6b41b21b9e879863dec6fac7b3855065.ppt

- Количество слайдов: 17

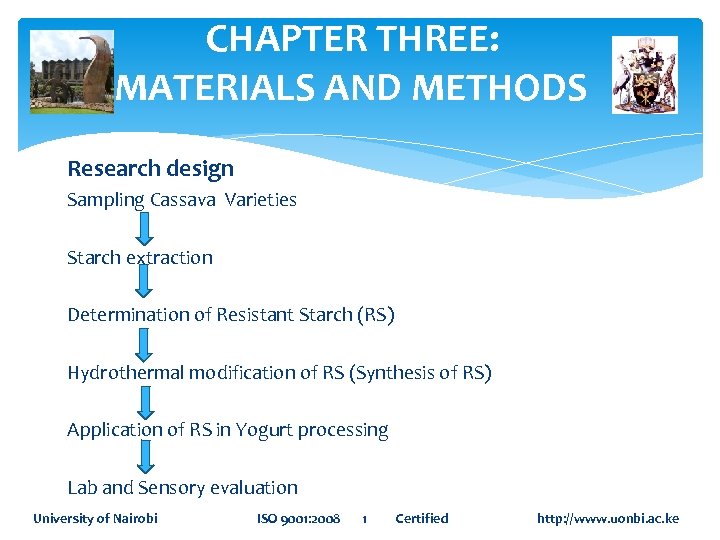

CHAPTER THREE: MATERIALS AND METHODS Research design Sampling Cassava Varieties Starch extraction Determination of Resistant Starch (RS) Hydrothermal modification of RS (Synthesis of RS) Application of RS in Yogurt processing Lab and Sensory evaluation University of Nairobi ISO 9001: 2008 1 Certified http: //www. uonbi. ac. ke

CHAPTER THREE: MATERIALS AND METHODS Research design Sampling Cassava Varieties Starch extraction Determination of Resistant Starch (RS) Hydrothermal modification of RS (Synthesis of RS) Application of RS in Yogurt processing Lab and Sensory evaluation University of Nairobi ISO 9001: 2008 1 Certified http: //www. uonbi. ac. ke

Objective 1: Determination of the levels of RS in three Rwandese cassava varieties Raw material acquisition Cassava roots samples from three different cassava varieties (NASE 14, THE I 92/0057 and GARUKUNSUBIRE) of 12 months in the field will be collected from RAB field research stations of Rubona and Rilima Starch extracting Measurement of RS University of Nairobi ISO 9001: 2008 2 Certified http: //www. uonbi. ac. ke

Objective 1: Determination of the levels of RS in three Rwandese cassava varieties Raw material acquisition Cassava roots samples from three different cassava varieties (NASE 14, THE I 92/0057 and GARUKUNSUBIRE) of 12 months in the field will be collected from RAB field research stations of Rubona and Rilima Starch extracting Measurement of RS University of Nairobi ISO 9001: 2008 2 Certified http: //www. uonbi. ac. ke

Determination of the levels of RS in three Rwandese cassava varieties con’t Starch Extraction Starch will be extracted using the wet method as described by Benesi et al. (2004). Starch properties Moisture content and dry matter content determination (ISO 1660 -1996), • Water absorption and Solubility Index will be carried out as per Anderson (1982), • Texture analysis: Texture Analyser will be used (Kaszab et al. , 2002), • Pasting profile of starch (AACC Approved Method 61. 02. ). • University of Nairobi ISO 9001: 2008 3 Certified http: //www. uonbi. ac. ke

Determination of the levels of RS in three Rwandese cassava varieties con’t Starch Extraction Starch will be extracted using the wet method as described by Benesi et al. (2004). Starch properties Moisture content and dry matter content determination (ISO 1660 -1996), • Water absorption and Solubility Index will be carried out as per Anderson (1982), • Texture analysis: Texture Analyser will be used (Kaszab et al. , 2002), • Pasting profile of starch (AACC Approved Method 61. 02. ). • University of Nairobi ISO 9001: 2008 3 Certified http: //www. uonbi. ac. ke

Determination of the levels of RS in three Rwandese cassava varieties con’t Resistant starch determination RS will be determined as per AOAC Method (2002. 02). Triplicate samples will be analyzed and ANOVA will be carried out to determine significant differences at 5% level of significance. University of Nairobi ISO 9001: 2008 4 Certified http: //www. uonbi. ac. ke

