33182d59afec20f0f9c844a6250eb70f.ppt

- Количество слайдов: 70

Chapter 8: Advanced Materials Dr. Siddhalingeshwar I. G.

Chapter 8: Advanced Materials Dr. Siddhalingeshwar I. G.

Chapter 8: Advanced materials n n n Introduction to advanced materials Composite materials– An overview, classification Fundamentals of production of FRP’s Fundamentals of production of MMC’s Advantages & application of composites Exotic alloys

Chapter 8: Advanced materials n n n Introduction to advanced materials Composite materials– An overview, classification Fundamentals of production of FRP’s Fundamentals of production of MMC’s Advantages & application of composites Exotic alloys

Learning Objectives n Identify the main divisions of composite materials and explain the characteristic features of each that make it a candidate material for suitable application. n Identify and explain the role of each of the constituents in a composite material. n Distinguish between different types of Fiber Reinforced Plastics in terms of their properties and applications. n Describe the manufacturing of FRPs and MMCs. n Discuss the importance of composite materials in engineering applications.

Learning Objectives n Identify the main divisions of composite materials and explain the characteristic features of each that make it a candidate material for suitable application. n Identify and explain the role of each of the constituents in a composite material. n Distinguish between different types of Fiber Reinforced Plastics in terms of their properties and applications. n Describe the manufacturing of FRPs and MMCs. n Discuss the importance of composite materials in engineering applications.

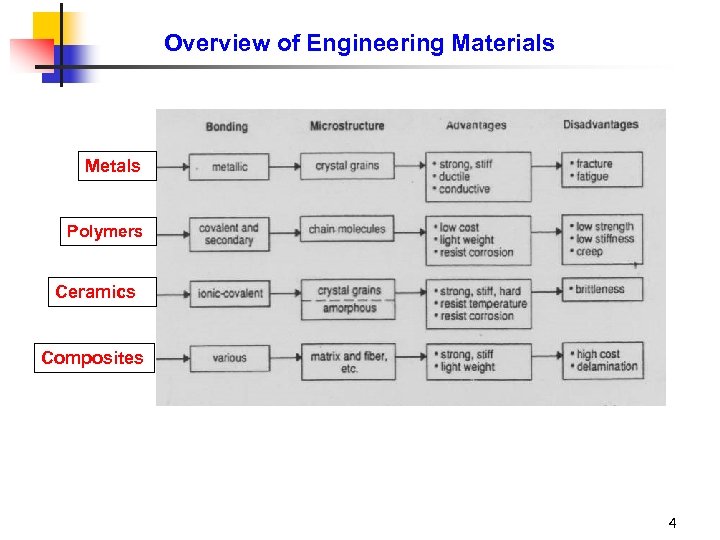

Overview of Engineering Materials Metals Polymers Ceramics Composites 4

Overview of Engineering Materials Metals Polymers Ceramics Composites 4

Composite materials – Introduction v Definition: a material composed of two or more constituents; n n Reinforcement phase (e. g. , Fibers) Binder phase (e. g. , compliant matrix) v Advantages: n n n High strength and stiffness Low weight ratio Material can be designed in addition to the structure 5

Composite materials – Introduction v Definition: a material composed of two or more constituents; n n Reinforcement phase (e. g. , Fibers) Binder phase (e. g. , compliant matrix) v Advantages: n n n High strength and stiffness Low weight ratio Material can be designed in addition to the structure 5

Composite materials – Introduction n n Definition: any combination of two or more different materials at the macroscopic level. Or Two inherently different materials that when combined together produce a material with properties that exceed the constituent materials. n n Reinforcement phase (e. g. , Fibers) Binder phase (e. g. , compliant matrix) 6

Composite materials – Introduction n n Definition: any combination of two or more different materials at the macroscopic level. Or Two inherently different materials that when combined together produce a material with properties that exceed the constituent materials. n n Reinforcement phase (e. g. , Fibers) Binder phase (e. g. , compliant matrix) 6

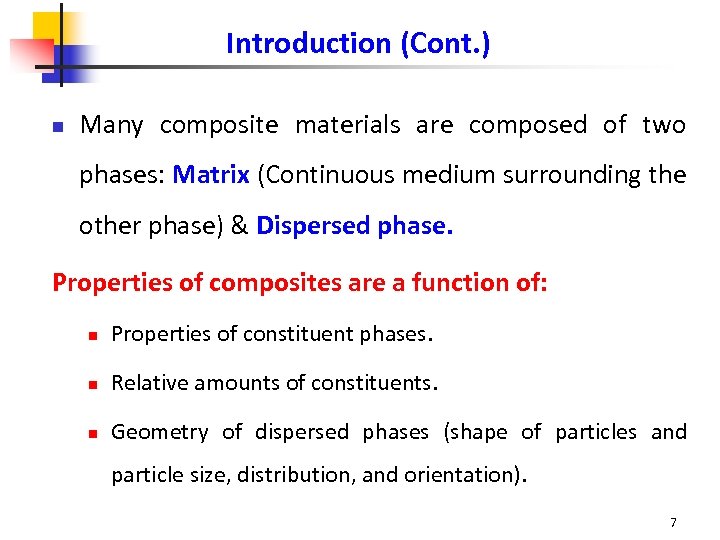

Introduction (Cont. ) n Many composite materials are composed of two phases: Matrix (Continuous medium surrounding the other phase) & Dispersed phase. Properties of composites are a function of: n Properties of constituent phases. n Relative amounts of constituents. n Geometry of dispersed phases (shape of particles and particle size, distribution, and orientation). 7

Introduction (Cont. ) n Many composite materials are composed of two phases: Matrix (Continuous medium surrounding the other phase) & Dispersed phase. Properties of composites are a function of: n Properties of constituent phases. n Relative amounts of constituents. n Geometry of dispersed phases (shape of particles and particle size, distribution, and orientation). 7

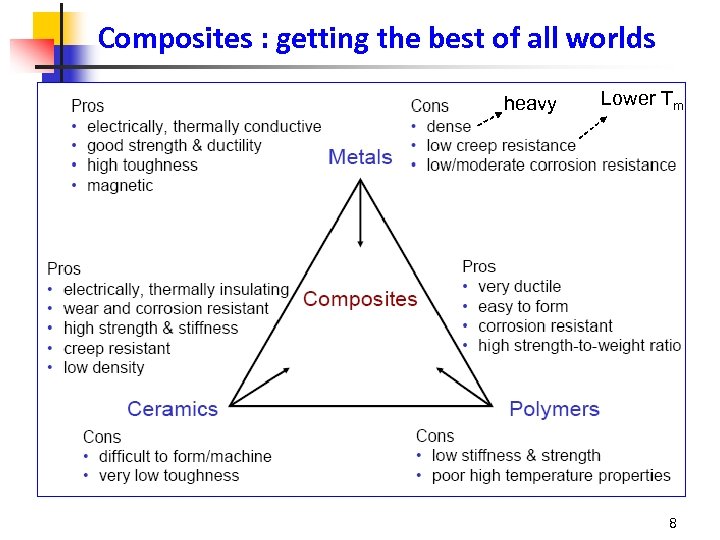

Composites : getting the best of all worlds heavy Lower Tm 8

Composites : getting the best of all worlds heavy Lower Tm 8

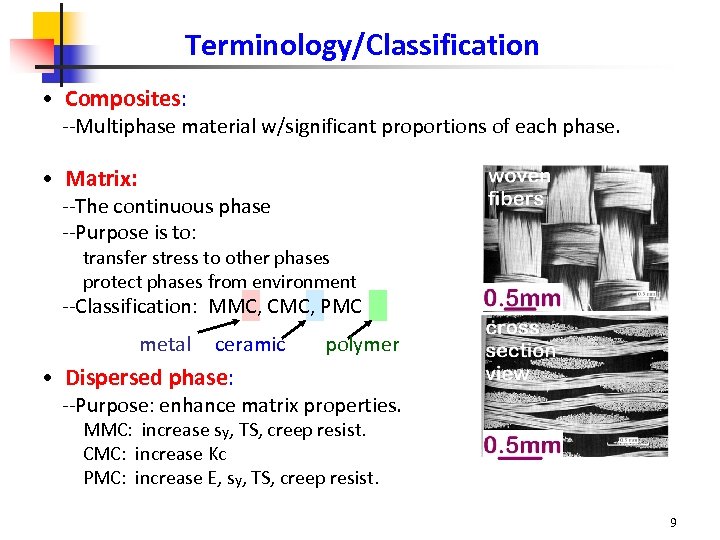

Terminology/Classification • Composites: --Multiphase material w/significant proportions of each phase. • Matrix: --The continuous phase --Purpose is to: transfer stress to other phases protect phases from environment --Classification: MMC, CMC, PMC metal ceramic polymer • Dispersed phase: --Purpose: enhance matrix properties. MMC: increase sy, TS, creep resist. CMC: increase Kc PMC: increase E, sy, TS, creep resist. 9

Terminology/Classification • Composites: --Multiphase material w/significant proportions of each phase. • Matrix: --The continuous phase --Purpose is to: transfer stress to other phases protect phases from environment --Classification: MMC, CMC, PMC metal ceramic polymer • Dispersed phase: --Purpose: enhance matrix properties. MMC: increase sy, TS, creep resist. CMC: increase Kc PMC: increase E, sy, TS, creep resist. 9

