0f860faeb4d13f80fbd48870aa850709.ppt

- Количество слайдов: 15

Clean Technology by Linde. CO 2 Supply “Milk Run” February 2013

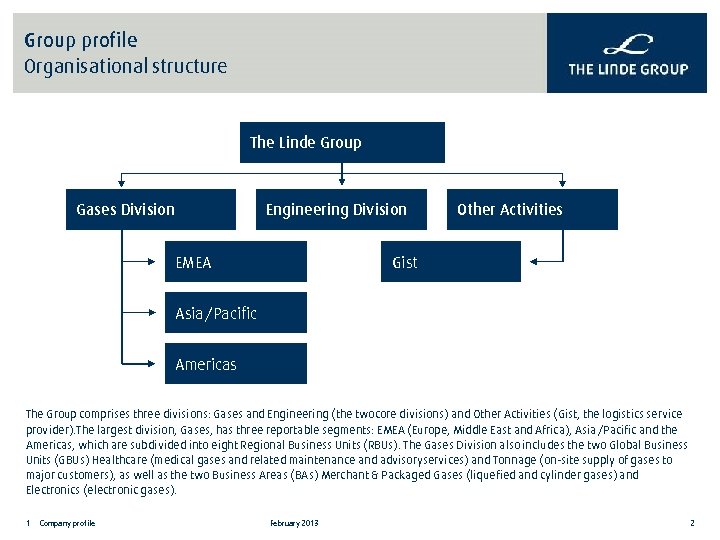

Group profile Organisational structure The Linde Group Gases Division Engineering Division EMEA Other Activities Gist Asia/Pacific Americas The Group comprises three divisions: Gases and Engineering (the twocore divisions) and Other Activities (Gist, the logistics service provider). The largest division, Gases, has three reportable segments: EMEA (Europe, Middle East and Africa), Asia/Pacific and the Americas, which are subdivided into eight Regional Business Units (RBUs). The Gases Division also includes the two Global Business Units (GBUs) Healthcare (medical gases and related maintenance and advisoryservices) and Tonnage (on-site supply of gases to major customers), as well as the two Business Areas (BAs) Merchant & Packaged Gases (liquefied and cylinder gases) and Electronics (electronic gases). 1 Company profile February 2013 2

The Linde Group worldwide Global presence in more than 100 countries 1 Company profile April 2012 3

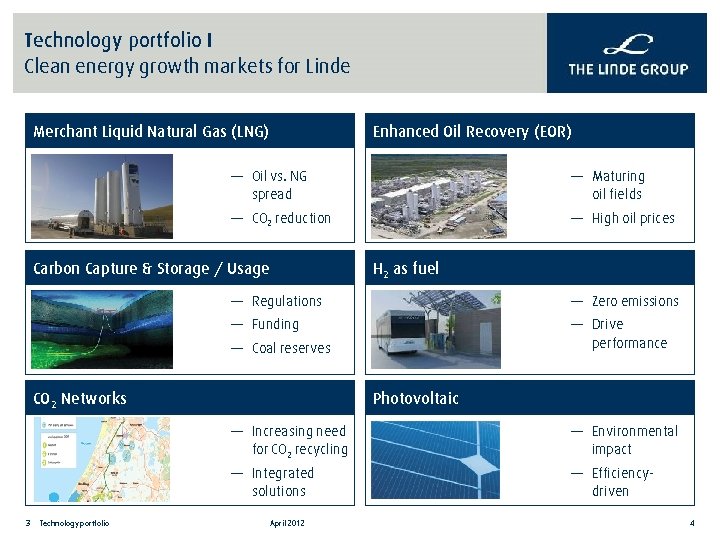

Technology portfolio I Clean energy growth markets for Linde Merchant Liquid Natural Gas (LNG) Enhanced Oil Recovery (EOR) — Oil vs. NG spread — Maturing oil fields — CO 2 reduction — High oil prices Carbon Capture & Storage / Usage H 2 as fuel — Regulations — Zero emissions — Funding — Drive performance — Coal reserves CO 2 Networks Photovoltaic — Increasing need for CO 2 recycling — Integrated solutions 3 Technology portfolio — Environmental impact — Efficiencydriven April 2012 4

