2b3ff133fef5e00362f34c7a6a9cf7fe.ppt

- Количество слайдов: 66

Chemical Inventory Management & Control for Water & Wastewater Treatment Plants 1150 -D Burnett Ave. , Concord, CA 94520 (800) 893 -6723 WWW. FORCEFLOW. COM

Chemical Inventory Management & Control for Water & Wastewater Treatment Plants 1150 -D Burnett Ave. , Concord, CA 94520 (800) 893 -6723 WWW. FORCEFLOW. COM

Technical Presentation Outline I. What is and why Specify Chemical Inventory Management II. Technologies: Sensors & Instrumentation III. Applications IV. Onsite Chemical Dilution Systems V. Installation Slide Show

Technical Presentation Outline I. What is and why Specify Chemical Inventory Management II. Technologies: Sensors & Instrumentation III. Applications IV. Onsite Chemical Dilution Systems V. Installation Slide Show

I. What is Chemical Inventory Management? • Inventory Monitoring • Daily Usage/Dosage Documentation • Feed Rate Verification and Monitoring

I. What is Chemical Inventory Management? • Inventory Monitoring • Daily Usage/Dosage Documentation • Feed Rate Verification and Monitoring

I. Why Specify Chemical Inventory Management? • Comply With Government Regulations • Safety • Cost Savings

I. Why Specify Chemical Inventory Management? • Comply With Government Regulations • Safety • Cost Savings

Why Specify? Comply With Government Regulations "The 10 states standards": Recommended Standards For Water Works 1997 Part 5 Chemical Application, Section 5. 1. 2 (e) reads: "Provisions shall be made for measuring the quantities of chemicals used. " Additionally, Section 5. 1. 2 (f) reads "Weighing scales: (1) shall be provided for weighing cylinders at all plants utilizing chlorine gas (2) may be required for fluoride solution feed (3) should be provided for volumetric dry chemical feeders, and (4) shall be capable of providing reasonable precision in relation to average daily dose. " Great Lakes Upper Mississippi River Board of State Public Health & Environmental Managers

Why Specify? Comply With Government Regulations "The 10 states standards": Recommended Standards For Water Works 1997 Part 5 Chemical Application, Section 5. 1. 2 (e) reads: "Provisions shall be made for measuring the quantities of chemicals used. " Additionally, Section 5. 1. 2 (f) reads "Weighing scales: (1) shall be provided for weighing cylinders at all plants utilizing chlorine gas (2) may be required for fluoride solution feed (3) should be provided for volumetric dry chemical feeders, and (4) shall be capable of providing reasonable precision in relation to average daily dose. " Great Lakes Upper Mississippi River Board of State Public Health & Environmental Managers

Why Specify? Various Other Regulations Requiring Scales • South Carolina Department of Health and Environmental Control's (DHEC) • Texas Natural Resource Conservation Commission (TNRCC) • Michigan Dept. Of Environmental Quality (DEQ) • New Mexico Surface Water Quality Bureau • Georgia Environmental Protection Division • New Foundland Dept. Of Environment • Duchess County, NY Health Dept. • Wisconsin Administrative Code • Wyoming Secretary Of State • Utah Administrative Code • Texas Dept. Of Health

Why Specify? Various Other Regulations Requiring Scales • South Carolina Department of Health and Environmental Control's (DHEC) • Texas Natural Resource Conservation Commission (TNRCC) • Michigan Dept. Of Environmental Quality (DEQ) • New Mexico Surface Water Quality Bureau • Georgia Environmental Protection Division • New Foundland Dept. Of Environment • Duchess County, NY Health Dept. • Wisconsin Administrative Code • Wyoming Secretary Of State • Utah Administrative Code • Texas Dept. Of Health

Why Specify? SAFETY! • Reduce Operator Exposure to Dangerous Chemicals • Feed Verification • Prevent Hazardous Spills Caused from Overfill • Safeguard Against Tank Running Empty

Why Specify? SAFETY! • Reduce Operator Exposure to Dangerous Chemicals • Feed Verification • Prevent Hazardous Spills Caused from Overfill • Safeguard Against Tank Running Empty

Why Specify? Cost Savings Proof of Delivered Amount Reduce Labor through Remote Monitoring Purchase Chemical in Most Economical Strength Available

Why Specify? Cost Savings Proof of Delivered Amount Reduce Labor through Remote Monitoring Purchase Chemical in Most Economical Strength Available

II. TECHNOLOGIES: Sensors & Instrumentation

II. TECHNOLOGIES: Sensors & Instrumentation

Technologies: Sensors & Instrumentation Sensors SCALES Pivoted vs. Hi Accuracy ULTRASONIC • Municipal Regulations Specify • Non-Intrusive, Non-Contacting • Only Reliable Method for Compressed Gas • Ease of Use With Portable Tanks • Most Accurate Form of Level Measurement • Cost Effective for Tanks 2000 gallons and Up

Technologies: Sensors & Instrumentation Sensors SCALES Pivoted vs. Hi Accuracy ULTRASONIC • Municipal Regulations Specify • Non-Intrusive, Non-Contacting • Only Reliable Method for Compressed Gas • Ease of Use With Portable Tanks • Most Accurate Form of Level Measurement • Cost Effective for Tanks 2000 gallons and Up

