COALS FOR COREX PROCESS dr kalyan sen, Director Central Fuel Research Institute, P. O. FRI, Dhanbad 828108 3/18/2018 COREX 2000 1

COALS FOR COREX PROCESS dr kalyan sen, Director Central Fuel Research Institute, P. O. FRI, Dhanbad 828108 3/18/2018 COREX 2000 1

IRON ORE: proven 13460 Mt ORE Resource BIHAR, ORISSA, M. P, KARNATAKA and GOA Reserves, Bt Haematite - 9. 6 Magnetite - 3. 1 3/18/2018 COREX 2000 2

IRON ORE: proven 13460 Mt ORE Resource BIHAR, ORISSA, M. P, KARNATAKA and GOA Reserves, Bt Haematite - 9. 6 Magnetite - 3. 1 3/18/2018 COREX 2000 2

WHY NOT COKE-OVEN BF ROUTE ? 6 High cost involvement 6 Stringent specifications of raw materials 6 not eco-friendly 3/18/2018 COREX 2000 3

WHY NOT COKE-OVEN BF ROUTE ? 6 High cost involvement 6 Stringent specifications of raw materials 6 not eco-friendly 3/18/2018 COREX 2000 3

SR PROCESS < COREX (Voest Alpine, Australia ) < HISMELT (Hismelt Corpn. , Australia) < DIOS ( JISF, Japan) < AISI (DOE, USA) < ROMELT (Moscow Inst. Steel & Alloy, Russia) 3/18/2018 COREX 2000 4

SR PROCESS < COREX (Voest Alpine, Australia ) < HISMELT (Hismelt Corpn. , Australia) < DIOS ( JISF, Japan) < AISI (DOE, USA) < ROMELT (Moscow Inst. Steel & Alloy, Russia) 3/18/2018 COREX 2000 4

WHY COREX PROCESS 4 Flexibility in raw materials • medium to low grade iron ore • iron waste & scraps • non-coking/ LVC coals 4 Less sensitive to physico-chemical characteristics of coal 4 Eco-friendly 4 Low capacity, low investment cost 3/18/2018 COREX 2000 5

WHY COREX PROCESS 4 Flexibility in raw materials • medium to low grade iron ore • iron waste & scraps • non-coking/ LVC coals 4 Less sensitive to physico-chemical characteristics of coal 4 Eco-friendly 4 Low capacity, low investment cost 3/18/2018 COREX 2000 5

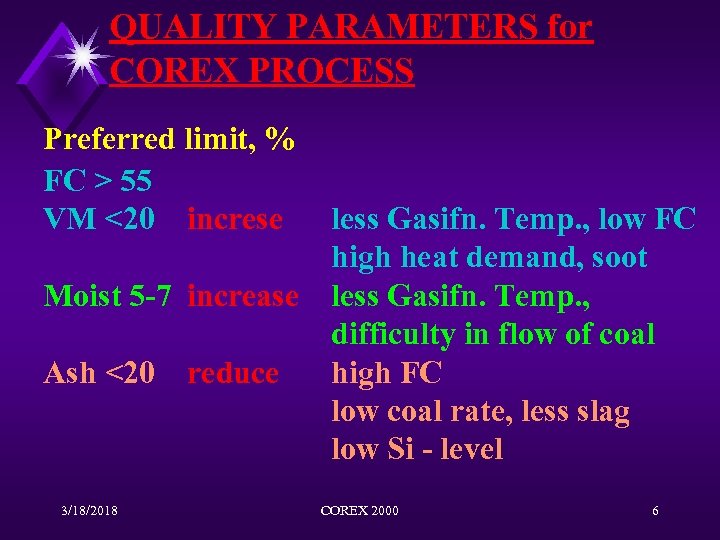

QUALITY PARAMETERS for COREX PROCESS Preferred limit, % FC > 55 VM <20 increse Moist 5 -7 increase Ash <20 3/18/2018 reduce less Gasifn. Temp. , low FC high heat demand, soot less Gasifn. Temp. , difficulty in flow of coal high FC low coal rate, less slag low Si - level COREX 2000 6

QUALITY PARAMETERS for COREX PROCESS Preferred limit, % FC > 55 VM <20 increse Moist 5 -7 increase Ash <20 3/18/2018 reduce less Gasifn. Temp. , low FC high heat demand, soot less Gasifn. Temp. , difficulty in flow of coal high FC low coal rate, less slag low Si - level COREX 2000 6

