7be06ada63e2e10838aaf7410eda58af.ppt

- Количество слайдов: 28

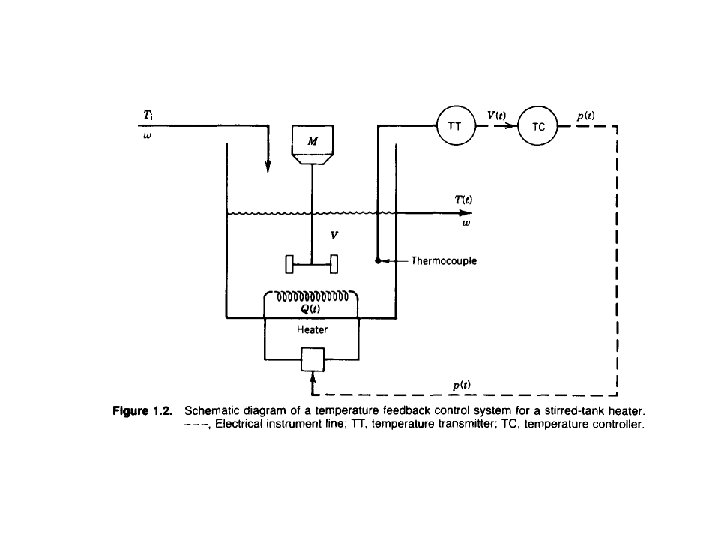

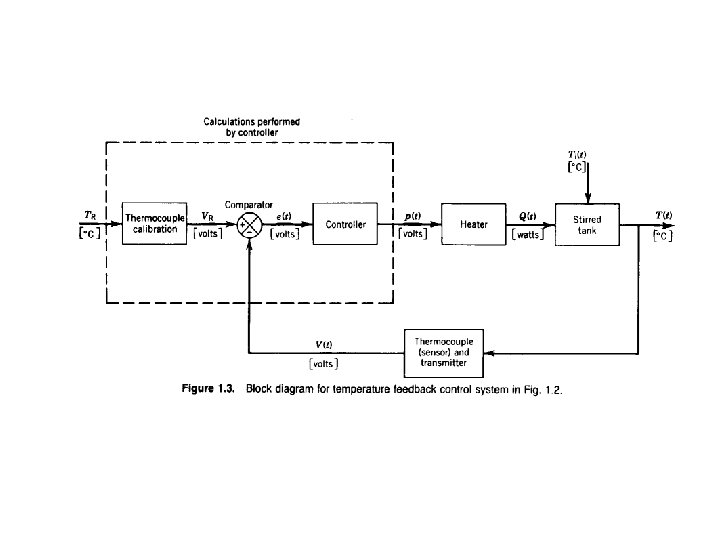

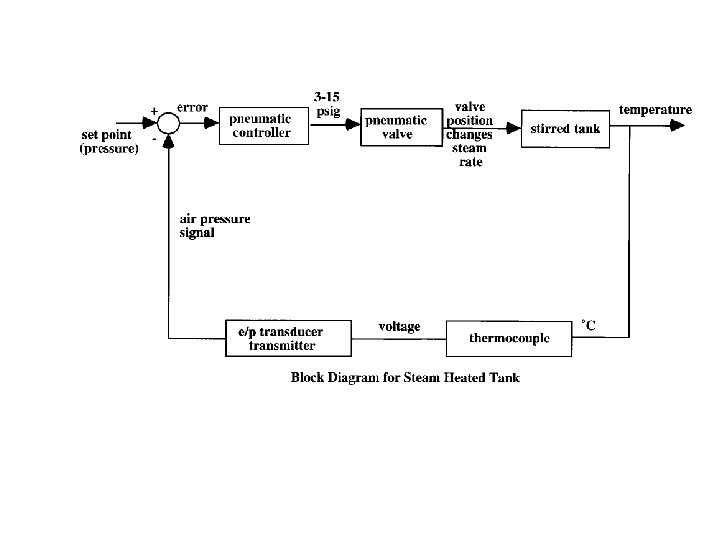

Chapter One Introduction to Process Control

Chapter One Introduction to Process Control

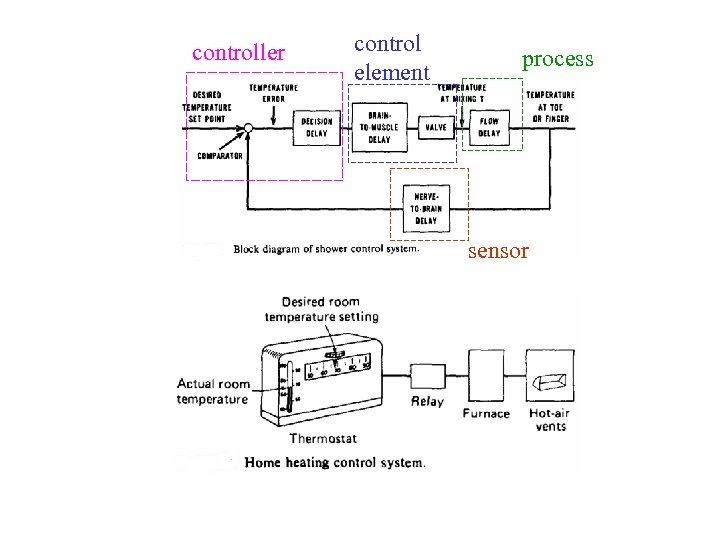

controller control element process sensor

controller control element process sensor

Control Terminology Controlled Variables - These are the variables which quantify the performance or quality of the final product, which are also called output variables. Manipulated Variables - These input variables are adjusted dynamically to keep the controlled variables at their set-points. Disturbances - These are also called the “load” variables and represent inputs that can cause the controlled variables to deviate from their respective set points.

Control Terminology Controlled Variables - These are the variables which quantify the performance or quality of the final product, which are also called output variables. Manipulated Variables - These input variables are adjusted dynamically to keep the controlled variables at their set-points. Disturbances - These are also called the “load” variables and represent inputs that can cause the controlled variables to deviate from their respective set points.

Control Terminology Servo control - The set-point signal is changed and the manipulated variable is adjusted appropriately to achieve the new operating conditions. Regulatory control – The set-point is fixed at a constant value. When any disturbance enters the system, the manipulated variable is adjusted to drive the controlled variable back to its fixed set-point.

Control Terminology Servo control - The set-point signal is changed and the manipulated variable is adjusted appropriately to achieve the new operating conditions. Regulatory control – The set-point is fixed at a constant value. When any disturbance enters the system, the manipulated variable is adjusted to drive the controlled variable back to its fixed set-point.