Technologies: Sensors & Instrumentation • Electronic • • Strain Gauge Load Cells Digital Instrumentation • Hydraulic • • Hydraulic Load Cells Analog Dial • Cross Technology™ • • Hydraulic Load Cells Digital Instrumentation

Technologies: Sensors & Instrumentation • Electronic • • Strain Gauge Load Cells Digital Instrumentation • Hydraulic • • Hydraulic Load Cells Analog Dial • Cross Technology™ • • Hydraulic Load Cells Digital Instrumentation

Wizard 4000® CHEMICAL INVENTORY MANAGEMENT SYSTEM • Independently monitors up to four scales or ultrasonic sensors • Outputs up to four 4 -20 m. A signals for remote monitoring • Up to four level alarms • Lbs, Kgs, Gallons • Datalogs each of the previous 10 days chemical usage • Net weight, Daily Usage, Feed rate, Amount Used, Days Til Empty, Tare weight, Gross weight

Wizard 4000® CHEMICAL INVENTORY MANAGEMENT SYSTEM • Independently monitors up to four scales or ultrasonic sensors • Outputs up to four 4 -20 m. A signals for remote monitoring • Up to four level alarms • Lbs, Kgs, Gallons • Datalogs each of the previous 10 days chemical usage • Net weight, Daily Usage, Feed rate, Amount Used, Days Til Empty, Tare weight, Gross weight

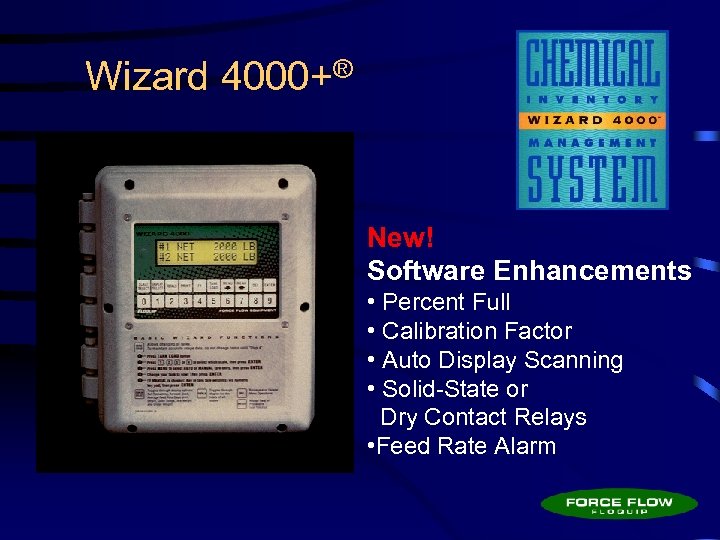

Wizard 4000+® New! Software Enhancements • Percent Full • Calibration Factor • Auto Display Scanning • Solid-State or Dry Contact Relays • Feed Rate Alarm

Wizard 4000+® New! Software Enhancements • Percent Full • Calibration Factor • Auto Display Scanning • Solid-State or Dry Contact Relays • Feed Rate Alarm

The SOLO® Digital Indicator • Single and Dual Channel • 4 -20 m. A Output • NEMA 4 X • Tare Adjust Knob • Level Alarm

The SOLO® Digital Indicator • Single and Dual Channel • 4 -20 m. A Output • NEMA 4 X • Tare Adjust Knob • Level Alarm

Century® Hydraulic Dials • No Power Required • Explosion Proof • 5 -Year Warranty • Easy Installation Four Different Sizes

Century® Hydraulic Dials • No Power Required • Explosion Proof • 5 -Year Warranty • Easy Installation Four Different Sizes

SOLO XT Weight Indicator ® • Battery or Loop Powered • Uses Hydraulic Load Cell • 4 -20 m. A Output • For Cylinder & Drum Scales

SOLO XT Weight Indicator ® • Battery or Loop Powered • Uses Hydraulic Load Cell • 4 -20 m. A Output • For Cylinder & Drum Scales

Technologies: Sensors & Instrumentation Wizard ARC™ Controller AUTOMATIC DAY TANK & HOPPER REFILLING SYSTEM Pause & Project™

Technologies: Sensors & Instrumentation Wizard ARC™ Controller AUTOMATIC DAY TANK & HOPPER REFILLING SYSTEM Pause & Project™

III. Applications SPECIFICATION SECTION 11200 Liquid Feed Hypo, Fluoride, Polymer Gas Feed Chlorine, SO 2, Ammonia Dry Feed Carbon, Lime, Potassium Permanganate

III. Applications SPECIFICATION SECTION 11200 Liquid Feed Hypo, Fluoride, Polymer Gas Feed Chlorine, SO 2, Ammonia Dry Feed Carbon, Lime, Potassium Permanganate

Applications Liquid Feed 5 to 35 Gallon Carboys 55 Gallon Drums • HYPO • POLYMER • FLUORIDE • ALUM • CAUSTIC Day Tanks IBC Tote Bins

