92cf81ad9d59872eb8b4480aa8fe3ba8.ppt

- Количество слайдов: 47

China Shipbuilding Industry Corporation CSIC (Chongqing) Haizhuang Windpower Equipment Co. , Ltd.

Introduction of CSIC ● A super large state-owned shipbuilding corporation in China ● Under direct control of the central government

Introduction of CSIC ● Public Company, stock code: 601989 ● Ranked 462 in the World Top 500 Enterprises, total assets over USD 35 billion. ● 1499 domestic and global patents, 34 National Science and Technology Progress Award, 593 National Defense Science and Technology Award, and a large number of national scientific and technological achievements. ● 28 R&D institutes, 48 industrial enterprises, 15 shareholding companies, 6 regional corporations. ● Distributed in 20 provinces and cities in China.

Business Scope l Builds and repairs a wide range of ships including chemical and product carriers, bulk carriers, containerships, Ro-Ro vessels, LPG, LNG and engineering vessels. The largest shipbuilding and ship repair facilities in China. l CSIC's business ranges from marine industries to civil projects. It has developed and produced hundreds of non-marine products that are used in more than 20 industries and sectors such as aerospace, hydropower, metallurgy, petrochemicals, oil exploitation platform, tobacco, railways, automotive and energy equipment. Like its ships and marine equipment, these non-marine products are also exported worldwide.

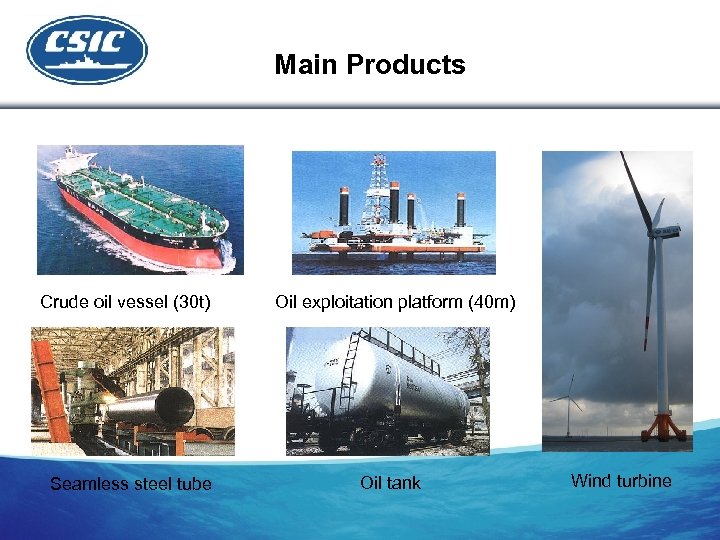

Main Products Crude oil vessel (30 t) Oil exploitation platform (40 m) Seamless steel tube Oil tank Wind turbine

Overview of HZ Windpower ● Established in Jan 2004 ● 17 shareholding companies ● USD 160 million total capital ● 700 employees ● High-tech company for wind turbine design, manufacture and sales ● Invested by related enterprises in CSIC, Guodian Nanzi Co. , Ltd. and CQ Energy Investment Group

Technological Strength ● The only National offshore wind power engineering technology research center ● Chongqing wind power generation equipment technology major projects unit ● Chongqing "ten billion wind power industry enterprise cluster" implementation unit ● Shoulders 2 national research projects “National 5. 0 MW offshore wind turbine technology to support national development plan" and "5. 0 MW offshore wind turbine technology developed by key international scientific and technological cooperation program"

Certificates ISO 9001 Quality Certificate Occupational Health and Safety Management System--Specification Environmental Management System Certificate

Reports & Certificates Test Report (DEWI) GL Certificate (2 MW)

