981abd1df6550a84385506f677a7a155.ppt

- Количество слайдов: 38

CMTF Cryogenics (status and plans) SRF program and AD/Cryogenics work presented by Arkadiy Klebaner May 21, 2013

CMTF Cryogenics (status and plans) SRF program and AD/Cryogenics work presented by Arkadiy Klebaner May 21, 2013

Outline • CMTF cryogenic system • Key system elements • CMTF work • Project X Cryogenics R&D • Current priorities • Summary Slide 2

Outline • CMTF cryogenic system • Key system elements • CMTF work • Project X Cryogenics R&D • Current priorities • Summary Slide 2

CMTF Cryogenics • Scope – Cryogenic plants, associated auxiliary equipment, and distribution systems in support of PXIE and Cryomodule Test Stands • Refrigerators – CTI - 4000 refrigerator (SLAC) Ø Will support CM test stands – ARRA funded Superfluid Cryogenic Plant (by Linde) Ø Will support PXIE or CM test stands Slide 3

CMTF Cryogenics • Scope – Cryogenic plants, associated auxiliary equipment, and distribution systems in support of PXIE and Cryomodule Test Stands • Refrigerators – CTI - 4000 refrigerator (SLAC) Ø Will support CM test stands – ARRA funded Superfluid Cryogenic Plant (by Linde) Ø Will support PXIE or CM test stands Slide 3

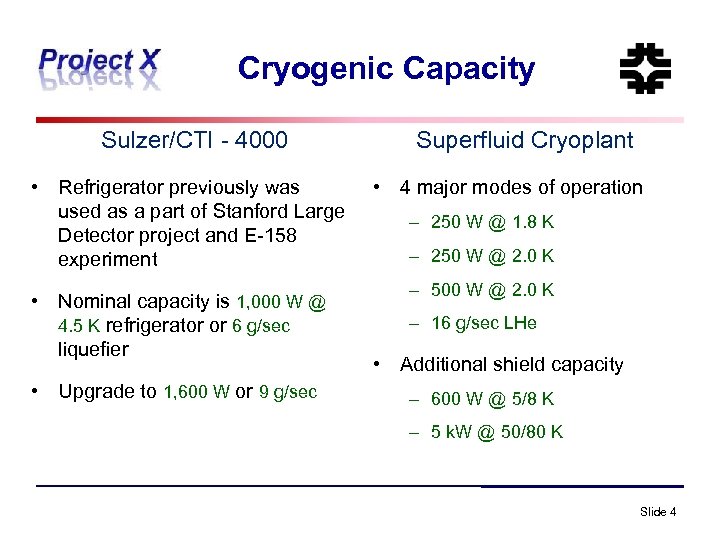

Cryogenic Capacity Sulzer/CTI - 4000 • Refrigerator previously was used as a part of Stanford Large Detector project and E-158 experiment • Nominal capacity is 1, 000 W @ 4. 5 K refrigerator or 6 g/sec liquefier • Upgrade to 1, 600 W or 9 g/sec Superfluid Cryoplant • 4 major modes of operation – 250 W @ 1. 8 K – 250 W @ 2. 0 K – 500 W @ 2. 0 K – 16 g/sec LHe • Additional shield capacity – 600 W @ 5/8 K – 5 k. W @ 50/80 K Slide 4

Cryogenic Capacity Sulzer/CTI - 4000 • Refrigerator previously was used as a part of Stanford Large Detector project and E-158 experiment • Nominal capacity is 1, 000 W @ 4. 5 K refrigerator or 6 g/sec liquefier • Upgrade to 1, 600 W or 9 g/sec Superfluid Cryoplant • 4 major modes of operation – 250 W @ 1. 8 K – 250 W @ 2. 0 K – 500 W @ 2. 0 K – 16 g/sec LHe • Additional shield capacity – 600 W @ 5/8 K – 5 k. W @ 50/80 K Slide 4