Applications Liquid Feed 5 to 35 Gallon Carboys 55 Gallon Drums • HYPO • POLYMER • FLUORIDE • ALUM • CAUSTIC Day Tanks IBC Tote Bins

Applications Liquid Bulk Storage • HYPO • POLYMER • FLUORIDE • ALUM • CAUSTIC For Liquid Tanks Larger than 2000 gallons

Applications Liquid Bulk Storage • HYPO • POLYMER • FLUORIDE • ALUM • CAUSTIC For Liquid Tanks Larger than 2000 gallons

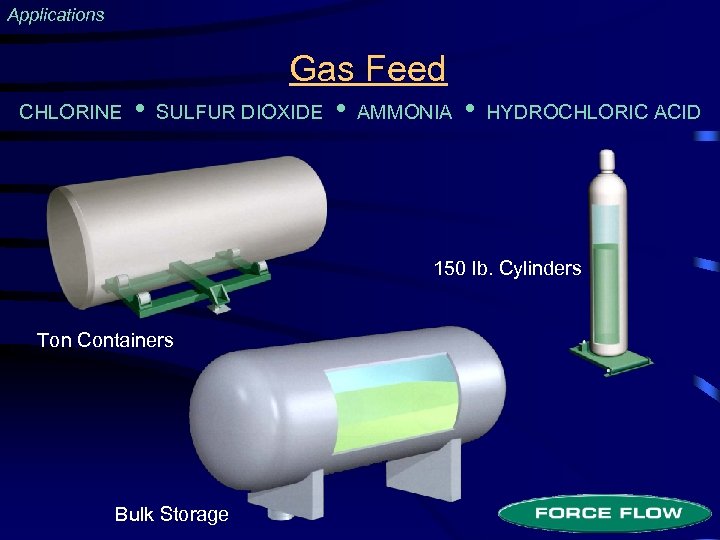

Applications Gas Feed CHLORINE • SULFUR DIOXIDE • AMMONIA • HYDROCHLORIC ACID 150 lb. Cylinders Ton Containers Bulk Storage

Applications Gas Feed CHLORINE • SULFUR DIOXIDE • AMMONIA • HYDROCHLORIC ACID 150 lb. Cylinders Ton Containers Bulk Storage

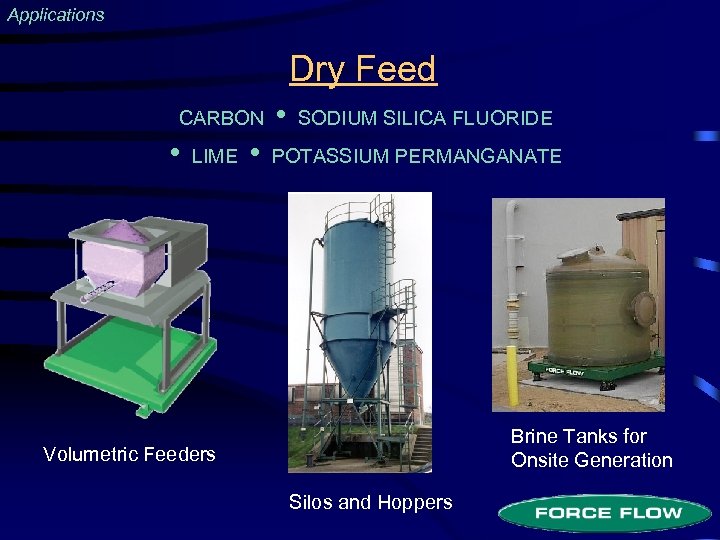

Applications Dry Feed CARBON • LIME • • SODIUM SILICA FLUORIDE POTASSIUM PERMANGANATE Brine Tanks for Onsite Generation Volumetric Feeders Silos and Hoppers

Applications Dry Feed CARBON • LIME • • SODIUM SILICA FLUORIDE POTASSIUM PERMANGANATE Brine Tanks for Onsite Generation Volumetric Feeders Silos and Hoppers

III. Onsite Chemical Dilution Systems

III. Onsite Chemical Dilution Systems

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller SODIUM HYPOCHLORITE SODIUM HYDROXIDE (CAUSTIC)

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller SODIUM HYPOCHLORITE SODIUM HYDROXIDE (CAUSTIC)

