23f11444dba952d9aec89e6ff06bf8f5.ppt

- Количество слайдов: 39

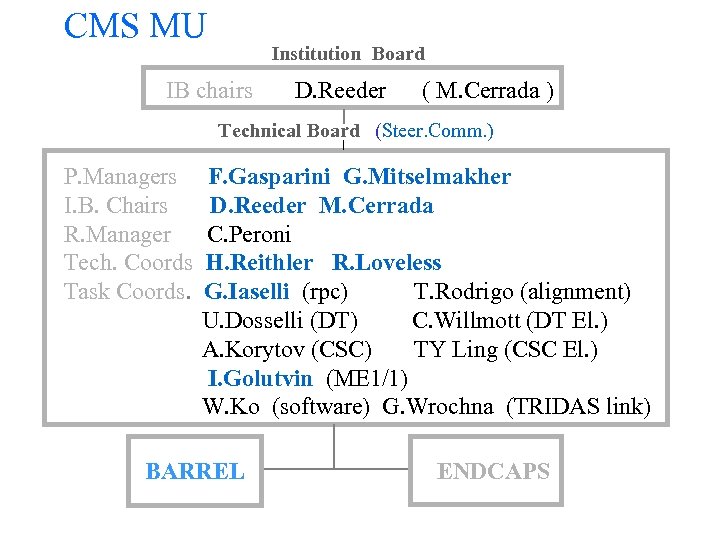

CMS MU Institution Board IB chairs D. Reeder ( M. Cerrada ) Technical Board (Steer. Comm. ) P. Managers I. B. Chairs R. Manager Tech. Coords Task Coords. F. Gasparini G. Mitselmakher D. Reeder M. Cerrada C. Peroni H. Reithler R. Loveless G. Iaselli (rpc) T. Rodrigo (alignment) U. Dosselli (DT) C. Willmott (DT El. ) A. Korytov (CSC) TY Ling (CSC El. ) I. Golutvin (ME 1/1) W. Ko (software) G. Wrochna (TRIDAS link) BARREL ENDCAPS

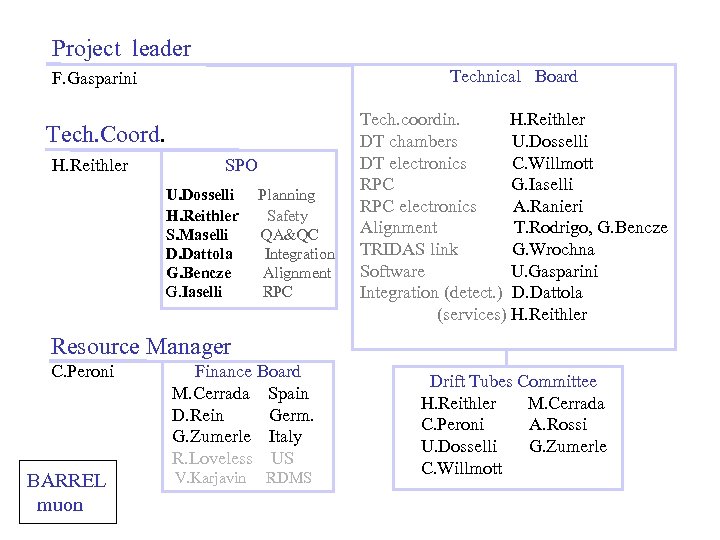

Project leader Technical Board F. Gasparini Tech. Coord. H. Reithler SPO U. Dosselli H. Reithler S. Maselli D. Dattola G. Bencze G. Iaselli Planning Safety QA&QC Integration Alignment RPC Tech. coordin. H. Reithler DT chambers U. Dosselli DT electronics C. Willmott RPC G. Iaselli RPC electronics A. Ranieri Alignment T. Rodrigo, G. Bencze TRIDAS link G. Wrochna Software U. Gasparini Integration (detect. ) D. Dattola (services) H. Reithler Resource Manager C. Peroni BARREL muon Finance Board M. Cerrada Spain D. Rein Germ. G. Zumerle Italy R. Loveless US V. Karjavin RDMS Drift Tubes Committee H. Reithler M. Cerrada C. Peroni A. Rossi U. Dosselli G. Zumerle C. Willmott

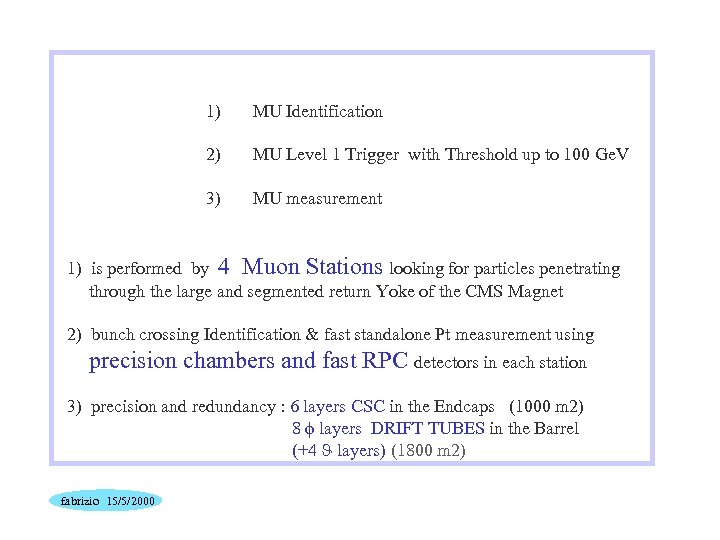

1) MU Identification 2) MU Level 1 Trigger with Threshold up to 100 Ge. V 3) MU measurement 1) is performed by 4 Muon Stations looking for particles penetrating through the large and segmented return Yoke of the CMS Magnet 2) bunch crossing Identification & fast standalone Pt measurement using precision chambers and fast RPC detectors in each station 3) precision and redundancy : 6 layers CSC in the Endcaps (1000 m 2) 8 layers DRIFT TUBES in the Barrel (+4 layers) (1800 m 2) fabrizio 15/5/2000

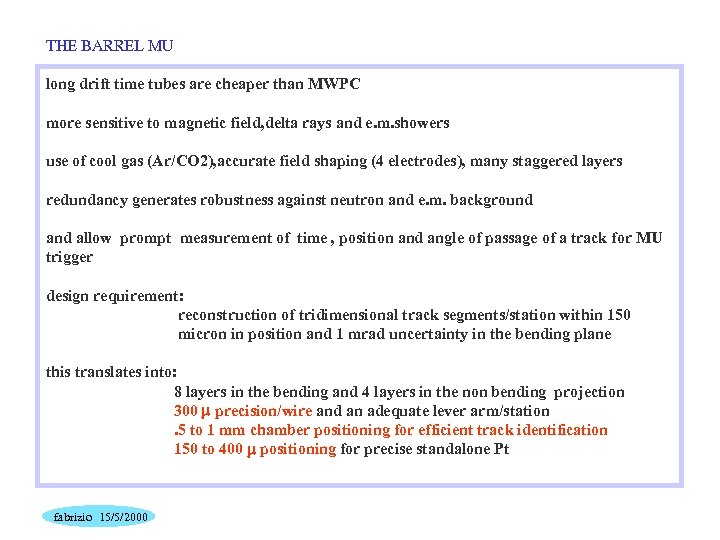

THE BARREL MU long drift time tubes are cheaper than MWPC more sensitive to magnetic field, delta rays and e. m. showers use of cool gas (Ar/CO 2), accurate field shaping (4 electrodes), many staggered layers redundancy generates robustness against neutron and e. m. background allow prompt measurement of time , position and angle of passage of a track for MU trigger design requirement: reconstruction of tridimensional track segments/station within 150 micron in position and 1 mrad uncertainty in the bending plane this translates into: 8 layers in the bending and 4 layers in the non bending projection 300 precision/wire and an adequate lever arm/station. 5 to 1 mm chamber positioning for efficient track identification 150 to 400 positioning for precise standalone Pt fabrizio 15/5/2000

