€ CO 2 € € CO 2 Workshop 3 Energy Efficiency CDM-Projects in China Case Study II Energy efficiency in the steel industry 6 th December 2006 Simone Ullrich, Fichtner Beijing, China

€ CO 2 € € CO 2 Workshop 3 Energy Efficiency CDM-Projects in China Case Study II Energy efficiency in the steel industry 6 th December 2006 Simone Ullrich, Fichtner Beijing, China

Content 1 Fichtner & steel sector references 2 Overview of steel sector in China & international context 3 4 2 Potential CDM projects & carbon benefits Regulations in the steel sector in China Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

Content 1 Fichtner & steel sector references 2 Overview of steel sector in China & international context 3 4 2 Potential CDM projects & carbon benefits Regulations in the steel sector in China Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

1 3 Fichtner & steel sector references Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

1 3 Fichtner & steel sector references Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

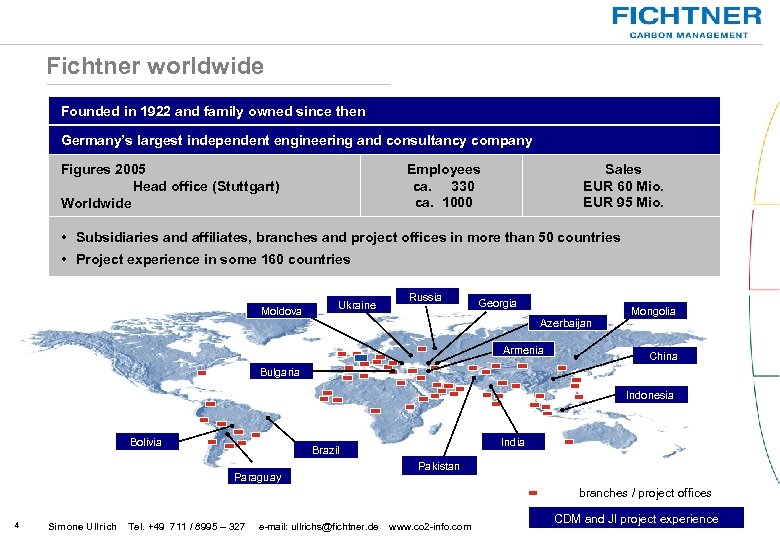

Fichtner worldwide Founded in 1922 and family owned since then Germany’s largest independent engineering and consultancy company Employees ca. 330 ca. 1000 Figures 2005 Head office (Stuttgart) Worldwide Sales EUR 60 Mio. EUR 95 Mio. • Subsidiaries and affiliates, branches and project offices in more than 50 countries • Project experience in some 160 countries Moldova Ukraine Russia Georgia Azerbaijan Armenia Mongolia China Bulgaria Indonesia Bolivia India Brazil Paraguay Pakistan branches / project offices 4 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com CDM and JI project experience

Fichtner worldwide Founded in 1922 and family owned since then Germany’s largest independent engineering and consultancy company Employees ca. 330 ca. 1000 Figures 2005 Head office (Stuttgart) Worldwide Sales EUR 60 Mio. EUR 95 Mio. • Subsidiaries and affiliates, branches and project offices in more than 50 countries • Project experience in some 160 countries Moldova Ukraine Russia Georgia Azerbaijan Armenia Mongolia China Bulgaria Indonesia Bolivia India Brazil Paraguay Pakistan branches / project offices 4 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com CDM and JI project experience

Fichtner’s strengths Engineering and consulting services • Conceptual and decisionmaking phase • Engineering and contract award • Construction • Operation CDM & JI services Engineering and consulting CDM, JI Technology know-how Fichtner's areas of activity • • 5 Simone Ullrich Tel. +49 711 / 8995 – 327 Energy Environment Water & Infrastructure Consulting & IT e-mail: ullrichs@fichtner. de www. co 2 -info. com • Implementation of DNA • Capacity building • Development of PIN, PDD, Methodology, ERPA • Monitoring • Marketing of CERs, ERUs

Fichtner’s strengths Engineering and consulting services • Conceptual and decisionmaking phase • Engineering and contract award • Construction • Operation CDM & JI services Engineering and consulting CDM, JI Technology know-how Fichtner's areas of activity • • 5 Simone Ullrich Tel. +49 711 / 8995 – 327 Energy Environment Water & Infrastructure Consulting & IT e-mail: ullrichs@fichtner. de www. co 2 -info. com • Implementation of DNA • Capacity building • Development of PIN, PDD, Methodology, ERPA • Monitoring • Marketing of CERs, ERUs

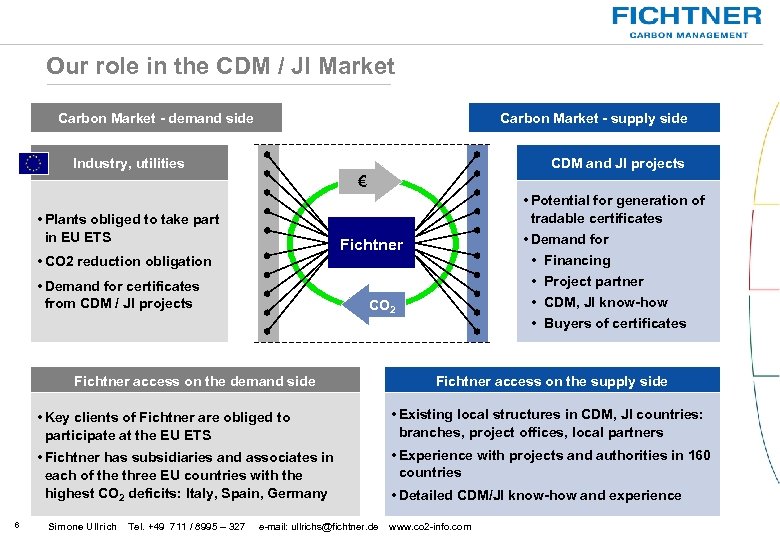

Our role in the CDM / JI Market Carbon Market - demand side Carbon Market - supply side Industry, utilities CDM and JI projects € Plants obliged to take part in EU ETS Potential for generation of tradable certificates Demand for Financing Project partner CDM, JI know-how Buyers of certificates Fichtner CO 2 reduction obligation Demand for certificates from CDM / JI projects CO 2 Fichtner access on the demand side Fichtner access on the supply side Key clients of Fichtner are obliged to participate at the EU ETS Fichtner has subsidiaries and associates in each of the three EU countries with the highest CO 2 deficits: Italy, Spain, Germany 6 Existing local structures in CDM, JI countries: branches, project offices, local partners Experience with projects and authorities in 160 countries Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de Detailed CDM/JI know-how and experience www. co 2 -info. com