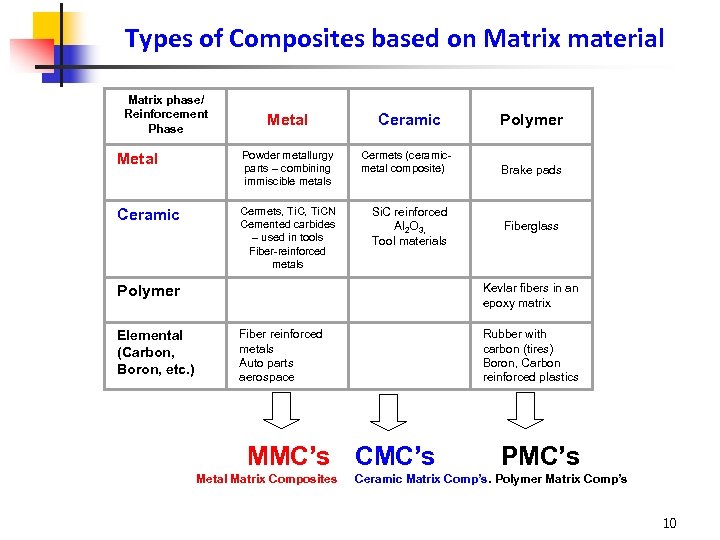

Types of Composites based on Matrix material Matrix phase/ Reinforcement Phase Metal Ceramic Polymer Metal Powder metallurgy parts – combining immiscible metals Cermets (ceramicmetal composite) Ceramic Cermets, Ti. CN Cemented carbides – used in tools Fiber-reinforced metals Si. C reinforced Al 2 O 3, Tool materials Polymer Kevlar fibers in an epoxy matrix Elemental (Carbon, Boron, etc. ) Fiber reinforced metals Auto parts aerospace Rubber with carbon (tires) Boron, Carbon reinforced plastics MMC’s CMC’s Metal Matrix Composites Brake pads Fiberglass PMC’s Ceramic Matrix Comp’s. Polymer Matrix Comp’s 10

Types of Composites based on Matrix material Matrix phase/ Reinforcement Phase Metal Ceramic Polymer Metal Powder metallurgy parts – combining immiscible metals Cermets (ceramicmetal composite) Ceramic Cermets, Ti. CN Cemented carbides – used in tools Fiber-reinforced metals Si. C reinforced Al 2 O 3, Tool materials Polymer Kevlar fibers in an epoxy matrix Elemental (Carbon, Boron, etc. ) Fiber reinforced metals Auto parts aerospace Rubber with carbon (tires) Boron, Carbon reinforced plastics MMC’s CMC’s Metal Matrix Composites Brake pads Fiberglass PMC’s Ceramic Matrix Comp’s. Polymer Matrix Comp’s 10

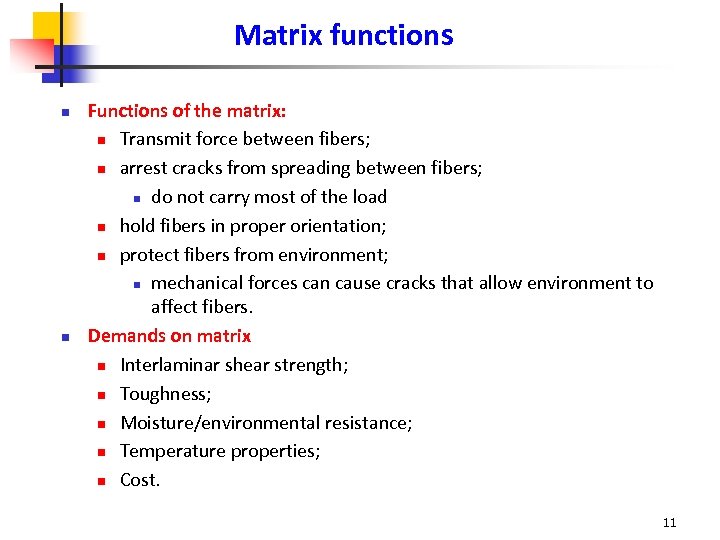

Matrix functions n n Functions of the matrix: n Transmit force between fibers; n arrest cracks from spreading between fibers; n do not carry most of the load n hold fibers in proper orientation; n protect fibers from environment; n mechanical forces can cause cracks that allow environment to affect fibers. Demands on matrix n Interlaminar shear strength; n Toughness; n Moisture/environmental resistance; n Temperature properties; n Cost. 11

Matrix functions n n Functions of the matrix: n Transmit force between fibers; n arrest cracks from spreading between fibers; n do not carry most of the load n hold fibers in proper orientation; n protect fibers from environment; n mechanical forces can cause cracks that allow environment to affect fibers. Demands on matrix n Interlaminar shear strength; n Toughness; n Moisture/environmental resistance; n Temperature properties; n Cost. 11

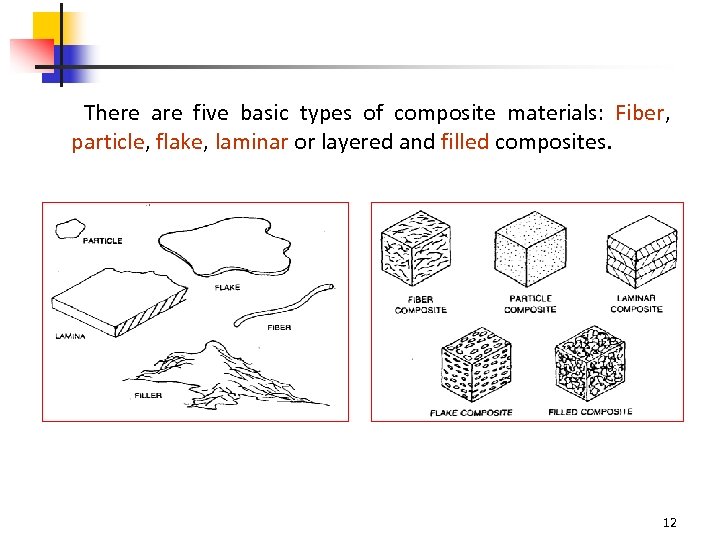

There are five basic types of composite materials: Fiber, particle, flake, laminar or layered and filled composites. 12

There are five basic types of composite materials: Fiber, particle, flake, laminar or layered and filled composites. 12

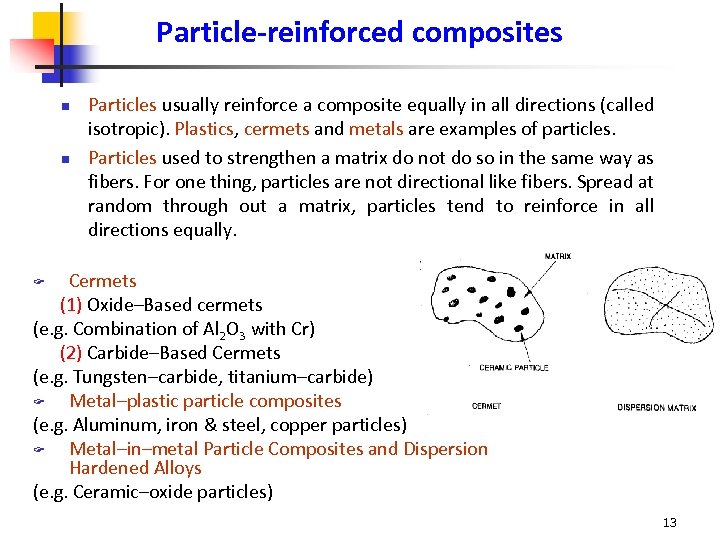

Particle-reinforced composites n n Particles usually reinforce a composite equally in all directions (called isotropic). Plastics, cermets and metals are examples of particles. Particles used to strengthen a matrix do not do so in the same way as fibers. For one thing, particles are not directional like fibers. Spread at random through out a matrix, particles tend to reinforce in all directions equally. Cermets (1) Oxide–Based cermets (e. g. Combination of Al 2 O 3 with Cr) (2) Carbide–Based Cermets (e. g. Tungsten–carbide, titanium–carbide) F Metal–plastic particle composites (e. g. Aluminum, iron & steel, copper particles) F Metal–in–metal Particle Composites and Dispersion Hardened Alloys (e. g. Ceramic–oxide particles) F 13

Particle-reinforced composites n n Particles usually reinforce a composite equally in all directions (called isotropic). Plastics, cermets and metals are examples of particles. Particles used to strengthen a matrix do not do so in the same way as fibers. For one thing, particles are not directional like fibers. Spread at random through out a matrix, particles tend to reinforce in all directions equally. Cermets (1) Oxide–Based cermets (e. g. Combination of Al 2 O 3 with Cr) (2) Carbide–Based Cermets (e. g. Tungsten–carbide, titanium–carbide) F Metal–plastic particle composites (e. g. Aluminum, iron & steel, copper particles) F Metal–in–metal Particle Composites and Dispersion Hardened Alloys (e. g. Ceramic–oxide particles) F 13

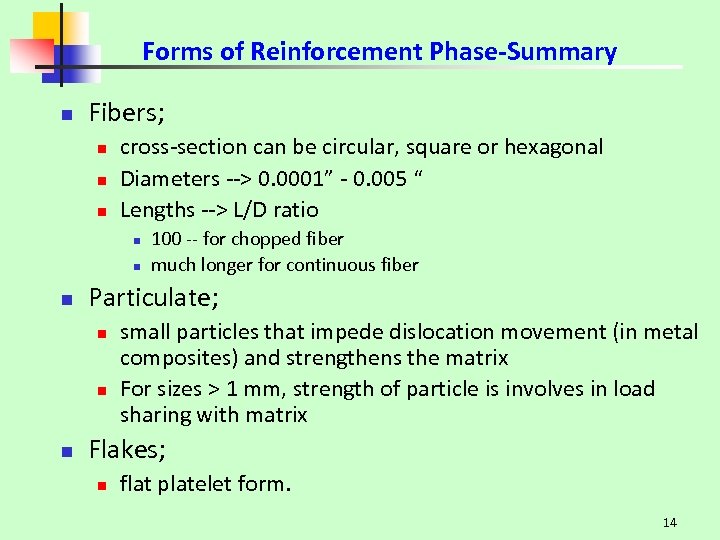

Forms of Reinforcement Phase-Summary n Fibers; n n n cross-section can be circular, square or hexagonal Diameters --> 0. 0001” - 0. 005 “ Lengths --> L/D ratio n n n Particulate; n n n 100 -- for chopped fiber much longer for continuous fiber small particles that impede dislocation movement (in metal composites) and strengthens the matrix For sizes > 1 mm, strength of particle is involves in load sharing with matrix Flakes; n flat platelet form. 14