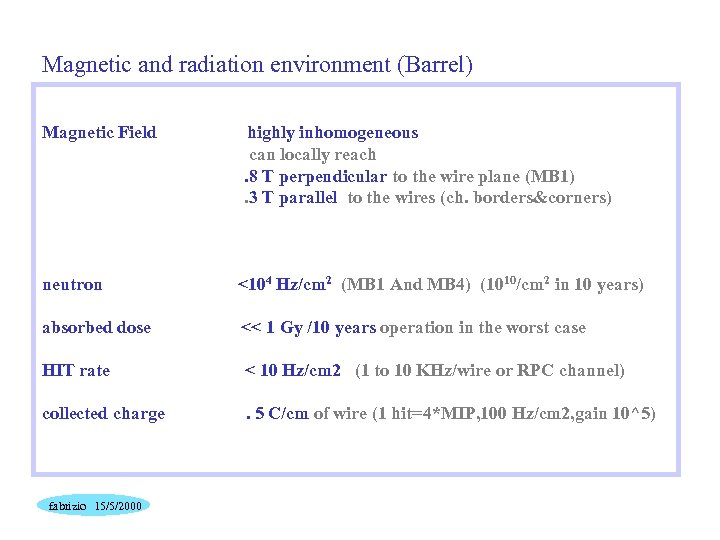

Magnetic and radiation environment (Barrel) Magnetic Field highly inhomogeneous can locally reach. 8 T perpendicular to the wire plane (MB 1). 3 T parallel to the wires (ch. borders&corners) neutron <104 Hz/cm 2 (MB 1 And MB 4) (1010/cm 2 in 10 years) absorbed dose << 1 Gy /10 years operation in the worst case HIT rate < 10 Hz/cm 2 (1 to 10 KHz/wire or RPC channel) collected charge . 5 C/cm of wire (1 hit=4*MIP, 100 Hz/cm 2, gain 10^5) fabrizio 15/5/2000

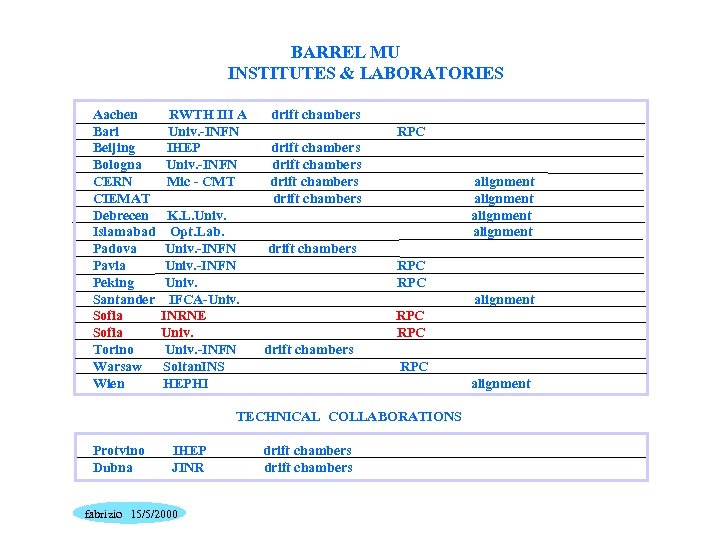

BARREL MU INSTITUTES & LABORATORIES Aachen Bari Beijing Bologna CERN CIEMAT Debrecen Islamabad Padova Pavia Peking Santander Sofia Torino Warsaw Wien RWTH III A Univ. -INFN IHEP Univ. -INFN Mic - CMT K. L. Univ. Opt. Lab. Univ. -INFN Univ. IFCA-Univ. INRNE Univ. -INFN Soltan. INS HEPHI drift chambers RPC drift chambers alignment drift chambers RPC alignment RPC drift chambers RPC alignment TECHNICAL COLLABORATIONS Protvino Dubna IHEP JINR fabrizio 15/5/2000 drift chambers

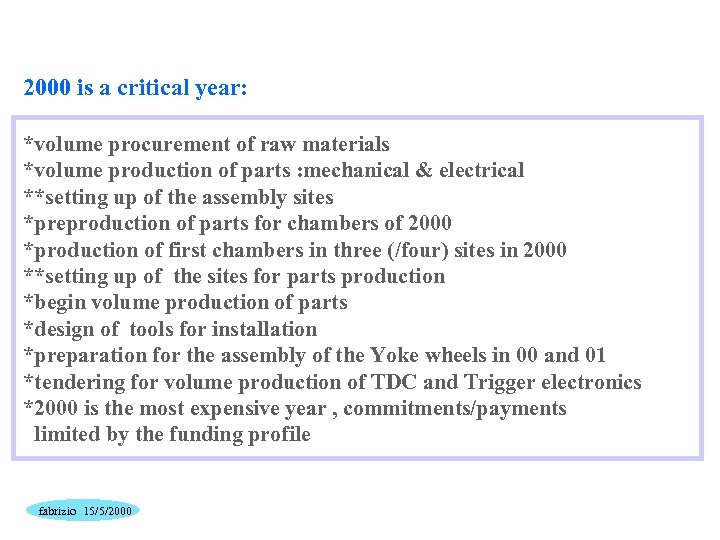

2000 is a critical year: *volume procurement of raw materials *volume production of parts : mechanical & electrical **setting up of the assembly sites *preproduction of parts for chambers of 2000 *production of first chambers in three (/four) sites in 2000 **setting up of the sites for parts production *begin volume production of parts *design of tools for installation *preparation for the assembly of the Yoke wheels in 00 and 01 *tendering for volume production of TDC and Trigger electronics *2000 is the most expensive year , commitments/payments limited by the funding profile fabrizio 15/5/2000

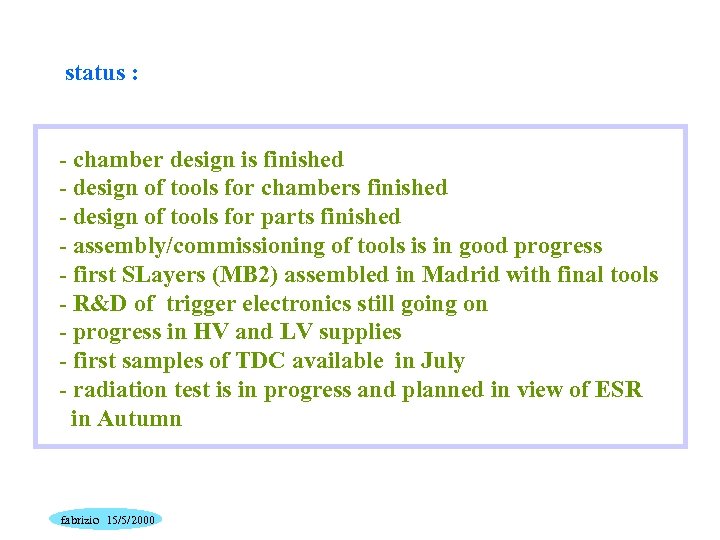

status : - chamber design is finished - design of tools for chambers finished - design of tools for parts finished - assembly/commissioning of tools is in good progress - first SLayers (MB 2) assembled in Madrid with final tools - R&D of trigger electronics still going on - progress in HV and LV supplies - first samples of TDC available in July - radiation test is in progress and planned in view of ESR in Autumn fabrizio 15/5/2000

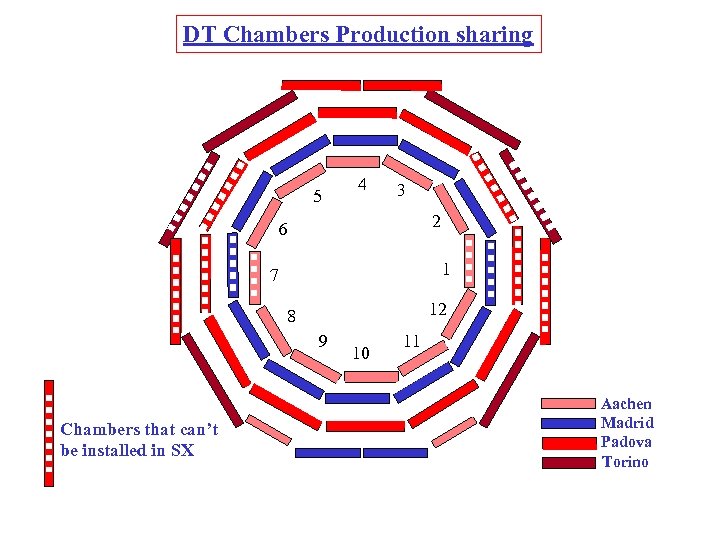

DT Chambers Production sharing 5 4 3 2 6 1 7 12 8 9 Chambers that can’t be installed in SX 10 11 Aachen Madrid Padova Torino