Our role in the CDM / JI Market Carbon Market - demand side Carbon Market - supply side Industry, utilities CDM and JI projects € Plants obliged to take part in EU ETS Potential for generation of tradable certificates Demand for Financing Project partner CDM, JI know-how Buyers of certificates Fichtner CO 2 reduction obligation Demand for certificates from CDM / JI projects CO 2 Fichtner access on the demand side Fichtner access on the supply side Key clients of Fichtner are obliged to participate at the EU ETS Fichtner has subsidiaries and associates in each of the three EU countries with the highest CO 2 deficits: Italy, Spain, Germany 6 Existing local structures in CDM, JI countries: branches, project offices, local partners Experience with projects and authorities in 160 countries Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de Detailed CDM/JI know-how and experience www. co 2 -info. com

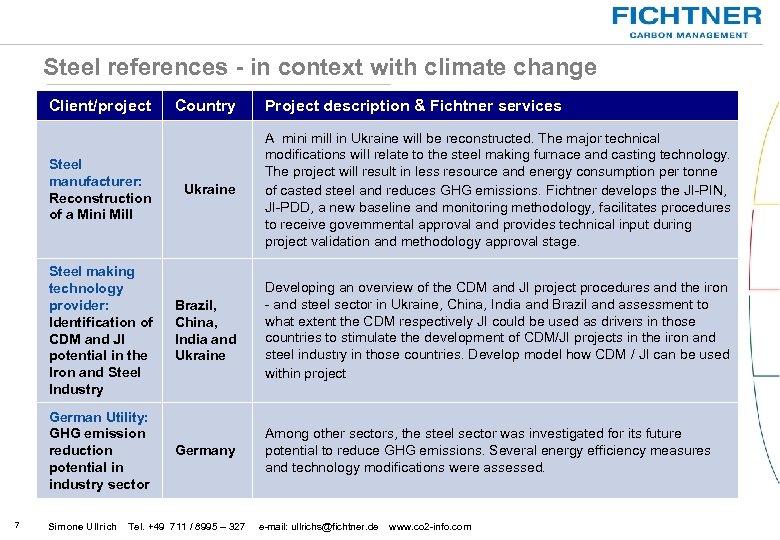

Steel references - in context with climate change Client/project Steel manufacturer: Reconstruction of a Mini Mill Steel making technology provider: Identification of CDM and JI potential in the Iron and Steel Industry German Utility: GHG emission reduction potential in industry sector 7 Simone Ullrich Country Project description & Fichtner services Ukraine A mini mill in Ukraine will be reconstructed. The major technical modifications will relate to the steel making furnace and casting technology. The project will result in less resource and energy consumption per tonne of casted steel and reduces GHG emissions. Fichtner develops the JI-PIN, JI-PDD, a new baseline and monitoring methodology, facilitates procedures to receive governmental approval and provides technical input during project validation and methodology approval stage. Brazil, China, India and Ukraine Developing an overview of the CDM and JI project procedures and the iron - and steel sector in Ukraine, China, India and Brazil and assessment to what extent the CDM respectively JI could be used as drivers in those countries to stimulate the development of CDM/JI projects in the iron and steel industry in those countries. Develop model how CDM / JI can be used within project Germany Among other sectors, the steel sector was investigated for its future potential to reduce GHG emissions. Several energy efficiency measures and technology modifications were assessed. Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

Steel references - in context with climate change Client/project Steel manufacturer: Reconstruction of a Mini Mill Steel making technology provider: Identification of CDM and JI potential in the Iron and Steel Industry German Utility: GHG emission reduction potential in industry sector 7 Simone Ullrich Country Project description & Fichtner services Ukraine A mini mill in Ukraine will be reconstructed. The major technical modifications will relate to the steel making furnace and casting technology. The project will result in less resource and energy consumption per tonne of casted steel and reduces GHG emissions. Fichtner develops the JI-PIN, JI-PDD, a new baseline and monitoring methodology, facilitates procedures to receive governmental approval and provides technical input during project validation and methodology approval stage. Brazil, China, India and Ukraine Developing an overview of the CDM and JI project procedures and the iron - and steel sector in Ukraine, China, India and Brazil and assessment to what extent the CDM respectively JI could be used as drivers in those countries to stimulate the development of CDM/JI projects in the iron and steel industry in those countries. Develop model how CDM / JI can be used within project Germany Among other sectors, the steel sector was investigated for its future potential to reduce GHG emissions. Several energy efficiency measures and technology modifications were assessed. Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