Blue Sky Award by UN

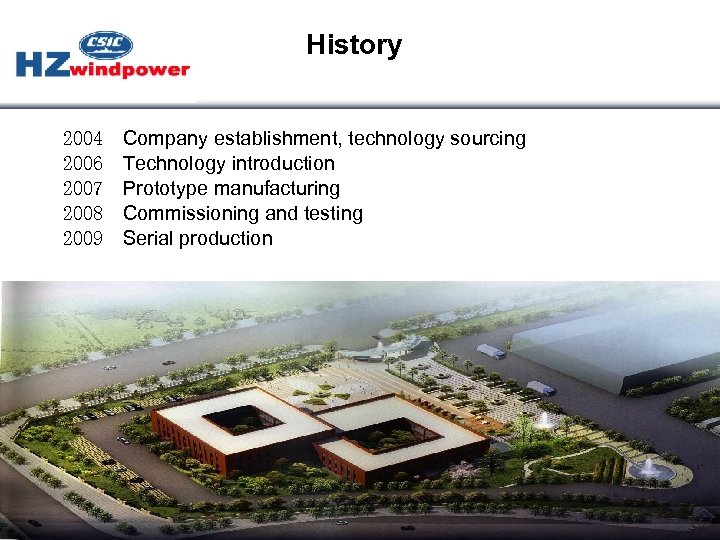

History 2004 2006 2007 2008 2009 Company establishment, technology sourcing Technology introduction Prototype manufacturing Commissioning and testing Serial production

Manufacturing Facility 1 st workshop in Chongqing other 3 workshops in: ü Inner Mongolia ü Xinjiang ü Jiangsu total production capacity: 1500 units/year Length: 300 m Width: 56 m Production capacity: 320 units/year (1 shift)

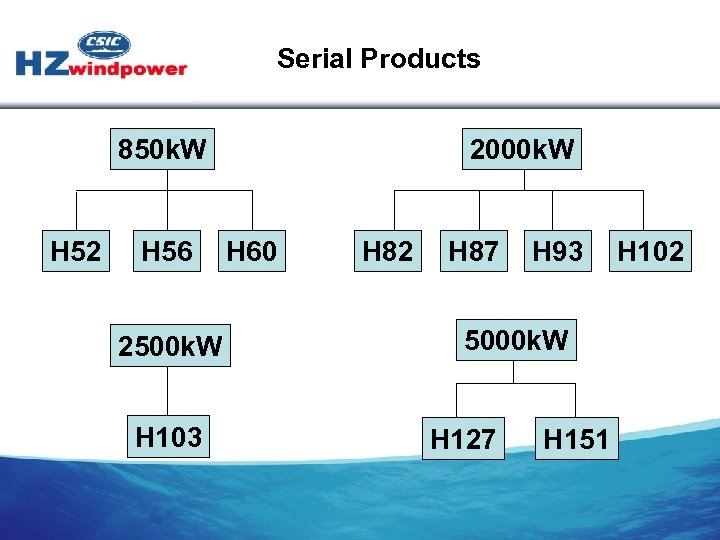

Serial Products 850 k. W H 52 H 56 2500 k. W H 103 2000 k. W H 60 H 82 H 87 H 93 5000 k. W H 127 H 151 H 102