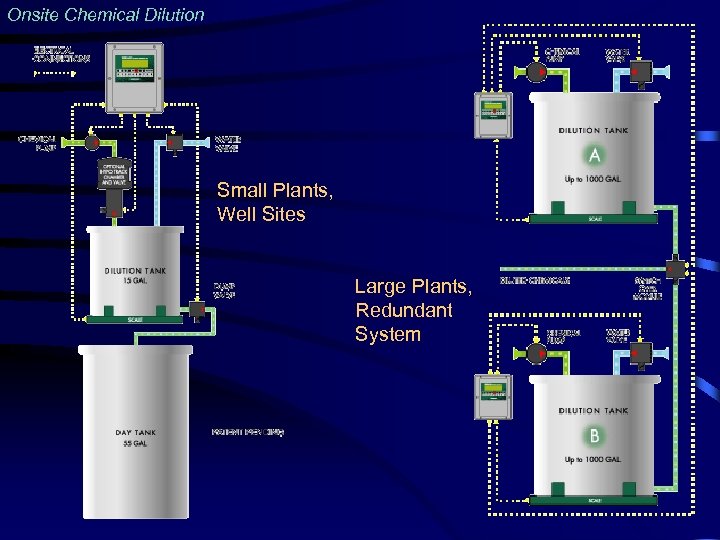

Onsite Chemical Dilution Small Plants, Well Sites Large Plants, Redundant System

Onsite Chemical Dilution Small Plants, Well Sites Large Plants, Redundant System

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller Safety KEEP PLANT PERSONNEL SAFE BY FEEDING LOWER STRENGTH CHEMICALS AUTOMATION & REMOTE MONITORING REDUCES OPERATOR EXPOSURE REDUNDANT CONTROLS & ALARMS

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller Safety KEEP PLANT PERSONNEL SAFE BY FEEDING LOWER STRENGTH CHEMICALS AUTOMATION & REMOTE MONITORING REDUCES OPERATOR EXPOSURE REDUNDANT CONTROLS & ALARMS

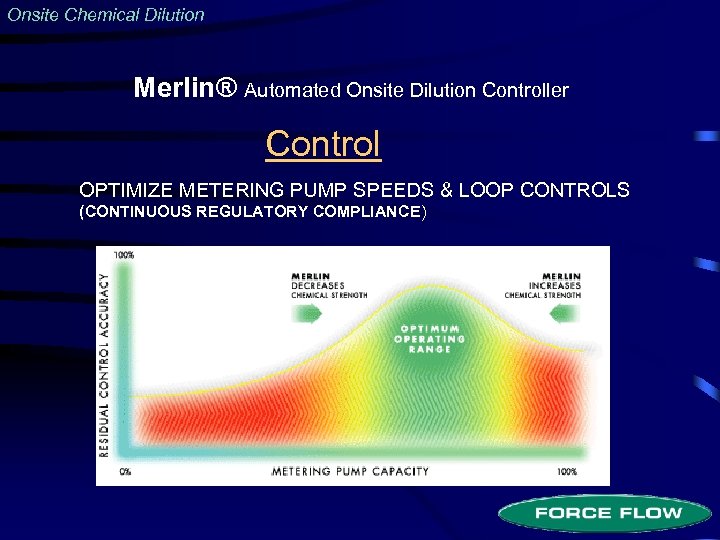

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller Control OPTIMIZE METERING PUMP SPEEDS & LOOP CONTROLS (CONTINUOUS REGULATORY COMPLIANCE)

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller Control OPTIMIZE METERING PUMP SPEEDS & LOOP CONTROLS (CONTINUOUS REGULATORY COMPLIANCE)

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller Control SUPERIOR ACCURACY & REPEATABILITY HIGH VOLUME / LOW STRENGTH MEANS BETTER CONTROL

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller Control SUPERIOR ACCURACY & REPEATABILITY HIGH VOLUME / LOW STRENGTH MEANS BETTER CONTROL

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller REDUCED LABOR, MAINTENANCE & CHEMICAL COSTS üLabor Savings üNo More Crystallization üReduced Off-Gassing and Leakage üEliminate Scaling üBuy Chemicals, Not Water

Onsite Chemical Dilution Merlin® Automated Onsite Dilution Controller REDUCED LABOR, MAINTENANCE & CHEMICAL COSTS üLabor Savings üNo More Crystallization üReduced Off-Gassing and Leakage üEliminate Scaling üBuy Chemicals, Not Water

Visit our extensive website for more information Download Library Includes: Literature, Drawings, Specs, Presentations, O&M Manuals

Visit our extensive website for more information Download Library Includes: Literature, Drawings, Specs, Presentations, O&M Manuals

IV. Installation Slide Show

IV. Installation Slide Show

Ton Containers & Cylinders

Ton Containers & Cylinders

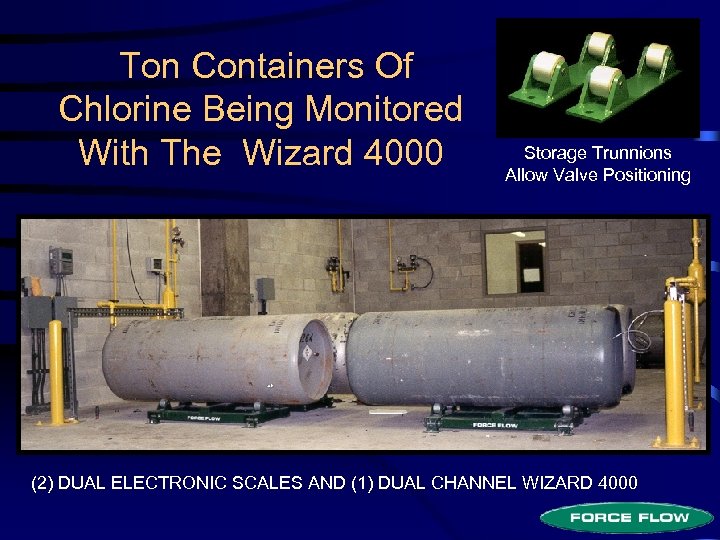

Ton Containers Of Chlorine Being Monitored With The Wizard 4000 Storage Trunnions Allow Valve Positioning (2) DUAL ELECTRONIC SCALES AND (1) DUAL CHANNEL WIZARD 4000