Determination of the levels of RS in three Rwandese cassava varieties con’t Resistant starch determination RS will be determined as per AOAC Method (2002. 02). Triplicate samples will be analyzed and ANOVA will be carried out to determine significant differences at 5% level of significance. University of Nairobi ISO 9001: 2008 4 Certified http: //www. uonbi. ac. ke

Objective 2: Hydrothermal modification of RS Heat-moisture treatment (HMT) The moisture levels of the starch samples will be increased to 18%, 24% and 30%, The samples will be sealed in glass jars and heated in an air oven at 80°C for 16 hours, The starch samples will be air dried and subjected to RS measurement. University of Nairobi ISO 9001: 2008 5 Certified http: //www. uonbi. ac. ke

Objective 2: Hydrothermal modification of RS Heat-moisture treatment (HMT) The moisture levels of the starch samples will be increased to 18%, 24% and 30%, The samples will be sealed in glass jars and heated in an air oven at 80°C for 16 hours, The starch samples will be air dried and subjected to RS measurement. University of Nairobi ISO 9001: 2008 5 Certified http: //www. uonbi. ac. ke

Hydrothermal modification of RS cont’ Annealing Starch (100 g) will be heated in excess water at a temperature of 45°C and 55°C for 24 hours, Samples will be centrifuged, air-dried and will be subjected to RS determination. University of Nairobi ISO 9001: 2008 6 Certified http: //www. uonbi. ac. ke

Hydrothermal modification of RS cont’ Annealing Starch (100 g) will be heated in excess water at a temperature of 45°C and 55°C for 24 hours, Samples will be centrifuged, air-dried and will be subjected to RS determination. University of Nairobi ISO 9001: 2008 6 Certified http: //www. uonbi. ac. ke

Hydrothermal modification of RS cont’ Starch profiling Moisture content and dry matter content determination (ISO 1660 -1996), • Water absorption and Solubility Index will be carried out as per Anderson (1982), • Texture analysis: Texture Analyser will be used (Kaszab et al. , 2002), • Pasting profile of starch (AACC Approved Method 61. 02. ). • University of Nairobi ISO 9001: 2008 7 Certified http: //www. uonbi. ac. ke

Hydrothermal modification of RS cont’ Starch profiling Moisture content and dry matter content determination (ISO 1660 -1996), • Water absorption and Solubility Index will be carried out as per Anderson (1982), • Texture analysis: Texture Analyser will be used (Kaszab et al. , 2002), • Pasting profile of starch (AACC Approved Method 61. 02. ). • University of Nairobi ISO 9001: 2008 7 Certified http: //www. uonbi. ac. ke

Hydrothermal modification of RS cont’ Pasting profile of starch (AACC Approved Method 61. 02. ) Flour (40 g) and water (420 ml) will be heated from 30°C to 93°C and held for 15 min, The temperature will be decreased at a constant rate of 1. 5°C/ min until 30°C and held there for 15 min. The resistance to stirring as a viscosity curve will be recorded, The pasting temperature, peak viscosity, hot paste viscosity and cold paste viscosity will be determined from the pasting curve. University of Nairobi ISO 9001: 2008 8 Certified http: //www. uonbi. ac. ke

Hydrothermal modification of RS cont’ Pasting profile of starch (AACC Approved Method 61. 02. ) Flour (40 g) and water (420 ml) will be heated from 30°C to 93°C and held for 15 min, The temperature will be decreased at a constant rate of 1. 5°C/ min until 30°C and held there for 15 min. The resistance to stirring as a viscosity curve will be recorded, The pasting temperature, peak viscosity, hot paste viscosity and cold paste viscosity will be determined from the pasting curve. University of Nairobi ISO 9001: 2008 8 Certified http: //www. uonbi. ac. ke