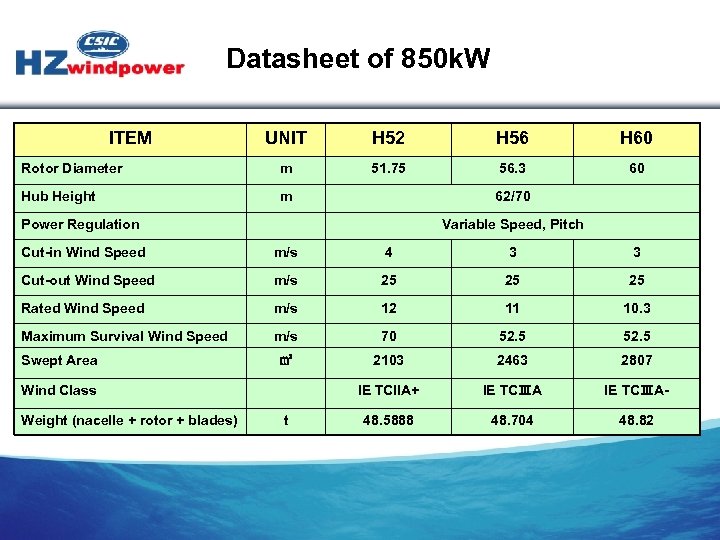

Datasheet of 850 k. W ITEM UNIT H 52 H 56 H 60 Rotor Diameter m 51. 75 56. 3 60 Hub Height m 62/70 Power Regulation Variable Speed, Pitch Cut-in Wind Speed m/s 4 3 3 Cut-out Wind Speed m/s 25 25 25 Rated Wind Speed m/s 12 11 10. 3 Maximum Survival Wind Speed m/s 70 52. 5 ㎡ 2103 2463 2807 IE TCIIA+ IE TCⅢA- 48. 5888 48. 704 48. 82 Swept Area Wind Class Weight (nacelle + rotor + blades) t

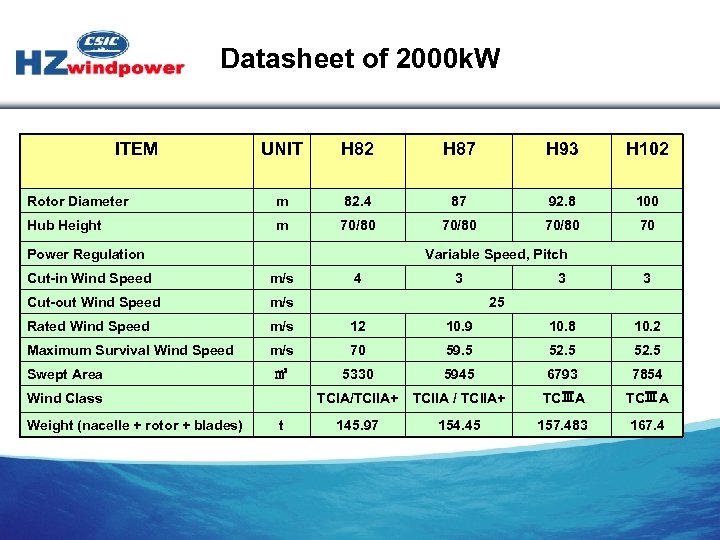

Datasheet of 2000 k. W ITEM UNIT H 82 H 87 H 93 H 102 Rotor Diameter m 82. 4 87 92. 8 100 Hub Height m 70/80 70 Power Regulation Variable Speed, Pitch Cut-in Wind Speed m/s Cut-out Wind Speed m/s Rated Wind Speed m/s 12 Maximum Survival Wind Speed m/s ㎡ Swept Area Weight (nacelle + rotor + blades) t 3 3 10. 9 10. 8 10. 2 70 59. 5 52. 5 5330 5945 6793 7854 TCIA/TCIIA+ Wind Class 4 3 TCIIA / TCIIA+ TCⅢA 145. 97 154. 45 157. 483 167. 4 25