Ton Containers Of Chlorine Being Monitored With The Wizard 4000 Storage Trunnions Allow Valve Positioning (2) DUAL ELECTRONIC SCALES AND (1) DUAL CHANNEL WIZARD 4000

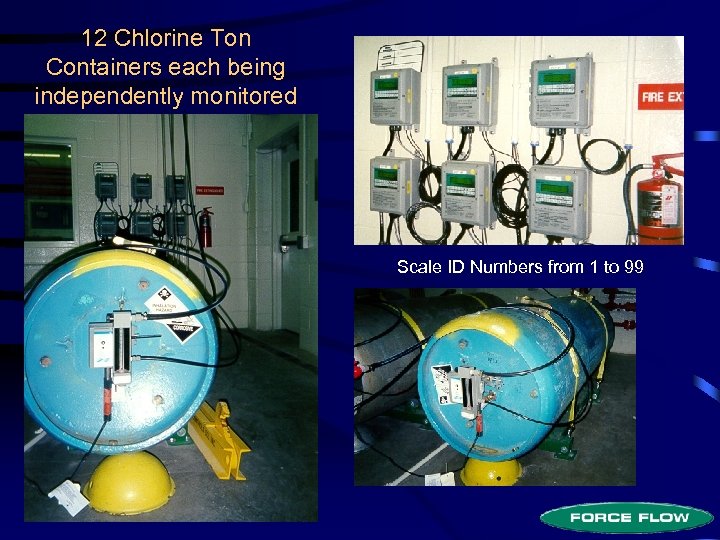

12 Chlorine Ton Containers each being independently monitored Scale ID Numbers from 1 to 99

12 Chlorine Ton Containers each being independently monitored Scale ID Numbers from 1 to 99

Wizard 4000® Multiple Tank Chlor-Scale • Lever design • ¼% Accuracy • Reliable Single Load Cell Design • Superior Ability to Handle Shock Loading

Wizard 4000® Multiple Tank Chlor-Scale • Lever design • ¼% Accuracy • Reliable Single Load Cell Design • Superior Ability to Handle Shock Loading

Wizard 4000® Multi. Tonner System • Optional Tank Restraint Straps • Elevated for Easy Operator Process Hook-Up

Wizard 4000® Multi. Tonner System • Optional Tank Restraint Straps • Elevated for Easy Operator Process Hook-Up

Wizard 4000® Multiple Scale Using Summed Platforms

Wizard 4000® Multiple Scale Using Summed Platforms

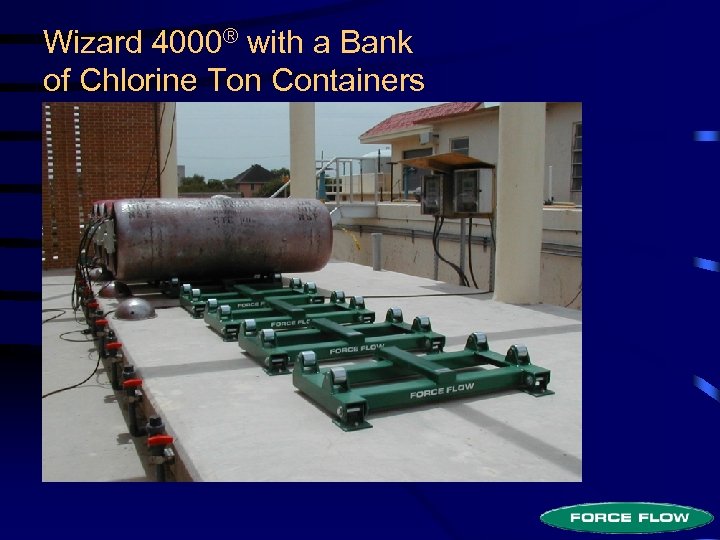

Wizard 4000® with a Bank of Chlorine Ton Containers

Wizard 4000® with a Bank of Chlorine Ton Containers

CHLOR-SCALE® Cart Scale Ideal for rooms where no overhead hoist is available Tank is loaded on scale by delivery truck, then rolled indoors V-Groove casters roll on track

CHLOR-SCALE® Cart Scale Ideal for rooms where no overhead hoist is available Tank is loaded on scale by delivery truck, then rolled indoors V-Groove casters roll on track

Chlor-Scale® 150 • No AC Power! • Uses Hydraulic Load Cell • Analog or Digital • 4 -20 m. A Output PVC Plastic Platform

Chlor-Scale® 150 • No AC Power! • Uses Hydraulic Load Cell • Analog or Digital • 4 -20 m. A Output PVC Plastic Platform