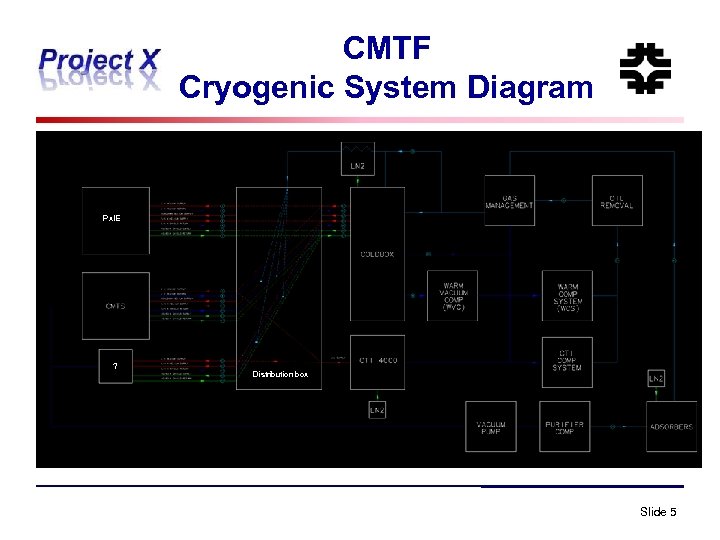

CMTF Cryogenic System Diagram Px. IE ? Distribution box Slide 5

CMTF Cryogenic System Diagram Px. IE ? Distribution box Slide 5

Key elements • • • Warm Compressor System Distribution box Vacuum pumps and compressors CTI – 4000 Superfluid cryogenic plants (SCP) Slide 6

Key elements • • • Warm Compressor System Distribution box Vacuum pumps and compressors CTI – 4000 Superfluid cryogenic plants (SCP) Slide 6

Warm Compressor System Slide 7

Warm Compressor System Slide 7

Warm Compressor System • Pre- commissioning – Jan 25, 2013 Received ORC – Feb 13, 2013 Preparing for commissioning startup • Commissioning: – – – • Feb 14, 2013 Started commissioning Feb 20, 2013 Completed commissioning of “purifier” compressor #7 Feb 22, 2013 Completed commissioning of compressors #4 and #5 Feb 26, 2013 Completed commissioning of compressor #6 Mar 01, 2013 Commissioning completed Post commissioning: – May 6, 2013 Completed helium purification – Current Checking oil content as a function of discharge pressure Slide 8

Warm Compressor System • Pre- commissioning – Jan 25, 2013 Received ORC – Feb 13, 2013 Preparing for commissioning startup • Commissioning: – – – • Feb 14, 2013 Started commissioning Feb 20, 2013 Completed commissioning of “purifier” compressor #7 Feb 22, 2013 Completed commissioning of compressors #4 and #5 Feb 26, 2013 Completed commissioning of compressor #6 Mar 01, 2013 Commissioning completed Post commissioning: – May 6, 2013 Completed helium purification – Current Checking oil content as a function of discharge pressure Slide 8

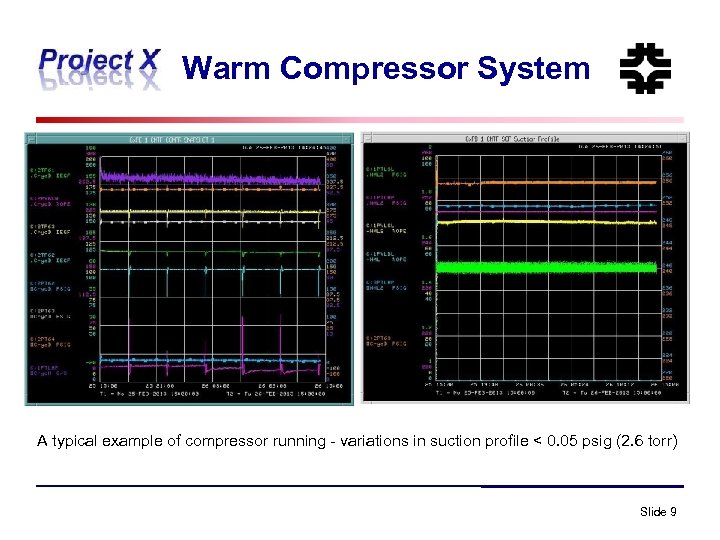

Warm Compressor System A typical example of compressor running - variations in suction profile < 0. 05 psig (2. 6 torr) Slide 9

Warm Compressor System A typical example of compressor running - variations in suction profile < 0. 05 psig (2. 6 torr) Slide 9