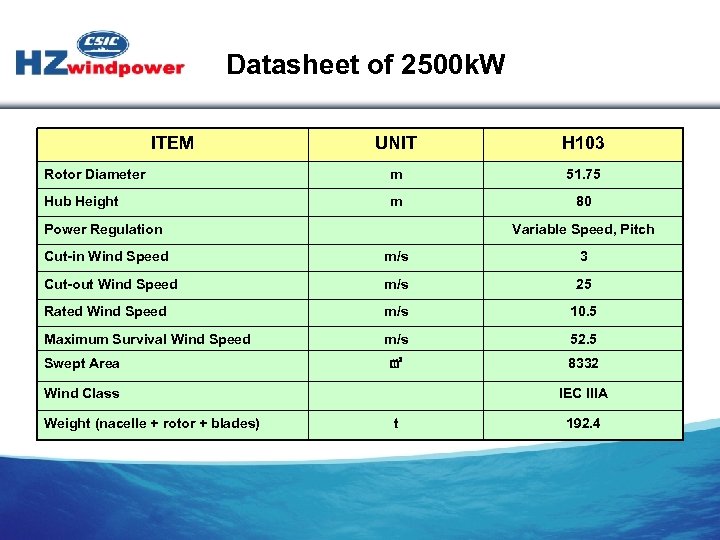

Datasheet of 2500 k. W ITEM UNIT H 103 Rotor Diameter m 51. 75 Hub Height m 80 Power Regulation Variable Speed, Pitch Cut-in Wind Speed m/s 3 Cut-out Wind Speed m/s 25 Rated Wind Speed m/s 10. 5 Maximum Survival Wind Speed m/s 52. 5 ㎡ 8332 Swept Area Wind Class Weight (nacelle + rotor + blades) IEC IIIA t 192. 4

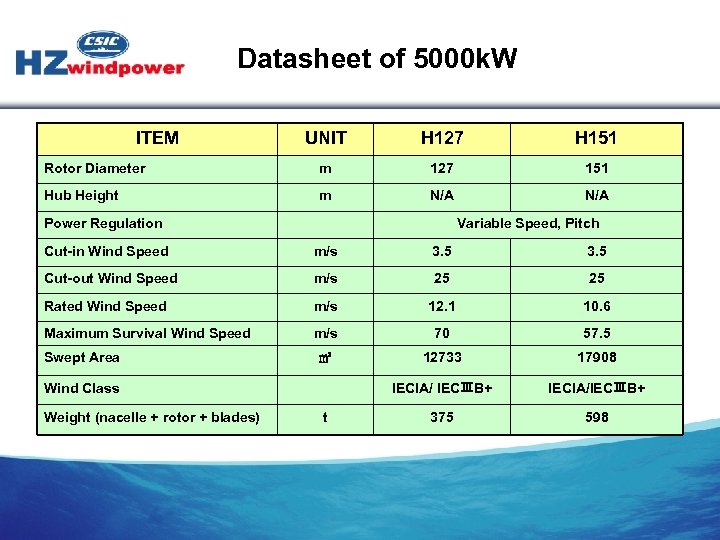

Datasheet of 5000 k. W ITEM UNIT H 127 H 151 Rotor Diameter m 127 151 Hub Height m N/A Power Regulation Variable Speed, Pitch Cut-in Wind Speed m/s 3. 5 Cut-out Wind Speed m/s 25 25 Rated Wind Speed m/s 12. 1 10. 6 Maximum Survival Wind Speed m/s 70 57. 5 ㎡ 12733 17908 IECIA/ IECⅢB+ IECIA/IECⅢB+ 375 598 Swept Area Wind Class Weight (nacelle + rotor + blades) t

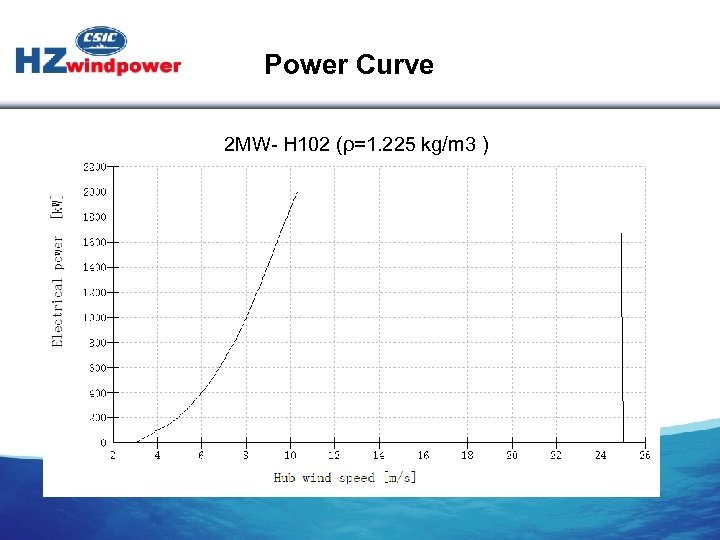

Power Curve 2 MW- H 102 (ρ=1. 225 kg/m 3 )