Forms of Reinforcement Phase-Summary n Fibers; n n n cross-section can be circular, square or hexagonal Diameters --> 0. 0001” - 0. 005 “ Lengths --> L/D ratio n n n Particulate; n n n 100 -- for chopped fiber much longer for continuous fiber small particles that impede dislocation movement (in metal composites) and strengthens the matrix For sizes > 1 mm, strength of particle is involves in load sharing with matrix Flakes; n flat platelet form. 14

Polymer Matrix Composites

Polymer Matrix Composites

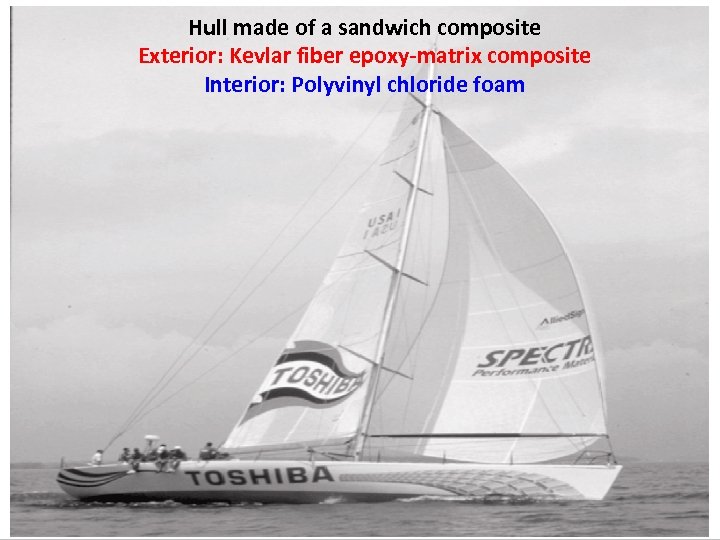

Hull made of a sandwich composite Exterior: Kevlar fiber epoxy-matrix composite Interior: Polyvinyl chloride foam

Hull made of a sandwich composite Exterior: Kevlar fiber epoxy-matrix composite Interior: Polyvinyl chloride foam

Glass fibers

Glass fibers

A carbon fiber tow © 2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning™ is a trademark used herein under license.

A carbon fiber tow © 2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning™ is a trademark used herein under license.

Types of Fibers The fibers are divided into two main groups: n Glass fibers: There are many different kinds of glass, ranging from ordinary bottle glass to high purity quartz glass. All of these glasses can be made into fibers. Each offers its own set of properties. n Advanced fibers: These materials offer high strength and high stiffness at low weight. Boron, silicon, carbide and graphite fibers are in this category. So are the aramids, a group of plastic fibers of the polyamide (nylon) family.

Types of Fibers The fibers are divided into two main groups: n Glass fibers: There are many different kinds of glass, ranging from ordinary bottle glass to high purity quartz glass. All of these glasses can be made into fibers. Each offers its own set of properties. n Advanced fibers: These materials offer high strength and high stiffness at low weight. Boron, silicon, carbide and graphite fibers are in this category. So are the aramids, a group of plastic fibers of the polyamide (nylon) family.

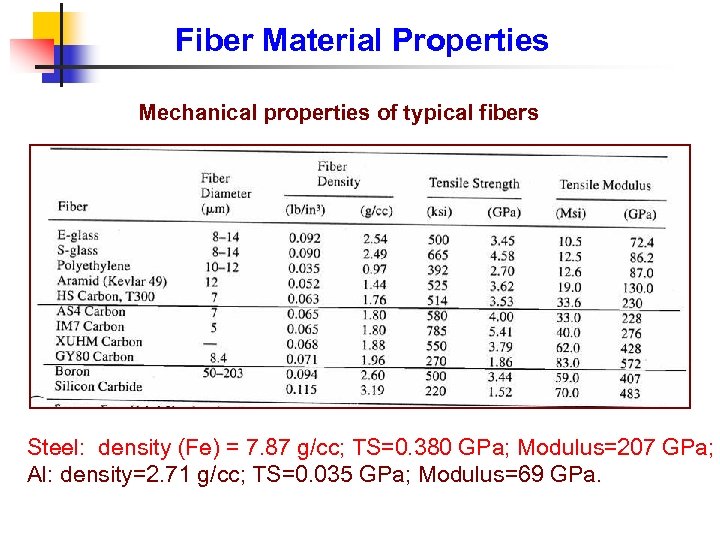

Fiber Material Properties Mechanical properties of typical fibers Steel: density (Fe) = 7. 87 g/cc; TS=0. 380 GPa; Modulus=207 GPa; Al: density=2. 71 g/cc; TS=0. 035 GPa; Modulus=69 GPa.

Fiber Material Properties Mechanical properties of typical fibers Steel: density (Fe) = 7. 87 g/cc; TS=0. 380 GPa; Modulus=207 GPa; Al: density=2. 71 g/cc; TS=0. 035 GPa; Modulus=69 GPa.

Matrices - Polymeric n Thermosets n n n cure by chemical reaction; Irreversible; Examples n Polyester, vinylester; n Most common, lower cost, solvent resistance; n Epoxy resins n Superior performance, relatively costly.

Matrices - Polymeric n Thermosets n n n cure by chemical reaction; Irreversible; Examples n Polyester, vinylester; n Most common, lower cost, solvent resistance; n Epoxy resins n Superior performance, relatively costly.

Matrices - Thermoplastics n n Formed by heating to elevated temperature at which softening occurs. n Reversible reaction; n Can be reformed and/or repaired - not common; o n Limited in temperature range to 150 C; Examples n Polypropylene; n with nylon or glass; n can be injected– inexpensive; n Soften layers of combined fiber and resin and place in a mold -- higher costs;

Matrices - Thermoplastics n n Formed by heating to elevated temperature at which softening occurs. n Reversible reaction; n Can be reformed and/or repaired - not common; o n Limited in temperature range to 150 C; Examples n Polypropylene; n with nylon or glass; n can be injected– inexpensive; n Soften layers of combined fiber and resin and place in a mold -- higher costs;

Shaping Processes For PMCs 1. Open Mold Processes; 2. Closed Mold Processes; 3. Filament Winding; 4. Pultrusion Processes; 5. Other PMC Shaping Processes.

Shaping Processes For PMCs 1. Open Mold Processes; 2. Closed Mold Processes; 3. Filament Winding; 4. Pultrusion Processes; 5. Other PMC Shaping Processes.

Categories of FRP Shape Processes n Open mold processes - some of the original FRP manual procedures for laying resins and fibers onto forms; n Closed mold processes - much the same as those used in plastic molding; n Filament winding - continuous filaments are dipped in liquid resin and wrapped around a rotating mandrel, producing a rigid, hollow, cylindrical shape; n Pultrusion - similar to extrusion only adapted to include continuous fiber reinforcement; n Others - operations not in previous categories.

Categories of FRP Shape Processes n Open mold processes - some of the original FRP manual procedures for laying resins and fibers onto forms; n Closed mold processes - much the same as those used in plastic molding; n Filament winding - continuous filaments are dipped in liquid resin and wrapped around a rotating mandrel, producing a rigid, hollow, cylindrical shape; n Pultrusion - similar to extrusion only adapted to include continuous fiber reinforcement; n Others - operations not in previous categories.

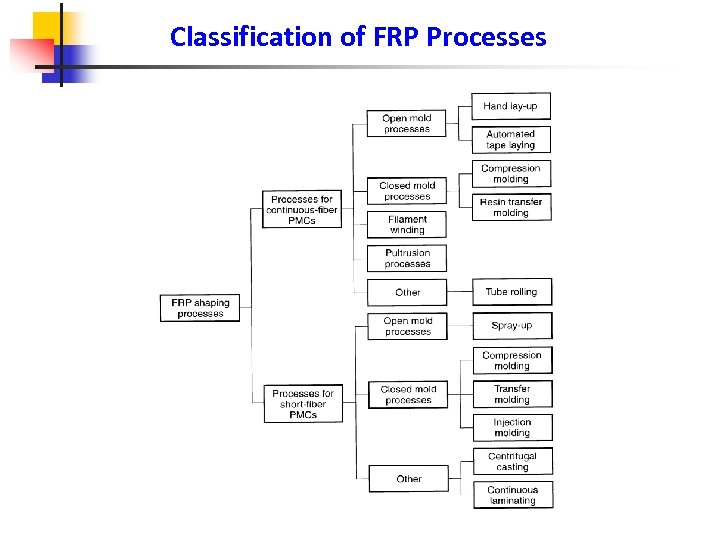

Classification of FRP Processes

Classification of FRP Processes

Open Mold FRP Processes 1. Hand lay‑up; 2. Spray‑up; 3. Vacuum Bagging – uses hand-lay-up, uses atmospheric pressure to compact laminate; 4. Automated tape‑laying machines; The differences are in the methods of applying the laminations to the mold, alternative curing techniques, and other differences.

Open Mold FRP Processes 1. Hand lay‑up; 2. Spray‑up; 3. Vacuum Bagging – uses hand-lay-up, uses atmospheric pressure to compact laminate; 4. Automated tape‑laying machines; The differences are in the methods of applying the laminations to the mold, alternative curing techniques, and other differences.

