bd47859276269517186f40f2077d25e6.ppt

- Количество слайдов: 35

CII Benchmarking and Metrics Implementation Session Don’t Gamble with Your Project’s Performance Harold Helland, Abbott Bob Herrington, Jacobs Stephen Mulva, CII

Agenda • Opening Remarks – Danny Scott, BE&K / KBR, Moderator • Executive Dashboard and Data Mining – Harold Helland, Abbott • CII Next. Gen Benchmarking System – Bob Herrington, Jacobs • CII Productivity Studies – Stephen Mulva, CII • Questions

Can A Performance Culture Improve Performance? 3

Harold Helland Abbott

History • Pharmaceutical and Biotechnology Metrics Program – Began in 2004, 4 Companies – Currently in 5 th Round, 10 Companies – 167 Projects Entered • CII Data Mining (Chart-O-Rama V. 2) • Executive Dashboard – Available to Pharma / Biotech Companies – Available to CII Members in 2010

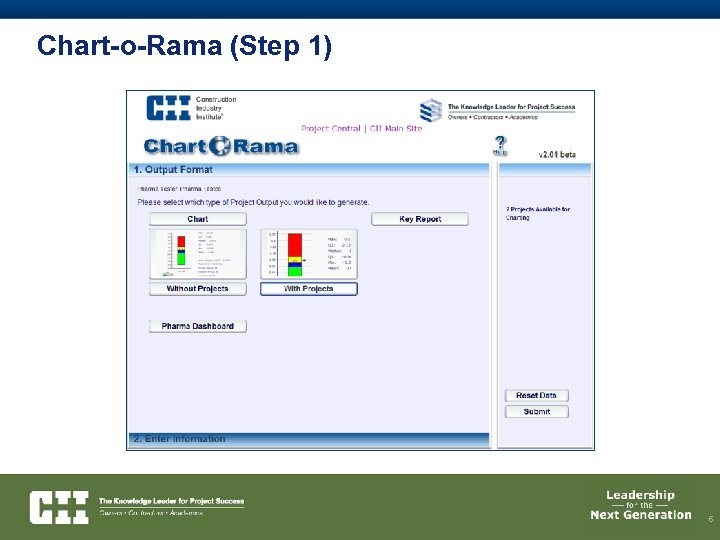

Chart-o-Rama (Step 1) 6

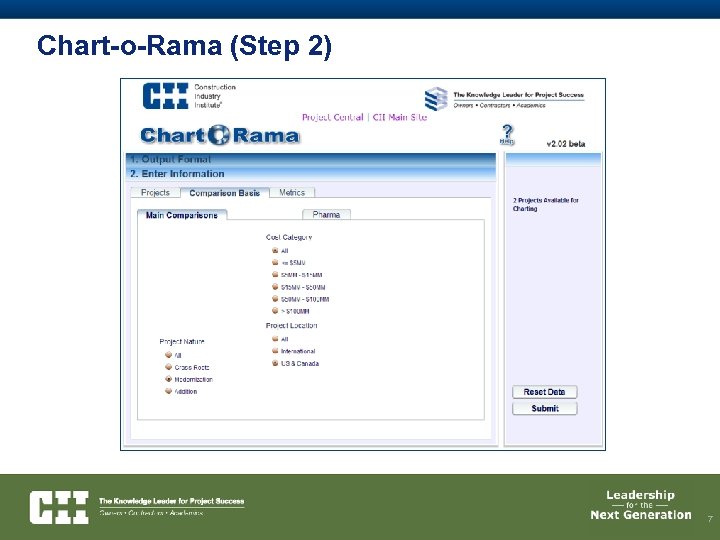

Chart-o-Rama (Step 2) 7

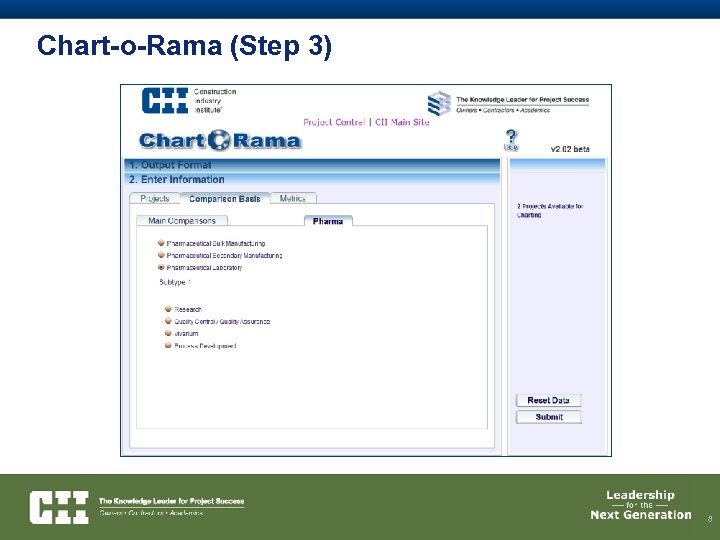

Chart-o-Rama (Step 3) 8

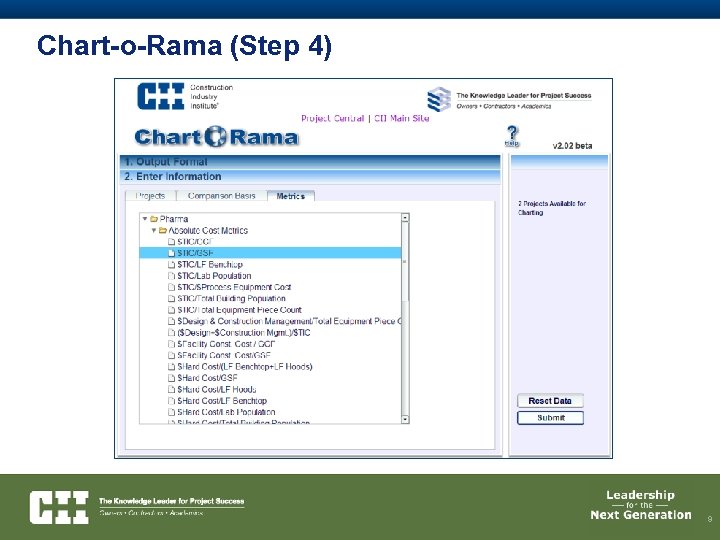

Chart-o-Rama (Step 4) 9

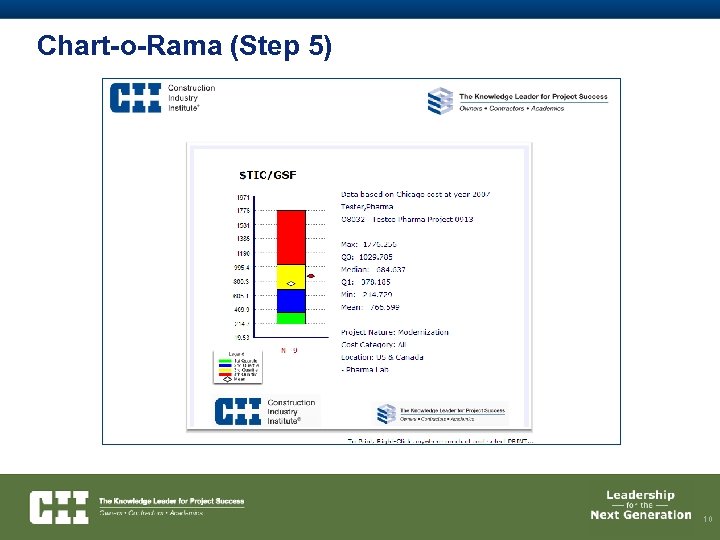