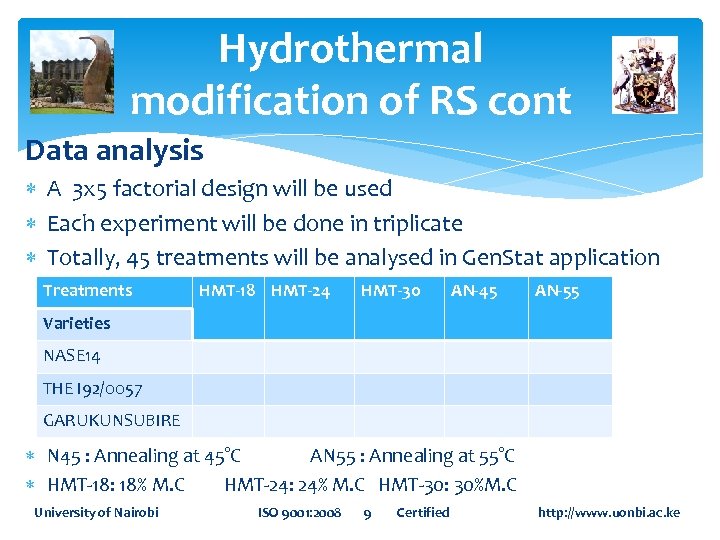

Hydrothermal modification of RS cont Data analysis A 3 x 5 factorial design will be used Each experiment will be done in triplicate Totally, 45 treatments will be analysed in Gen. Stat application Treatments HMT-18 HMT-24 HMT-30 AN-45 AN-55 Varieties NASE 14 THE I 92/0057 GARUKUNSUBIRE N 45 : Annealing at 45°C AN 55 : Annealing at 55°C HMT-18: 18% M. C HMT-24: 24% M. C HMT-30: 30%M. C University of Nairobi ISO 9001: 2008 9 Certified http: //www. uonbi. ac. ke

Hydrothermal modification of RS cont Data analysis A 3 x 5 factorial design will be used Each experiment will be done in triplicate Totally, 45 treatments will be analysed in Gen. Stat application Treatments HMT-18 HMT-24 HMT-30 AN-45 AN-55 Varieties NASE 14 THE I 92/0057 GARUKUNSUBIRE N 45 : Annealing at 45°C AN 55 : Annealing at 55°C HMT-18: 18% M. C HMT-24: 24% M. C HMT-30: 30%M. C University of Nairobi ISO 9001: 2008 9 Certified http: //www. uonbi. ac. ke

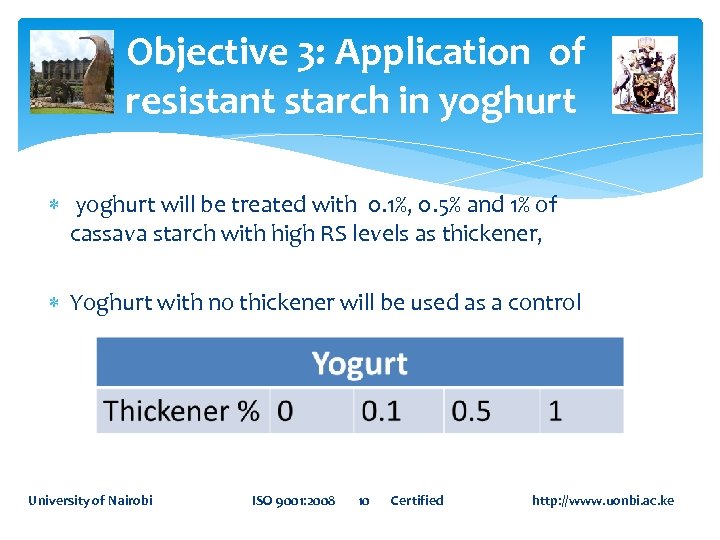

Objective 3: Application of resistant starch in yoghurt will be treated with 0. 1%, 0. 5% and 1% of cassava starch with high RS levels as thickener, Yoghurt with no thickener will be used as a control University of Nairobi ISO 9001: 2008 10 Certified http: //www. uonbi. ac. ke

Objective 3: Application of resistant starch in yoghurt will be treated with 0. 1%, 0. 5% and 1% of cassava starch with high RS levels as thickener, Yoghurt with no thickener will be used as a control University of Nairobi ISO 9001: 2008 10 Certified http: //www. uonbi. ac. ke

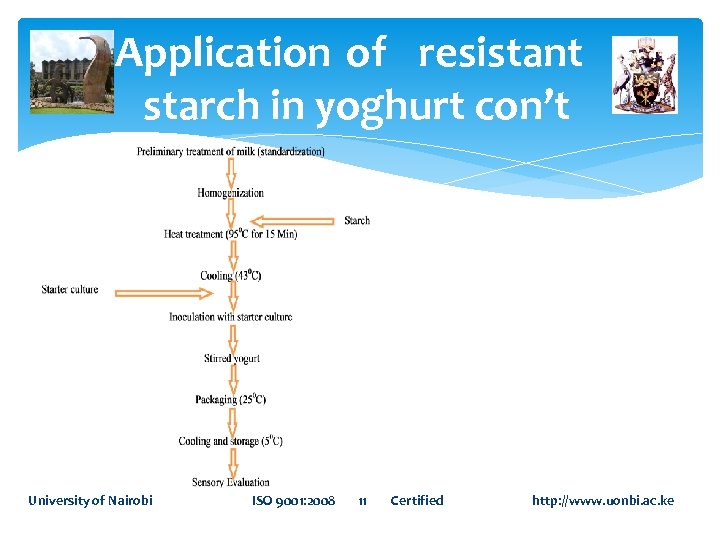

Application of resistant starch in yoghurt con’t University of Nairobi ISO 9001: 2008 11 Certified http: //www. uonbi. ac. ke