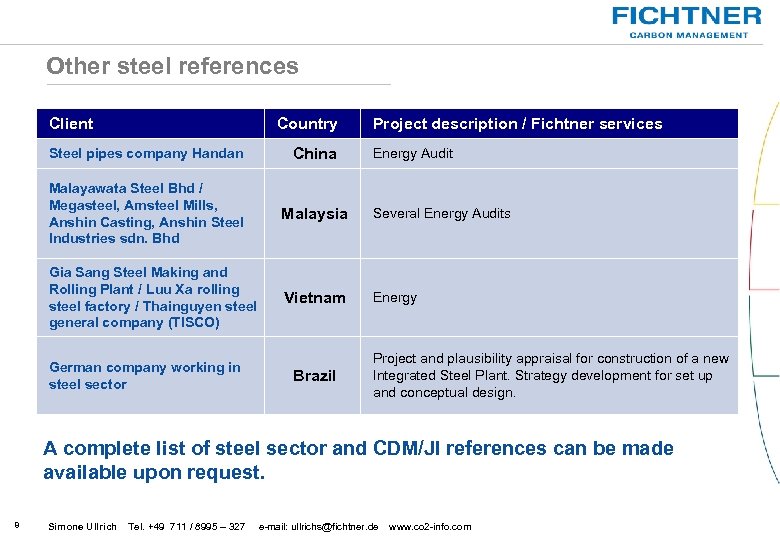

Other steel references Client Country Project description / Fichtner services Steel pipes company Handan China Malayawata Steel Bhd / Megasteel, Amsteel Mills, Anshin Casting, Anshin Steel Industries sdn. Bhd Malaysia Several Energy Audits Gia Sang Steel Making and Rolling Plant / Luu Xa rolling steel factory / Thainguyen steel general company (TISCO) Vietnam Energy German company working in steel sector Brazil Energy Audit Project and plausibility appraisal for construction of a new Integrated Steel Plant. Strategy development for set up and conceptual design. A complete list of steel sector and CDM/JI references can be made available upon request. 8 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

Other steel references Client Country Project description / Fichtner services Steel pipes company Handan China Malayawata Steel Bhd / Megasteel, Amsteel Mills, Anshin Casting, Anshin Steel Industries sdn. Bhd Malaysia Several Energy Audits Gia Sang Steel Making and Rolling Plant / Luu Xa rolling steel factory / Thainguyen steel general company (TISCO) Vietnam Energy German company working in steel sector Brazil Energy Audit Project and plausibility appraisal for construction of a new Integrated Steel Plant. Strategy development for set up and conceptual design. A complete list of steel sector and CDM/JI references can be made available upon request. 8 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

2 9 Overview of steel sector in China & international context Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

2 9 Overview of steel sector in China & international context Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

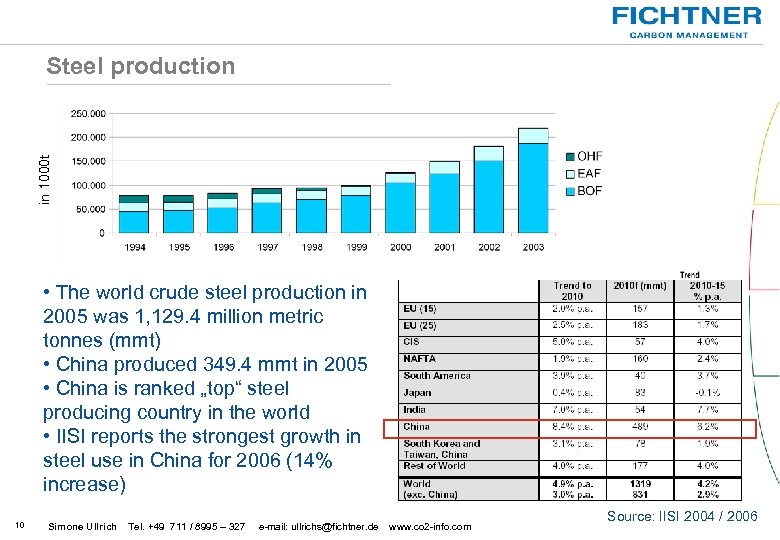

in 1000 t Steel production • The world crude steel production in 2005 was 1, 129. 4 million metric tonnes (mmt) • China produced 349. 4 mmt in 2005 • China is ranked „top“ steel producing country in the world • IISI reports the strongest growth in steel use in China for 2006 (14% increase) 10 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com Source: IISI 2004 / 2006

in 1000 t Steel production • The world crude steel production in 2005 was 1, 129. 4 million metric tonnes (mmt) • China produced 349. 4 mmt in 2005 • China is ranked „top“ steel producing country in the world • IISI reports the strongest growth in steel use in China for 2006 (14% increase) 10 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com Source: IISI 2004 / 2006

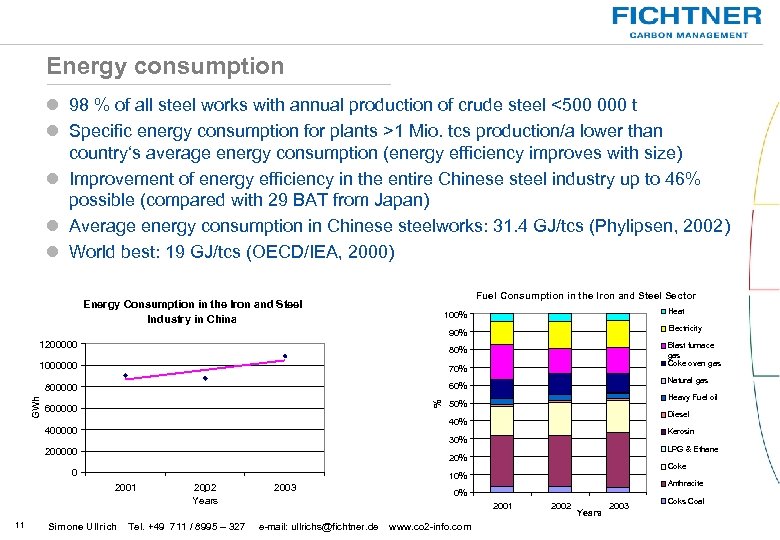

Energy consumption l 98 % of all steel works with annual production of crude steel <500 000 t l Specific energy consumption for plants >1 Mio. tcs production/a lower than country‘s average energy consumption (energy efficiency improves with size) l Improvement of energy efficiency in the entire Chinese steel industry up to 46% possible (compared with 29 BAT from Japan) l Average energy consumption in Chinese steelworks: 31. 4 GJ/tcs (Phylipsen, 2002) l World best: 19 GJ/tcs (OECD/IEA, 2000) Fuel Consumption in the Iron and Steel Sector Energy Consumption in the Iron and Steel Industry in China Heat 100% Electricity 90% 1200000 800000 60% % 70% GWh 1000000 600000 Natural gas Heavy Fuel oil 50% Diesel 40% 400000 Kerosin 30% 200000 LPG & Ethane 20% 0 Coke 10% 2001 11 Blast furnace gas Coke oven gas 80% Simone Ullrich 2002 J Years Tel. +49 711 / 8995 – 327 2003 Anthracite 0% 2001 e-mail: ullrichs@fichtner. de www. co 2 -info. com 2002 Years 2003 Coks Coal