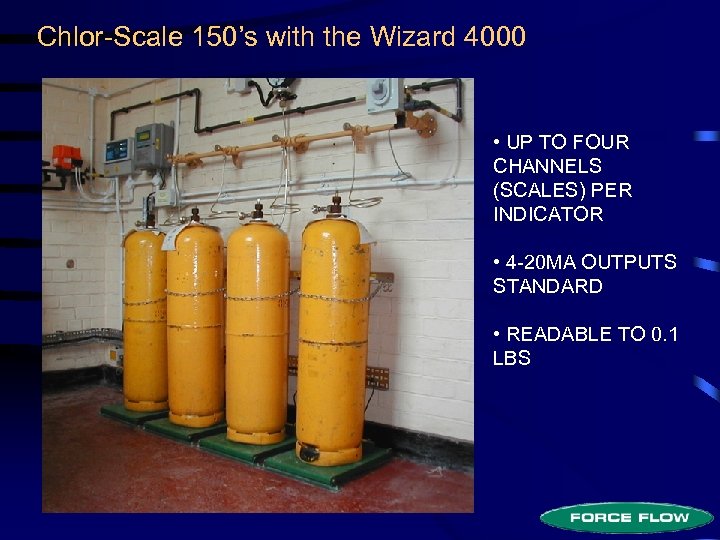

Chlor-Scale 150’s with the Wizard 4000 • UP TO FOUR CHANNELS (SCALES) PER INDICATOR • 4 -20 MA OUTPUTS STANDARD • READABLE TO 0. 1 LBS

Chlor-Scale 150’s with the Wizard 4000 • UP TO FOUR CHANNELS (SCALES) PER INDICATOR • 4 -20 MA OUTPUTS STANDARD • READABLE TO 0. 1 LBS

Bulk Stationary Tanks

Bulk Stationary Tanks

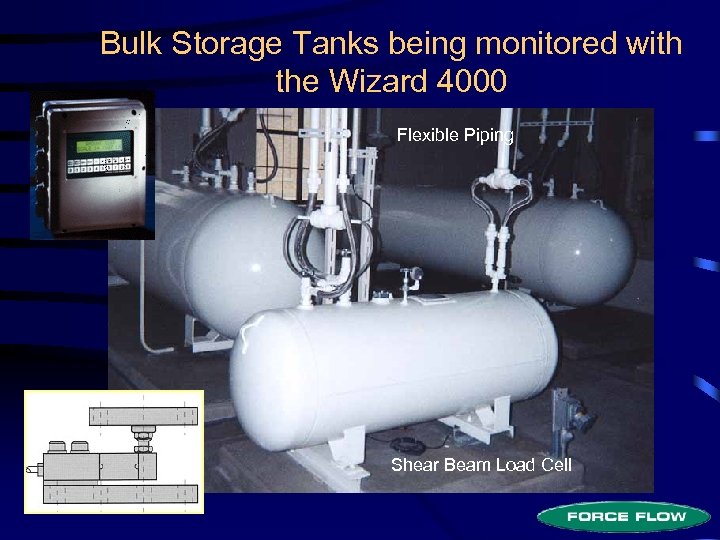

Bulk Storage Tanks being monitored with the Wizard 4000 Flexible Piping Shear Beam Load Cell

Bulk Storage Tanks being monitored with the Wizard 4000 Flexible Piping Shear Beam Load Cell

Ammonia Stationary Tank With Century® Hydraulic System Satellite™ 4 -20 m. A Transmitter

Ammonia Stationary Tank With Century® Hydraulic System Satellite™ 4 -20 m. A Transmitter

Lime Silo

Lime Silo

Day Tanks and IBC Totes

Day Tanks and IBC Totes

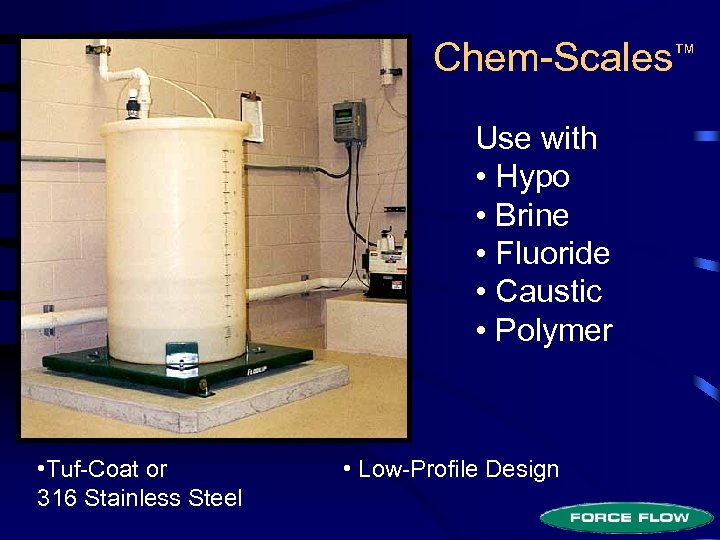

Chem-Scales™ Use with • Hypo • Brine • Fluoride • Caustic • Polymer • Tuf-Coat or 316 Stainless Steel • Low-Profile Design