Technology portfolio II Linde is involved in the clean energy business worldwide Biogas refuelling station, LNG back-up, Sweden LNG plant, Statoil, Hammerfest, Norway LNG import terminal, Statoil. Hydro , Nynäshamn , Sweden PCC flue gas wash, RWE, Niederaußem , Germany Landfill gas LNG plant, Waste Management, Altamont, USA Oxyfuel pilot plant, Vattenfall , Schwarze Pumpe, Germany N 2 EOR plant, Pemex, Cantarell , Mexico Hydrogen refuelling stations: Germany, USA, Japan, China 3 CO 2 network, OCAP, Rotterdam/Amsterdam, Netherlands CO 2 injection for EGR, Gaz de France, Maxdorf , Germany Technology portfolio CO 2 injection/storage, GFZ Potsdam, Ketzin, Germany April 2012 N 2 EOR ASU plant, ADNOC, Mirfa, Abu Dhabi Network of LNG plants for truck fleet fuelling, Australia 5

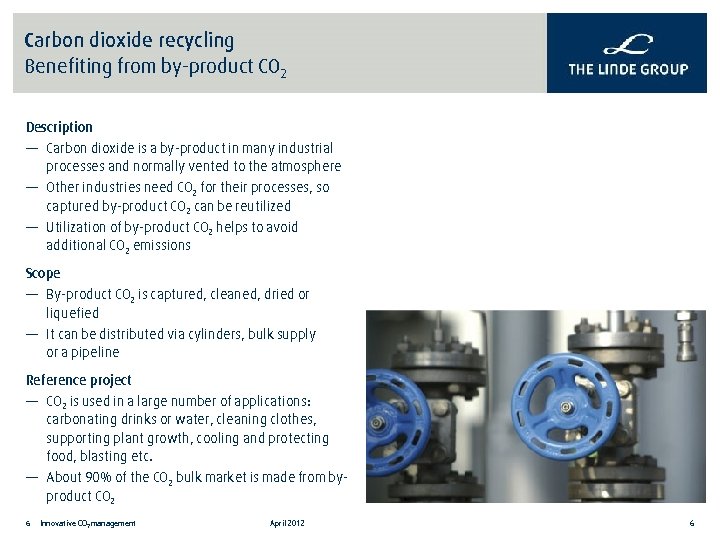

Carbon dioxide recycling Benefiting from by-product CO 2 Description — Carbon dioxide is a by-product in many industrial processes and normally vented to the atmosphere — Other industries need CO 2 for their processes, so captured by-product CO 2 can be reutilized — Utilization of by-product CO 2 helps to avoid additional CO 2 emissions Scope — By-product CO 2 is captured, cleaned, dried or liquefied — It can be distributed via cylinders, bulk supply or a pipeline Reference project — CO 2 is used in a large number of applications: carbonating drinks or water, cleaning clothes, supporting plant growth, cooling and protecting food, blasting etc. — About 90% of the CO 2 bulk market is made from byproduct CO 2 6 Innovative CO 2 management April 2012 6