Energy consumption l 98 % of all steel works with annual production of crude steel <500 000 t l Specific energy consumption for plants >1 Mio. tcs production/a lower than country‘s average energy consumption (energy efficiency improves with size) l Improvement of energy efficiency in the entire Chinese steel industry up to 46% possible (compared with 29 BAT from Japan) l Average energy consumption in Chinese steelworks: 31. 4 GJ/tcs (Phylipsen, 2002) l World best: 19 GJ/tcs (OECD/IEA, 2000) Fuel Consumption in the Iron and Steel Sector Energy Consumption in the Iron and Steel Industry in China Heat 100% Electricity 90% 1200000 800000 60% % 70% GWh 1000000 600000 Natural gas Heavy Fuel oil 50% Diesel 40% 400000 Kerosin 30% 200000 LPG & Ethane 20% 0 Coke 10% 2001 11 Blast furnace gas Coke oven gas 80% Simone Ullrich 2002 J Years Tel. +49 711 / 8995 – 327 2003 Anthracite 0% 2001 e-mail: ullrichs@fichtner. de www. co 2 -info. com 2002 Years 2003 Coks Coal

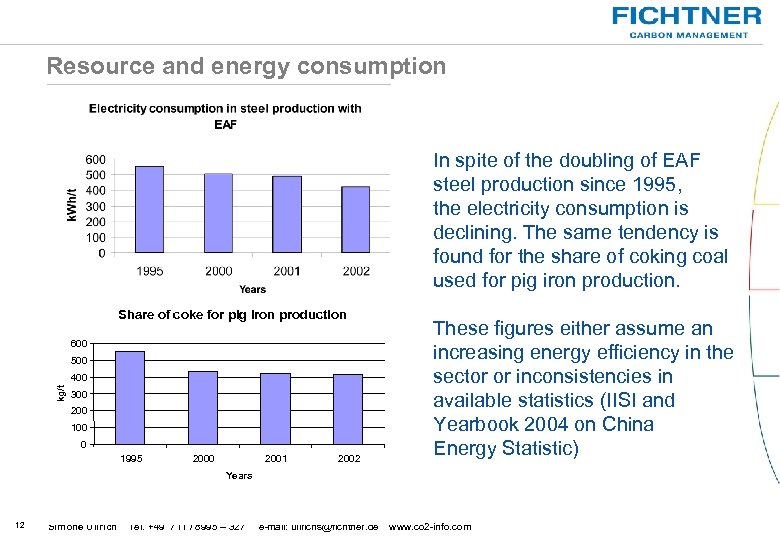

Resource and energy consumption In spite of the doubling of EAF steel production since 1995, the electricity consumption is declining. The same tendency is found for the share of coking coal used for pig iron production. Share of coke for pig iron production 600 500 kg/t 400 300 200 100 0 1995 2000 2001 2002 These figures either assume an increasing energy efficiency in the sector or inconsistencies in available statistics (IISI and Yearbook 2004 on China Energy Statistic) Years 12 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

Resource and energy consumption In spite of the doubling of EAF steel production since 1995, the electricity consumption is declining. The same tendency is found for the share of coking coal used for pig iron production. Share of coke for pig iron production 600 500 kg/t 400 300 200 100 0 1995 2000 2001 2002 These figures either assume an increasing energy efficiency in the sector or inconsistencies in available statistics (IISI and Yearbook 2004 on China Energy Statistic) Years 12 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

3 13 Potential CDM projects & carbon benefits Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

3 13 Potential CDM projects & carbon benefits Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

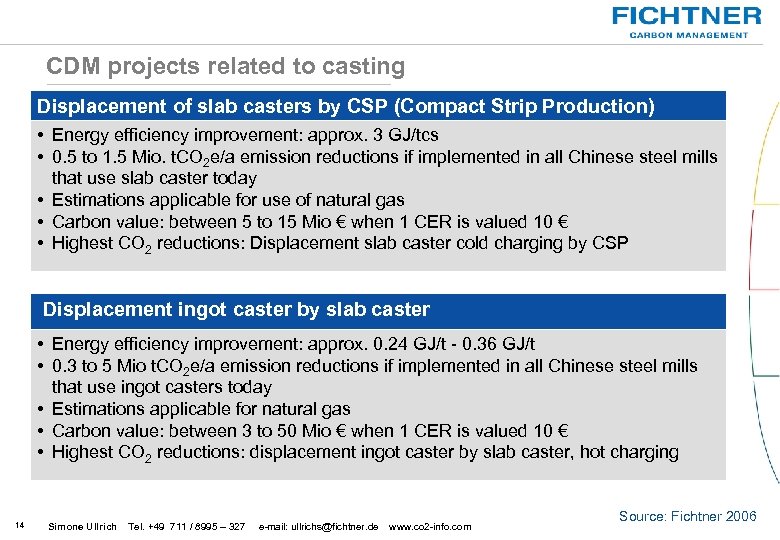

CDM projects related to casting Displacement of slab casters by CSP (Compact Strip Production) • Energy efficiency improvement: approx. 3 GJ/tcs • 0. 5 to 1. 5 Mio. t. CO 2 e/a emission reductions if implemented in all Chinese steel mills that use slab caster today • Estimations applicable for use of natural gas • Carbon value: between 5 to 15 Mio € when 1 CER is valued 10 € • Highest CO 2 reductions: Displacement slab caster cold charging by CSP Displacement ingot caster by slab caster • Energy efficiency improvement: approx. 0. 24 GJ/t - 0. 36 GJ/t • 0. 3 to 5 Mio t. CO 2 e/a emission reductions if implemented in all Chinese steel mills that use ingot casters today • Estimations applicable for natural gas • Carbon value: between 3 to 50 Mio € when 1 CER is valued 10 € • Highest CO 2 reductions: displacement ingot caster by slab caster, hot charging 14 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com Source: Fichtner 2006