Chem-Scales™ Use with • Hypo • Brine • Fluoride • Caustic • Polymer • Tuf-Coat or 316 Stainless Steel • Low-Profile Design

Electronic Chem-Scales™ Monitoring Coagulant Tanks

Electronic Chem-Scales™ Monitoring Coagulant Tanks

Chem-Scales Monitoring Large Spun Fiberglass Day Tanks

Chem-Scales Monitoring Large Spun Fiberglass Day Tanks

Chem-Scale™ TO MAXIMIZE ACCURACY, MATCH TANK TO PLATFORM • Capacity • Diameter

Chem-Scale™ TO MAXIMIZE ACCURACY, MATCH TANK TO PLATFORM • Capacity • Diameter

60" Chem-Scale with Wizard 4000 • Use flexible piping • Position over pivot • Clips or backstop

60" Chem-Scale with Wizard 4000 • Use flexible piping • Position over pivot • Clips or backstop

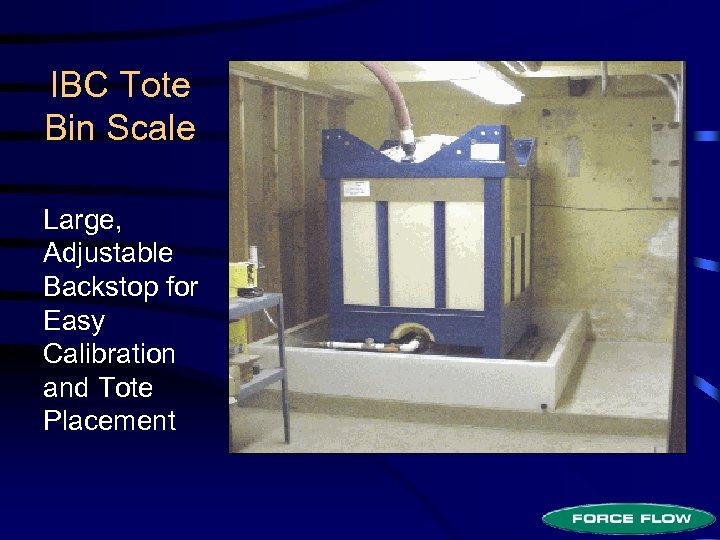

IBC Tote Bin Scale Large, Adjustable Backstop for Easy Calibration and Tote Placement

IBC Tote Bin Scale Large, Adjustable Backstop for Easy Calibration and Tote Placement

Electronic Brine. Scales™ Monitoring Onsite Hypo Generation Brine Tanks

Electronic Brine. Scales™ Monitoring Onsite Hypo Generation Brine Tanks

ECHO-SCALE™ Ultrasonic Sensor • 4 -20 m. A Output Allows Sensor To Be Used Stand-Alone • PVC Construction Resists Chemical Attacks • Excellent for Hypo!

ECHO-SCALE™ Ultrasonic Sensor • 4 -20 m. A Output Allows Sensor To Be Used Stand-Alone • PVC Construction Resists Chemical Attacks • Excellent for Hypo!