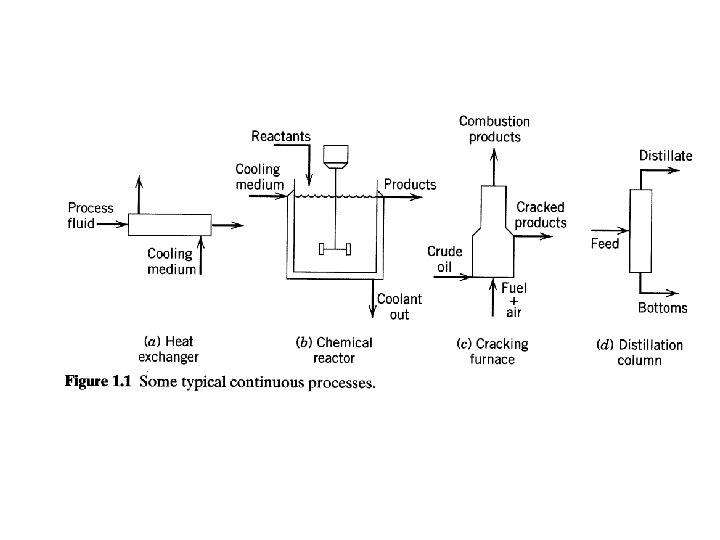

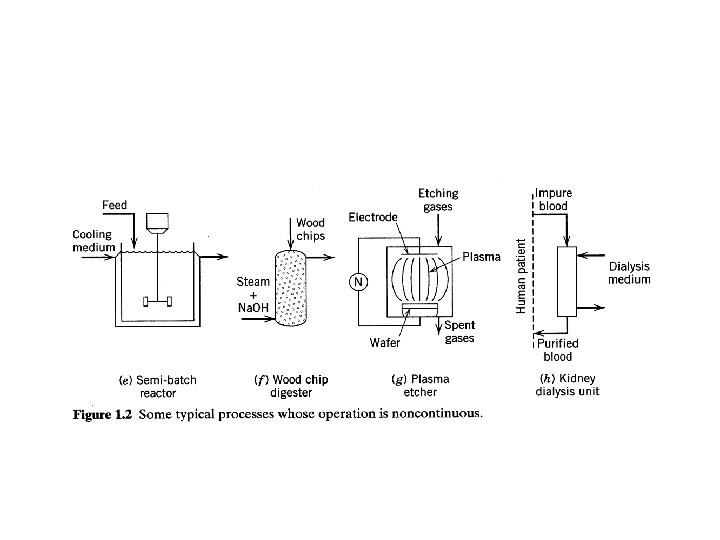

Chapter 1

Chapter 1

Why do we need automatic process control? • Industrial processes are not static but rather very dynamic; they are continuously changing as a result of many types of disturbances. • It is principally because of this dynamic nature that control systems are needed to continuously and automatically watch over the variables that must be controlled.

Why do we need automatic process control? • Industrial processes are not static but rather very dynamic; they are continuously changing as a result of many types of disturbances. • It is principally because of this dynamic nature that control systems are needed to continuously and automatically watch over the variables that must be controlled.

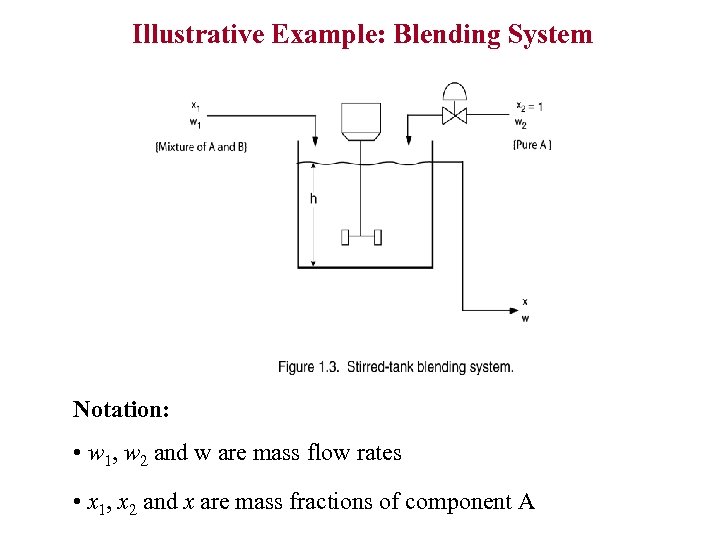

Illustrative Example: Blending System Notation: • w 1, w 2 and w are mass flow rates • x 1, x 2 and x are mass fractions of component A

Illustrative Example: Blending System Notation: • w 1, w 2 and w are mass flow rates • x 1, x 2 and x are mass fractions of component A

Assumptions: 1. w 1 is constant 2. x 2 = constant = 1 (stream 2 is pure A) 3. Perfect mixing in the tank Control Objective: Keep x at a desired value (or “set point”) xsp, by adjusting flow rate w 2, despite variations in x 1. . Terminology: • Controlled variable (or “output variable”): x • Manipulated variable (or “input variable”): w 2 • Disturbance variable (or “load variable”): x 1