CDM projects related to casting Displacement of slab casters by CSP (Compact Strip Production) • Energy efficiency improvement: approx. 3 GJ/tcs • 0. 5 to 1. 5 Mio. t. CO 2 e/a emission reductions if implemented in all Chinese steel mills that use slab caster today • Estimations applicable for use of natural gas • Carbon value: between 5 to 15 Mio € when 1 CER is valued 10 € • Highest CO 2 reductions: Displacement slab caster cold charging by CSP Displacement ingot caster by slab caster • Energy efficiency improvement: approx. 0. 24 GJ/t - 0. 36 GJ/t • 0. 3 to 5 Mio t. CO 2 e/a emission reductions if implemented in all Chinese steel mills that use ingot casters today • Estimations applicable for natural gas • Carbon value: between 3 to 50 Mio € when 1 CER is valued 10 € • Highest CO 2 reductions: displacement ingot caster by slab caster, hot charging 14 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com Source: Fichtner 2006

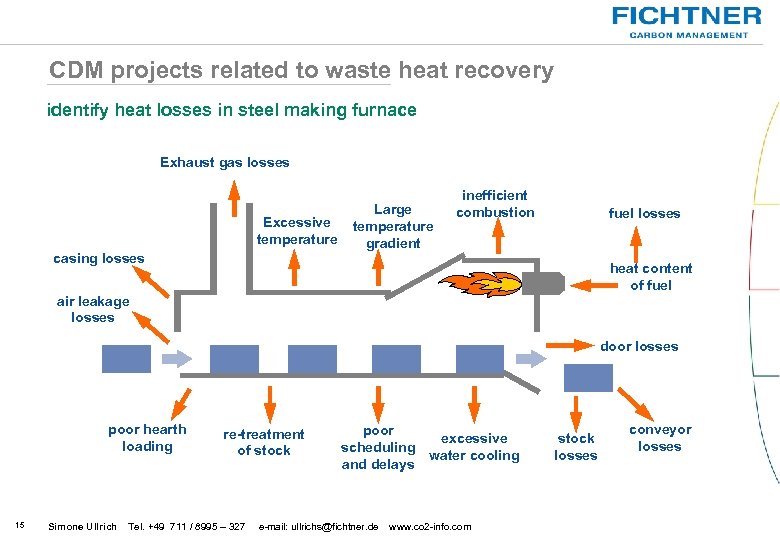

CDM projects related to waste heat recovery identify heat losses in steel making furnace Exhaust gas losses Excessive temperature casing losses Large temperature gradient inefficient combustion fuel losses heat content of fuel air leakage losses door losses poor hearth loading 15 Simone Ullrich re-treatment of stock Tel. +49 711 / 8995 – 327 poor scheduling and delays e-mail: ullrichs@fichtner. de excessive water cooling www. co 2 -info. com stock losses conveyor losses

CDM projects related to waste heat recovery identify heat losses in steel making furnace Exhaust gas losses Excessive temperature casing losses Large temperature gradient inefficient combustion fuel losses heat content of fuel air leakage losses door losses poor hearth loading 15 Simone Ullrich re-treatment of stock Tel. +49 711 / 8995 – 327 poor scheduling and delays e-mail: ullrichs@fichtner. de excessive water cooling www. co 2 -info. com stock losses conveyor losses

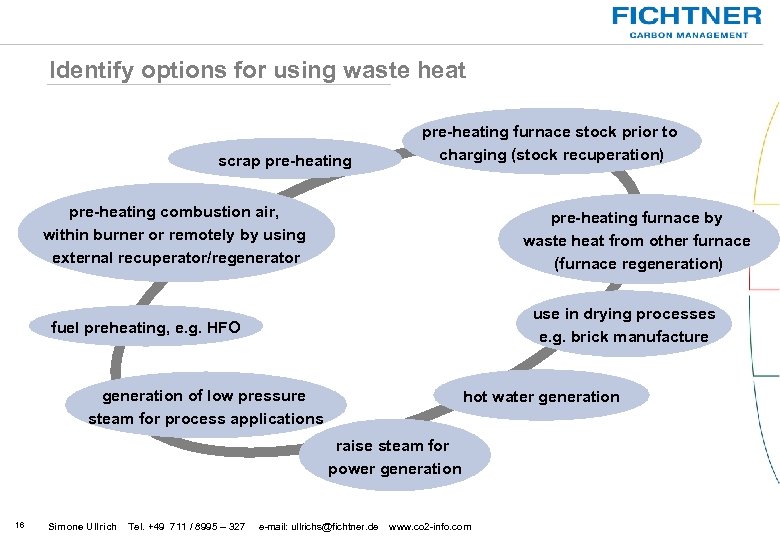

Identify options for using waste heat scrap pre-heating furnace stock prior to charging (stock recuperation) pre-heating combustion air, within burner or remotely by using external recuperator/regenerator pre-heating furnace by waste heat from other furnace (furnace regeneration) use in drying processes e. g. brick manufacture fuel preheating, e. g. HFO generation of low pressure steam for process applications hot water generation raise steam for power generation 16 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

Identify options for using waste heat scrap pre-heating furnace stock prior to charging (stock recuperation) pre-heating combustion air, within burner or remotely by using external recuperator/regenerator pre-heating furnace by waste heat from other furnace (furnace regeneration) use in drying processes e. g. brick manufacture fuel preheating, e. g. HFO generation of low pressure steam for process applications hot water generation raise steam for power generation 16 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