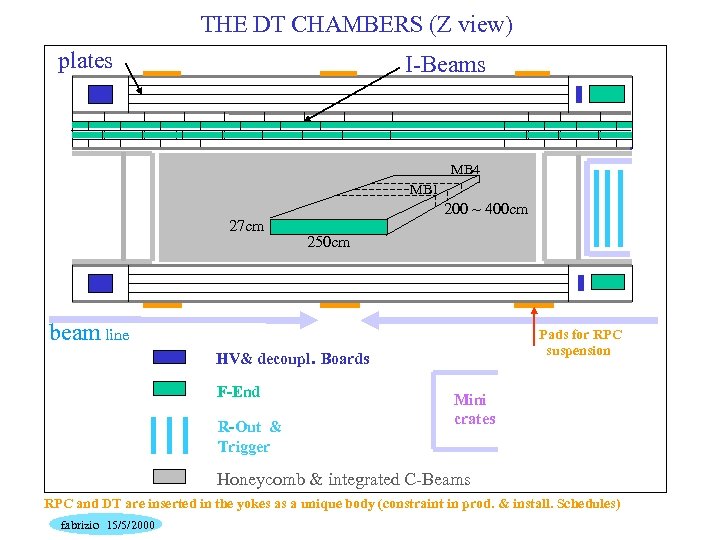

THE DT CHAMBERS (Z view) plates I-Beams MB 4 MB 1 27 cm 200 ~ 400 cm 250 cm beam line Pads for RPC suspension HV& decoupl. Boards F-End R-Out & Trigger Mini crates Honeycomb & integrated C-Beams RPC and DT are inserted in the yokes as a unique body (constraint in prod. & install. Schedules) fabrizio 15/5/2000

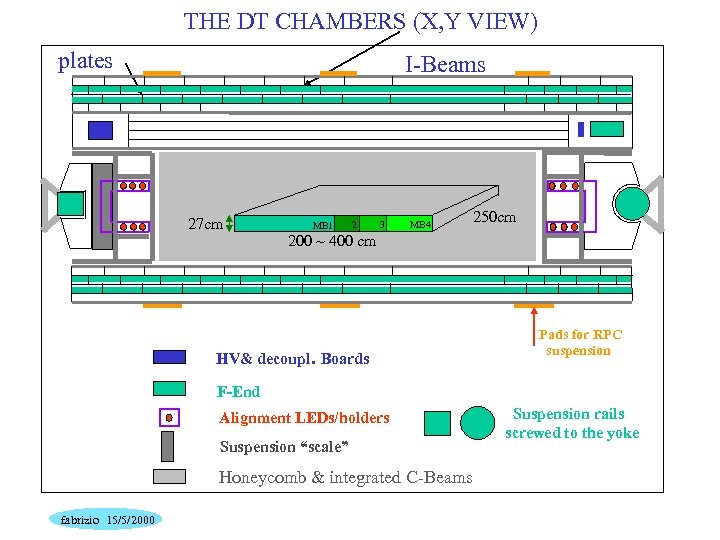

THE DT CHAMBERS (X, Y VIEW) plates I-Beams 27 cm MB 1 2 3 MB 4 250 cm 200 ~ 400 cm HV& decoupl. Boards Pads for RPC suspension F-End Alignment LEDs/holders Suspension “scale” Honeycomb & integrated C-Beams fabrizio 15/5/2000 Suspension rails screwed to the yoke

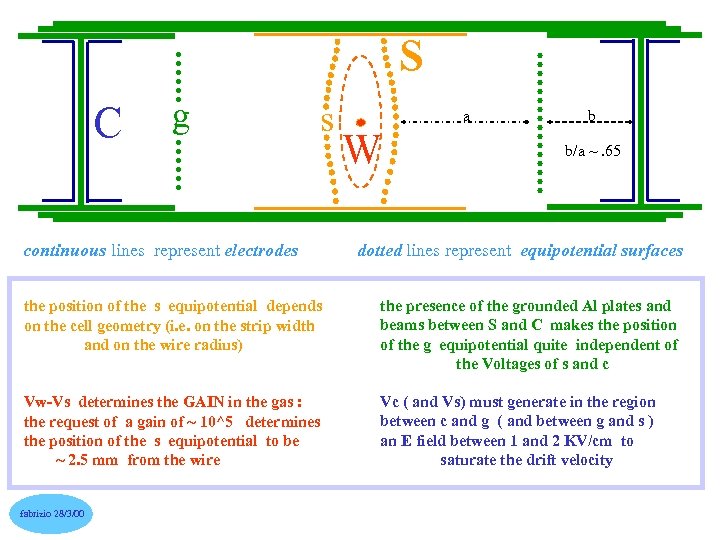

S C g s continuous lines represent electrodes a W b b/a ~. 65 dotted lines represent equipotential surfaces the position of the s equipotential depends on the cell geometry (i. e. on the strip width and on the wire radius) the presence of the grounded Al plates and beams between S and C makes the position of the g equipotential quite independent of the Voltages of s and c Vw-Vs determines the GAIN in the gas : the request of a gain of ~ 10^5 determines the position of the s equipotential to be ~ 2. 5 mm from the wire Vc ( and Vs) must generate in the region between c and g ( and between g and s ) an E field between 1 and 2 KV/cm to saturate the drift velocity fabrizio 28/3/00

For practical and safety reasons many components are inside the gas volume of the chamber An intensive campaign of measurements to identify possible aging effects from these materials was organized and done ( and will continue, for safety reasons, to check each delivery of materials): - glues on Mylar and Aluminum strips bare HV, Decoupling and F-End Boards cables & connectors fully equipped boards Many components were investigated also after neutron irradiation (@ PROSPERO , Valduc, F) - to look for effects from FR 4. - for effects on structural glues (results are published , or submitted, as CMS N. , IN. , scient. papers) fabrizio 28/3/00

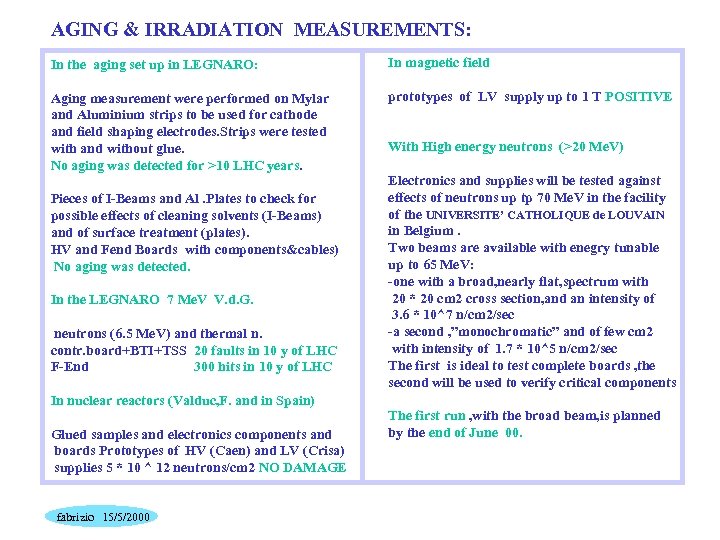

AGING & IRRADIATION MEASUREMENTS: In the aging set up in LEGNARO: In magnetic field Aging measurement were performed on Mylar and Aluminium strips to be used for cathode and field shaping electrodes. Strips were tested with and without glue. No aging was detected for >10 LHC years. prototypes of LV supply up to 1 T POSITIVE Pieces of I-Beams and Al. Plates to check for possible effects of cleaning solvents (I-Beams) and of surface treatment (plates). HV and Fend Boards with components&cables) No aging was detected. In the LEGNARO 7 Me. V V. d. G. neutrons (6. 5 Me. V) and thermal n. contr. board+BTI+TSS 20 faults in 10 y of LHC F-End 300 hits in 10 y of LHC In nuclear reactors (Valduc, F. and in Spain) Glued samples and electronics components and boards Prototypes of HV (Caen) and LV (Crisa) supplies 5 * 10 ^ 12 neutrons/cm 2 NO DAMAGE fabrizio 15/5/2000 With High energy neutrons (>20 Me. V) Electronics and supplies will be tested against effects of neutrons up tp 70 Me. V in the facility of the UNIVERSITE’ CATHOLIQUE de LOUVAIN in Belgium. Two beams are available with enegry tunable up to 65 Me. V: -one with a broad, nearly flat, spectrum with 20 * 20 cm 2 cross section, and an intensity of 3. 6 * 10^7 n/cm 2/sec -a second , ”monochromatic” and of few cm 2 with intensity of 1. 7 * 10^5 n/cm 2/sec The first is ideal to test complete boards , the second will be used to verify critical components The first run , with the broad beam, is planned by the end of June 00.