Assumptions: 1. w 1 is constant 2. x 2 = constant = 1 (stream 2 is pure A) 3. Perfect mixing in the tank Control Objective: Keep x at a desired value (or “set point”) xsp, by adjusting flow rate w 2, despite variations in x 1. . Terminology: • Controlled variable (or “output variable”): x • Manipulated variable (or “input variable”): w 2 • Disturbance variable (or “load variable”): x 1

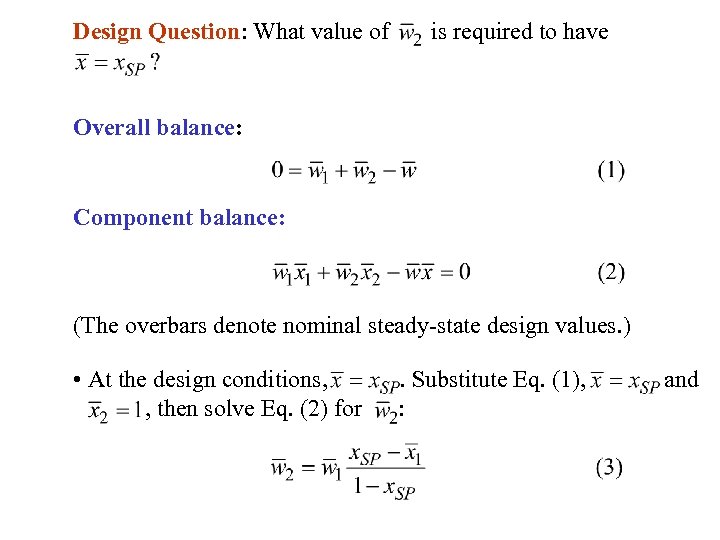

Design Question: What value of is required to have Overall balance: Component balance: (The overbars denote nominal steady-state design values. ) • At the design conditions, , then solve Eq. (2) for . Substitute Eq. (1), : and

Design Question: What value of is required to have Overall balance: Component balance: (The overbars denote nominal steady-state design values. ) • At the design conditions, , then solve Eq. (2) for . Substitute Eq. (1), : and

Control Question Suppose that the inlet concentration changes with time. How can we ensure that x remains at or near the set point ? As a specific example, if. and , then

Control Question Suppose that the inlet concentration changes with time. How can we ensure that x remains at or near the set point ? As a specific example, if. and , then