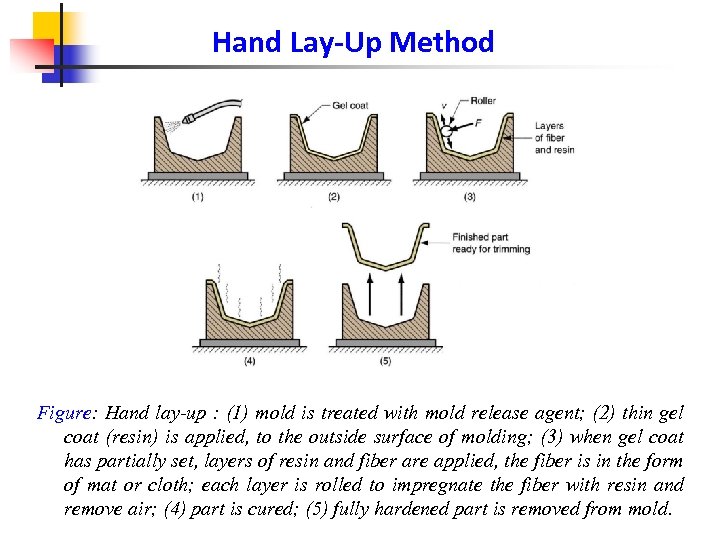

Hand Lay‑Up Method v. Open mold shaping method in which successive layers of resin and reinforcement are manually applied to an open mold to build the laminated FRP composite structure; v. Labor‑intensive; v. Finished molding must usually be trimmed with a power saw to size outside edges; v. Oldest open mold method for FRP laminates, dating to the 1940 s when it was first used for boat hulls.

Hand Lay‑Up Method v. Open mold shaping method in which successive layers of resin and reinforcement are manually applied to an open mold to build the laminated FRP composite structure; v. Labor‑intensive; v. Finished molding must usually be trimmed with a power saw to size outside edges; v. Oldest open mold method for FRP laminates, dating to the 1940 s when it was first used for boat hulls.

Hand Lay-Up Method Figure: Hand lay‑up : (1) mold is treated with mold release agent; (2) thin gel coat (resin) is applied, to the outside surface of molding; (3) when gel coat has partially set, layers of resin and fiber are applied, the fiber is in the form of mat or cloth; each layer is rolled to impregnate the fiber with resin and remove air; (4) part is cured; (5) fully hardened part is removed from mold.

Hand Lay-Up Method Figure: Hand lay‑up : (1) mold is treated with mold release agent; (2) thin gel coat (resin) is applied, to the outside surface of molding; (3) when gel coat has partially set, layers of resin and fiber are applied, the fiber is in the form of mat or cloth; each layer is rolled to impregnate the fiber with resin and remove air; (4) part is cured; (5) fully hardened part is removed from mold.

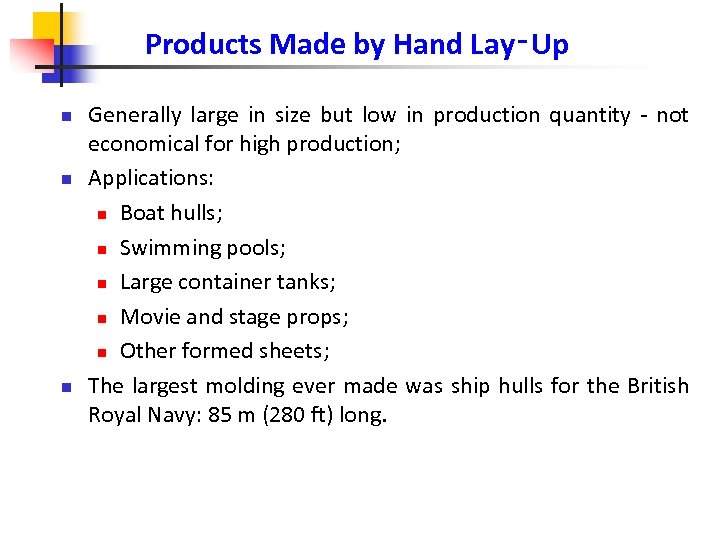

Products Made by Hand Lay‑Up n n n Generally large in size but low in production quantity - not economical for high production; Applications: n Boat hulls; n Swimming pools; n Large container tanks; n Movie and stage props; n Other formed sheets; The largest molding ever made was ship hulls for the British Royal Navy: 85 m (280 ft) long.

Products Made by Hand Lay‑Up n n n Generally large in size but low in production quantity - not economical for high production; Applications: n Boat hulls; n Swimming pools; n Large container tanks; n Movie and stage props; n Other formed sheets; The largest molding ever made was ship hulls for the British Royal Navy: 85 m (280 ft) long.

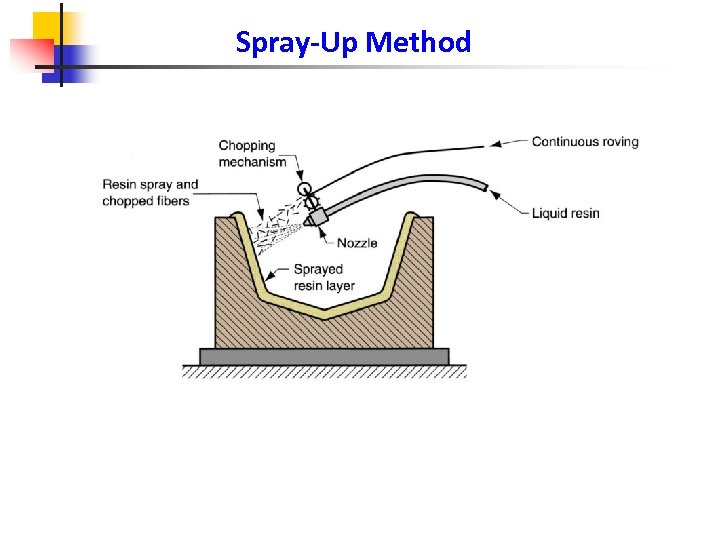

Spray‑Up Method v. Liquid resin and chopped fibers are sprayed onto an open mold to build successive FRP laminations; v. Attempt to mechanize application of resin‑fiber layers and reduce lay‑up time; v. Alternative for step (3) in the hand lay‑up procedure.

Spray‑Up Method v. Liquid resin and chopped fibers are sprayed onto an open mold to build successive FRP laminations; v. Attempt to mechanize application of resin‑fiber layers and reduce lay‑up time; v. Alternative for step (3) in the hand lay‑up procedure.

Spray-Up Method

Spray-Up Method

Products Made by Spray‑Up n Boat hulls, bathtubs, shower stalls, automobile and truck body parts, recreational vehicle components, furniture, large structural panels, and containers; n Movie and stage props are sometimes made by this method; n Since products made by spray‑up have randomly oriented short fibers, they are not as strong as those made by lay‑up, in which the fibers are continuous and directed.

Products Made by Spray‑Up n Boat hulls, bathtubs, shower stalls, automobile and truck body parts, recreational vehicle components, furniture, large structural panels, and containers; n Movie and stage props are sometimes made by this method; n Since products made by spray‑up have randomly oriented short fibers, they are not as strong as those made by lay‑up, in which the fibers are continuous and directed.

Closed Mold Processes n Performed in molds consisting of two sections that open and close each molding cycle; n Tooling cost is more than twice the cost of a comparable open mold due to the more complex equipment required in these processes; n Advantages of a closed mold are: (1) good finish on all part surfaces, (2) higher production rates, (3) closer control over tolerances, and (4) more complex three‑dimensional shapes are possible.

Closed Mold Processes n Performed in molds consisting of two sections that open and close each molding cycle; n Tooling cost is more than twice the cost of a comparable open mold due to the more complex equipment required in these processes; n Advantages of a closed mold are: (1) good finish on all part surfaces, (2) higher production rates, (3) closer control over tolerances, and (4) more complex three‑dimensional shapes are possible.

Classification of Closed Mold Processes n Three classes based on their counterparts in conventional plastic molding; 1. Compression molding 2. Transfer molding 3. Injection molding n The terminology is often different when polymer matrix composites are molded.

Classification of Closed Mold Processes n Three classes based on their counterparts in conventional plastic molding; 1. Compression molding 2. Transfer molding 3. Injection molding n The terminology is often different when polymer matrix composites are molded.

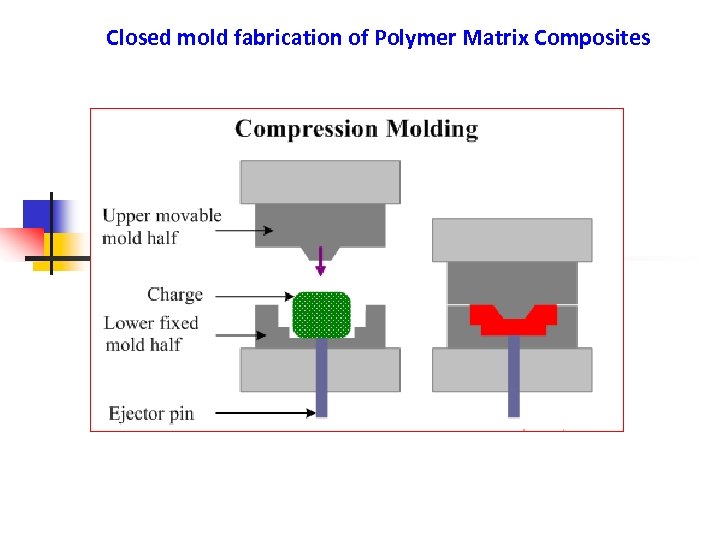

Compression Molding PMC Processes A charge is placed in lower mold section, and the sections are brought together under pressure, causing charge to take the shape of the cavity; n Mold halves are heated to cure TS polymer; n n When molding is sufficiently cured, the mold is opened and part is removed; Several shaping processes for PMCs based on compression molding; n The differences are mostly in the form of the starting materials.

Compression Molding PMC Processes A charge is placed in lower mold section, and the sections are brought together under pressure, causing charge to take the shape of the cavity; n Mold halves are heated to cure TS polymer; n n When molding is sufficiently cured, the mold is opened and part is removed; Several shaping processes for PMCs based on compression molding; n The differences are mostly in the form of the starting materials.