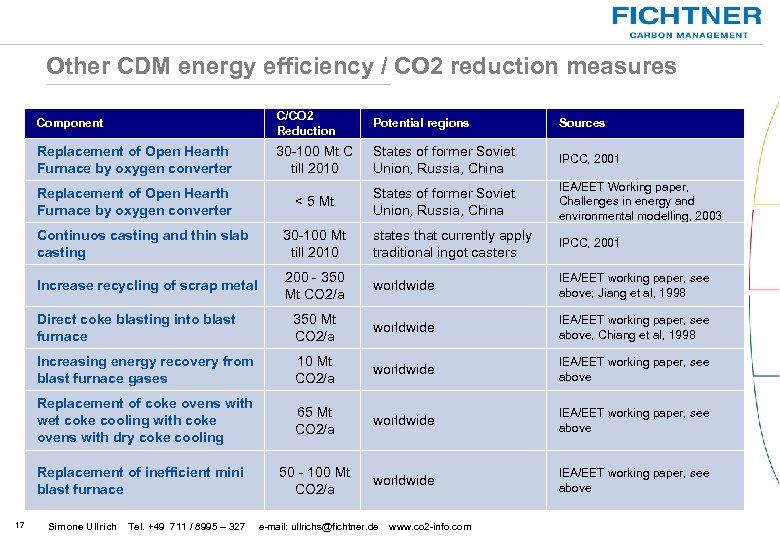

Other CDM energy efficiency / CO 2 reduction measures Component C/CO 2 Reduction Potential regions Sources Replacement of Open Hearth Furnace by oxygen converter 30 -100 Mt C till 2010 States of former Soviet Union, Russia, China IPCC, 2001 < 5 Mt States of former Soviet Union, Russia, China IEA/EET Working paper, Challenges in energy and environmental modelling, 2003 Replacement of Open Hearth Furnace by oxygen converter Continuos casting and thin slab casting 30 -100 Mt till 2010 states that currently apply traditional ingot casters IPCC, 2001 Increase recycling of scrap metal 200 - 350 Mt CO 2/a worldwide IEA/EET working paper, see above; Jiang et al, 1998 Direct coke blasting into blast furnace 350 Mt CO 2/a worldwide IEA/EET working paper, see above, Chiang et al, 1998 Increasing energy recovery from blast furnace gases 10 Mt CO 2/a worldwide IEA/EET working paper, see above Replacement of coke ovens with wet coke cooling with coke ovens with dry coke cooling 65 Mt CO 2/a worldwide IEA/EET working paper, see above 50 - 100 Mt CO 2/a worldwide IEA/EET working paper, see above Replacement of inefficient mini blast furnace 17 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

Other CDM energy efficiency / CO 2 reduction measures Component C/CO 2 Reduction Potential regions Sources Replacement of Open Hearth Furnace by oxygen converter 30 -100 Mt C till 2010 States of former Soviet Union, Russia, China IPCC, 2001 < 5 Mt States of former Soviet Union, Russia, China IEA/EET Working paper, Challenges in energy and environmental modelling, 2003 Replacement of Open Hearth Furnace by oxygen converter Continuos casting and thin slab casting 30 -100 Mt till 2010 states that currently apply traditional ingot casters IPCC, 2001 Increase recycling of scrap metal 200 - 350 Mt CO 2/a worldwide IEA/EET working paper, see above; Jiang et al, 1998 Direct coke blasting into blast furnace 350 Mt CO 2/a worldwide IEA/EET working paper, see above, Chiang et al, 1998 Increasing energy recovery from blast furnace gases 10 Mt CO 2/a worldwide IEA/EET working paper, see above Replacement of coke ovens with wet coke cooling with coke ovens with dry coke cooling 65 Mt CO 2/a worldwide IEA/EET working paper, see above 50 - 100 Mt CO 2/a worldwide IEA/EET working paper, see above Replacement of inefficient mini blast furnace 17 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

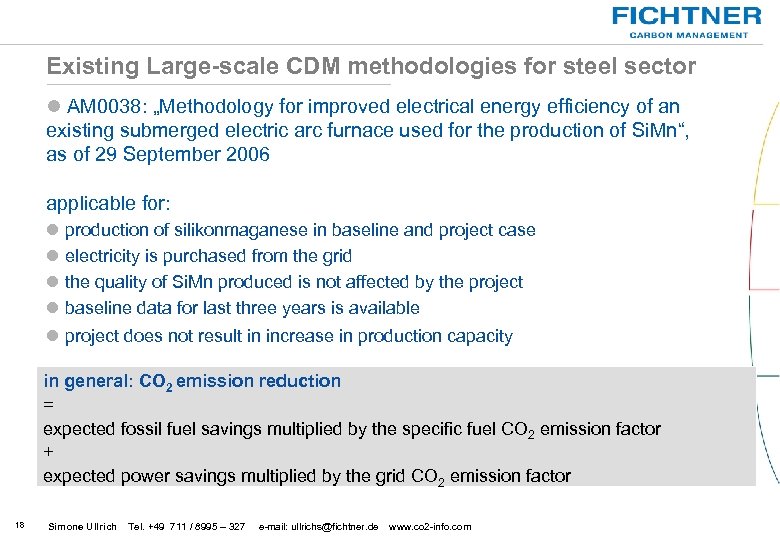

Existing Large-scale CDM methodologies for steel sector l AM 0038: „Methodology for improved electrical energy efficiency of an existing submerged electric arc furnace used for the production of Si. Mn“, as of 29 September 2006 applicable for: l production of silikonmaganese in baseline and project case l electricity is purchased from the grid l the quality of Si. Mn produced is not affected by the project l baseline data for last three years is available l project does not result in increase in production capacity in general: CO 2 emission reduction = expected fossil fuel savings multiplied by the specific fuel CO 2 emission factor + expected power savings multiplied by the grid CO 2 emission factor 18 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

Existing Large-scale CDM methodologies for steel sector l AM 0038: „Methodology for improved electrical energy efficiency of an existing submerged electric arc furnace used for the production of Si. Mn“, as of 29 September 2006 applicable for: l production of silikonmaganese in baseline and project case l electricity is purchased from the grid l the quality of Si. Mn produced is not affected by the project l baseline data for last three years is available l project does not result in increase in production capacity in general: CO 2 emission reduction = expected fossil fuel savings multiplied by the specific fuel CO 2 emission factor + expected power savings multiplied by the grid CO 2 emission factor 18 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

4 19 Regulations in the steel sector in China Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

4 19 Regulations in the steel sector in China Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