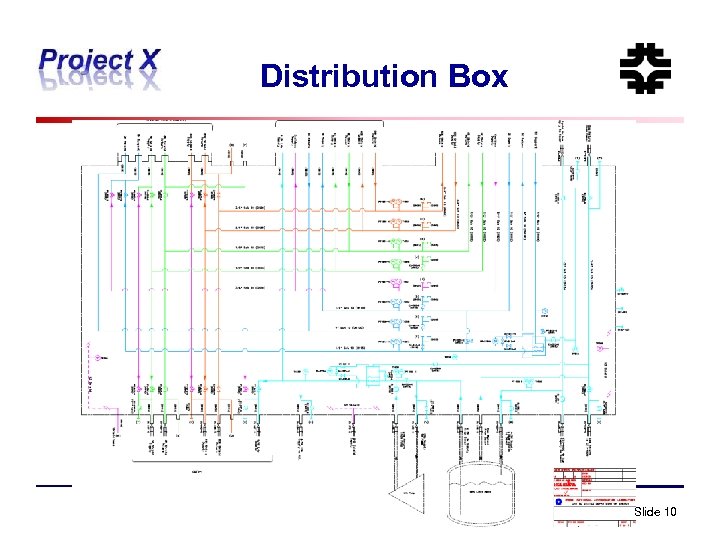

Distribution Box Slide 10

Distribution Box Slide 10

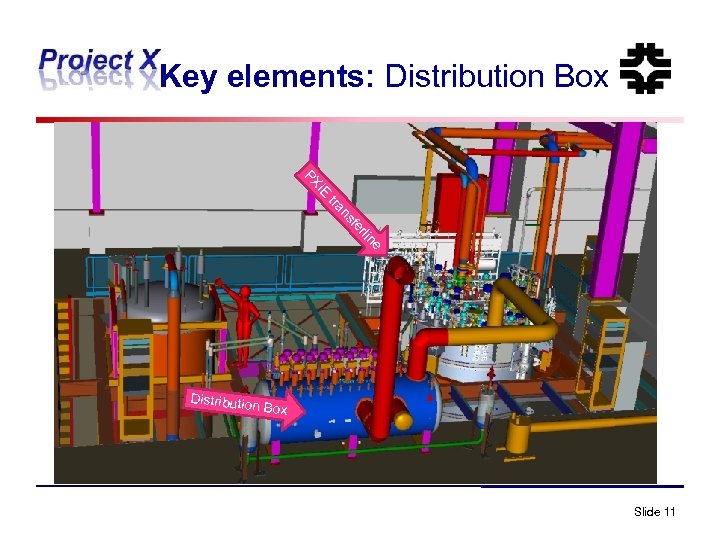

Key elements: Distribution Box PX IE rli fe ns tra ne Distributio n Box Slide 11

Key elements: Distribution Box PX IE rli fe ns tra ne Distributio n Box Slide 11

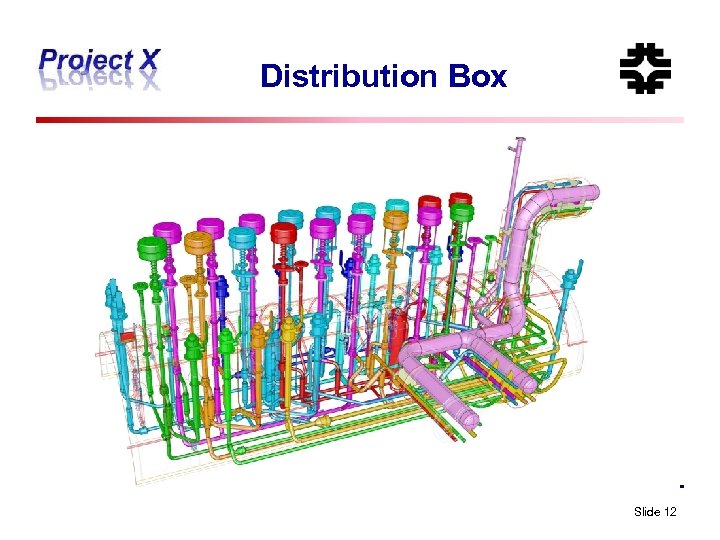

Distribution Box Slide 12

Distribution Box Slide 12

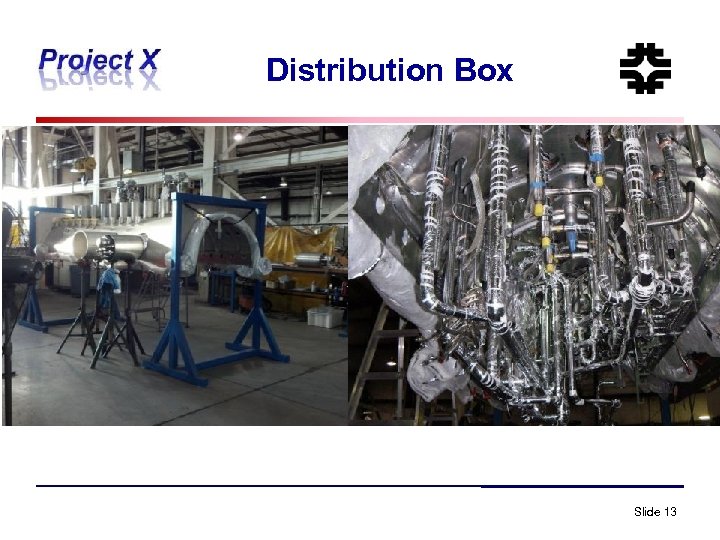

Distribution Box Slide 13

Distribution Box Slide 13

Distribution Box Slide 14

Distribution Box Slide 14

CTI – 4000 Refrigerator Modifications and Upgrades • Two new Fermilab style bayonets added for Wet Engine Expander to increase refrigeration/liquefaction capacity • Internal Adsorber Re-certified to higher 285 psig MAWP to increase overall process pressure and capacity • Fabricated u-tube jumper from BC-2 to BC-5 with bypass valve for cooldown and HX 1 -2 bypass interlock protection • Vacuum shell and support structure modification to allow disassembly of vacuum shell in pit for potential coldbox repairs • Turbines overhauled and upgraded to magnetically levitated bearings. Brake coolers replaced • Obtained Turbine Control Block for S 7 control and software interlocks/alarms. Began initial implementation into program Slide 15