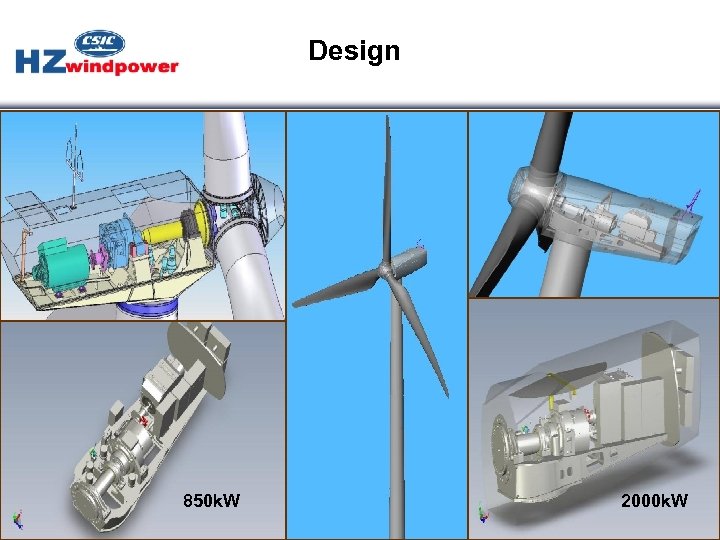

Design 850 k. W 2000 k. W

Technical Features of 2000 KW ● High energy produced, high-quality electricity ● Suitable for cold climate, high-altitude, firm, icing, sandstorm, typhoon, salt fog, etc. ● Improved adaptability, power regulation, power prediction, LVRT ● Concentrated lubrication system ● Filtering and cooling system for gearbox oil ● Double bearing support for the drive train ● Advanced control system and protection system

Technical Features of 850 KW ● Adopting electrically excitative synchronous generator ● Pitch & variable speed, 30% higher in energy yield than wind turbine with fixed pitch & constant speed ● Power regulation, power prediction, LVRT, grid friendly ● Continuous working ability under rough conditions like hot/cold climate, high altitude, etc ● Cost- efficient and high reliability

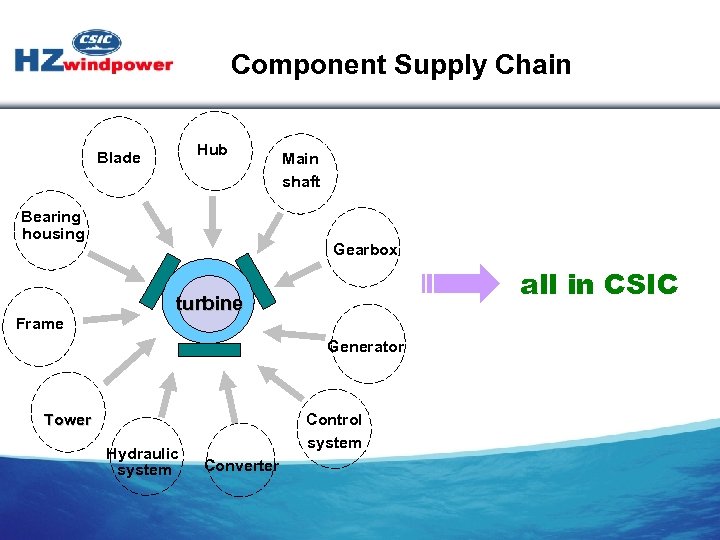

Component Supply Chain Hub Blade Bearing housing Frame Main shaft Gearbox all in CSIC turbine Generator Control system Tower Hydraulic system Converter