Chart-o-Rama (Step 5) 10

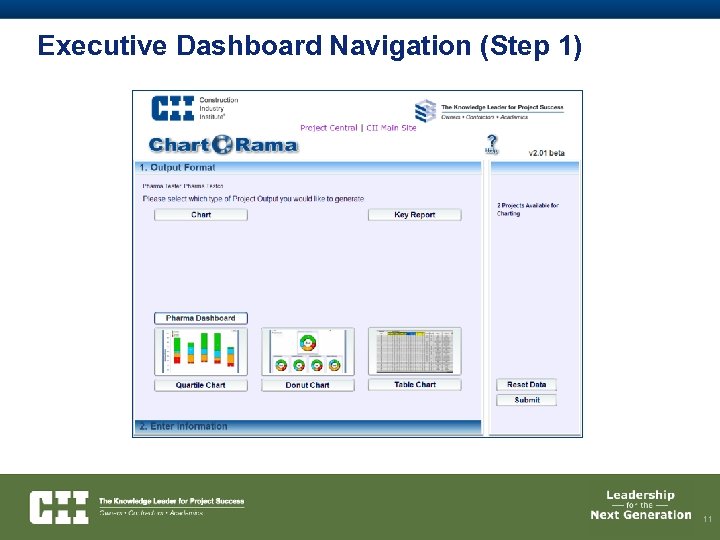

Executive Dashboard Navigation (Step 1) 11

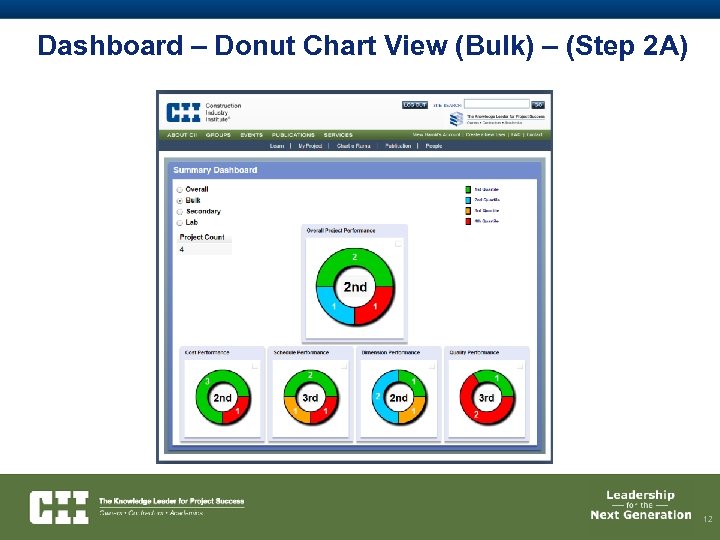

Dashboard – Donut Chart View (Bulk) – (Step 2 A) 12

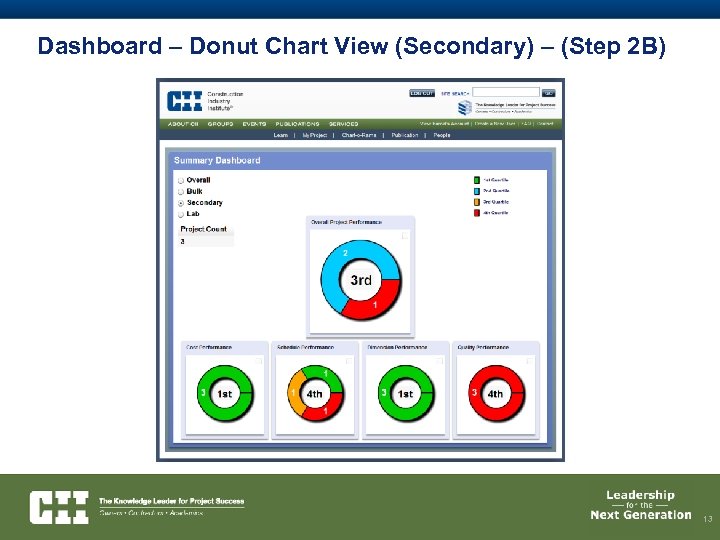

Dashboard – Donut Chart View (Secondary) – (Step 2 B) 13

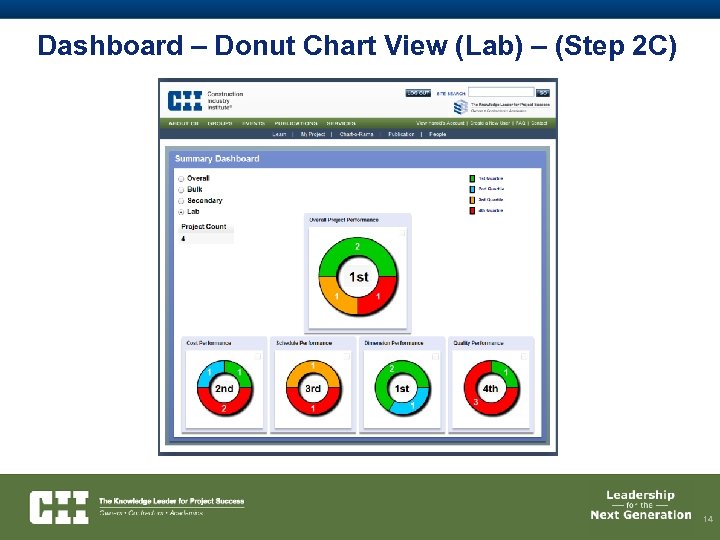

Dashboard – Donut Chart View (Lab) – (Step 2 C) 14

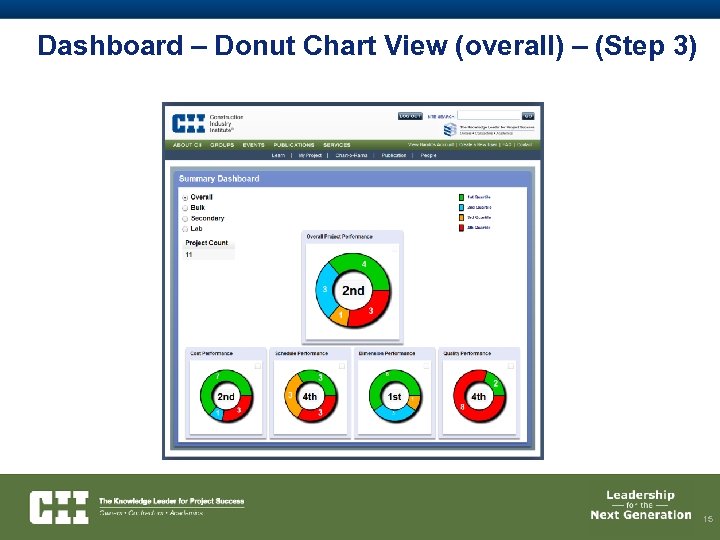

Dashboard – Donut Chart View (overall) – (Step 3) 15

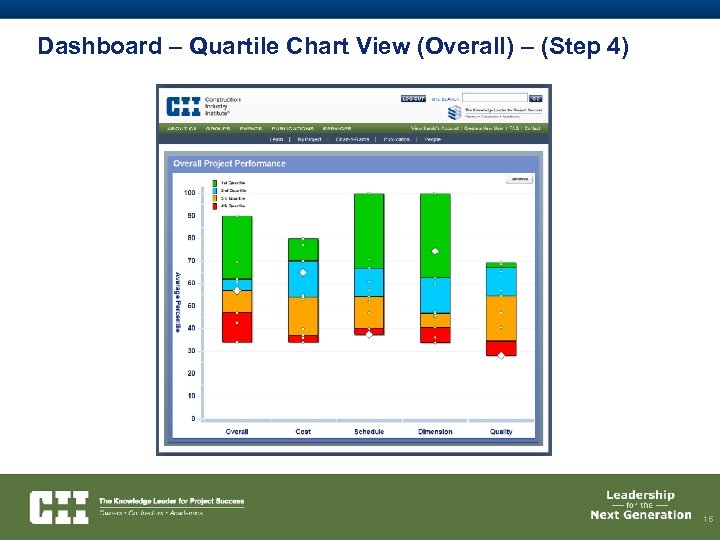