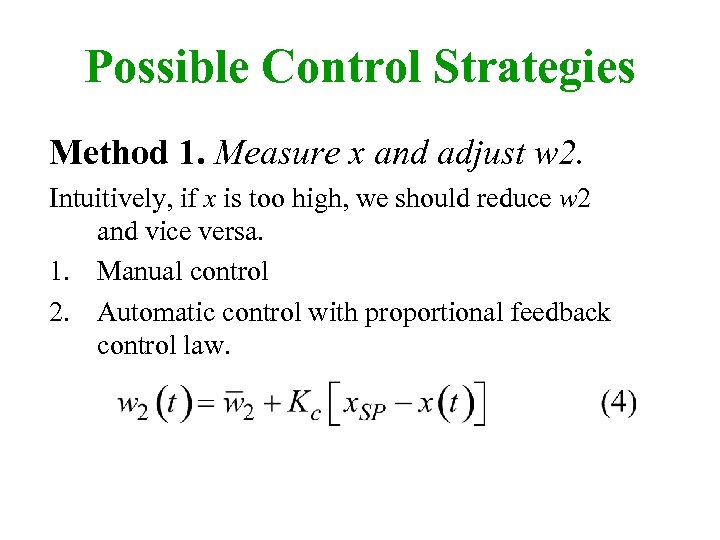

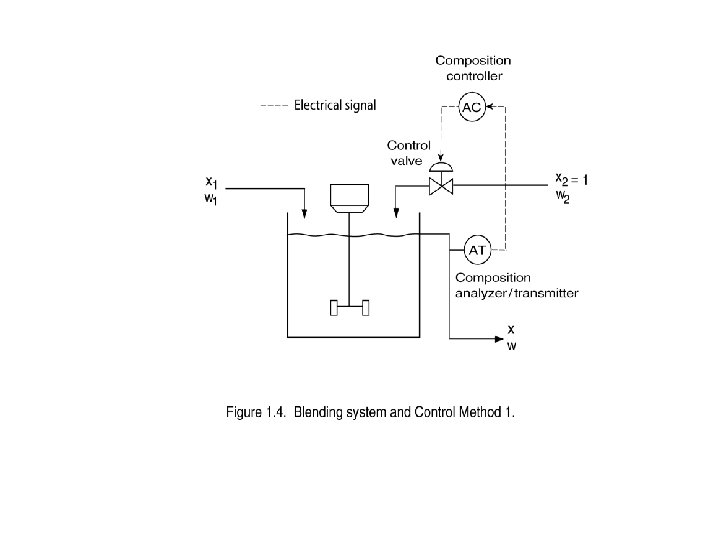

Possible Control Strategies Method 1. Measure x and adjust w 2. Intuitively, if x is too high, we should reduce w 2 and vice versa. 1. Manual control 2. Automatic control with proportional feedback control law.

Possible Control Strategies Method 1. Measure x and adjust w 2. Intuitively, if x is too high, we should reduce w 2 and vice versa. 1. Manual control 2. Automatic control with proportional feedback control law.

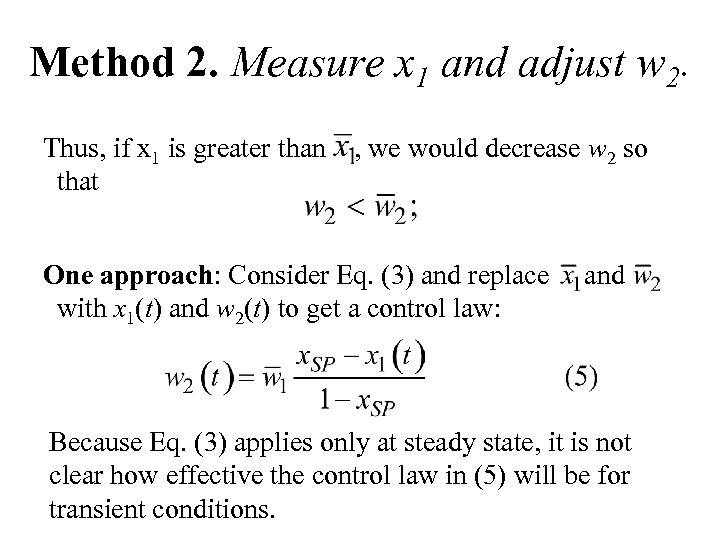

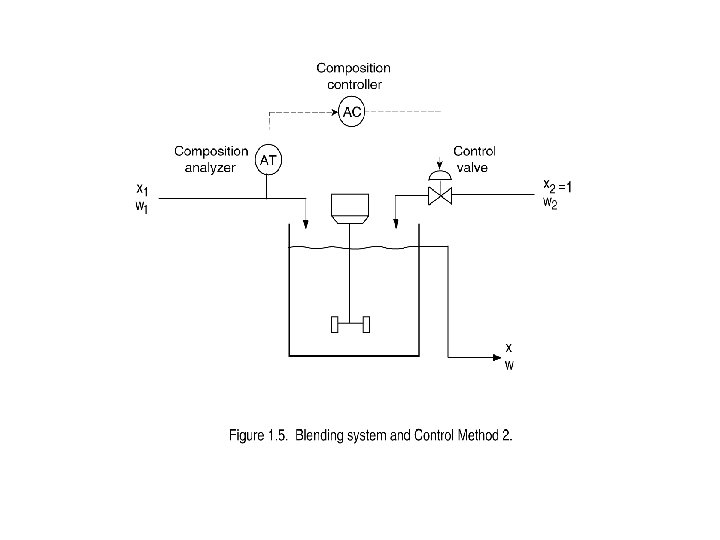

Method 2. Measure x 1 and adjust w 2. Thus, if x 1 is greater than that , we would decrease w 2 so One approach: Consider Eq. (3) and replace with x 1(t) and w 2(t) to get a control law: and Because Eq. (3) applies only at steady state, it is not clear how effective the control law in (5) will be for transient conditions.