CTI – 4000 Refrigerator Modifications and Upgrades • Two new Fermilab style bayonets added for Wet Engine Expander to increase refrigeration/liquefaction capacity • Internal Adsorber Re-certified to higher 285 psig MAWP to increase overall process pressure and capacity • Fabricated u-tube jumper from BC-2 to BC-5 with bypass valve for cooldown and HX 1 -2 bypass interlock protection • Vacuum shell and support structure modification to allow disassembly of vacuum shell in pit for potential coldbox repairs • Turbines overhauled and upgraded to magnetically levitated bearings. Brake coolers replaced • Obtained Turbine Control Block for S 7 control and software interlocks/alarms. Began initial implementation into program Slide 15

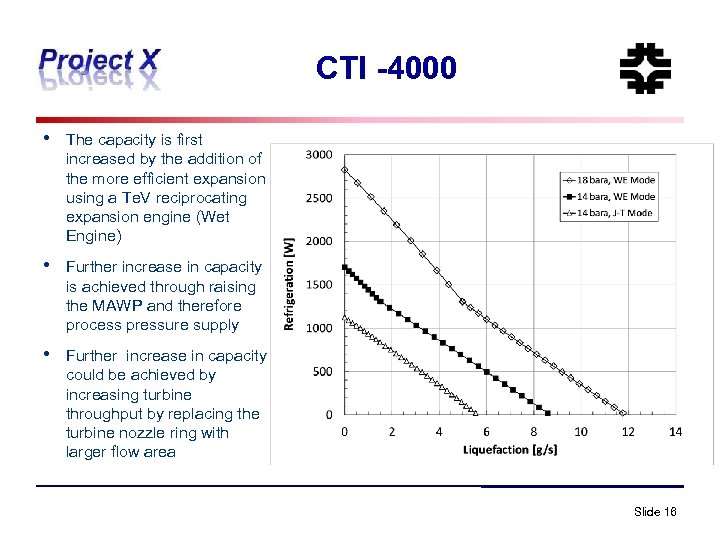

CTI -4000 • The capacity is first increased by the addition of the more efficient expansion using a Te. V reciprocating expansion engine (Wet Engine) • Further increase in capacity is achieved through raising the MAWP and therefore process pressure supply • Further increase in capacity could be achieved by increasing turbine throughput by replacing the turbine nozzle ring with larger flow area Slide 16

CTI -4000 • The capacity is first increased by the addition of the more efficient expansion using a Te. V reciprocating expansion engine (Wet Engine) • Further increase in capacity is achieved through raising the MAWP and therefore process pressure supply • Further increase in capacity could be achieved by increasing turbine throughput by replacing the turbine nozzle ring with larger flow area Slide 16