Dashboard – Quartile Chart View (Overall) – (Step 4) 16

Bob Herrington Jacobs

CII Next. Gen Benchmarking System • Tier 1 (80% less questions), Tier 2, Tier 3 Questionnaire • Internal (Business Unit, Product Line) Benchmarks • Instant Feedback with Monthly Quartile Updates • Automated Data Entry (XML) • Worldwide University Benchmarking Labs • CII Summer Intern Program

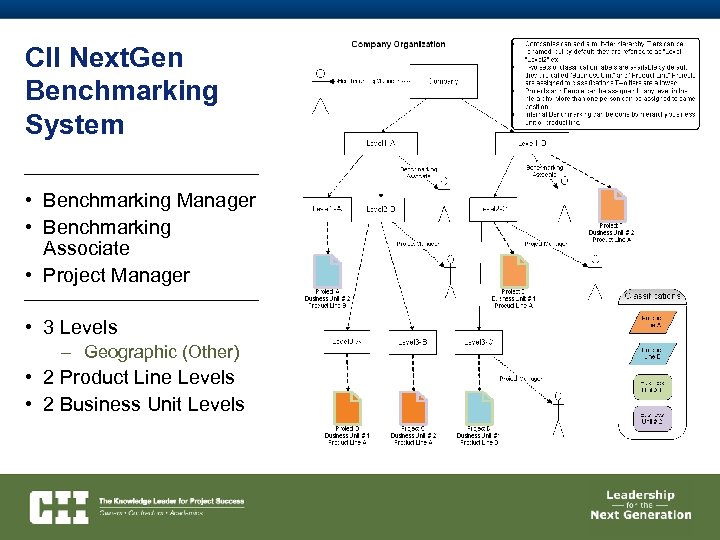

CII Next. Gen Benchmarking System • Benchmarking Manager • Benchmarking Associate • Project Manager • 3 Levels – Geographic (Other) • 2 Product Line Levels • 2 Business Unit Levels