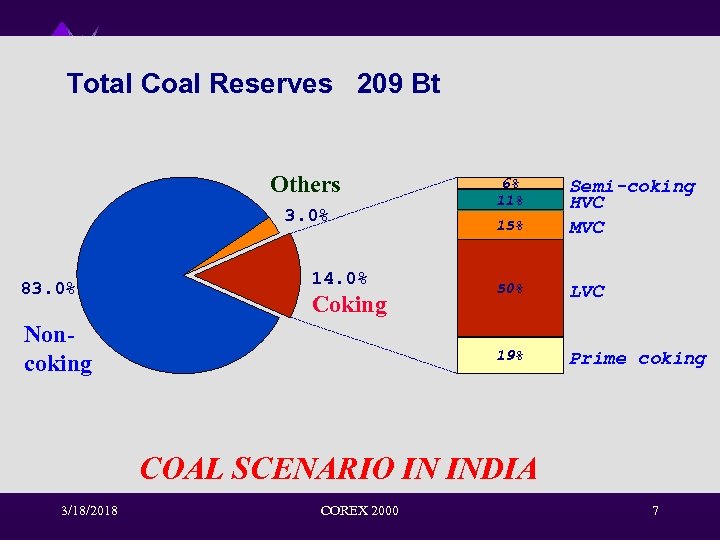

Total Coal Reserves 209 Bt Others 14. 0% Coking Noncoking 15% Semi-coking HVC MVC 50% LVC 19% 3. 0% 83. 0% 6% 11% Prime coking COAL SCENARIO IN INDIA 3/18/2018 COREX 2000 7

Total Coal Reserves 209 Bt Others 14. 0% Coking Noncoking 15% Semi-coking HVC MVC 50% LVC 19% 3. 0% 83. 0% 6% 11% Prime coking COAL SCENARIO IN INDIA 3/18/2018 COREX 2000 7

Availability of Coal for COREX process 3/18/2018 COREX 2000 8

Availability of Coal for COREX process 3/18/2018 COREX 2000 8

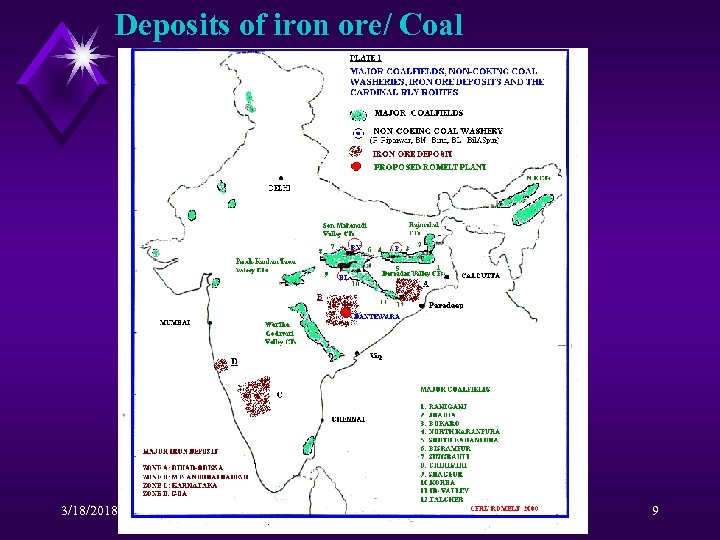

Deposits of iron ore/ Coal 3/18/2018 COREX 2000 9

Deposits of iron ore/ Coal 3/18/2018 COREX 2000 9

Judicious beneficiation of available coal is a necessity 3/18/2018 COREX 2000 10

Judicious beneficiation of available coal is a necessity 3/18/2018 COREX 2000 10

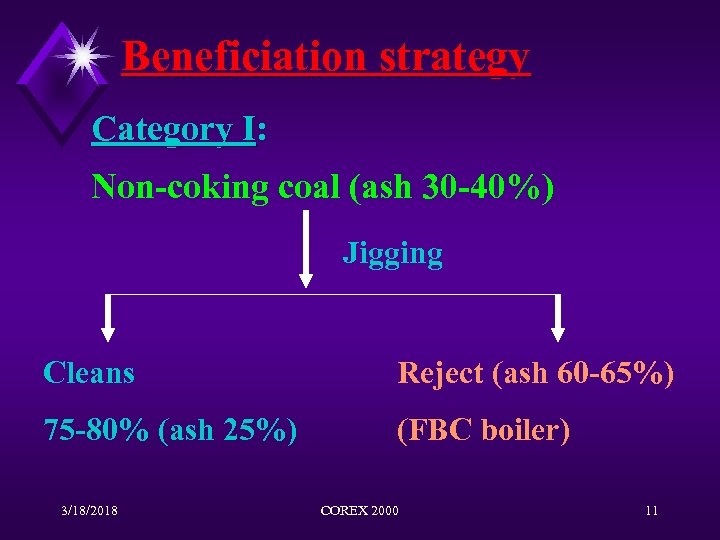

Beneficiation strategy Category I: I Non-coking coal (ash 30 -40%) Jigging Cleans Reject (ash 60 -65%) 75 -80% (ash 25%) (FBC boiler) 3/18/2018 COREX 2000 11

Beneficiation strategy Category I: I Non-coking coal (ash 30 -40%) Jigging Cleans Reject (ash 60 -65%) 75 -80% (ash 25%) (FBC boiler) 3/18/2018 COREX 2000 11