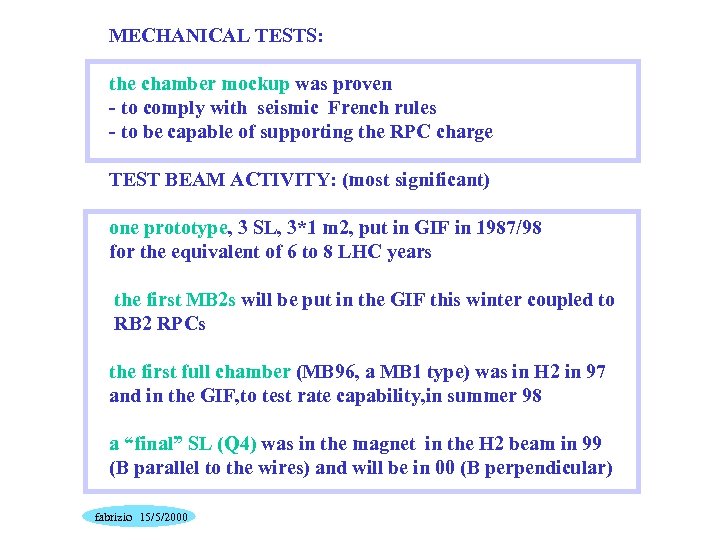

MECHANICAL TESTS: the chamber mockup was proven - to comply with seismic French rules - to be capable of supporting the RPC charge TEST BEAM ACTIVITY: (most significant) one prototype, 3 SL, 3*1 m 2, put in GIF in 1987/98 for the equivalent of 6 to 8 LHC years the first MB 2 s will be put in the GIF this winter coupled to RB 2 RPCs the first full chamber (MB 96, a MB 1 type) was in H 2 in 97 and in the GIF, to test rate capability, in summer 98 a “final” SL (Q 4) was in the magnet in the H 2 beam in 99 (B parallel to the wires) and will be in 00 (B perpendicular) fabrizio 15/5/2000

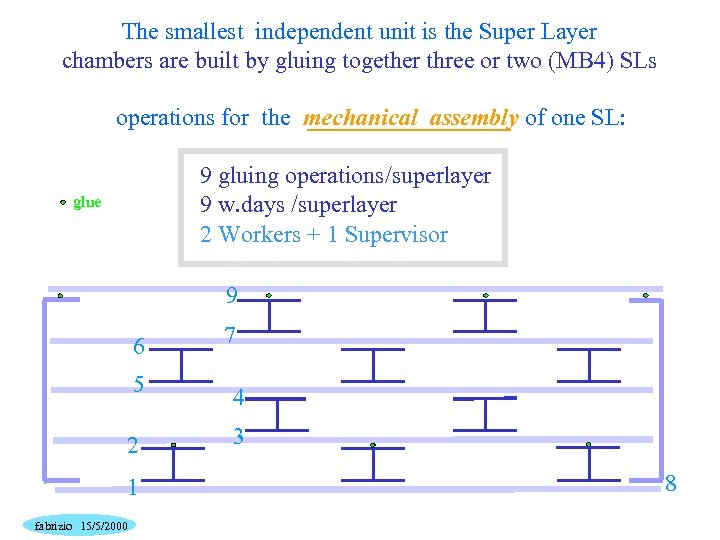

The smallest independent unit is the Super Layer chambers are built by gluing together three or two (MB 4) SLs operations for the mechanical assembly of one SL: 9 gluing operations/superlayer 9 w. days /superlayer 2 Workers + 1 Supervisor glue 9 6 5 2 1 fabrizio 15/5/2000 7 4 3 8

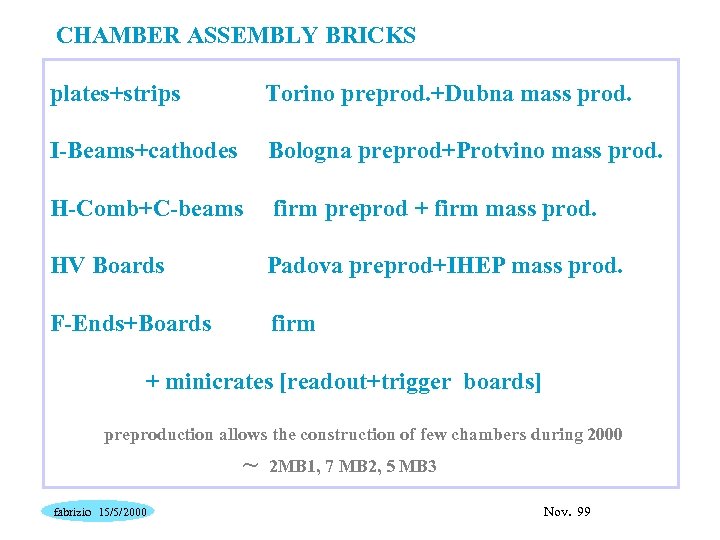

CHAMBER ASSEMBLY BRICKS plates+strips Torino preprod. +Dubna mass prod. I-Beams+cathodes Bologna preprod+Protvino mass prod. H-Comb+C-beams firm preprod + firm mass prod. HV Boards Padova preprod+IHEP mass prod. F-Ends+Boards firm + minicrates [readout+trigger boards] preproduction allows the construction of few chambers during 2000 ~ fabrizio 15/5/2000 2 MB 1, 7 MB 2, 5 MB 3 Nov. 99

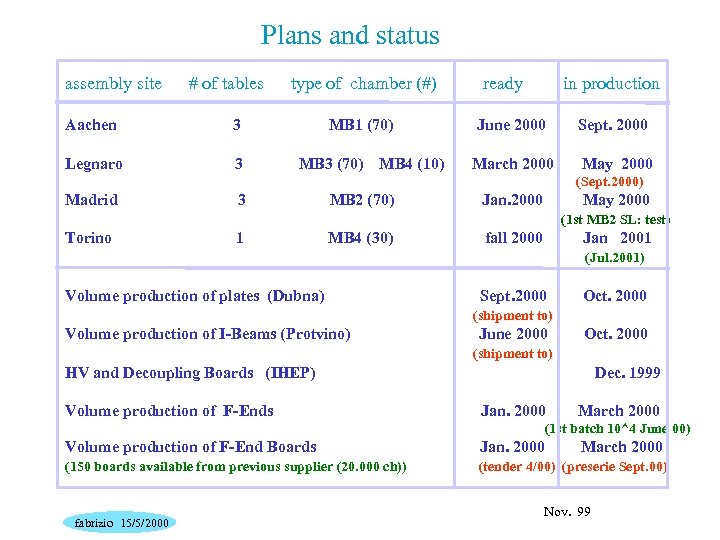

Plans and status assembly site # of tables Aachen 3 Legnaro 3 type of chamber (#) MB 1 (70) MB 3 (70) MB 4 (10) ready in production June 2000 Sept. 2000 March 2000 May 2000 (Sept. 2000) Madrid 3 MB 2 (70) Jan. 2000 May 2000 (1 st MB 2 SL: test) Torino 1 MB 4 (30) fall 2000 Jan 2001 (Jul. 2001) Volume production of plates (Dubna) Sept. 2000 Oct. 2000 (shipment to) Volume production of I-Beams (Protvino) June 2000 Oct. 2000 (shipment to) HV and Decoupling Boards (IHEP) Volume production of F-Ends Dec. 1999 Jan. 2000 March 2000 (1 st batch 10^4 June 00) Volume production of F-End Boards Jan. 2000 (150 boards available from previous supplier (20. 000 ch)) (tender 4/00) (preserie Sept. 00) fabrizio 15/5/2000 March 2000 Nov. 99

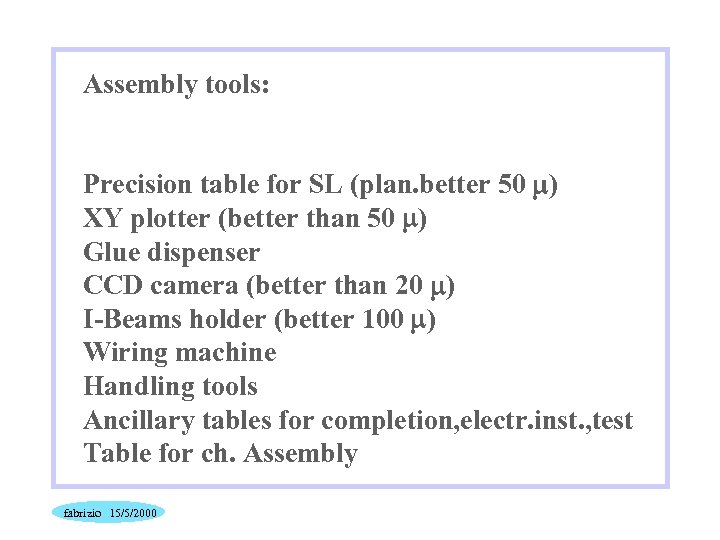

Assembly tools: Precision table for SL (plan. better 50 ) XY plotter (better than 50 ) Glue dispenser CCD camera (better than 20 ) I-Beams holder (better 100 ) Wiring machine Handling tools Ancillary tables for completion, electr. inst. , test Table for ch. Assembly fabrizio 15/5/2000