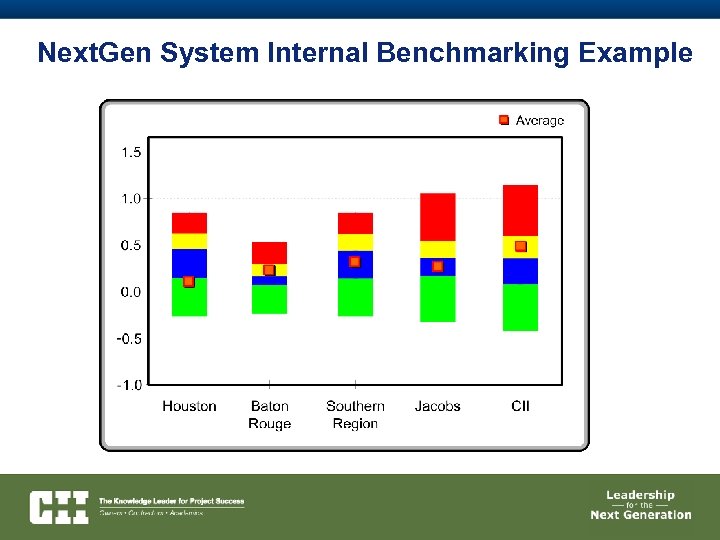

Next. Gen System Internal Benchmarking Example

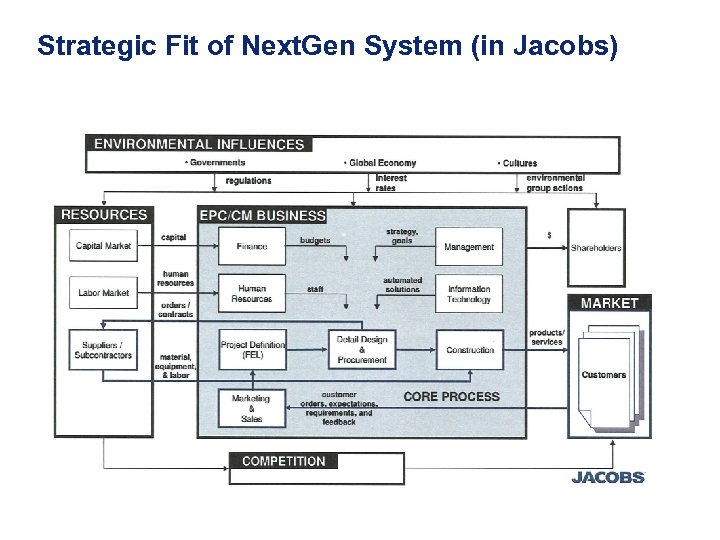

Strategic Fit of Next. Gen System (in Jacobs)

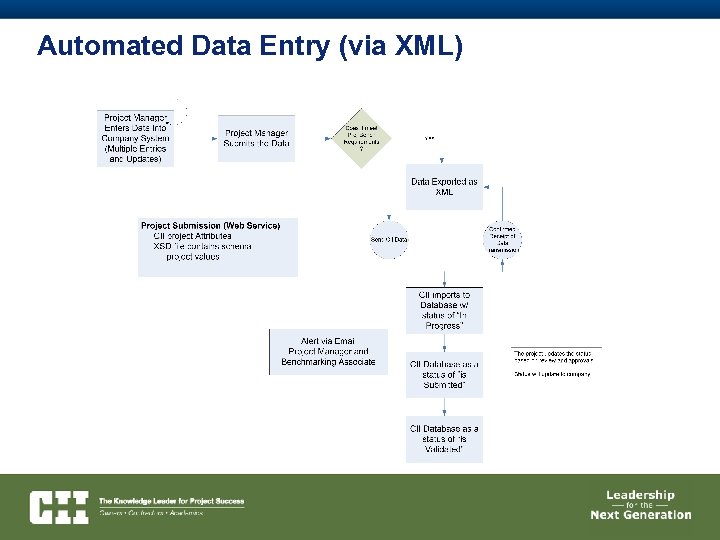

Automated Data Entry (via XML)

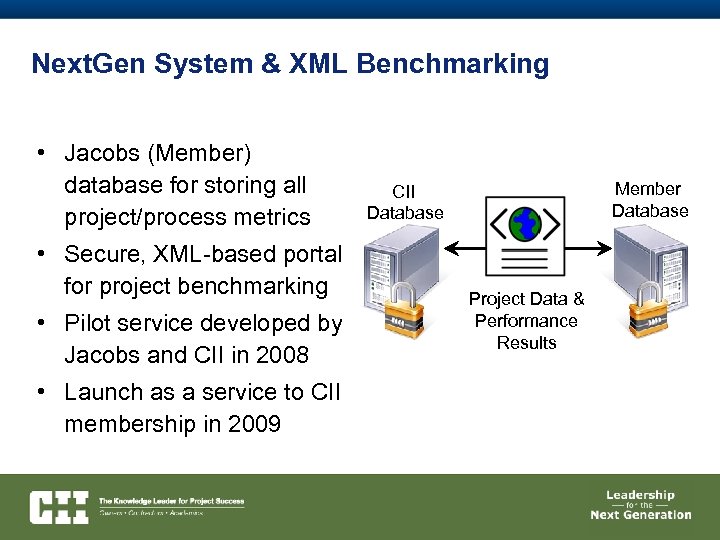

Next. Gen System & XML Benchmarking • Jacobs (Member) database for storing all project/process metrics • Secure, XML-based portal for project benchmarking • Pilot service developed by Jacobs and CII in 2008 • Launch as a service to CII membership in 2009 Member Database CII Database Project Data & Performance Results