Method 2. Measure x 1 and adjust w 2. Thus, if x 1 is greater than that , we would decrease w 2 so One approach: Consider Eq. (3) and replace with x 1(t) and w 2(t) to get a control law: and Because Eq. (3) applies only at steady state, it is not clear how effective the control law in (5) will be for transient conditions.

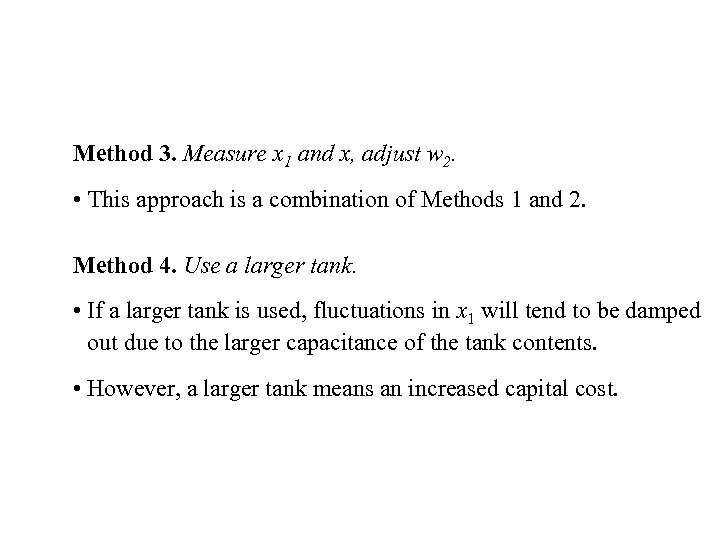

Method 3. Measure x 1 and x, adjust w 2. • This approach is a combination of Methods 1 and 2. Method 4. Use a larger tank. • If a larger tank is used, fluctuations in x 1 will tend to be damped out due to the larger capacitance of the tank contents. • However, a larger tank means an increased capital cost.

Method 3. Measure x 1 and x, adjust w 2. • This approach is a combination of Methods 1 and 2. Method 4. Use a larger tank. • If a larger tank is used, fluctuations in x 1 will tend to be damped out due to the larger capacitance of the tank contents. • However, a larger tank means an increased capital cost.

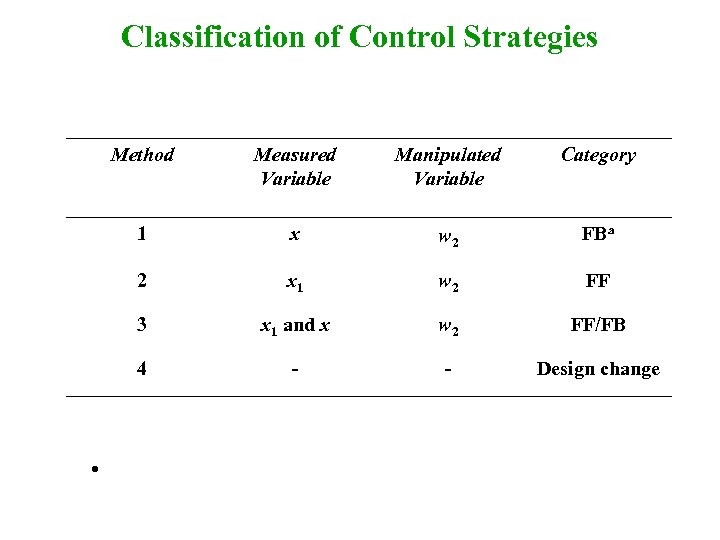

Classification of Control Strategies Method Manipulated Variable Category 1 x w 2 FBa 2 x 1 w 2 FF 3 x 1 and x w 2 FF/FB 4 • Measured Variable - - Design change