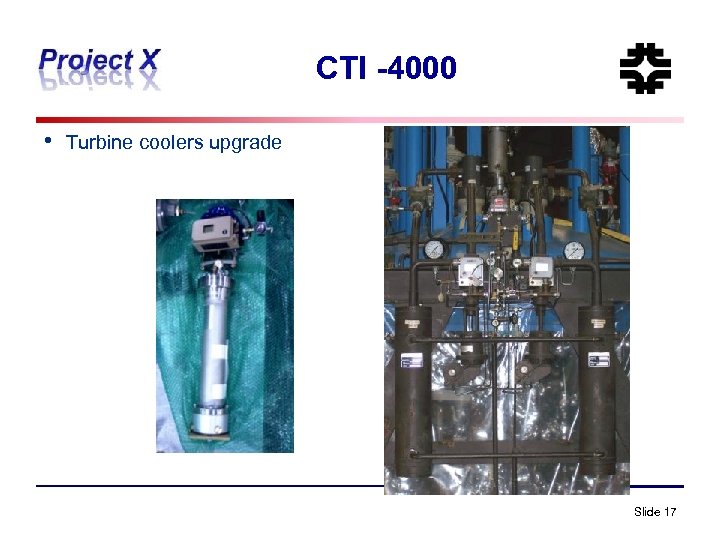

CTI -4000 • Turbine coolers upgrade Slide 17

CTI -4000 • Turbine coolers upgrade Slide 17

Vacuum Pump • Acquired two vacuum pump skids from SNS Slide 18

Vacuum Pump • Acquired two vacuum pump skids from SNS Slide 18

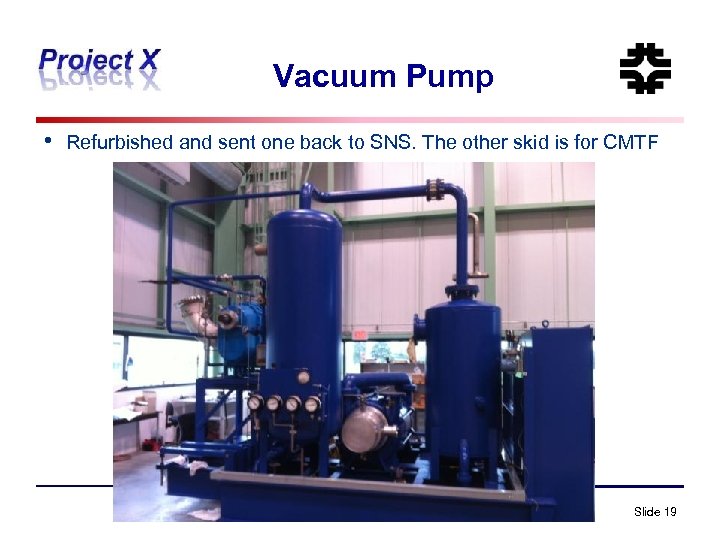

Vacuum Pump • Refurbished and sent one back to SNS. The other skid is for CMTF Slide 19

Vacuum Pump • Refurbished and sent one back to SNS. The other skid is for CMTF Slide 19