Application of resistant starch in yoghurt con’t University of Nairobi ISO 9001: 2008 11 Certified http: //www. uonbi. ac. ke

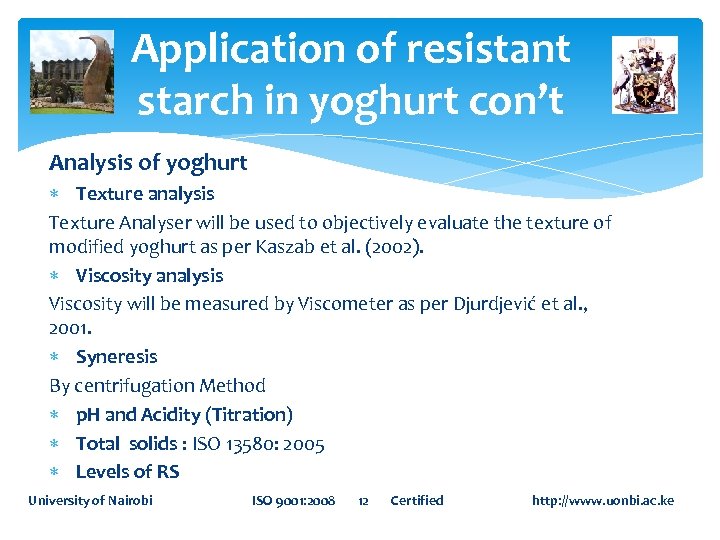

Application of resistant starch in yoghurt con’t Analysis of yoghurt Texture analysis Texture Analyser will be used to objectively evaluate the texture of modified yoghurt as per Kaszab et al. (2002). Viscosity analysis Viscosity will be measured by Viscometer as per Djurdjević et al. , 2001. Syneresis By centrifugation Method p. H and Acidity (Titration) Total solids : ISO 13580: 2005 Levels of RS University of Nairobi ISO 9001: 2008 12 Certified http: //www. uonbi. ac. ke

Application of resistant starch in yoghurt con’t Analysis of yoghurt Texture analysis Texture Analyser will be used to objectively evaluate the texture of modified yoghurt as per Kaszab et al. (2002). Viscosity analysis Viscosity will be measured by Viscometer as per Djurdjević et al. , 2001. Syneresis By centrifugation Method p. H and Acidity (Titration) Total solids : ISO 13580: 2005 Levels of RS University of Nairobi ISO 9001: 2008 12 Certified http: //www. uonbi. ac. ke

Application of resistant starch in yoghurt con’t Sensory evaluation A panel of 20 people will be tasked to evaluate the quality characteristics (taste, colour, flavour, aftertaste, texture and overall acceptability), A 7 point hedonic scale will be used: where 7= like very much, 6= like moderately, 5= like slightly, 4= dislike slightly, 3= dislike moderately, 2= dislike very much and 1= dislike extremely. University of Nairobi ISO 9001: 2008 13 Certified http: //www. uonbi. ac. ke

Application of resistant starch in yoghurt con’t Sensory evaluation A panel of 20 people will be tasked to evaluate the quality characteristics (taste, colour, flavour, aftertaste, texture and overall acceptability), A 7 point hedonic scale will be used: where 7= like very much, 6= like moderately, 5= like slightly, 4= dislike slightly, 3= dislike moderately, 2= dislike very much and 1= dislike extremely. University of Nairobi ISO 9001: 2008 13 Certified http: //www. uonbi. ac. ke