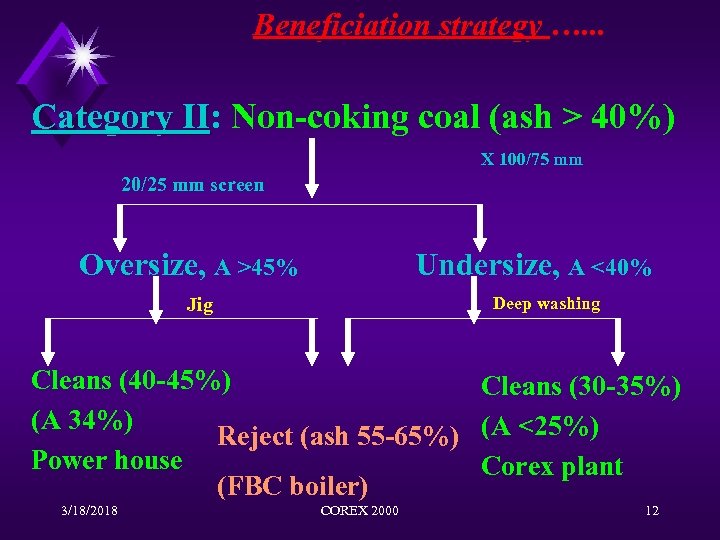

Beneficiation strategy …. . . Category II: Non-coking coal (ash > 40%) II X 100/75 mm 20/25 mm screen Oversize, A >45% Undersize, A <40% Deep washing Jig Cleans (40 -45%) Cleans (30 -35%) (A 34%) Reject (ash 55 -65%) (A <25%) Power house Corex plant (FBC boiler) 3/18/2018 COREX 2000 12

Beneficiation strategy …. . . Category II: Non-coking coal (ash > 40%) II X 100/75 mm 20/25 mm screen Oversize, A >45% Undersize, A <40% Deep washing Jig Cleans (40 -45%) Cleans (30 -35%) (A 34%) Reject (ash 55 -65%) (A <25%) Power house Corex plant (FBC boiler) 3/18/2018 COREX 2000 12

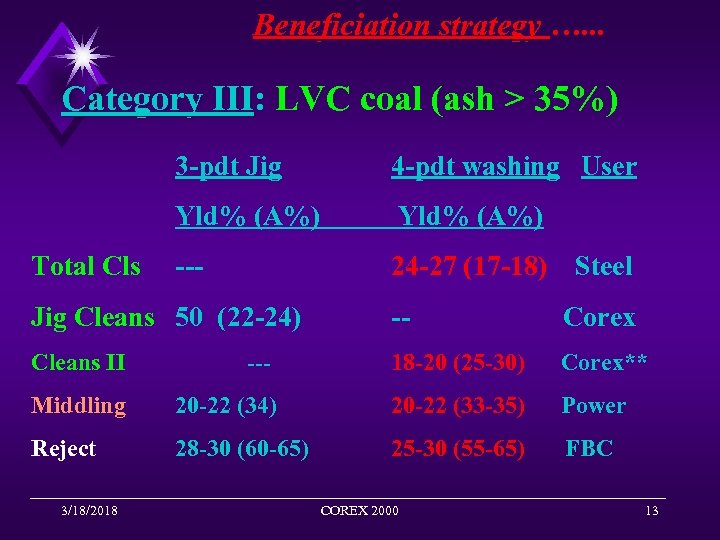

Beneficiation strategy …. . . Category III: LVC coal (ash > 35%) III 3 -pdt Jig Yld% (A%) Total Cls 4 -pdt washing User Yld% (A%) --- 24 -27 (17 -18) Steel Jig Cleans 50 (22 -24) -- Corex Cleans II --- 18 -20 (25 -30) Corex** Middling 20 -22 (34) 20 -22 (33 -35) Power Reject 28 -30 (60 -65) 25 -30 (55 -65) FBC 3/18/2018 COREX 2000 13

Beneficiation strategy …. . . Category III: LVC coal (ash > 35%) III 3 -pdt Jig Yld% (A%) Total Cls 4 -pdt washing User Yld% (A%) --- 24 -27 (17 -18) Steel Jig Cleans 50 (22 -24) -- Corex Cleans II --- 18 -20 (25 -30) Corex** Middling 20 -22 (34) 20 -22 (33 -35) Power Reject 28 -30 (60 -65) 25 -30 (55 -65) FBC 3/18/2018 COREX 2000 13

REMARKS THE PROCESS EXHIBITS A POSITIVE PROFILE UNDER INDIAN CONTEXT HOWEVER, DETAILED STUDIES ON IDENTIFICATION OF SUITABLE SOURCES AND CHOICE OF WASHING STRATEGY IS NECESSARY 3/18/2018 COREX 2000 14

REMARKS THE PROCESS EXHIBITS A POSITIVE PROFILE UNDER INDIAN CONTEXT HOWEVER, DETAILED STUDIES ON IDENTIFICATION OF SUITABLE SOURCES AND CHOICE OF WASHING STRATEGY IS NECESSARY 3/18/2018 COREX 2000 14