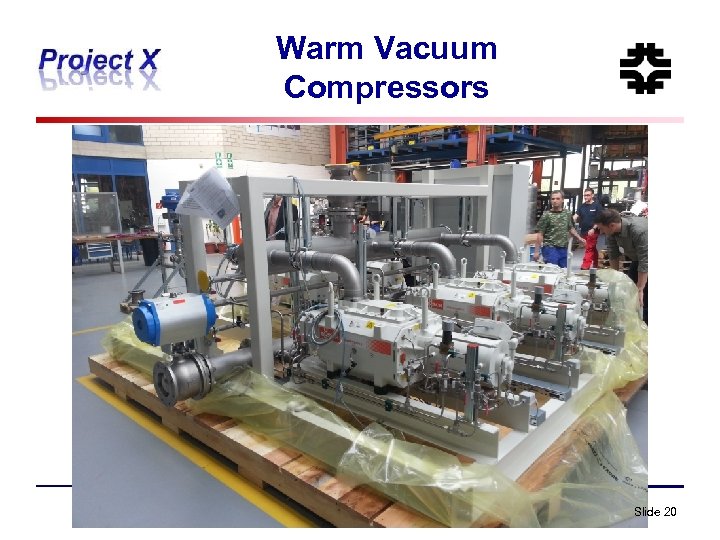

Warm Vacuum Compressors Slide 20

Warm Vacuum Compressors Slide 20

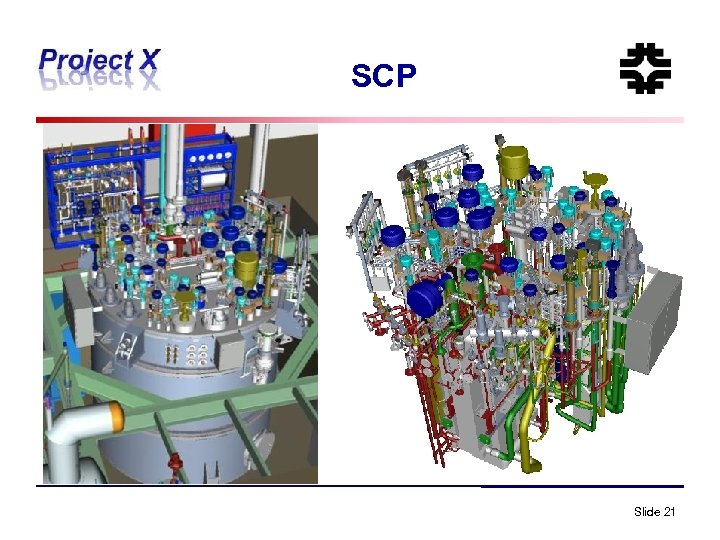

SCP Slide 21

SCP Slide 21

SCP Slide 22

SCP Slide 22

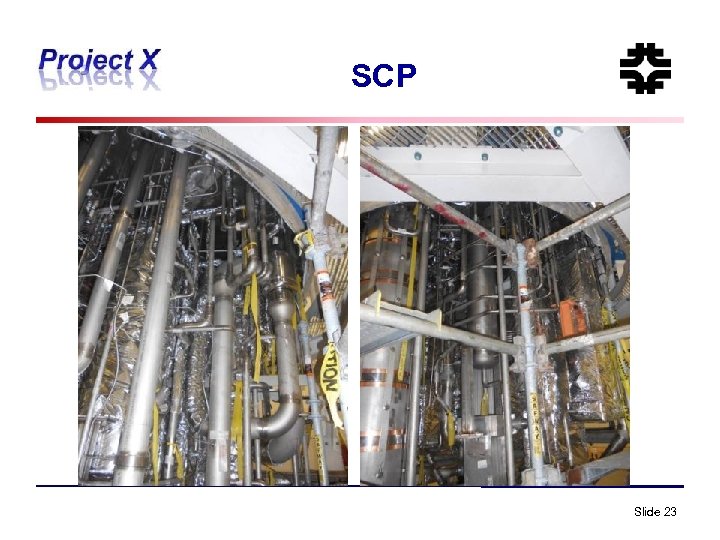

SCP Slide 23

SCP Slide 23

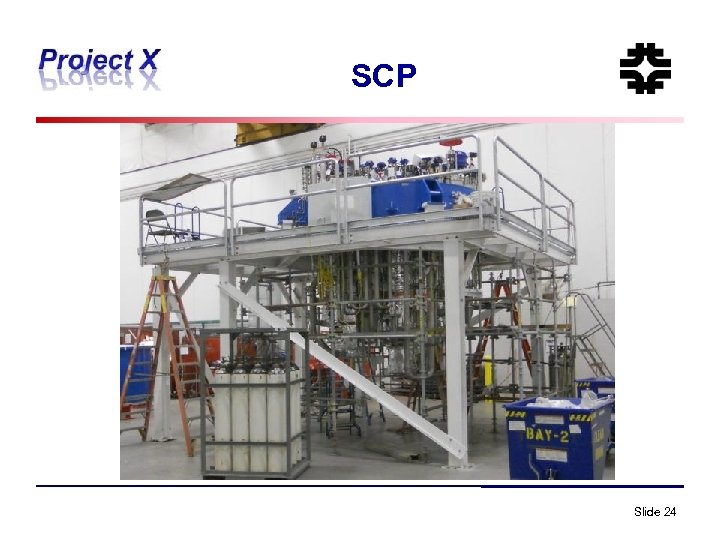

SCP Slide 24

SCP Slide 24

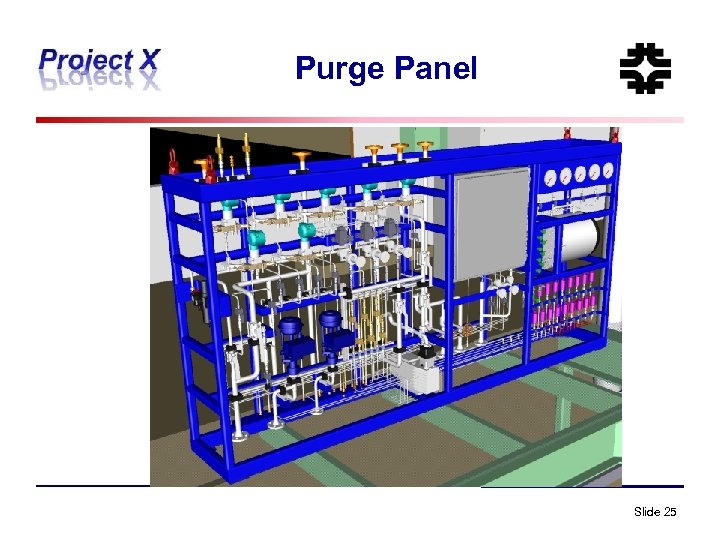

Purge Panel Slide 25

Purge Panel Slide 25

Purge Panel Slide 26

Purge Panel Slide 26

LHe Dewar Commissioning this month Slide 27

LHe Dewar Commissioning this month Slide 27

Controls Slide 28

Controls Slide 28

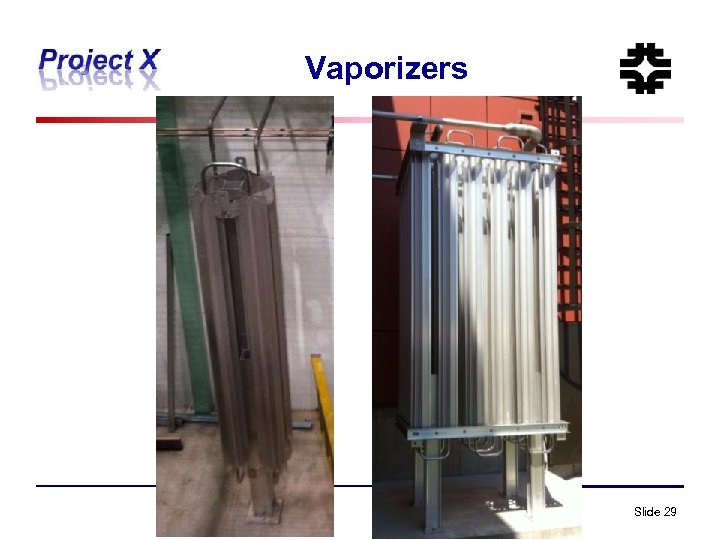

Vaporizers Slide 29

Vaporizers Slide 29

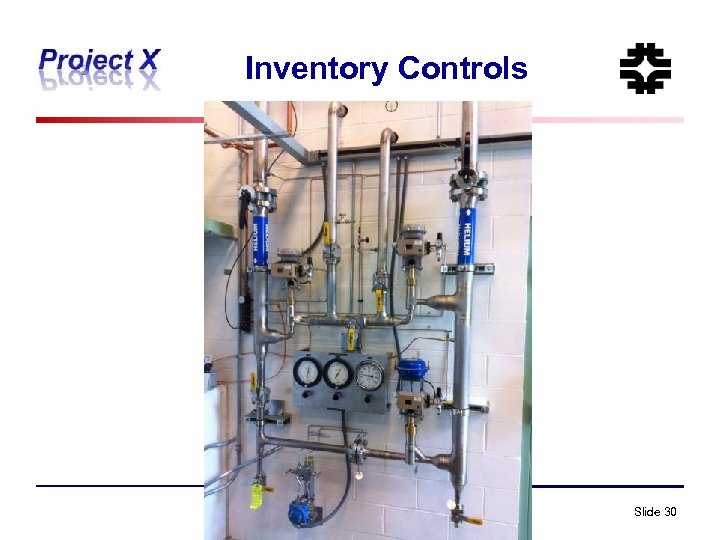

Inventory Controls Slide 30

Inventory Controls Slide 30

Gas Analyzers Slide 31

Gas Analyzers Slide 31

LN 2 System Slide 32

LN 2 System Slide 32

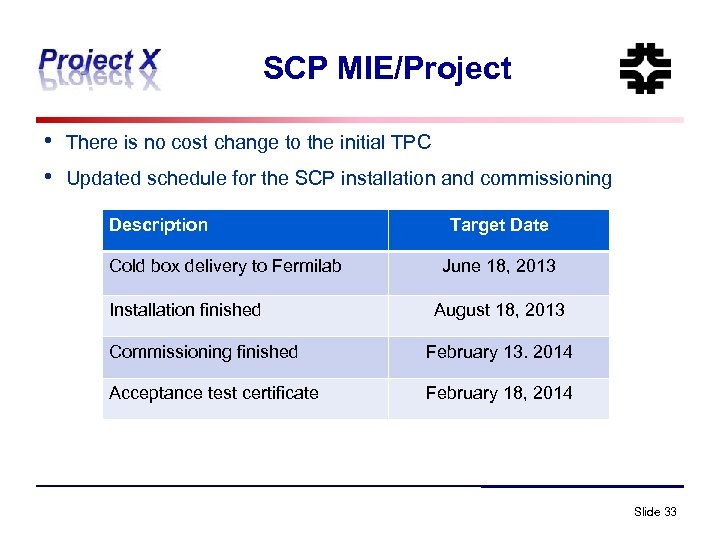

SCP MIE/Project • • There is no cost change to the initial TPC Updated schedule for the SCP installation and commissioning Description Cold box delivery to Fermilab Installation finished Target Date June 18, 2013 August 18, 2013 Commissioning finished February 13. 2014 Acceptance test certificate February 18, 2014 Slide 33

SCP MIE/Project • • There is no cost change to the initial TPC Updated schedule for the SCP installation and commissioning Description Cold box delivery to Fermilab Installation finished Target Date June 18, 2013 August 18, 2013 Commissioning finished February 13. 2014 Acceptance test certificate February 18, 2014 Slide 33

SCP • Vendor is working 7 days x 12 hours shift to meet delivery to Fermilab current deadline • Estimated time for installation and commissioning activities is based on 12 hrs shifts • Large amount of work by many groups is and will be happening in the next several month at CMTF • Concerted effort between Fermilab personal, T&M workers and Linde is essential to minimize cost and schedule risk Slide 34