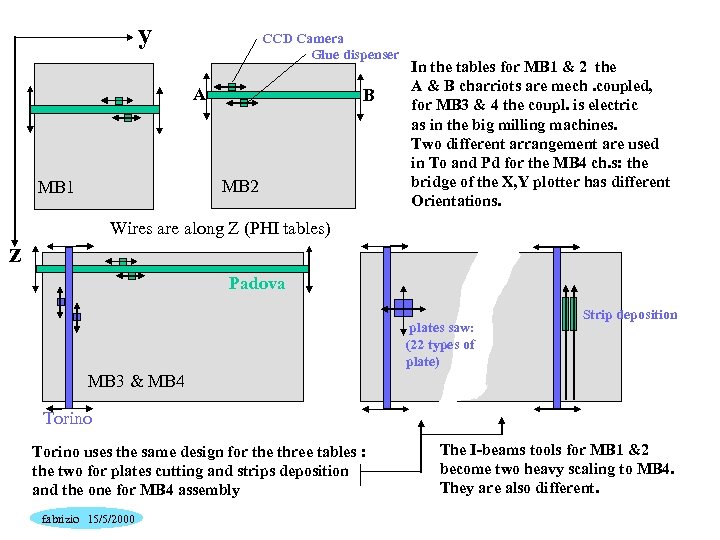

y CCD Camera Glue dispenser A B MB 2 MB 1 In the tables for MB 1 & 2 the A & B charriots are mech. coupled, for MB 3 & 4 the coupl. is electric as in the big milling machines. Two different arrangement are used in To and Pd for the MB 4 ch. s: the bridge of the X, Y plotter has different Orientations. Wires are along Z (PHI tables) z Padova plates saw: (22 types of plate) Strip deposition MB 3 & MB 4 Torino uses the same design for the three tables : the two for plates cutting and strips deposition and the one for MB 4 assembly fabrizio 15/5/2000 The I-beams tools for MB 1 &2 become two heavy scaling to MB 4. They are also different.

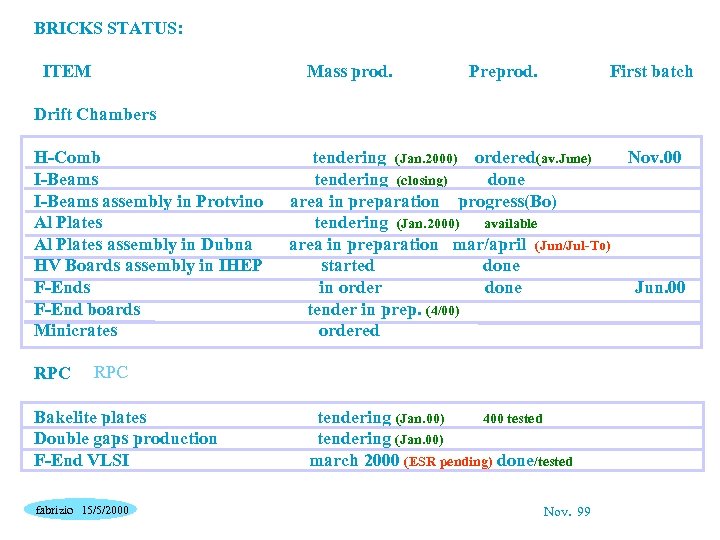

BRICKS STATUS: ITEM Mass prod. Preprod. First batch Drift Chambers H-Comb I-Beams assembly in Protvino Al Plates assembly in Dubna HV Boards assembly in IHEP F-Ends F-End boards Minicrates RPC tendering (Jan. 2000) ordered(av. June) Nov. 00 tendering (closing) done area in preparation progress(Bo) tendering (Jan. 2000) available area in preparation mar/april (Jun/Jul-To) started done in order done Jun. 00 tender in prep. (4/00) ordered RPC Bakelite plates Double gaps production F-End VLSI fabrizio 15/5/2000 tendering (Jan. 00) 400 tested tendering (Jan. 00) march 2000 (ESR pending) done/tested Nov. 99

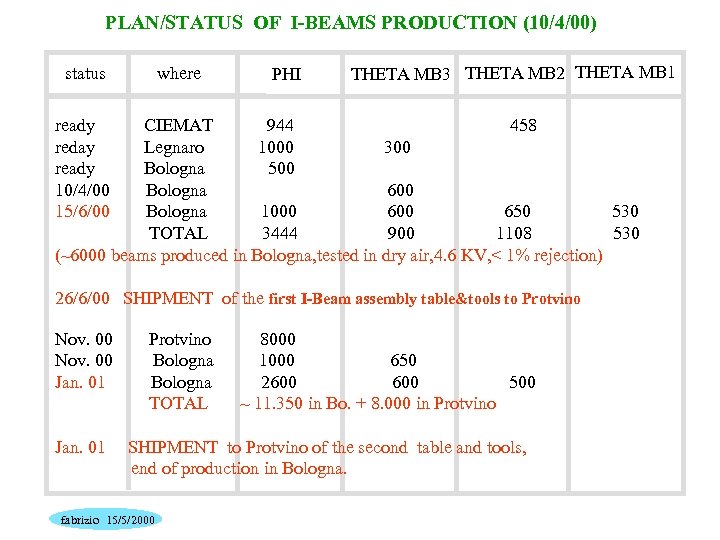

PLAN/STATUS OF I-BEAMS PRODUCTION (10/4/00) status where PHI THETA MB 3 THETA MB 2 THETA MB 1 ready reday ready 10/4/00 15/6/00 CIEMAT 944 458 Legnaro 1000 300 Bologna 500 Bologna 600 Bologna 1000 650 530 TOTAL 3444 900 1108 530 (~6000 beams produced in Bologna, tested in dry air, 4. 6 KV, < 1% rejection) 26/6/00 SHIPMENT of the first I-Beam assembly table&tools to Protvino Nov. 00 Jan. 01 Protvino Bologna TOTAL 8000 1000 650 2600 500 ~ 11. 350 in Bo. + 8. 000 in Protvino SHIPMENT to Protvino of the second table and tools, end of production in Bologna. fabrizio 15/5/2000

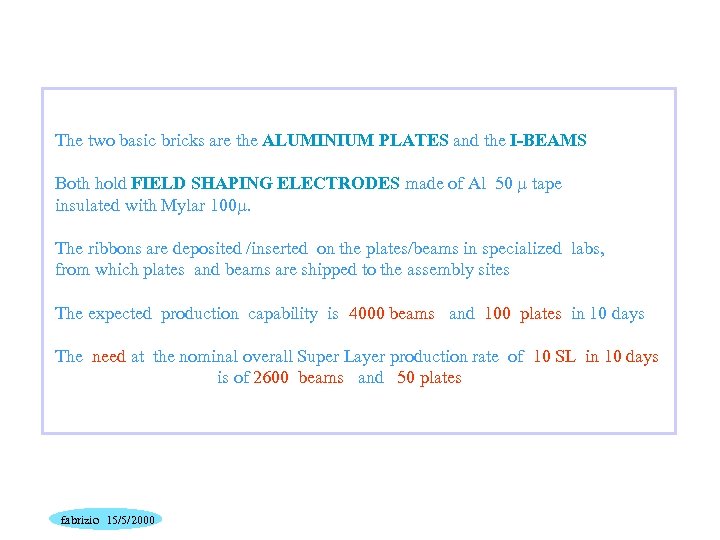

The two basic bricks are the ALUMINIUM PLATES and the I-BEAMS Both hold FIELD SHAPING ELECTRODES made of Al 50 tape insulated with Mylar 100. The ribbons are deposited /inserted on the plates/beams in specialized labs, from which plates and beams are shipped to the assembly sites The expected production capability is 4000 beams and 100 plates in 10 days The need at the nominal overall Super Layer production rate of 10 SL in 10 days is of 2600 beams and 50 plates fabrizio 15/5/2000