Portable Drums & Carboys

Portable Drums & Carboys

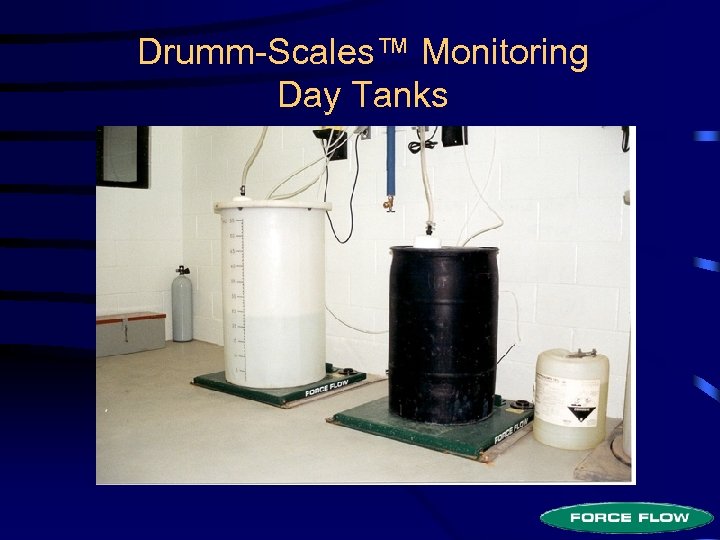

Drumm-Scales™ Monitoring Day Tanks

Drumm-Scales™ Monitoring Day Tanks

316 SS Drumm -Scale with Century® Dial • Available Standard in Tuf-Coat® Steel

316 SS Drumm -Scale with Century® Dial • Available Standard in Tuf-Coat® Steel

Drumm-Scale™ with Semblex Polymer Blending Unit Optional Loading Ramp

Drumm-Scale™ with Semblex Polymer Blending Unit Optional Loading Ramp

316 SS Drumm-Scale™ Monitoring a Polymer Day Tank

316 SS Drumm-Scale™ Monitoring a Polymer Day Tank

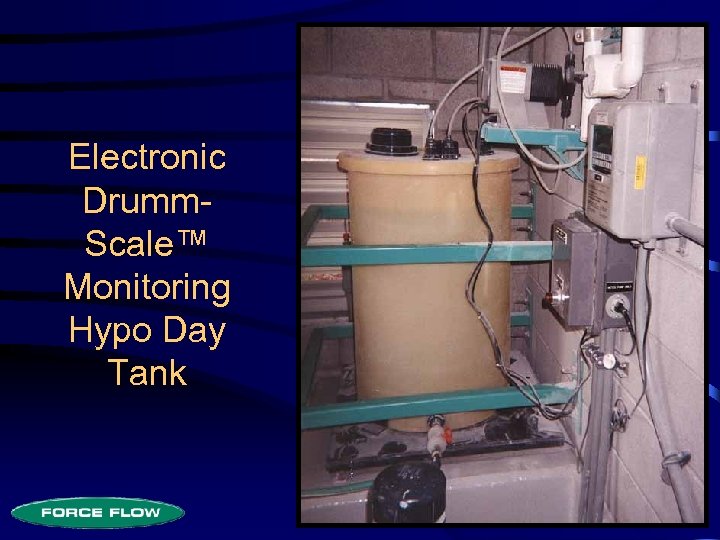

Electronic Drumm. Scale™ Monitoring Hypo Day Tank

Electronic Drumm. Scale™ Monitoring Hypo Day Tank

Electronic Drumm-Scale™ Monitoring Hypo Day Tank

Electronic Drumm-Scale™ Monitoring Hypo Day Tank

Merlin Onsite Dilution Systems

Merlin Onsite Dilution Systems

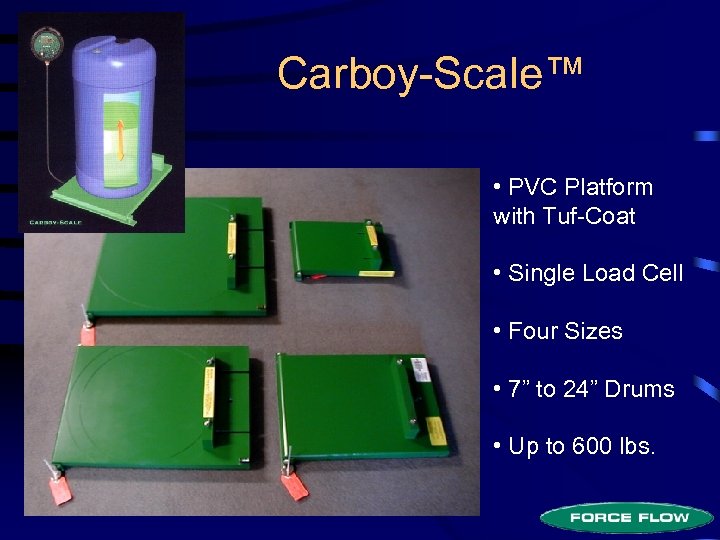

Carboy-Scale™ • PVC Platform with Tuf-Coat • Single Load Cell • Four Sizes • 7” to 24” Drums • Up to 600 lbs.

Carboy-Scale™ • PVC Platform with Tuf-Coat • Single Load Cell • Four Sizes • 7” to 24” Drums • Up to 600 lbs.

IV Warranty, Guarantee and Custom Drawings

IV Warranty, Guarantee and Custom Drawings

Warranty & Performance Guarantee • 5 -Year Warranty • Performance Guarantee • 48 HR Factory Service • (800) Help Hotline

Warranty & Performance Guarantee • 5 -Year Warranty • Performance Guarantee • 48 HR Factory Service • (800) Help Hotline

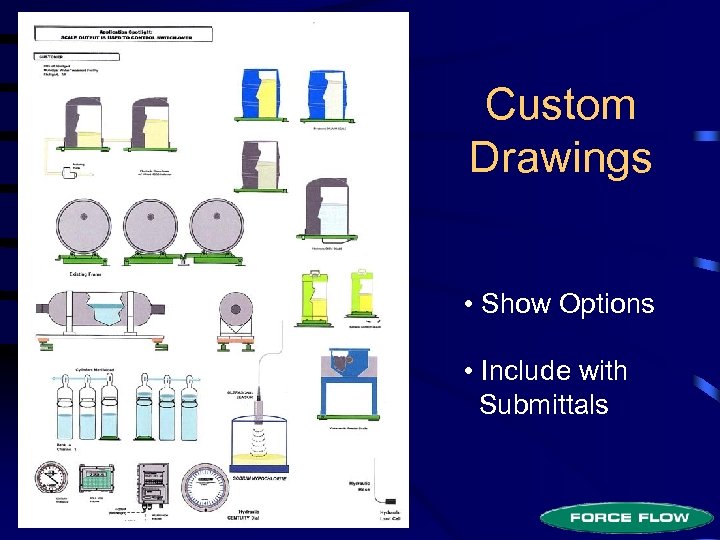

Custom Drawings • Show Options • Include with Submittals

Custom Drawings • Show Options • Include with Submittals