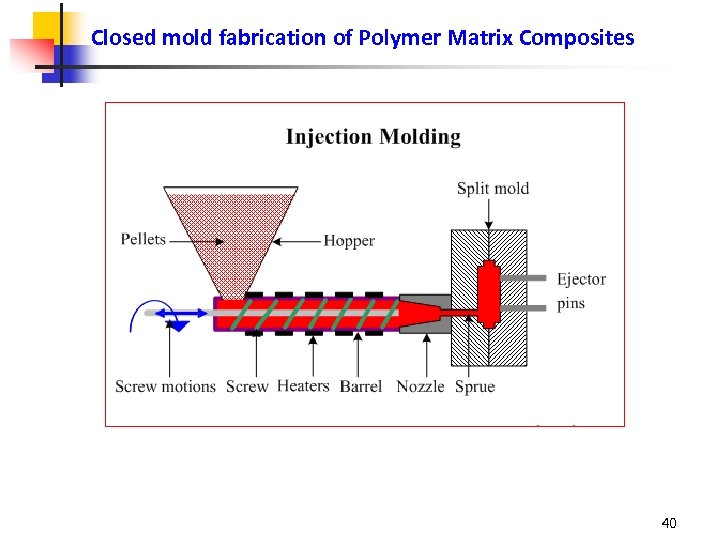

Closed mold fabrication of Polymer Matrix Composites

Closed mold fabrication of Polymer Matrix Composites

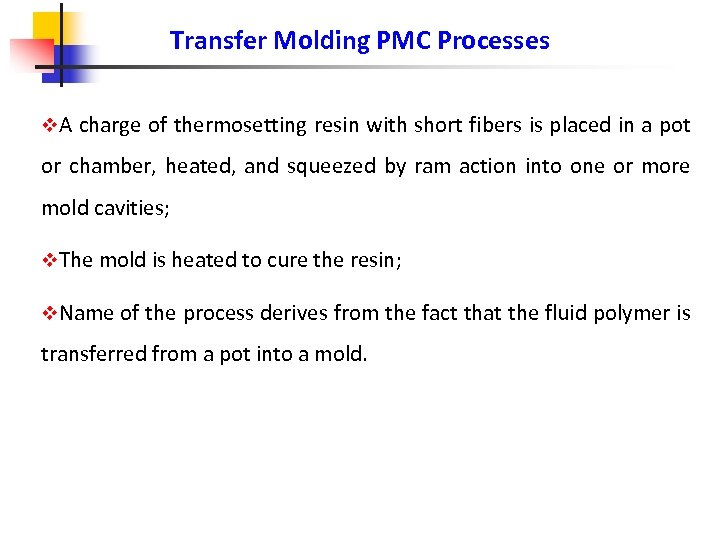

Transfer Molding PMC Processes v. A charge of thermosetting resin with short fibers is placed in a pot or chamber, heated, and squeezed by ram action into one or more mold cavities; v. The mold is heated to cure the resin; v. Name of the process derives from the fact that the fluid polymer is transferred from a pot into a mold.

Transfer Molding PMC Processes v. A charge of thermosetting resin with short fibers is placed in a pot or chamber, heated, and squeezed by ram action into one or more mold cavities; v. The mold is heated to cure the resin; v. Name of the process derives from the fact that the fluid polymer is transferred from a pot into a mold.

Closed mold fabrication of Polymer Matrix Composites

Closed mold fabrication of Polymer Matrix Composites

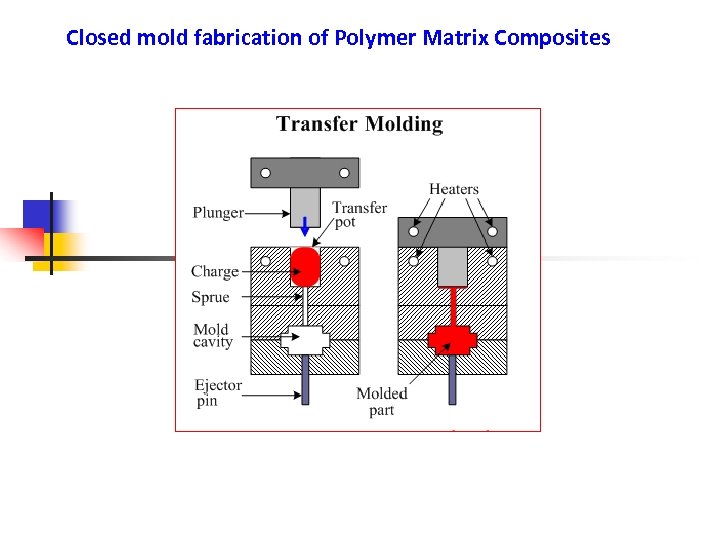

Injection Molding PMC Processes n Injection molding is noted for low cost production of plastic parts in large quantities; n Although most closely associated with thermoplastics, the process can also be adapted to thermosets; n Processes of interest in the context of PMCs: n Conventional injection molding; n Reinforced reaction injection molding;

Injection Molding PMC Processes n Injection molding is noted for low cost production of plastic parts in large quantities; n Although most closely associated with thermoplastics, the process can also be adapted to thermosets; n Processes of interest in the context of PMCs: n Conventional injection molding; n Reinforced reaction injection molding;

Closed mold fabrication of Polymer Matrix Composites 40

Closed mold fabrication of Polymer Matrix Composites 40

Conventional Injection Molding n Used for both TP and TS type FRPs; n Virtually all TPs can be reinforced with fibers; n Chopped fibers must be used; n n Continuous fibers would be reduced by the action of the rotating screw in the barrel; During injection into the mold cavity, fibers tend to become aligned as they pass the nozzle; n Part designers can sometimes exploit this feature to optimize directional properties in the part.

Conventional Injection Molding n Used for both TP and TS type FRPs; n Virtually all TPs can be reinforced with fibers; n Chopped fibers must be used; n n Continuous fibers would be reduced by the action of the rotating screw in the barrel; During injection into the mold cavity, fibers tend to become aligned as they pass the nozzle; n Part designers can sometimes exploit this feature to optimize directional properties in the part.

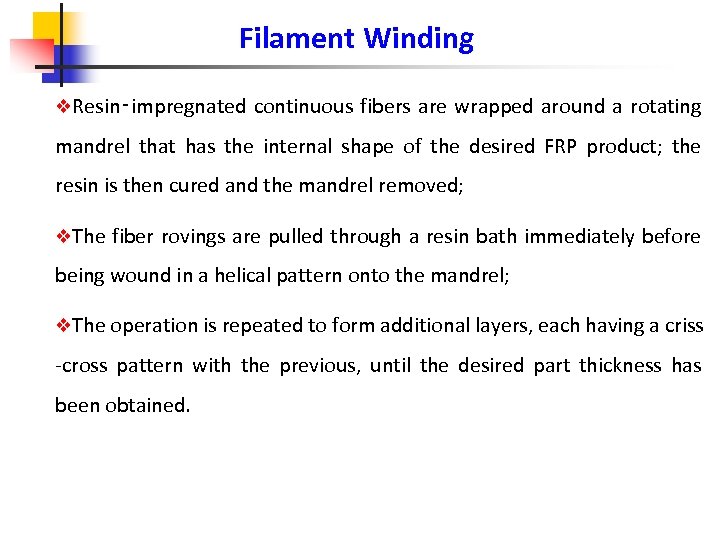

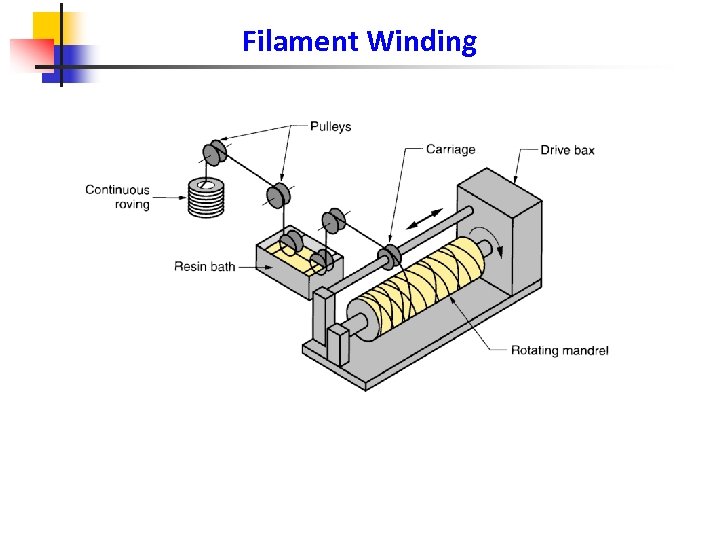

Filament Winding v. Resin‑impregnated continuous fibers are wrapped around a rotating mandrel that has the internal shape of the desired FRP product; the resin is then cured and the mandrel removed; v. The fiber rovings are pulled through a resin bath immediately before being wound in a helical pattern onto the mandrel; v. The operation is repeated to form additional layers, each having a criss -cross pattern with the previous, until the desired part thickness has been obtained.

Filament Winding v. Resin‑impregnated continuous fibers are wrapped around a rotating mandrel that has the internal shape of the desired FRP product; the resin is then cured and the mandrel removed; v. The fiber rovings are pulled through a resin bath immediately before being wound in a helical pattern onto the mandrel; v. The operation is repeated to form additional layers, each having a criss -cross pattern with the previous, until the desired part thickness has been obtained.

Filament Winding

Filament Winding

Filament Winding Characteristics v. Because of the tension, reentrant shapes cannot be produced; v. The filament (or tape, tow, or band) is either precoated with the polymer or is drawn through a polymer bath so that it picks up polymer on its way to the winder; v. Void volume can be higher (3%); v. The cost is about half that of tape laying; v. Productivity is high (50 kg/h); v. Applications include: fabrication of composite pipes, tanks, and pressure vessels. Carbon fiber reinforced rocket motor cases used for Space Shuttle and other rockets are made this way.

Filament Winding Characteristics v. Because of the tension, reentrant shapes cannot be produced; v. The filament (or tape, tow, or band) is either precoated with the polymer or is drawn through a polymer bath so that it picks up polymer on its way to the winder; v. Void volume can be higher (3%); v. The cost is about half that of tape laying; v. Productivity is high (50 kg/h); v. Applications include: fabrication of composite pipes, tanks, and pressure vessels. Carbon fiber reinforced rocket motor cases used for Space Shuttle and other rockets are made this way.