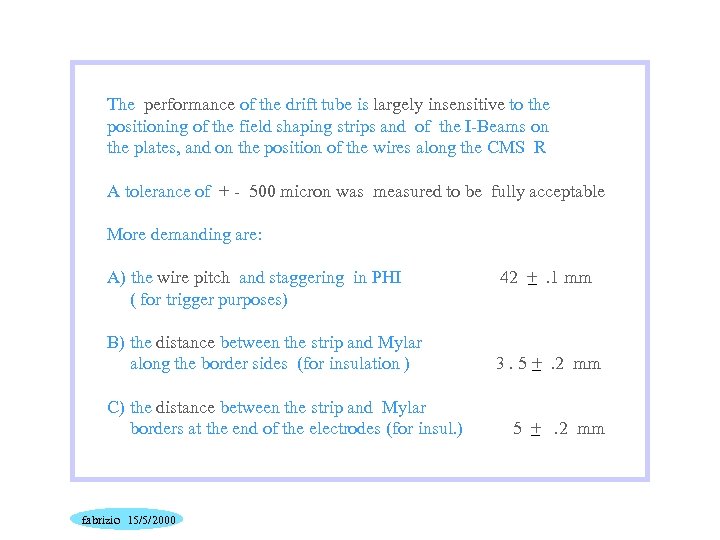

The performance of the drift tube is largely insensitive to the positioning of the field shaping strips and of the I-Beams on the plates, and on the position of the wires along the CMS R A tolerance of + - 500 micron was measured to be fully acceptable More demanding are: A) the wire pitch and staggering in PHI ( for trigger purposes) B) the distance between the strip and Mylar along the border sides (for insulation ) C) the distance between the strip and Mylar borders at the end of the electrodes (for insul. ) fabrizio 15/5/2000 _ 42 +. 1 mm _ 3. 5 +. 2 mm _ 5 +. 2 mm

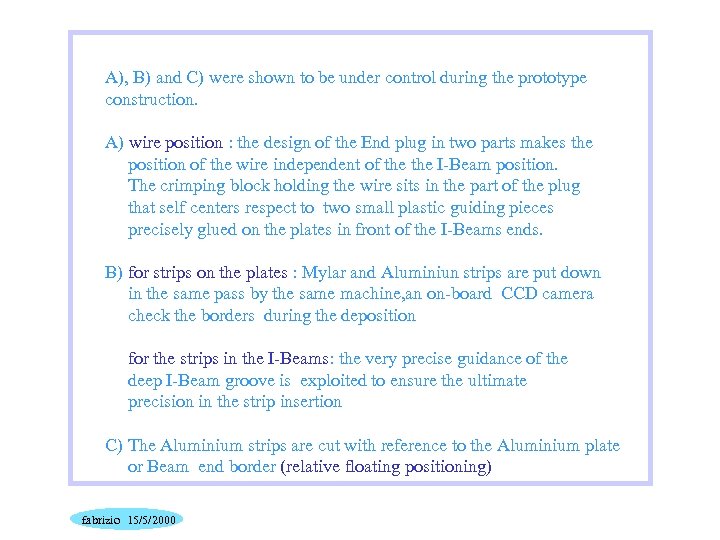

A), B) and C) were shown to be under control during the prototype construction. A) wire position : the design of the End plug in two parts makes the position of the wire independent of the I-Beam position. The crimping block holding the wire sits in the part of the plug that self centers respect to two small plastic guiding pieces precisely glued on the plates in front of the I-Beams ends. B) for strips on the plates : Mylar and Aluminiun strips are put down in the same pass by the same machine, an on-board CCD camera check the borders during the deposition for the strips in the I-Beams: the very precise guidance of the deep I-Beam groove is exploited to ensure the ultimate precision in the strip insertion C) The Aluminium strips are cut with reference to the Aluminium plate or Beam end border (relative floating positioning) fabrizio 15/5/2000

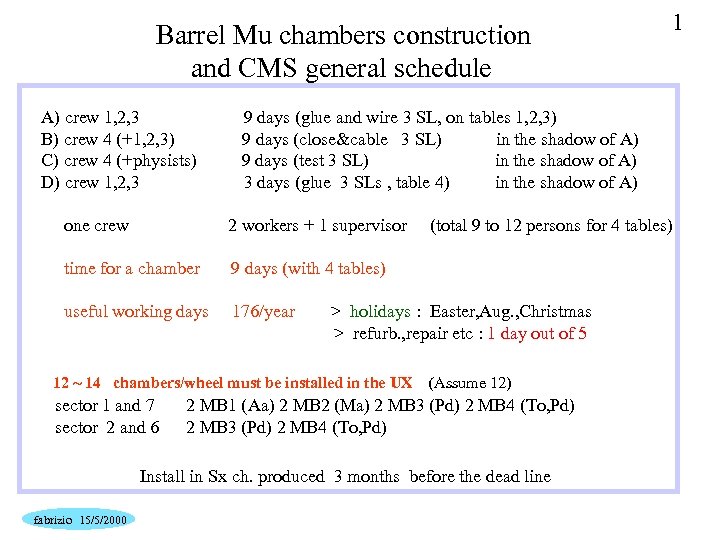

Barrel Mu chambers construction and CMS general schedule A) crew 1, 2, 3 B) crew 4 (+1, 2, 3) C) crew 4 (+physists) D) crew 1, 2, 3 9 days (glue and wire 3 SL, on tables 1, 2, 3) 9 days (close&cable 3 SL) in the shadow of A) 9 days (test 3 SL) in the shadow of A) 3 days (glue 3 SLs , table 4) in the shadow of A) one crew 2 workers + 1 supervisor time for a chamber 9 days (with 4 tables) useful working days 176/year (total 9 to 12 persons for 4 tables) > holidays : Easter, Aug. , Christmas > refurb. , repair etc : 1 day out of 5 12 ~ 14 chambers/wheel must be installed in the UX sector 1 and 7 sector 2 and 6 (Assume 12) 2 MB 1 (Aa) 2 MB 2 (Ma) 2 MB 3 (Pd) 2 MB 4 (To, Pd) Install in Sx ch. produced 3 months before the dead line fabrizio 15/5/2000 1

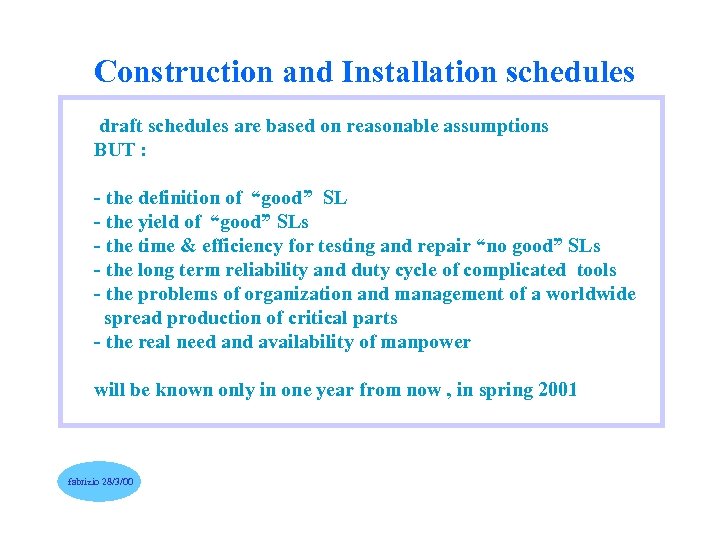

Construction and Installation schedules draft schedules are based on reasonable assumptions BUT : - the definition of “good” SL - the yield of “good” SLs - the time & efficiency for testing and repair “no good” SLs - the long term reliability and duty cycle of complicated tools - the problems of organization and management of a worldwide spread production of critical parts - the real need and availability of manpower will be known only in one year from now , in spring 2001 fabrizio 28/3/00

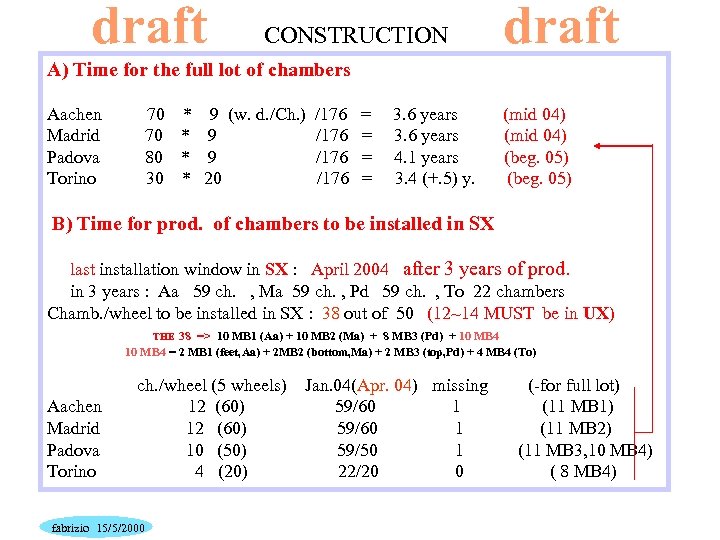

draft CONSTRUCTION draft A) Time for the full lot of chambers Aachen Madrid Padova Torino 70 * 9 (w. d. /Ch. ) 70 * 9 80 * 9 30 * 20 /176 = = 3. 6 years 4. 1 years 3. 4 (+. 5) y. (mid 04) (beg. 05) B) Time for prod. of chambers to be installed in SX last installation window in SX : April 2004 after 3 years of prod. in 3 years : Aa 59 ch. , Ma 59 ch. , Pd 59 ch. , To 22 chambers Chamb. /wheel to be installed in SX : 38 out of 50 (12~14 MUST be in UX) 38 => 10 MB 1 (Aa) + 10 MB 2 (Ma) + 8 MB 3 (Pd) + 10 MB 4 = 2 MB 1 (feet, Aa) + 2 MB 2 (bottom, Ma) + 2 MB 3 (top, Pd) + 4 MB 4 (To) THE Aachen Madrid Padova Torino ch. /wheel (5 wheels) 12 (60) 10 (50) 4 (20) fabrizio 15/5/2000 Jan. 04(Apr. 04) missing 59/60 1 59/50 1 22/20 0 (-for full lot) (11 MB 1) (11 MB 2) (11 MB 3, 10 MB 4) ( 8 MB 4)