SCP • Vendor is working 7 days x 12 hours shift to meet delivery to Fermilab current deadline • Estimated time for installation and commissioning activities is based on 12 hrs shifts • Large amount of work by many groups is and will be happening in the next several month at CMTF • Concerted effort between Fermilab personal, T&M workers and Linde is essential to minimize cost and schedule risk Slide 34

SCP • To reduce cost and schedule risks: – Installation plan and detailed commissioning schedule is finalized; – Installation team is formed; – Medical qualifications for the installation team are being collected; – FESHM Contractor safety is being addressed; – Weekly web based fabrication progress review meetings; – Bi-weekly fabrication site visits to the fabrication site; – Bi-weekly facility planning coordination meetings; – Bi-weekly CMTF layout coordination meetings; – Daily one-on-one meetings. Slide 35

SCP • To reduce cost and schedule risks: – Installation plan and detailed commissioning schedule is finalized; – Installation team is formed; – Medical qualifications for the installation team are being collected; – FESHM Contractor safety is being addressed; – Weekly web based fabrication progress review meetings; – Bi-weekly fabrication site visits to the fabrication site; – Bi-weekly facility planning coordination meetings; – Bi-weekly CMTF layout coordination meetings; – Daily one-on-one meetings. Slide 35

Project X R&D Active pursued goals (for details see PXIE handbook, chapter on Cryogenics ) 1. Develop cryogenic system control strategies for all modes of operation, including RF On/RF Off modes 2. Develop design solutions and control algorithms to minimize helium pressure fluctuation 3. Develop expertise in operating cryogenic turbo expanders with gas bearings, oil free warm vacuum pumps, and cold compressors Improve expertise in cryogenic process and component design 5. Develop expertise in defining multi stage cold compressors train hydrodynamic field 4. 6. Improve the Project X cryogenic system acquisition strategy and cost estimate based on the procurement experience with PXIE cryogenic system 7. Improve capacity margin estimate for Project X cryogenic system 8. Develop engineering and technical expertise in support of the Project X superfluid cryogenic system design and operation Slide 36

Project X R&D Active pursued goals (for details see PXIE handbook, chapter on Cryogenics ) 1. Develop cryogenic system control strategies for all modes of operation, including RF On/RF Off modes 2. Develop design solutions and control algorithms to minimize helium pressure fluctuation 3. Develop expertise in operating cryogenic turbo expanders with gas bearings, oil free warm vacuum pumps, and cold compressors Improve expertise in cryogenic process and component design 5. Develop expertise in defining multi stage cold compressors train hydrodynamic field 4. 6. Improve the Project X cryogenic system acquisition strategy and cost estimate based on the procurement experience with PXIE cryogenic system 7. Improve capacity margin estimate for Project X cryogenic system 8. Develop engineering and technical expertise in support of the Project X superfluid cryogenic system design and operation Slide 36

Priorities 1. Commission SCP and close out ARRA/MIE project 2. Install CTI-4000 (so that additional infrastructure work can continue) 3. Design PXIE cryogenic distribution system – Work with HWR CM (ANL) and SSR 1 CM (TD) teams to assure proper integration – Need to incorporate CMTS 1 requirements for future work 4. Construct PXIE cryo distribution system – Ready for CM testing in ~2016 5. Prepare for CMTS 1 construction so that distribution system is ready when required – 1. 3 GHz Cryo boxes (from BARC) arrive – for test (~late 2015/2016) – Need to be able to test 650 MHz 6 cavity CM in 2017 time frame (pre-CD 3) 6. Connect CMTF CTI - 4000 to NML Slide 37

Priorities 1. Commission SCP and close out ARRA/MIE project 2. Install CTI-4000 (so that additional infrastructure work can continue) 3. Design PXIE cryogenic distribution system – Work with HWR CM (ANL) and SSR 1 CM (TD) teams to assure proper integration – Need to incorporate CMTS 1 requirements for future work 4. Construct PXIE cryo distribution system – Ready for CM testing in ~2016 5. Prepare for CMTS 1 construction so that distribution system is ready when required – 1. 3 GHz Cryo boxes (from BARC) arrive – for test (~late 2015/2016) – Need to be able to test 650 MHz 6 cavity CM in 2017 time frame (pre-CD 3) 6. Connect CMTF CTI - 4000 to NML Slide 37

Summary • Project X Cryogenic R&D work is progressing • Current focus is on the Superfluid Cryogenic Plant • Basic engineering design work on PXIE distribution system has started Slide 38

Summary • Project X Cryogenic R&D work is progressing • Current focus is on the Superfluid Cryogenic Plant • Basic engineering design work on PXIE distribution system has started Slide 38