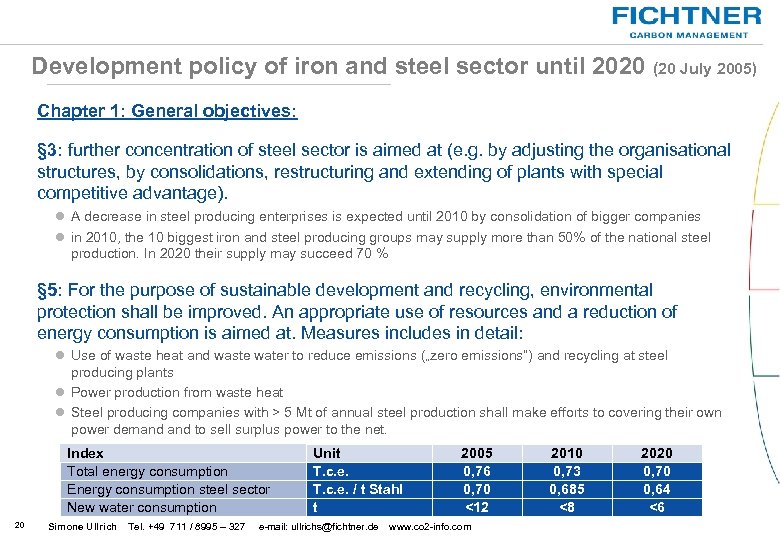

Development policy of iron and steel sector until 2020 (20 July 2005) Chapter 1: General objectives: § 3: further concentration of steel sector is aimed at (e. g. by adjusting the organisational structures, by consolidations, restructuring and extending of plants with special competitive advantage). l A decrease in steel producing enterprises is expected until 2010 by consolidation of bigger companies l in 2010, the 10 biggest iron and steel producing groups may supply more than 50% of the national steel production. In 2020 their supply may succeed 70 % § 5: For the purpose of sustainable development and recycling, environmental protection shall be improved. An appropriate use of resources and a reduction of energy consumption is aimed at. Measures includes in detail: l Use of waste heat and waste water to reduce emissions („zero emissions“) and recycling at steel producing plants l Power production from waste heat l Steel producing companies with > 5 Mt of annual steel production shall make efforts to covering their own power demand to sell surplus power to the net. Index Total energy consumption Energy consumption steel sector New water consumption 20 Simone Ullrich Tel. +49 711 / 8995 – 327 Unit T. c. e. / t Stahl t e-mail: ullrichs@fichtner. de 2005 0, 76 0, 70 <12 www. co 2 -info. com 2010 0, 73 0, 685 <8 2020 0, 70 0, 64 <6

Development policy of iron and steel sector until 2020 (20 July 2005) Chapter 1: General objectives: § 3: further concentration of steel sector is aimed at (e. g. by adjusting the organisational structures, by consolidations, restructuring and extending of plants with special competitive advantage). l A decrease in steel producing enterprises is expected until 2010 by consolidation of bigger companies l in 2010, the 10 biggest iron and steel producing groups may supply more than 50% of the national steel production. In 2020 their supply may succeed 70 % § 5: For the purpose of sustainable development and recycling, environmental protection shall be improved. An appropriate use of resources and a reduction of energy consumption is aimed at. Measures includes in detail: l Use of waste heat and waste water to reduce emissions („zero emissions“) and recycling at steel producing plants l Power production from waste heat l Steel producing companies with > 5 Mt of annual steel production shall make efforts to covering their own power demand to sell surplus power to the net. Index Total energy consumption Energy consumption steel sector New water consumption 20 Simone Ullrich Tel. +49 711 / 8995 – 327 Unit T. c. e. / t Stahl t e-mail: ullrichs@fichtner. de 2005 0, 76 0, 70 <12 www. co 2 -info. com 2010 0, 73 0, 685 <8 2020 0, 70 0, 64 <6

Further developing goals in the steel sector Chapter 10: l No establishment of new Integrated steelworks l Steel production shall be restructured l The construction of separated steel rolling mills is not recommended l Possible extension of existing plants by mergers in areas with competitive advantages (water resources, raw material availability, transportation infrastructure for resource delivery) l New capacity shall replace old production capacities l No expansion of steel production in vulnerable areas (such as areas with scarce water resources as well as metropolitan areas) l Companies located in vulnerable areas are urged to reduce their steel production or shift it to meet the developing statutory requirements of nature and environmental protection. 21 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

Further developing goals in the steel sector Chapter 10: l No establishment of new Integrated steelworks l Steel production shall be restructured l The construction of separated steel rolling mills is not recommended l Possible extension of existing plants by mergers in areas with competitive advantages (water resources, raw material availability, transportation infrastructure for resource delivery) l New capacity shall replace old production capacities l No expansion of steel production in vulnerable areas (such as areas with scarce water resources as well as metropolitan areas) l Companies located in vulnerable areas are urged to reduce their steel production or shift it to meet the developing statutory requirements of nature and environmental protection. 21 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

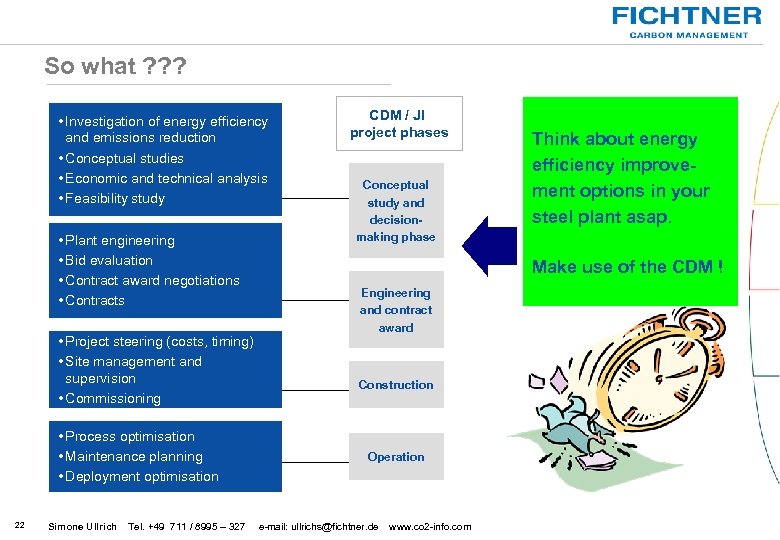

So what ? ? ? Investigation of energy efficiency and emissions reduction Conceptual studies Economic and technical analysis Feasibility study Plant engineering Bid evaluation Contract award negotiations Contracts Project steering (costs, timing) Site management and supervision Commissioning Process optimisation Maintenance planning Deployment optimisation 22 Simone Ullrich Tel. +49 711 / 8995 – 327 CDM / JI project phases Conceptual study and decisionmaking phase Think about energy efficiency improvement options in your steel plant asap. Make use of the CDM ! Engineering and contract award Construction Operation e-mail: ullrichs@fichtner. de www. co 2 -info. com

