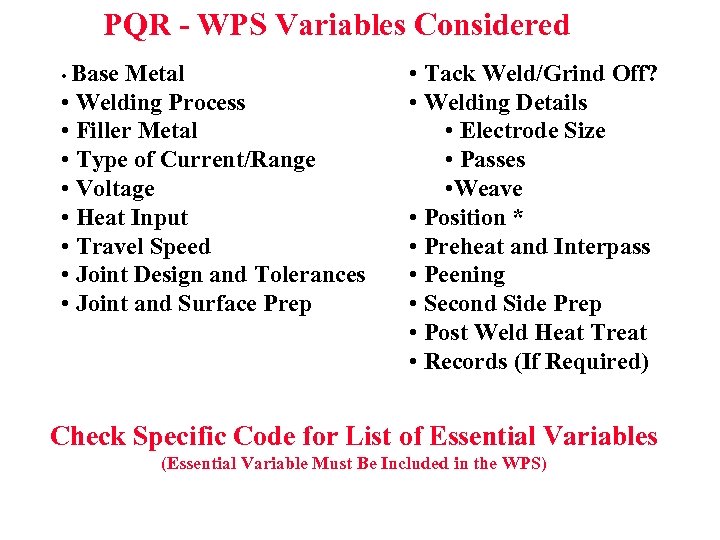

PQR - WPS Variables Considered • Base Metal • Welding Process • Filler Metal • Type of Current/Range • Voltage • Heat Input • Travel Speed • Joint Design and Tolerances • Joint and Surface Prep • Tack Weld/Grind Off? • Welding Details • Electrode Size • Passes • Weave • Position * • Preheat and Interpass • Peening • Second Side Prep • Post Weld Heat Treat • Records (If Required) Check Specific Code for List of Essential Variables (Essential Variable Must Be Included in the WPS)

PQR - WPS Variables Considered • Base Metal • Welding Process • Filler Metal • Type of Current/Range • Voltage • Heat Input • Travel Speed • Joint Design and Tolerances • Joint and Surface Prep • Tack Weld/Grind Off? • Welding Details • Electrode Size • Passes • Weave • Position * • Preheat and Interpass • Peening • Second Side Prep • Post Weld Heat Treat • Records (If Required) Check Specific Code for List of Essential Variables (Essential Variable Must Be Included in the WPS)

PQR Page 1

PQR Page 1

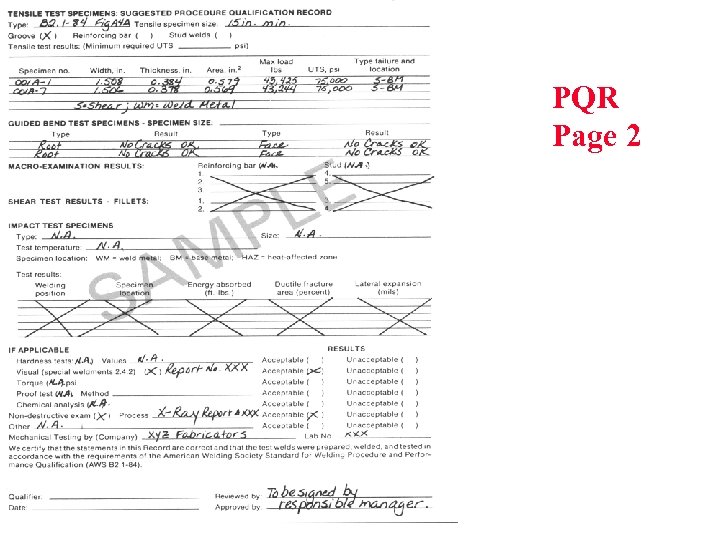

PQR Page 2

PQR Page 2

Tests Commonly Used for PQR’s

Tests Commonly Used for PQR’s

WPS

WPS

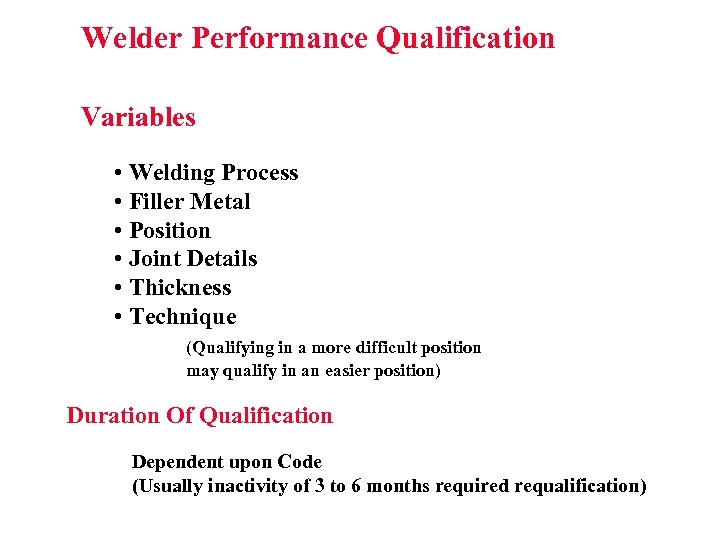

Welder Performance Qualification Variables • Welding Process • Filler Metal • Position • Joint Details • Thickness • Technique (Qualifying in a more difficult position may qualify in an easier position) Duration Of Qualification Dependent upon Code (Usually inactivity of 3 to 6 months required requalification)

Welder Performance Qualification Variables • Welding Process • Filler Metal • Position • Joint Details • Thickness • Technique (Qualifying in a more difficult position may qualify in an easier position) Duration Of Qualification Dependent upon Code (Usually inactivity of 3 to 6 months required requalification)

Performance Qualification Record

Performance Qualification Record

Run the “Welding Procedure Specification” from the “Demonstration Page” of the WE 300 Web Page

Run the “Welding Procedure Specification” from the “Demonstration Page” of the WE 300 Web Page

Please do Assignment 14

Please do Assignment 14