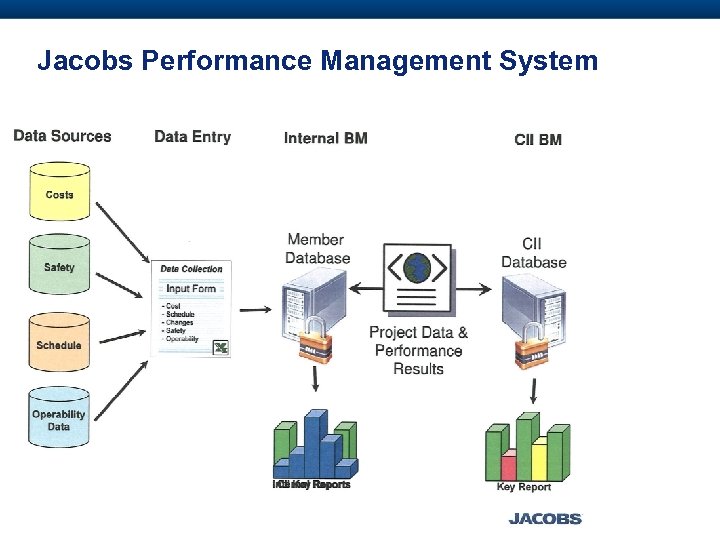

Jacobs Performance Management System

Stephen Mulva CII

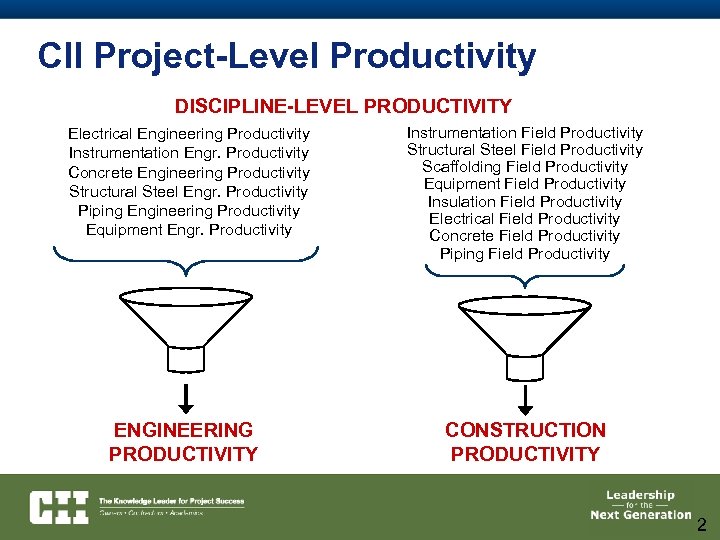

CII Project-Level Productivity DISCIPLINE-LEVEL PRODUCTIVITY Electrical Engineering Productivity Instrumentation Engr. Productivity Concrete Engineering Productivity Structural Steel Engr. Productivity Piping Engineering Productivity Equipment Engr. Productivity ENGINEERING PRODUCTIVITY Instrumentation Field Productivity Structural Steel Field Productivity Scaffolding Field Productivity Equipment Field Productivity Insulation Field Productivity Electrical Field Productivity Concrete Field Productivity Piping Field Productivity CONSTRUCTION PRODUCTIVITY 2

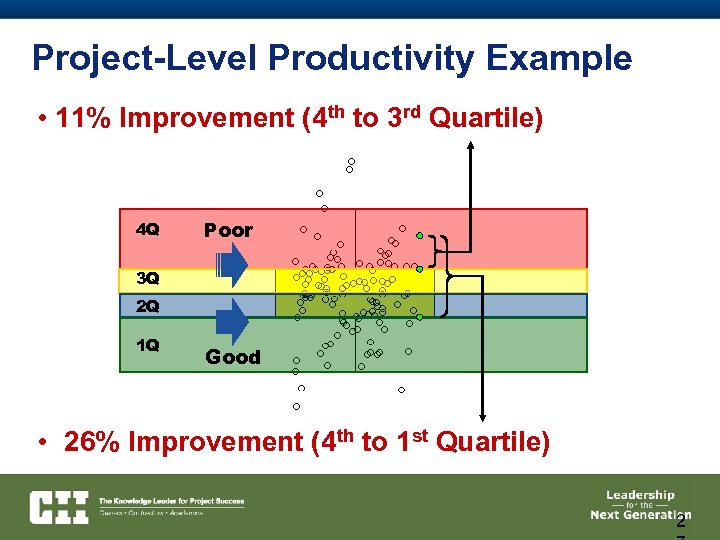

Project-Level Productivity Example • 11% Improvement (4 th to 3 rd Quartile) 4 Q Poor 3 Q 2 Q 1 Q Good • 26% Improvement (4 th to 1 st Quartile) 2