draft INSTALLATION draft Chambers are installed in a wheel when the 38 DT and RPC of that wheel are available: constructed+shipped to ISR+tested+measured(Alignm. )+moved to P 5 time for installation in a wheel: - services (gas/cooling/cables/balcony electronics) are ready - trigger and R-out electronics sitting on the chambers is installed - installation is : DT/RPC coupling, insertion, test of all connections (photogrammetry not included , MAB cabling partially) time for install. of 38 ch. in SX => 1 Month (half a day/chamber) constraints: availability of electronics / DT <=> RPC schedule fabrizio 15/5/2000

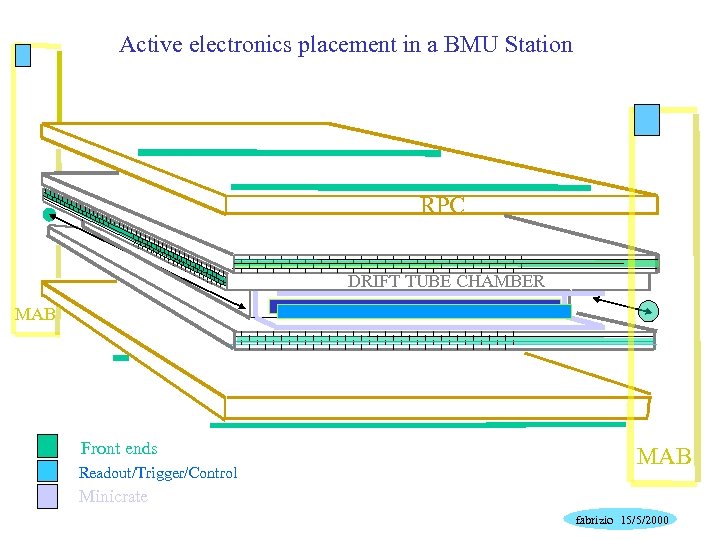

Active electronics placement in a BMU Station RPC DRIFT TUBE CHAMBER MAB Front ends Readout/Trigger/Control MAB Minicrate fabrizio 15/5/2000

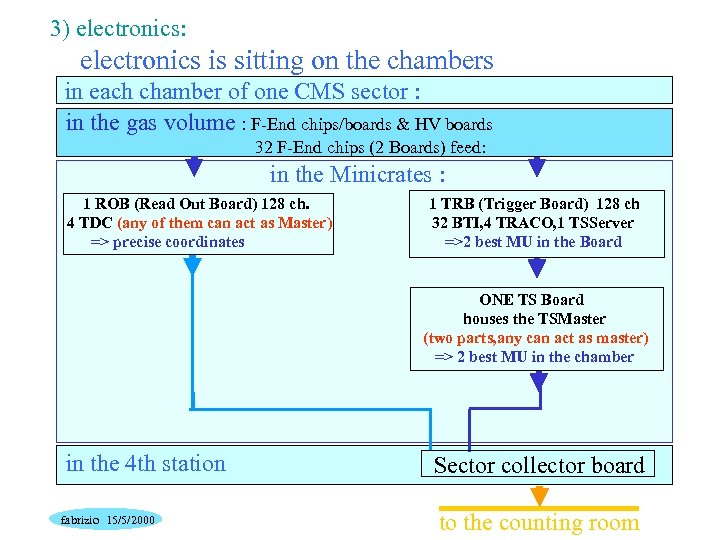

3) electronics: electronics is sitting on the chambers in each chamber of one CMS sector : in the gas volume : F-End chips/boards & HV boards 32 F-End chips (2 Boards) feed: in the Minicrates : 1 ROB (Read Out Board) 128 ch. 4 TDC (any of them can act as Master) => precise coordinates 1 TRB (Trigger Board) 128 ch 32 BTI, 4 TRACO, 1 TSServer =>2 best MU in the Board ONE TS Board houses the TSMaster (two parts, any can act as master) => 2 best MU in the chamber in the 4 th station fabrizio 15/5/2000 Sector collector board to the counting room

![A=Amperes W=Watts DT POWER REQUIREMENTS: ONE CHAMBER ch. type (#) [sector] minicrates f-ends 3. A=Amperes W=Watts DT POWER REQUIREMENTS: ONE CHAMBER ch. type (#) [sector] minicrates f-ends 3.](https://present5.com/presentation/23f11444dba952d9aec89e6ff06bf8f5/image-32.jpg)

A=Amperes W=Watts DT POWER REQUIREMENTS: ONE CHAMBER ch. type (#) [sector] minicrates f-ends 3. 3 V A W MB 1 MB 2 MB 3 MB 4 MB 4 (60) [all] (30) [1, 2, 3, 5, 6, 7] (10) [8, 12] (10) [9, 11] (5) [4 left] (5) [4 right] (5) [10 left] (5) [10 right] 5 V total (F-End) 2. 5 V 5 V A W 26 29 34 34 34 20 26 29 25 25 86 96 112 112 66 86 96 83 83 1 1 1 1 1 5 5 5 5 5 4 4 5 5 4 2 4 4 3 3 10 10 13 13 10 5 10 10 8 8 2 2 2 1 1 1560 1740 2085 5160 5760 6720 6880 60 60 60 110 300 300 350 240 300 280 600 780 720 120 120 600 600 7425 24520 290 1250 1060 2700 480 2400 A W 10 10 10 5 5 W 111 121 140 137 81 111 121 101 (20) (23) (20) (10) (20) (13) ALL CHAMBERS : MB 1 MB 2 MB 3 MB 4 TOTAL GRAND TOTAL fabrizio 15/5/2000 6660 7260 8400 8550 31 KW

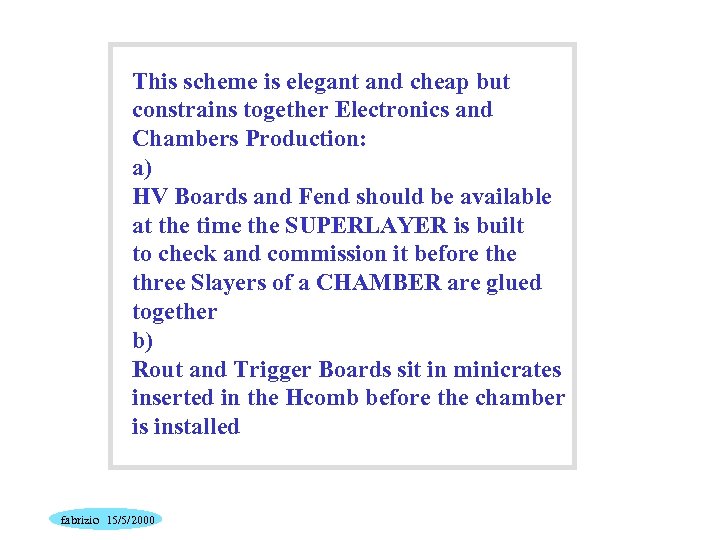

This scheme is elegant and cheap but constrains together Electronics and Chambers Production: a) HV Boards and Fend should be available at the time the SUPERLAYER is built to check and commission it before three Slayers of a CHAMBER are glued together b) Rout and Trigger Boards sit in minicrates inserted in the Hcomb before the chamber is installed fabrizio 15/5/2000

a) the first final protos of Fends will be available by end Nov. 99 2000 chips for first ch. will be available Dec. 99 (on loan from COMPASS exp. ) OK OK tender for CMS mass prod. is at the latest days begin of mass prod. expected in spring 2000 OK fabrizio 15/5/2000