Technologies Introduction 850 k. W-technology transfer from Germany with IP right 2000 k. W-co-developed with aerodyn (Germany) with IP right

5 MW Offshore Development Dec 2009 | Project feasibility approved Apr 2010 | Concept study Jul-Aug 2010 | Visit to Europe for co-design Jun 2011 | Completion of design end of 2011 | Prototype assembly

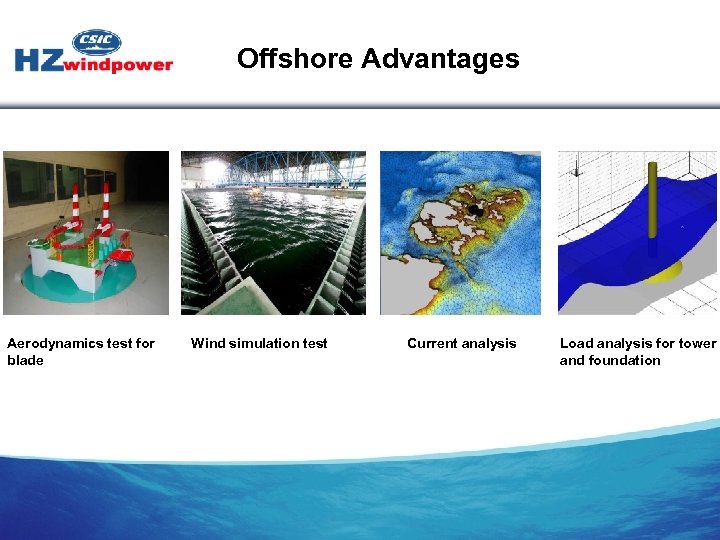

Offshore Advantages Aerodynamics test for blade Wind simulation test Current analysis Load analysis for tower and foundation

Partners

Partners

Development Strategies ● To develop turbines and components in parallel, with each being the driving force behind the other. ● To build up a complete wind power industry chain. ● To develop onshore & offshore wind turbines at the same time with domestic & international cooperation.

International Cooperation ● Co-design with famous foreign design companies ● Outsource components from abroad ● Joint-venture for wind turbine assembly and components manufacturing and sales ● Co-develop overseas wind farms

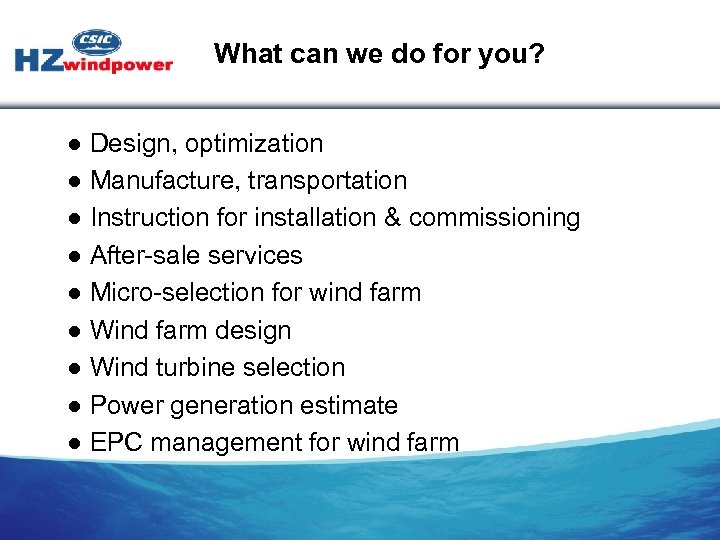

What can we do for you? ● Design, optimization ● Manufacture, transportation ● Instruction for installation & commissioning ● After-sale services ● Micro-selection for wind farm ● Wind farm design ● Wind turbine selection ● Power generation estimate ● EPC management for wind farm