Pultrusion Process ØSimilar to extrusion (hence the name similarity) but workpiece is pulled through die (so prefix "pul‑" in place of "ex‑"); ØLike extrusion, pultrusion produces continuous straight sections of constant cross section; ØDeveloped around 1950 for making fishing rods of glass fiber reinforced polymer (GFRP); ØA related process, called pulforming, is used to make parts that are curved and which may have variations in cross section throughout their lengths.

Pultrusion Process ØSimilar to extrusion (hence the name similarity) but workpiece is pulled through die (so prefix "pul‑" in place of "ex‑"); ØLike extrusion, pultrusion produces continuous straight sections of constant cross section; ØDeveloped around 1950 for making fishing rods of glass fiber reinforced polymer (GFRP); ØA related process, called pulforming, is used to make parts that are curved and which may have variations in cross section throughout their lengths.

v. Continuous fiber rovings are dipped into a resin bath and pulled through a shaping die where the impregnated resin cures; v. The sections produced are reinforced throughout their length by continuous fibers; v. Like extrusion, the pieces have a constant cross section, whose profile is determined by the shape of the die opening; v. The cured product is cut into long straight sections.

v. Continuous fiber rovings are dipped into a resin bath and pulled through a shaping die where the impregnated resin cures; v. The sections produced are reinforced throughout their length by continuous fibers; v. Like extrusion, the pieces have a constant cross section, whose profile is determined by the shape of the die opening; v. The cured product is cut into long straight sections.

Materials and Products in Pultrusion n Common resins: unsaturated polyesters, epoxies, and silicones, all thermosetting polymers Reinforcing phase: E‑glass is most widely, in proportions from 30% to 70% Products: solid rods, tubing, long flat sheets, structural sections (such as channels, angled and flanged beams), tool handles for high voltage work, and third rail covers for subways.

Materials and Products in Pultrusion n Common resins: unsaturated polyesters, epoxies, and silicones, all thermosetting polymers Reinforcing phase: E‑glass is most widely, in proportions from 30% to 70% Products: solid rods, tubing, long flat sheets, structural sections (such as channels, angled and flanged beams), tool handles for high voltage work, and third rail covers for subways.

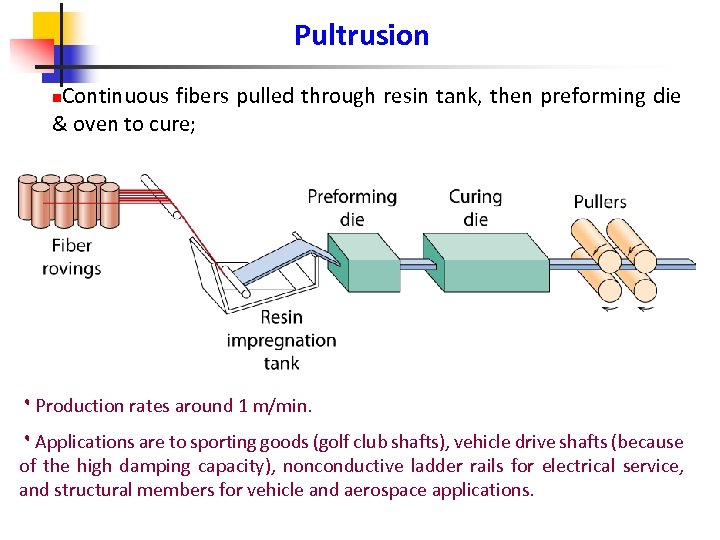

Pultrusion Continuous fibers pulled through resin tank, then preforming die & oven to cure; n ۰ Production rates around 1 m/min. ۰ Applications are to sporting goods (golf club shafts), vehicle drive shafts (because of the high damping capacity), nonconductive ladder rails for electrical service, and structural members for vehicle and aerospace applications.

Pultrusion Continuous fibers pulled through resin tank, then preforming die & oven to cure; n ۰ Production rates around 1 m/min. ۰ Applications are to sporting goods (golf club shafts), vehicle drive shafts (because of the high damping capacity), nonconductive ladder rails for electrical service, and structural members for vehicle and aerospace applications.

Metal Matrix Composites (MMCs)

Metal Matrix Composites (MMCs)

Introduction n Metal Matrix Composite (MMC) is a material consisting of a metallic matrix combined with a ceramic (oxides, carbides) or metallic (lead, tungsten, molybdenum) dispersed phase. Aluminum Matrix Composites (AMC); Magnesium Matrix Composites; Titanium Matrix Composites; Copper Matrix Composites.

Introduction n Metal Matrix Composite (MMC) is a material consisting of a metallic matrix combined with a ceramic (oxides, carbides) or metallic (lead, tungsten, molybdenum) dispersed phase. Aluminum Matrix Composites (AMC); Magnesium Matrix Composites; Titanium Matrix Composites; Copper Matrix Composites.

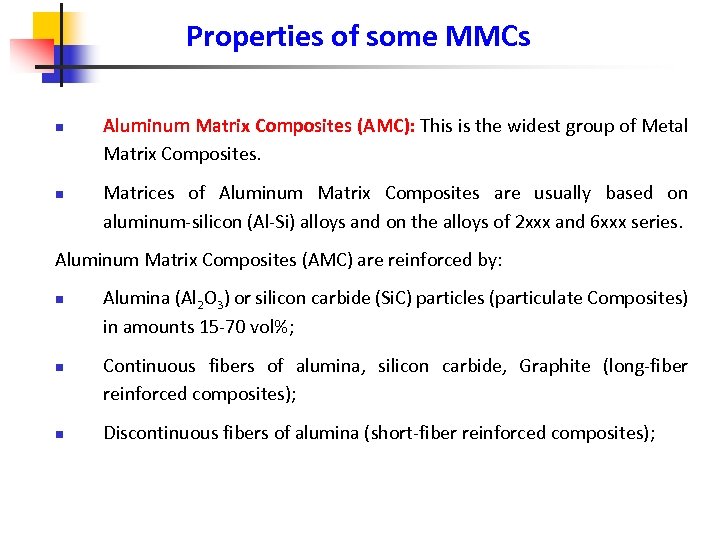

Properties of some MMCs n n Aluminum Matrix Composites (AMC): This is the widest group of Metal Matrix Composites. Matrices of Aluminum Matrix Composites are usually based on aluminum-silicon (Al-Si) alloys and on the alloys of 2 xxx and 6 xxx series. Aluminum Matrix Composites (AMC) are reinforced by: n n n Alumina (Al 2 O 3) or silicon carbide (Si. C) particles (particulate Composites) in amounts 15 -70 vol%; Continuous fibers of alumina, silicon carbide, Graphite (long-fiber reinforced composites); Discontinuous fibers of alumina (short-fiber reinforced composites);

Properties of some MMCs n n Aluminum Matrix Composites (AMC): This is the widest group of Metal Matrix Composites. Matrices of Aluminum Matrix Composites are usually based on aluminum-silicon (Al-Si) alloys and on the alloys of 2 xxx and 6 xxx series. Aluminum Matrix Composites (AMC) are reinforced by: n n n Alumina (Al 2 O 3) or silicon carbide (Si. C) particles (particulate Composites) in amounts 15 -70 vol%; Continuous fibers of alumina, silicon carbide, Graphite (long-fiber reinforced composites); Discontinuous fibers of alumina (short-fiber reinforced composites);

Aluminum Matrix Composites are manufactured by the following fabrication methods: n Powder metallurgy (sintering); n Stir casting; &Infiltration. The following properties are typical for Aluminum Matrix Composites: ØHigh strength even at elevated temperatures; ØHigh stiffness (modulus of elasticity); ØLow density; ØHigh thermal conductivity; ØExcellent abrasion resistance.

Aluminum Matrix Composites are manufactured by the following fabrication methods: n Powder metallurgy (sintering); n Stir casting; &Infiltration. The following properties are typical for Aluminum Matrix Composites: ØHigh strength even at elevated temperatures; ØHigh stiffness (modulus of elasticity); ØLow density; ØHigh thermal conductivity; ØExcellent abrasion resistance.

Magnesium Matrix Composites are reinforced mainly by silicon carbide (Si. C) particles (particulate composites). n The following properties are typical for Magnesium Matrix Composites: n. Low density; n. High stiffness (modulus of elasticity); n. High wear resistance; n. Good strength even at elevated temperatures; n. Better creep resistance. Magnesium Matrix Composites are used for manufacturing components for racing cars, lightweight automotive brake system, aircraft parts for: gearboxes, transmissions, compressors and engine.

Magnesium Matrix Composites are reinforced mainly by silicon carbide (Si. C) particles (particulate composites). n The following properties are typical for Magnesium Matrix Composites: n. Low density; n. High stiffness (modulus of elasticity); n. High wear resistance; n. Good strength even at elevated temperatures; n. Better creep resistance. Magnesium Matrix Composites are used for manufacturing components for racing cars, lightweight automotive brake system, aircraft parts for: gearboxes, transmissions, compressors and engine.

Titanium Matrix Composites are reinforced mainly by: n Continuous monofilament silicon carbide fiber (long-fiber reinforced composites); n Titanium boride (Ti. B 2) and titanium carbide (Ti. C) particles (particulate composites). n Powder metallurgy (sintering)is used for fabrication of Titanium Matrix Composites. The following properties are typical for Titanium Matrix Composites: n High strength; High stiffness (modulus of elasticity); n High creep resistance; High thermal stability; & High wear resistance. Titanium Matrix Composites are used for manufacturing structural components of the F-16 jet’s landing gear, turbine engine components (fan blades, actuator pistons, synchronization rings, connecting links, shafts, and discs), automotive engine components, drive train parts, general machine components.

Titanium Matrix Composites are reinforced mainly by: n Continuous monofilament silicon carbide fiber (long-fiber reinforced composites); n Titanium boride (Ti. B 2) and titanium carbide (Ti. C) particles (particulate composites). n Powder metallurgy (sintering)is used for fabrication of Titanium Matrix Composites. The following properties are typical for Titanium Matrix Composites: n High strength; High stiffness (modulus of elasticity); n High creep resistance; High thermal stability; & High wear resistance. Titanium Matrix Composites are used for manufacturing structural components of the F-16 jet’s landing gear, turbine engine components (fan blades, actuator pistons, synchronization rings, connecting links, shafts, and discs), automotive engine components, drive train parts, general machine components.