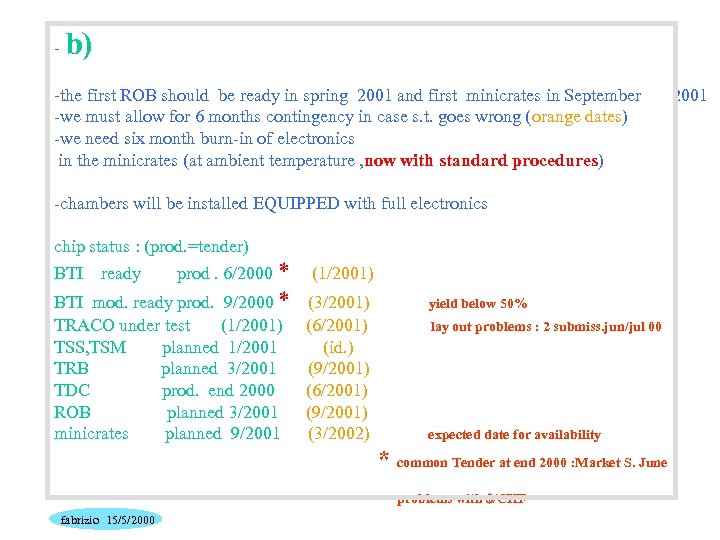

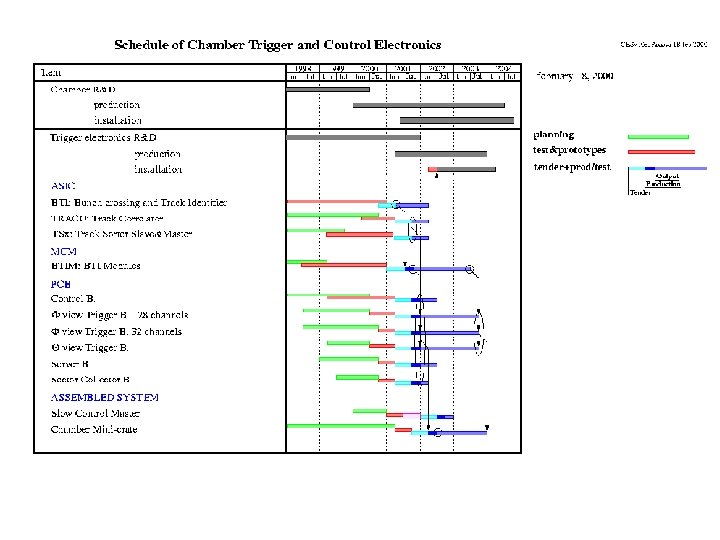

- b) -the first ROB should be ready in spring 2001 and first minicrates in September -we must allow for 6 months contingency in case s. t. goes wrong (orange dates) -we need six month burn-in of electronics in the minicrates (at ambient temperature , now with standard procedures) -chambers will be installed EQUIPPED with full electronics chip status : (prod. =tender) prod. 6/2000 * (1/2001) BTI mod. ready prod. 9/2000 * TRACO under test (1/2001) TSS, TSM planned 1/2001 TRB planned 3/2001 TDC prod. end 2000 ROB planned 3/2001 minicrates planned 9/2001 (3/2001) (6/2001) (id. ) (9/2001) (6/2001) (9/2001) (3/2002) BTI ready yield below 50% lay out problems : 2 submiss. jun/jul 00 expected date for availability * common Tender at end 2000 : Market S. June problems with $/CHF fabrizio 15/5/2000 2001

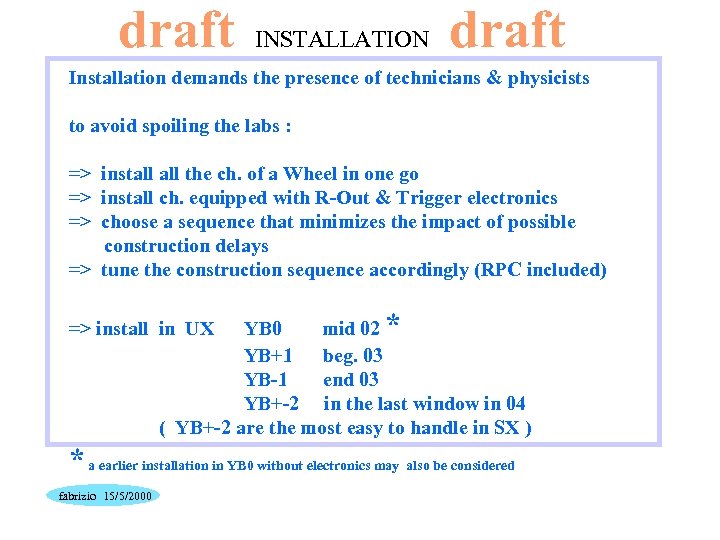

draft INSTALLATION draft Installation demands the presence of technicians & physicists to avoid spoiling the labs : => install the ch. of a Wheel in one go => install ch. equipped with R-Out & Trigger electronics => choose a sequence that minimizes the impact of possible construction delays => tune the construction sequence accordingly (RPC included) => install in UX * YB 0 mid 02 YB+1 beg. 03 YB-1 end 03 YB+-2 in the last window in 04 ( YB+-2 are the most easy to handle in SX ) * a earlier installation in YB 0 without electronics may also be considered fabrizio 15/5/2000

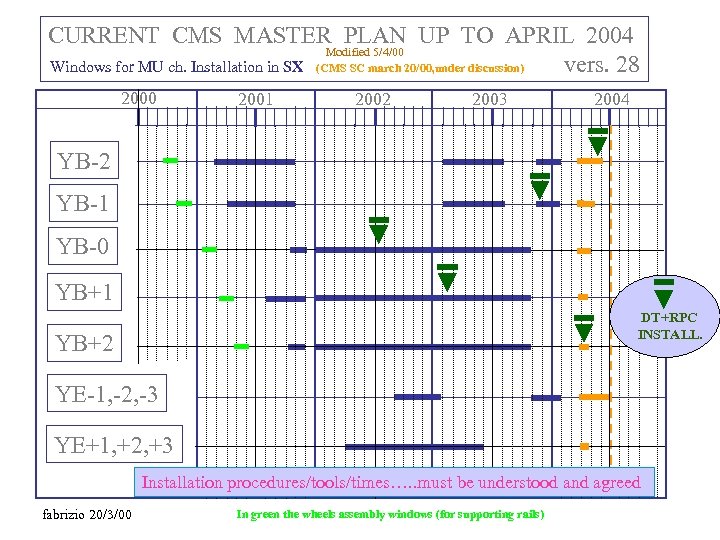

CURRENT CMS MASTER PLAN UP TO APRIL 2004 Modified 5/4/00 vers. 28 Windows for MU ch. Installation in SX (CMS SC march 20/00, under discussion) 2000 2001 2002 2003 2004 YB-2 YB-1 YB-0 YB+1 DT+RPC INSTALL. YB+2 YE-1, -2, -3 YE+1, +2, +3 Installation procedures/tools/times…. . must be understood and agreed fabrizio 20/3/00 In green the wheels assembly windows (for supporting rails)

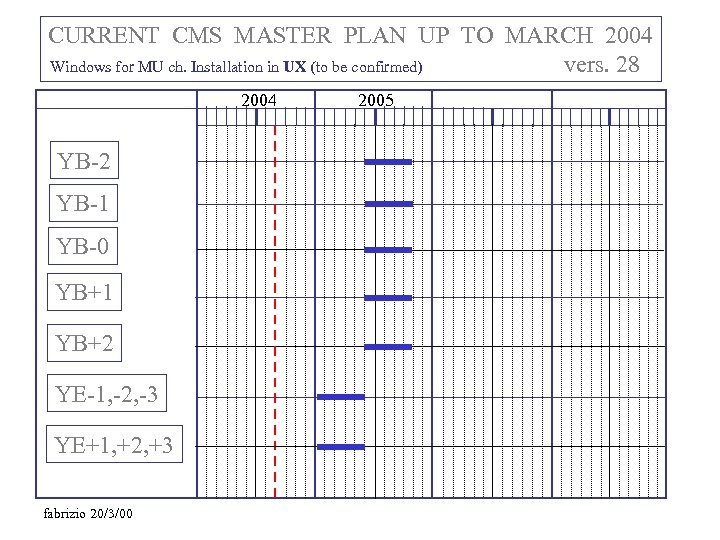

CURRENT CMS MASTER PLAN UP TO MARCH 2004 vers. 28 Windows for MU ch. Installation in UX (to be confirmed) 2004 YB-2 YB-1 YB-0 YB+1 YB+2 YE-1, -2, -3 YE+1, +2, +3 fabrizio 20/3/00 2005

23f11444dba952d9aec89e6ff06bf8f5.ppt