Classification of Control Strategies Method Manipulated Variable Category 1 x w 2 FBa 2 x 1 w 2 FF 3 x 1 and x w 2 FF/FB 4 • Measured Variable - - Design change

Feedback Control • Distinguishing feature: – measure the controlled variable. – It is important to make a distinction between negative feedback and positive feedback. • Advantages: – Corrective action is taken regardless of the source of the disturbance. – Reduces sensitivity of the controlled variable to disturbances and changes in the process (shown later). • Disadvantages: – No corrective action occurs until after the disturbance has upset the process, that is, until after x differs from xsp. – Very oscillatory responses, or even instability

Feedback Control • Distinguishing feature: – measure the controlled variable. – It is important to make a distinction between negative feedback and positive feedback. • Advantages: – Corrective action is taken regardless of the source of the disturbance. – Reduces sensitivity of the controlled variable to disturbances and changes in the process (shown later). • Disadvantages: – No corrective action occurs until after the disturbance has upset the process, that is, until after x differs from xsp. – Very oscillatory responses, or even instability

Feed Forward Control • Distinguishing Feature: Measure a disturbance. • Advantage: Correct for disturbance before it upsets the process. • Disadvantage: – Must be able to measure the disturbance – No corrective action for unmeasured disturbances.

Feed Forward Control • Distinguishing Feature: Measure a disturbance. • Advantage: Correct for disturbance before it upsets the process. • Disadvantage: – Must be able to measure the disturbance – No corrective action for unmeasured disturbances.

Justification of Process Control • • • Increased product throughput Increased yield of higher valued products Decreased energy consumption Decreased pollution Decreased off-spec product Increased Safety Extended life of equipment Improved Operability Decreased production labor

Justification of Process Control • • • Increased product throughput Increased yield of higher valued products Decreased energy consumption Decreased pollution Decreased off-spec product Increased Safety Extended life of equipment Improved Operability Decreased production labor