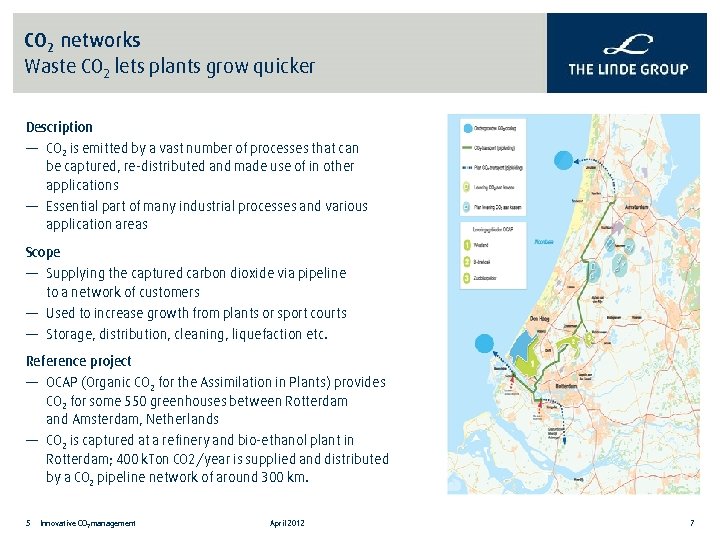

CO 2 networks Waste CO 2 lets plants grow quicker Description — CO 2 is emitted by a vast number of processes that can be captured, re-distributed and made use of in other applications — Essential part of many industrial processes and various application areas Scope — Supplying the captured carbon dioxide via pipeline to a network of customers — Used to increase growth from plants or sport courts — Storage, distribution, cleaning, liquefaction etc. Reference project — OCAP (Organic CO 2 for the Assimilation in Plants) provides CO 2 for some 550 greenhouses between Rotterdam and Amsterdam, Netherlands — CO 2 is captured at a refinery and bio-ethanol plant in Rotterdam; 400 k. Ton CO 2/year is supplied and distributed by a CO 2 pipeline network of around 300 km. 5 Innovative CO 2 management April 2012 7

Recent Achievement ABENGOA - OCAP • OCAP Investment approx. 35 Mio Euro including: • - CO 2 Purification & Compression • - Abengoa -OCAP 26” pipeline connection • - Pipeline Infrastructure Zuidplaspolder 8

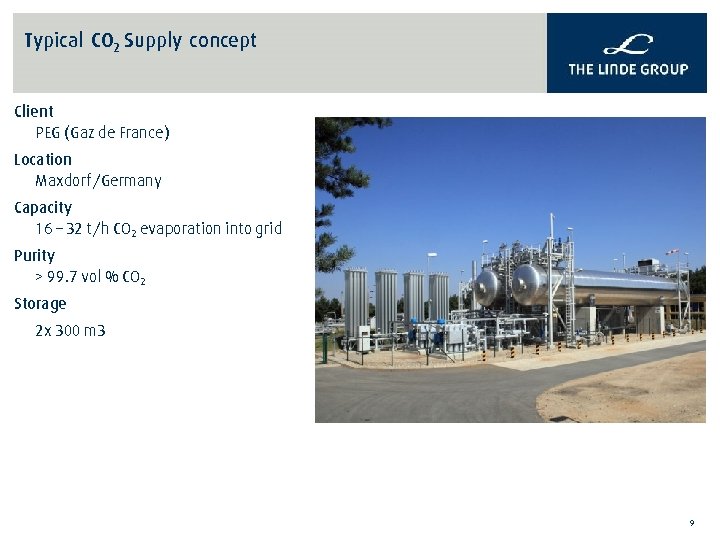

Typical CO 2 Supply concept Client PEG (Gaz de France) Location Maxdorf/Germany Capacity 16 – 32 t/h CO 2 evaporation into grid Purity > 99. 7 vol % CO 2 Storage 2 x 300 m 3 9

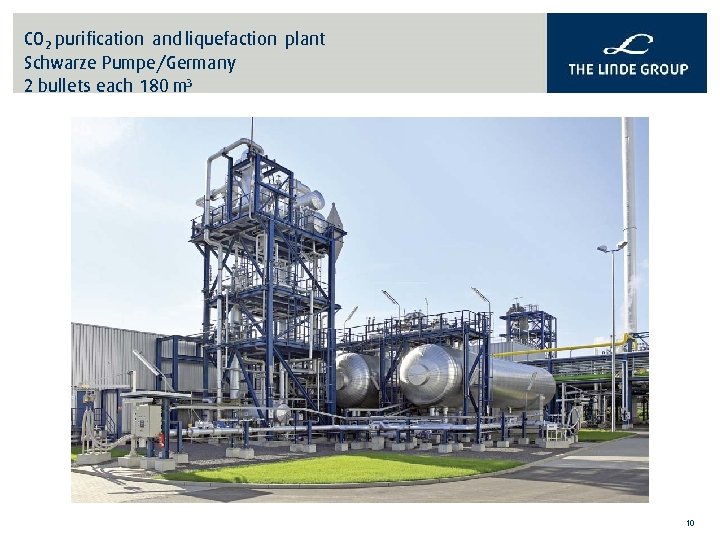

CO 2 purification and liquefaction plant Schwarze Pumpe/Germany 2 bullets each 180 m 3 10