Copper Matrix Composites are reinforced by: n Continuous fibers of carbon (**C**), silicon carbon (Si. C), tungsten (W), stainless steel 304 (long-fiber reinforced composites); n Silicon carbide particles (particulate composites). n Powder metallurgy (sintering) and infiltration technique are used for fabrication Copper Matrix Composites. The following properties are typical for Copper Matrix Composites: n Low coefficient of thermal expansion; n High stiffness (modulus of elasticity); n Good electrical conductivity; High thermal conductivity; n Good wear resistance. Copper Matrix Composites are used for manufacturing hybrid modules, electronic relays, electrically conducting springs and other electrical and electronic components

Copper Matrix Composites are reinforced by: n Continuous fibers of carbon (**C**), silicon carbon (Si. C), tungsten (W), stainless steel 304 (long-fiber reinforced composites); n Silicon carbide particles (particulate composites). n Powder metallurgy (sintering) and infiltration technique are used for fabrication Copper Matrix Composites. The following properties are typical for Copper Matrix Composites: n Low coefficient of thermal expansion; n High stiffness (modulus of elasticity); n Good electrical conductivity; High thermal conductivity; n Good wear resistance. Copper Matrix Composites are used for manufacturing hybrid modules, electronic relays, electrically conducting springs and other electrical and electronic components

Purpose of using MMCs n higher specific modulus and strength; n better properties at elevated temperature; n lower CTE; n better wear resistance; Disadvantages of using MMCs: n less toughness; n more expensive.

Purpose of using MMCs n higher specific modulus and strength; n better properties at elevated temperature; n lower CTE; n better wear resistance; Disadvantages of using MMCs: n less toughness; n more expensive.

Solid state fabrication of MMCs n Solid state fabrication of MMCs is the process, in which MMCs are formed as a result of bonding matrix metal and dispersed phase due to mutual diffusion occurring between them in solid states at elevated temperature and under pressure. n Low temperature of solid state fabrication process (as compared to Liquid state fabrication of MMCs) depresses undesirable reactions on the boundary between the matrix and disperse phases. n MMCs may be deformed also after sintering operation by rolling, Forging, pressing, Drawing or Extrusion. n The deformation operation may be either cold (below the recrystallization temperature) or hot (above the recrystallization temperature).

Solid state fabrication of MMCs n Solid state fabrication of MMCs is the process, in which MMCs are formed as a result of bonding matrix metal and dispersed phase due to mutual diffusion occurring between them in solid states at elevated temperature and under pressure. n Low temperature of solid state fabrication process (as compared to Liquid state fabrication of MMCs) depresses undesirable reactions on the boundary between the matrix and disperse phases. n MMCs may be deformed also after sintering operation by rolling, Forging, pressing, Drawing or Extrusion. n The deformation operation may be either cold (below the recrystallization temperature) or hot (above the recrystallization temperature).

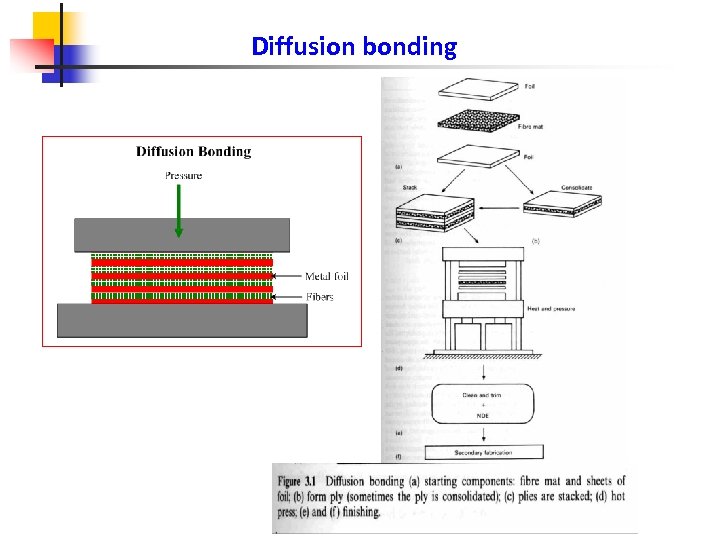

Solid-state processing: suitable for composite with large surface area of high energy solid-gas interface, e. g. matrix in particle or fail form. n n Diffusion bonding: using foil matrix Fig 3. 1; e. g. Ti, Ni, Cu, Al reinforced with boron; n Powder metallurgy: using particle materials, suitable for particle or whisker reinforced composites, Vf < 25%; n Co-extrusion, drawing: limited to ductile reinforcement and matrix.

Solid-state processing: suitable for composite with large surface area of high energy solid-gas interface, e. g. matrix in particle or fail form. n n Diffusion bonding: using foil matrix Fig 3. 1; e. g. Ti, Ni, Cu, Al reinforced with boron; n Powder metallurgy: using particle materials, suitable for particle or whisker reinforced composites, Vf < 25%; n Co-extrusion, drawing: limited to ductile reinforcement and matrix.

Diffusion bonding Diffusion Bonding is a solid state fabrication method, in which a matrix in form of foils and a dispersed phase in form of long fibers are stacked in a particular order and then pressed at elevated temperature. n n The finished laminate composite material has a multilayer structure. n Diffusion Bonding is used for fabrication of simple shape parts (plates, tubes). Variants of diffusion bonding are roll bonding and wire/fiber winding: Roll Bonding is a process of combined rolling (hot or cold) strips of two different metals (e. g. steel and aluminum alloy) resulting in formation of a laminated composite material with a metallurgical bonding between the two layers. n Wire/fiber winding is a process of combined winding continuous ceramic fibers and metallic wires followed by pressing at elevated temperature. n

Diffusion bonding Diffusion Bonding is a solid state fabrication method, in which a matrix in form of foils and a dispersed phase in form of long fibers are stacked in a particular order and then pressed at elevated temperature. n n The finished laminate composite material has a multilayer structure. n Diffusion Bonding is used for fabrication of simple shape parts (plates, tubes). Variants of diffusion bonding are roll bonding and wire/fiber winding: Roll Bonding is a process of combined rolling (hot or cold) strips of two different metals (e. g. steel and aluminum alloy) resulting in formation of a laminated composite material with a metallurgical bonding between the two layers. n Wire/fiber winding is a process of combined winding continuous ceramic fibers and metallic wires followed by pressing at elevated temperature. n

Diffusion bonding

Diffusion bonding

Sintering fabrication of MMCs is a process, in which a powder of a matrix metal is mixed with a powder of dispersed phase in the form of particles or short fibers for subsequent compacting and sintering in solid state (sometimes with some presence of liquid). n Sintering is the method involving consolidation of powder grains by heating the “green” compact part to a high temperature below the melting point, when the material of the separate particles diffuse to the neighboring powder particles. n In contrast to the liquid state fabrication of MMCs, sintering method allows obtaining materials containing up to 50% of dispersed phase. n

Sintering fabrication of MMCs is a process, in which a powder of a matrix metal is mixed with a powder of dispersed phase in the form of particles or short fibers for subsequent compacting and sintering in solid state (sometimes with some presence of liquid). n Sintering is the method involving consolidation of powder grains by heating the “green” compact part to a high temperature below the melting point, when the material of the separate particles diffuse to the neighboring powder particles. n In contrast to the liquid state fabrication of MMCs, sintering method allows obtaining materials containing up to 50% of dispersed phase. n

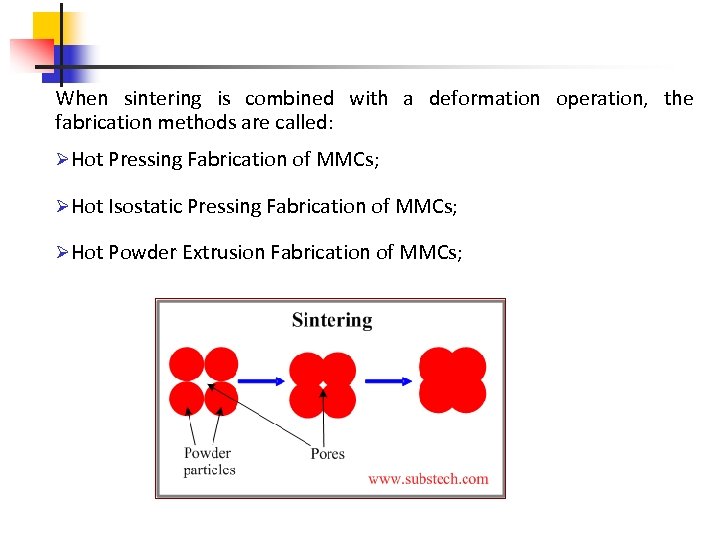

When sintering is combined with a deformation operation, the fabrication methods are called: ØHot Pressing Fabrication of MMCs; ØHot Isostatic Pressing Fabrication of MMCs; ØHot Powder Extrusion Fabrication of MMCs;

When sintering is combined with a deformation operation, the fabrication methods are called: ØHot Pressing Fabrication of MMCs; ØHot Isostatic Pressing Fabrication of MMCs; ØHot Powder Extrusion Fabrication of MMCs;