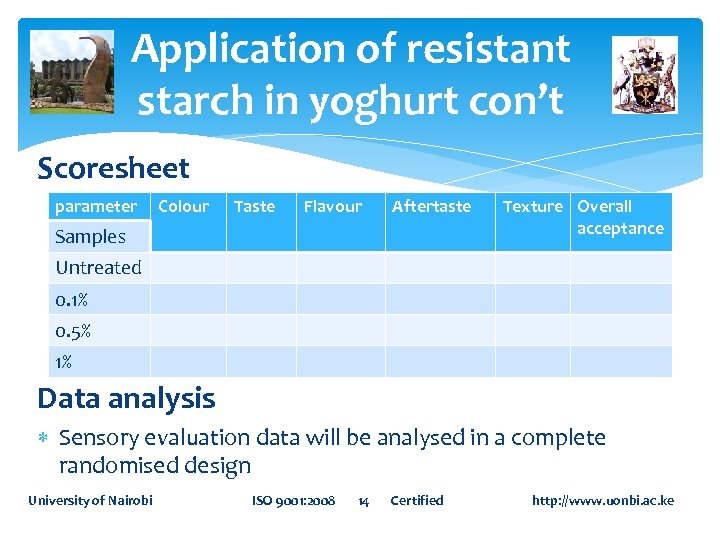

Application of resistant starch in yoghurt con’t Scoresheet parameter Colour Taste Flavour Aftertaste Samples Texture Overall acceptance Untreated 0. 1% 0. 5% 1% Data analysis Sensory evaluation data will be analysed in a complete randomised design University of Nairobi ISO 9001: 2008 14 Certified http: //www. uonbi. ac. ke

Application of resistant starch in yoghurt con’t Scoresheet parameter Colour Taste Flavour Aftertaste Samples Texture Overall acceptance Untreated 0. 1% 0. 5% 1% Data analysis Sensory evaluation data will be analysed in a complete randomised design University of Nairobi ISO 9001: 2008 14 Certified http: //www. uonbi. ac. ke

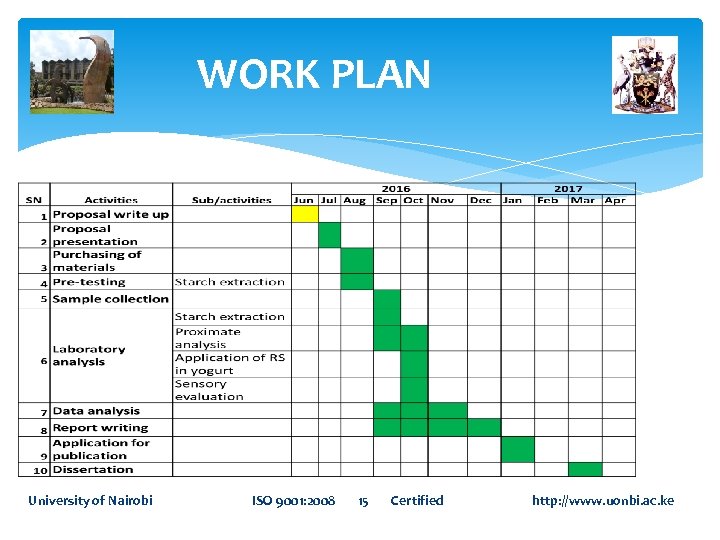

WORK PLAN University of Nairobi ISO 9001: 2008 15 Certified http: //www. uonbi. ac. ke

WORK PLAN University of Nairobi ISO 9001: 2008 15 Certified http: //www. uonbi. ac. ke

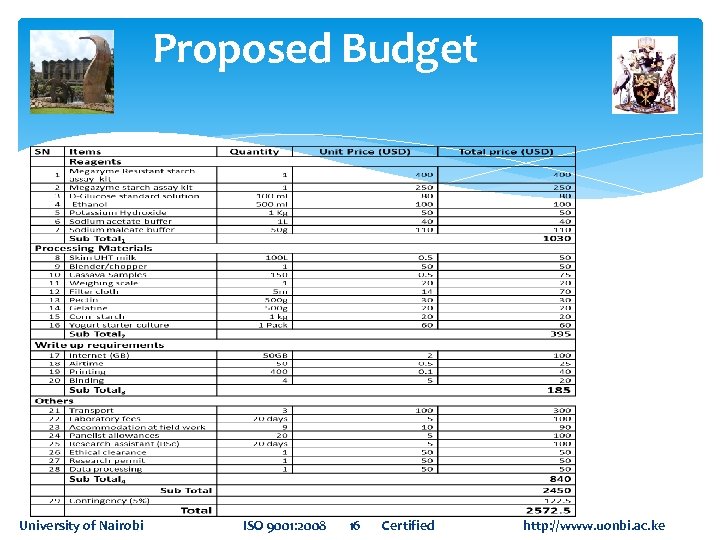

Proposed Budget University of Nairobi ISO 9001: 2008 16 Certified http: //www. uonbi. ac. ke

Proposed Budget University of Nairobi ISO 9001: 2008 16 Certified http: //www. uonbi. ac. ke

THANK YOU University of Nairobi ISO 9001: 2008 17 Certified http: //www. uonbi. ac. ke

THANK YOU University of Nairobi ISO 9001: 2008 17 Certified http: //www. uonbi. ac. ke