Linde view on sustainable CO 2 production Biomassa : op basis van verschillende biomassabronnen zijn duurzame CO 2 -stromen te produceren. Er bestaat een redelijke flexibiliteit om op de gewenste locatie een CO 2 -bron met de gewenste beschikbaarheid "op maat" te produceren. Door de landelijke herkomst van de biomassa (mest & mais) vormt een CO-vergistingsinstallatie een goede match met menig glastuinbouwbedrijf. Vanwege de actuele trend naar verduurzaming en integratie is het waarschijnlijk dat ook dergelijke synergieprojecten talrijker worden. 11

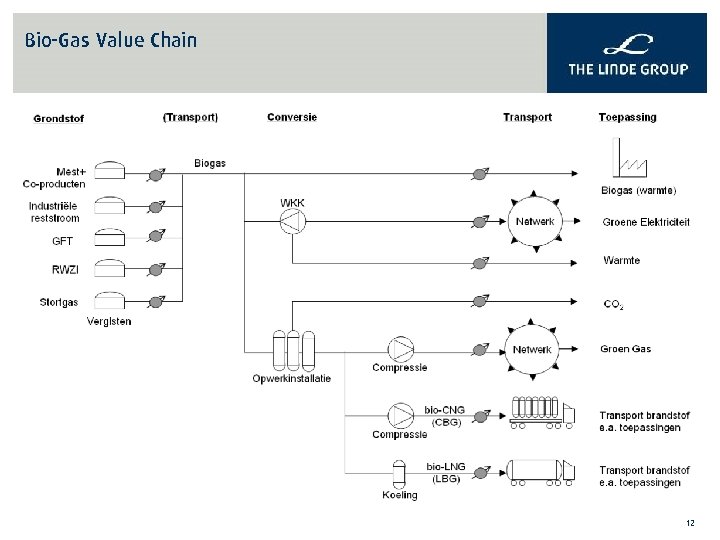

Bio-Gas Value Chain 12

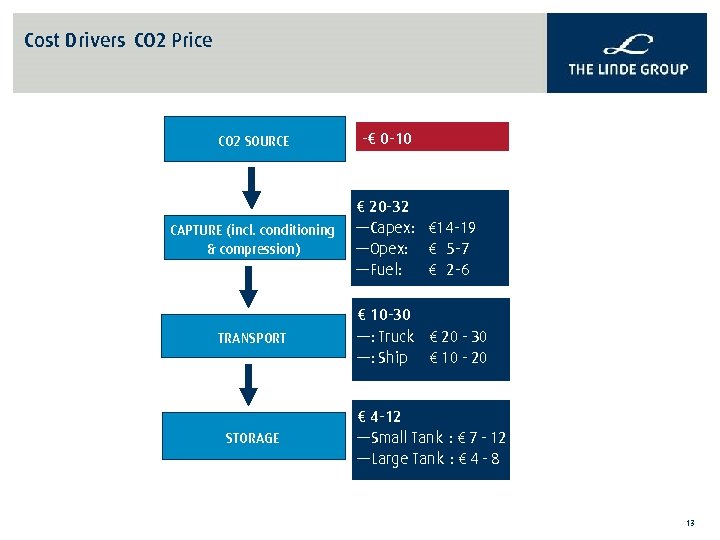

Cost Drivers CO 2 Price CO 2 SOURCE CAPTURE (incl. conditioning & compression) TRANSPORT STORAGE -€ 0 -10 € 20 -32 —Capex: € 14 -19 —Opex: € 5 -7 —Fuel: € 2 -6 € 10 -30 —: Truck € 20 - 30 —: Ship € 10 - 20 € 4 -12 —Small Tank : € 7 - 12 —Large Tank : € 4 - 8 13

Carbon Capture and Utilization (CCU) Transport cooling Description — Replacing diesel-powered refrigeration unit to keep the goods at desired temperature — 100 trucks using diesel units for cooling emit roughly the same amount of CO 2 as 250 oil-heated single family houses Scope — Environmental friendly alternative is to use liquid/frozen CO 2 for refrigeration — Zero CO 2 emission since only recycled CO 2 from industrial processes is used — CO 2 should otherwise have been emitted into the atmosphere Reference projects — Eleven automated LIC filling station systems installed in Norway, Sweden and Finland. — Driver enters station and uses a credit card system to fill the onboard LIC tank. — Snowcool® – CO 2 refrigerated container for transport of chilled and frozen products. 6 Innovative CO 2 management April 2012 14

Thank you for your attention.

0f860faeb4d13f80fbd48870aa850709.ppt