So what ? ? ? Investigation of energy efficiency and emissions reduction Conceptual studies Economic and technical analysis Feasibility study Plant engineering Bid evaluation Contract award negotiations Contracts Project steering (costs, timing) Site management and supervision Commissioning Process optimisation Maintenance planning Deployment optimisation 22 Simone Ullrich Tel. +49 711 / 8995 – 327 CDM / JI project phases Conceptual study and decisionmaking phase Think about energy efficiency improvement options in your steel plant asap. Make use of the CDM ! Engineering and contract award Construction Operation e-mail: ullrichs@fichtner. de www. co 2 -info. com

HFC CO 2 Thank you for your attention ! N 2 O PFC CH 4 SF 6 FICHTNER Fichtner Gmb. H & Co. KG Sarweystr. 3 70191 Stuttgart / Germany www. fichtner. de Simone Ullrich Nino Turek Martin Hollnaicher CDM & JI Expert Business Development CDM / JI Phone: +49 (0) 711 8995 -327 Fax: +49 (0)711 8995 -459 E-mail: ullrichs@fichtner. de Phone: +49 (0) 711 8995 -746 Fax: +49 (0)711 8995 -459 E-mail: turekn@fichtner. de Director Business Development East Asia Phone: +49 (0) 711 8995 -575 Fax: +49 (0)711 8995 -459 E-mail: hollnaicherm@fichtner. de www. co 2 -info. com 23 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

HFC CO 2 Thank you for your attention ! N 2 O PFC CH 4 SF 6 FICHTNER Fichtner Gmb. H & Co. KG Sarweystr. 3 70191 Stuttgart / Germany www. fichtner. de Simone Ullrich Nino Turek Martin Hollnaicher CDM & JI Expert Business Development CDM / JI Phone: +49 (0) 711 8995 -327 Fax: +49 (0)711 8995 -459 E-mail: ullrichs@fichtner. de Phone: +49 (0) 711 8995 -746 Fax: +49 (0)711 8995 -459 E-mail: turekn@fichtner. de Director Business Development East Asia Phone: +49 (0) 711 8995 -575 Fax: +49 (0)711 8995 -459 E-mail: hollnaicherm@fichtner. de www. co 2 -info. com 23 Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

A 24 Annex Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

A 24 Annex Simone Ullrich Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com

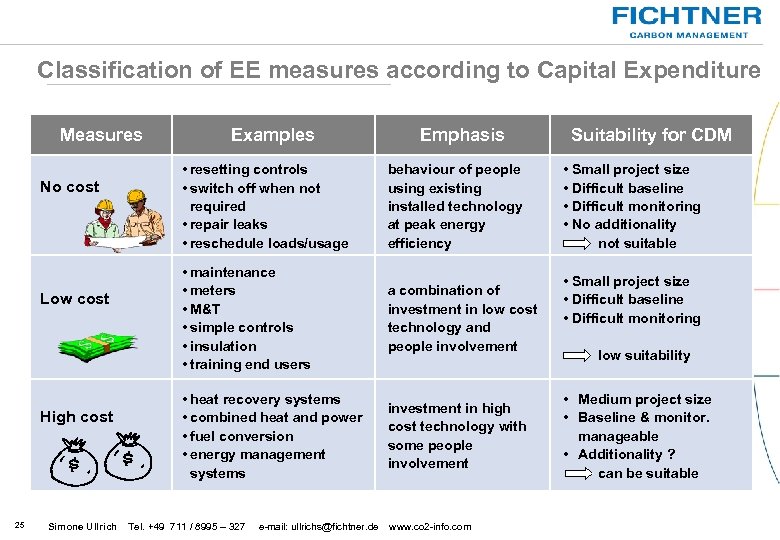

Classification of EE measures according to Capital Expenditure Measures No cost Low cost High cost 25 Simone Ullrich Examples Emphasis • resetting controls • switch off when not required • repair leaks • reschedule loads/usage behaviour of people using existing installed technology at peak energy efficiency • maintenance • meters • M&T • simple controls • insulation • training end users a combination of investment in low cost technology and people involvement • heat recovery systems • combined heat and power • fuel conversion • energy management systems investment in high cost technology with some people involvement Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com Suitability for CDM • Small project size • Difficult baseline • Difficult monitoring • No additionality not suitable • Small project size • Difficult baseline • Difficult monitoring low suitability • Medium project size • Baseline & monitor. manageable • Additionality ? can be suitable

Classification of EE measures according to Capital Expenditure Measures No cost Low cost High cost 25 Simone Ullrich Examples Emphasis • resetting controls • switch off when not required • repair leaks • reschedule loads/usage behaviour of people using existing installed technology at peak energy efficiency • maintenance • meters • M&T • simple controls • insulation • training end users a combination of investment in low cost technology and people involvement • heat recovery systems • combined heat and power • fuel conversion • energy management systems investment in high cost technology with some people involvement Tel. +49 711 / 8995 – 327 e-mail: ullrichs@fichtner. de www. co 2 -info. com Suitability for CDM • Small project size • Difficult baseline • Difficult monitoring • No additionality not suitable • Small project size • Difficult baseline • Difficult monitoring low suitability • Medium project size • Baseline & monitor. manageable • Additionality ? can be suitable