International Business ● WECS exportation (manufacture, delivery, guide for installation & commissioning, after-sale services) ● Invest overseas wind farms (wind turbines as investment) ● Build overseas wind farms in EPC, BT, BOT (install HZ wind turbines) ● Cooperate with local partner to co-invest in promising wind farm projects

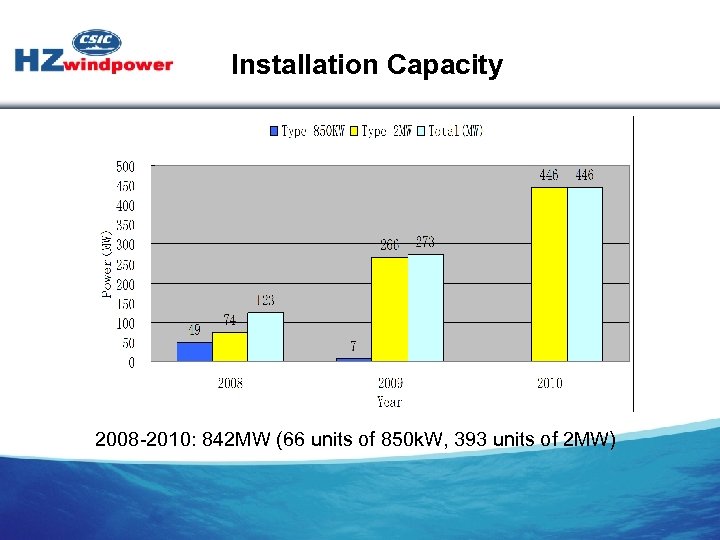

Installation Capacity 2008 -2010: 842 MW (66 units of 850 k. W, 393 units of 2 MW)

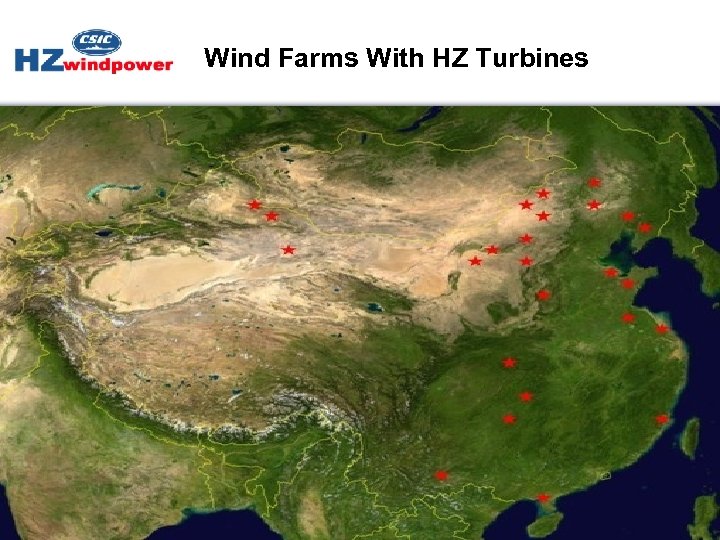

Wind Farms With HZ Turbines

Wind Farm in Wulong 850 k. W, 58 units

Wind Farms in Inner Mongolia 2 MW, 88 units

Wind Farm in Rudong 2 MW near-shore, 2 units of prototypes

Wind Farms in Northeast China 2 MW, 125 units

Wind Farm in Lian Yungang 2 MW, 50 units

Wind Farms in Jin Bian, Shanxi 2 MW, 49 units

Dear sir, We are pleased to invite you and your colleagues to visit HZ windpower head office, R&D center and assembly workshop in Chongqing China. We are looking forward to establishing a long-term relationship between both parties and a win-win cooperation.

Contact • HZ Windpower NA Inc. • 101 W Big Beaver Rd. Suite 245 • Tel : 641 -414 -5112 • Email: sales@hzwindpowerna. com • Website: www. HZWindpower. NA. com

CATCH THE WIND EQUIP THE WORLD

92cf81ad9d59872eb8b4480aa8fe3ba8.ppt