Recent CII Productivity Study • Measuring Interoperability and Best Practices Impacts on Capital Project Productivity – Sponsored by U. S. Department of Commerce – National Institute for Standards and Technology (NIST) • Report Available from CII – BMM 107 -11

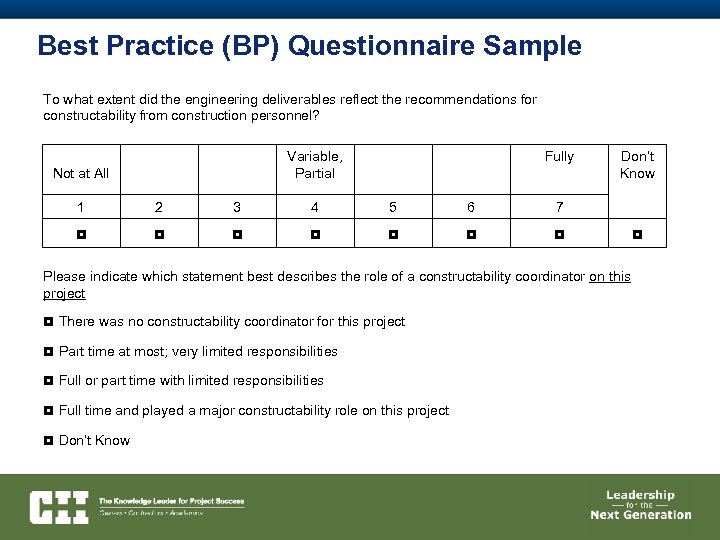

Best Practice (BP) Questionnaire Sample To what extent did the engineering deliverables reflect the recommendations for constructability from construction personnel? Variable, Partial Not at All Fully 1 2 3 4 5 6 7 ◘ ◘ ◘ Don’t Know ◘ Please indicate which statement best describes the role of a constructability coordinator on this project ◘ There was no constructability coordinator for this project ◘ Part time at most; very limited responsibilities ◘ Full or part time with limited responsibilities ◘ Full time and played a major constructability role on this project ◘ Don’t Know ◘

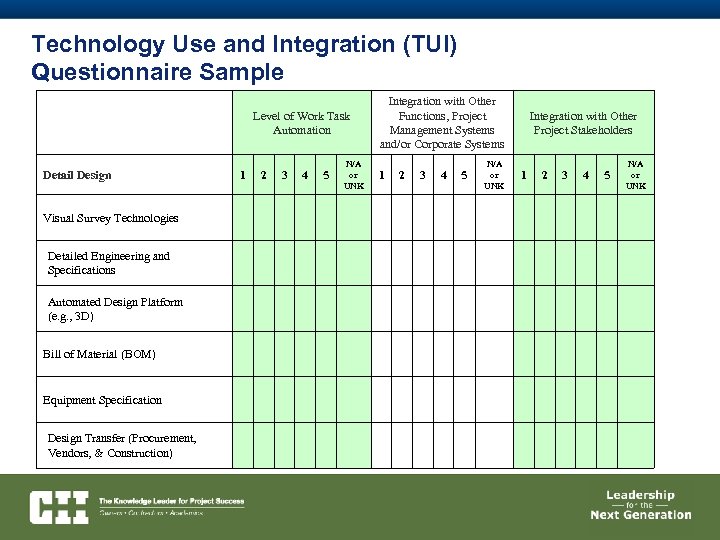

Technology Use and Integration (TUI) Questionnaire Sample Level of Work Task Automation Detail Design Visual Survey Technologies Detailed Engineering and Specifications Automated Design Platform (e. g. , 3 D) Bill of Material (BOM) Equipment Specification Design Transfer (Procurement, Vendors, & Construction) 1 2 3 4 5 N/A or UNK Integration with Other Functions, Project Management Systems and/or Corporate Systems 1 2 3 4 5 N/A or UNK Integration with Other Project Stakeholders 1 2 3 4 5 N/A or UNK