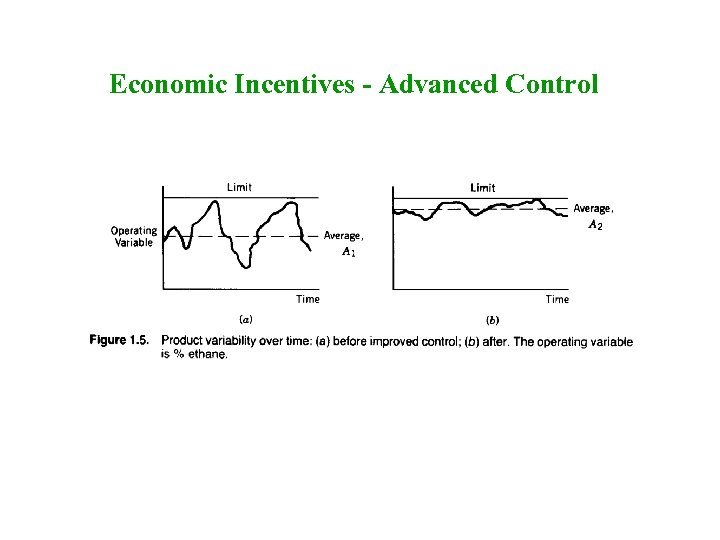

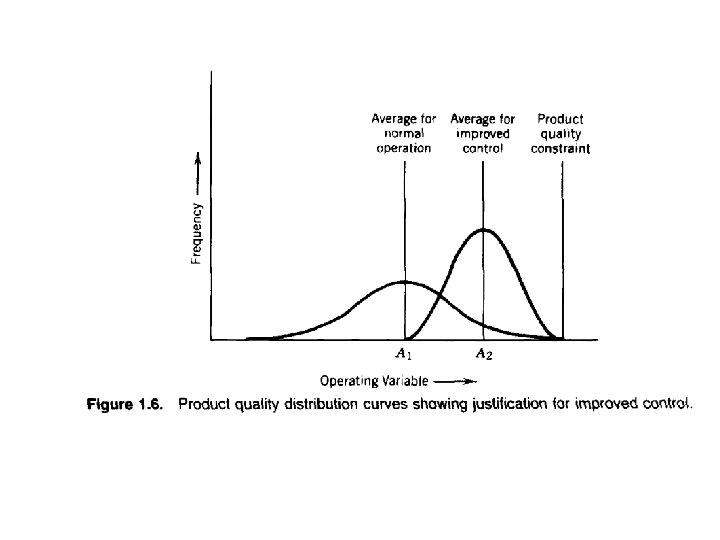

Economic Incentives - Advanced Control

Economic Incentives - Advanced Control

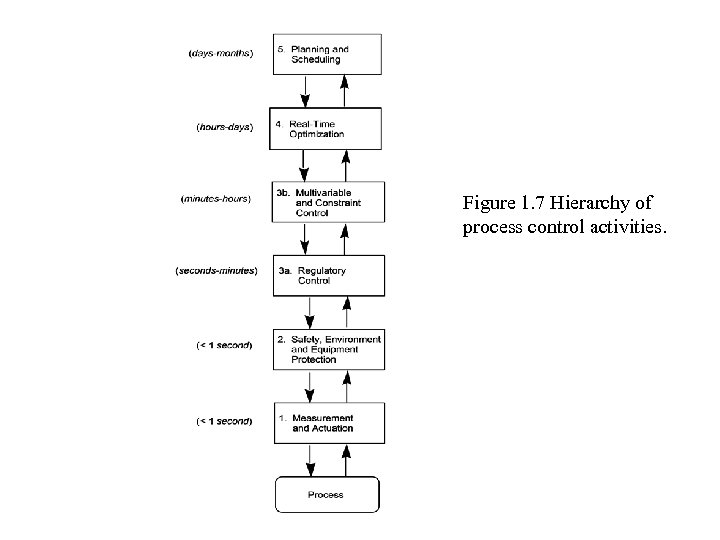

Figure 1. 7 Hierarchy of process control activities.

Figure 1. 7 Hierarchy of process control activities.

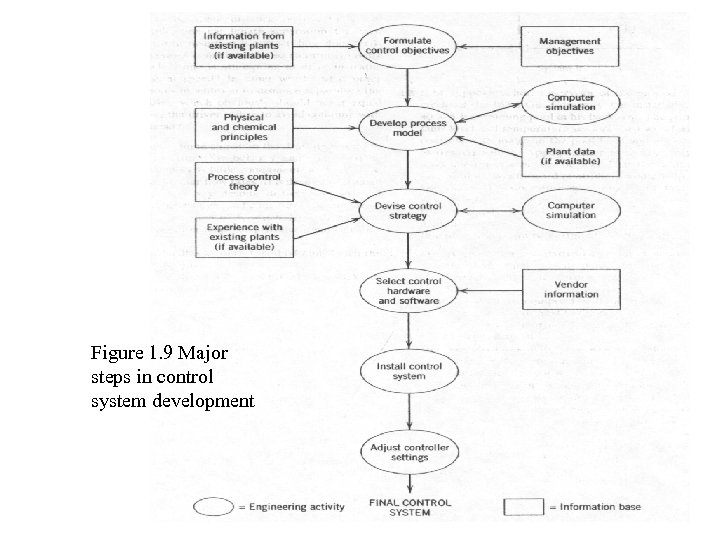

Figure 1. 9 Major steps in control system development

Figure 1. 9 Major steps in control system development