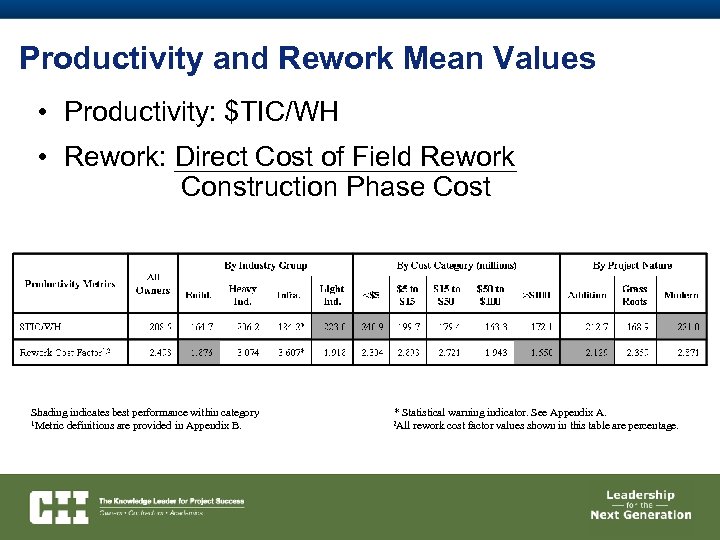

Productivity and Rework Mean Values • Productivity: $TIC/WH • Rework: Direct Cost of Field Rework Construction Phase Cost Shading indicates best performance within category 1 Metric definitions are provided in Appendix B. * Statistical warning indicator. See Appendix A. rework cost factor values shown in this table are percentage. 2 All

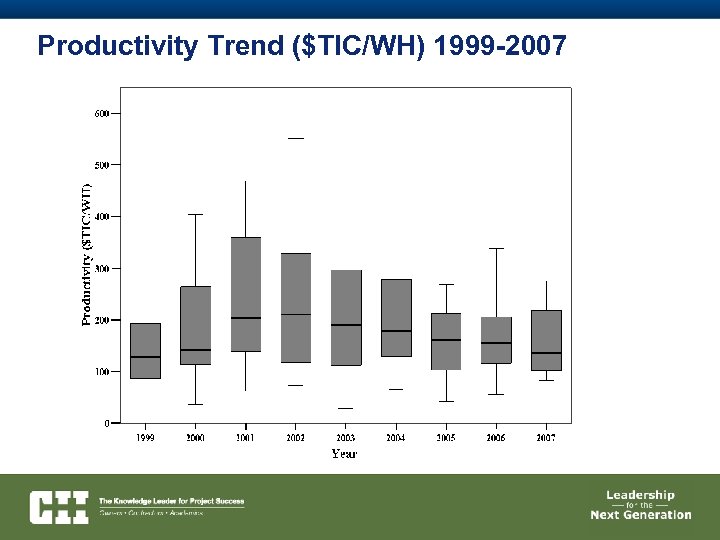

Productivity Trend ($TIC/WH) 1999 -2007

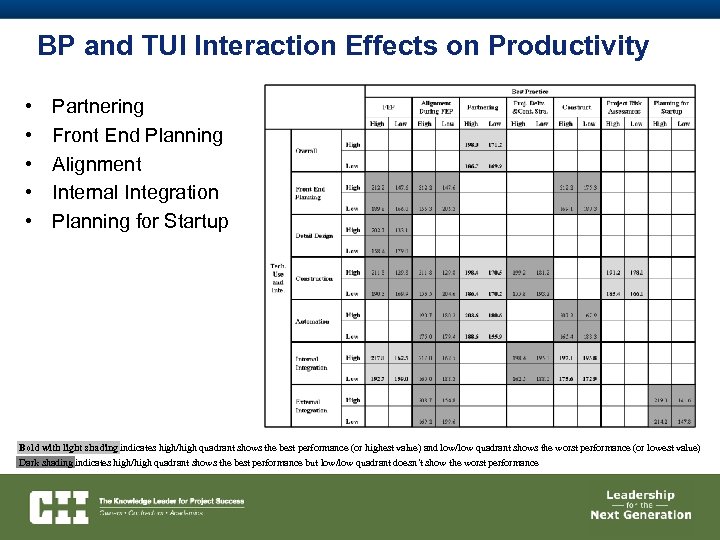

BP and TUI Interaction Effects on Productivity • • • Partnering Front End Planning Alignment Internal Integration Planning for Startup Bold with light shading indicates high/high quadrant shows the best performance (or highest value) and low/low quadrant shows the worst performance (or lowest value) Dark shading indicates high/high quadrant shows the best performance but low/low quadrant doesn ’t show the worst performance

CII Productivity Measures • • Have Proven to be Excellent Metrics New Project-Level Metrics Increasing Use Validation of EVS?

Questions?

bd47859276269517186f40f2077d25e6.ppt