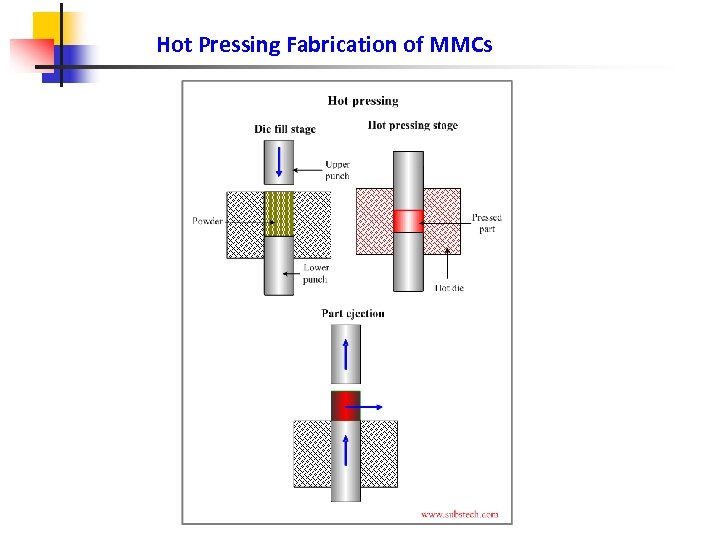

Hot Pressing Fabrication of MMCs

Hot Pressing Fabrication of MMCs

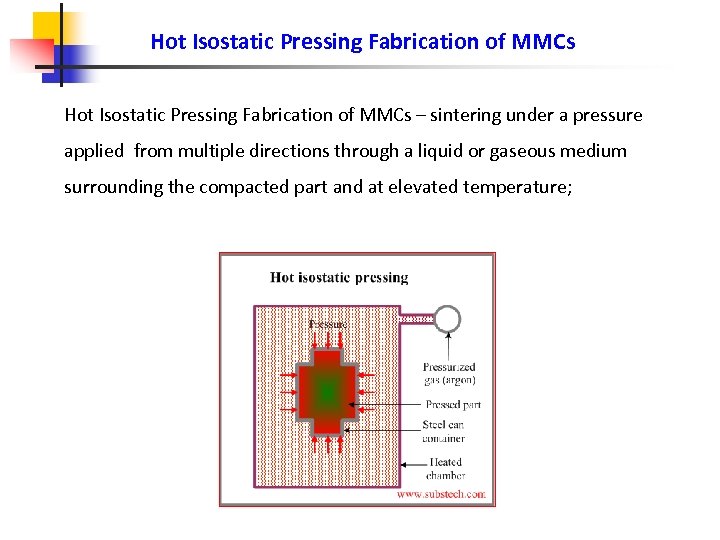

Hot Isostatic Pressing Fabrication of MMCs – sintering under a pressure applied from multiple directions through a liquid or gaseous medium surrounding the compacted part and at elevated temperature;

Hot Isostatic Pressing Fabrication of MMCs – sintering under a pressure applied from multiple directions through a liquid or gaseous medium surrounding the compacted part and at elevated temperature;

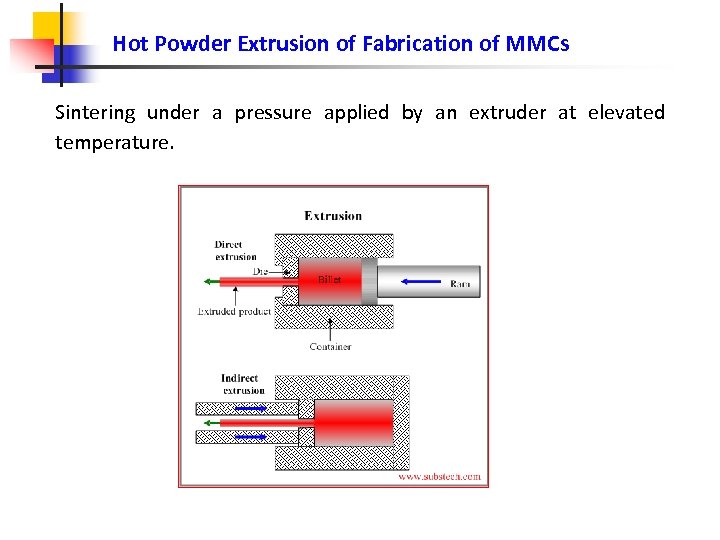

Hot Powder Extrusion of Fabrication of MMCs Sintering under a pressure applied by an extruder at elevated temperature.

Hot Powder Extrusion of Fabrication of MMCs Sintering under a pressure applied by an extruder at elevated temperature.

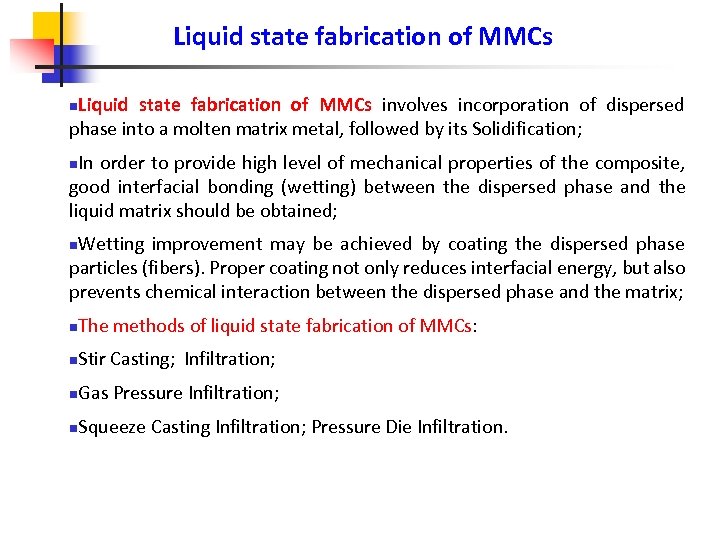

Liquid state fabrication of MMCs involves incorporation of dispersed phase into a molten matrix metal, followed by its Solidification; n In order to provide high level of mechanical properties of the composite, good interfacial bonding (wetting) between the dispersed phase and the liquid matrix should be obtained; n Wetting improvement may be achieved by coating the dispersed phase particles (fibers). Proper coating not only reduces interfacial energy, but also prevents chemical interaction between the dispersed phase and the matrix; n n The methods of liquid state fabrication of MMCs: n Stir Casting; Infiltration; n Gas Pressure Infiltration; n Squeeze Casting Infiltration; Pressure Die Infiltration.

Liquid state fabrication of MMCs involves incorporation of dispersed phase into a molten matrix metal, followed by its Solidification; n In order to provide high level of mechanical properties of the composite, good interfacial bonding (wetting) between the dispersed phase and the liquid matrix should be obtained; n Wetting improvement may be achieved by coating the dispersed phase particles (fibers). Proper coating not only reduces interfacial energy, but also prevents chemical interaction between the dispersed phase and the matrix; n n The methods of liquid state fabrication of MMCs: n Stir Casting; Infiltration; n Gas Pressure Infiltration; n Squeeze Casting Infiltration; Pressure Die Infiltration.

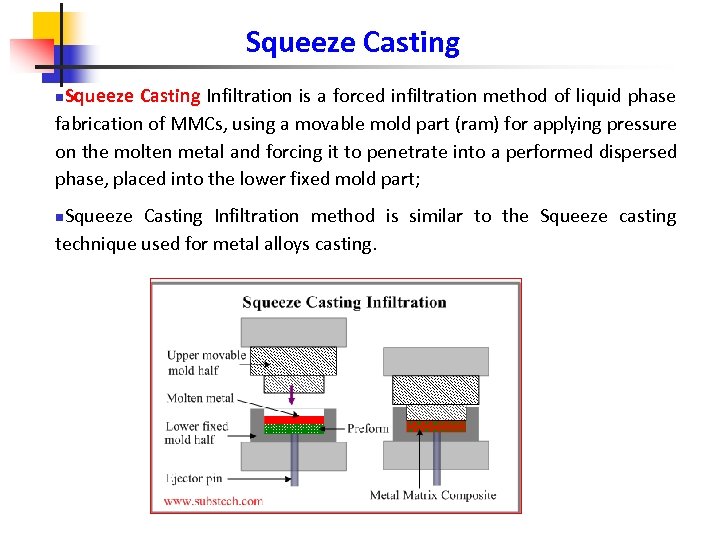

Squeeze Casting Infiltration is a forced infiltration method of liquid phase fabrication of MMCs, using a movable mold part (ram) for applying pressure on the molten metal and forcing it to penetrate into a performed dispersed phase, placed into the lower fixed mold part; n Squeeze Casting Infiltration method is similar to the Squeeze casting technique used for metal alloys casting. n

Squeeze Casting Infiltration is a forced infiltration method of liquid phase fabrication of MMCs, using a movable mold part (ram) for applying pressure on the molten metal and forcing it to penetrate into a performed dispersed phase, placed into the lower fixed mold part; n Squeeze Casting Infiltration method is similar to the Squeeze casting technique used for metal alloys casting. n

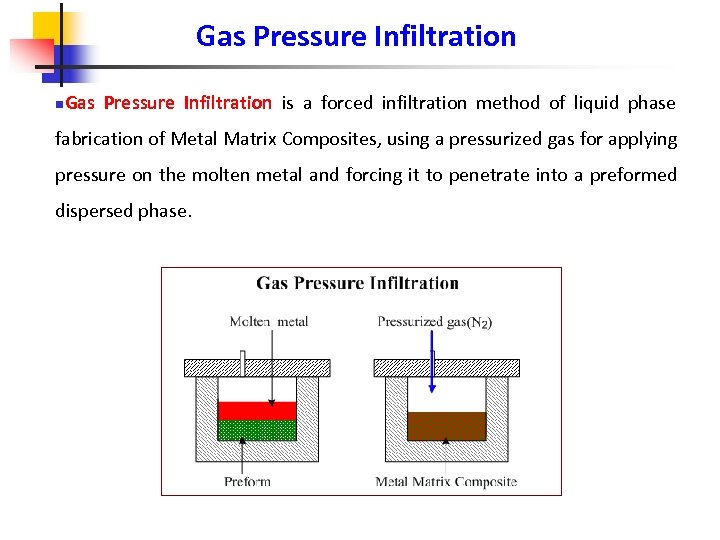

Gas Pressure Infiltration n Gas Pressure Infiltration is a forced infiltration method of liquid phase fabrication of Metal Matrix Composites, using a pressurized gas for applying pressure on the molten metal and forcing it to penetrate into a preformed dispersed phase.

Gas Pressure Infiltration n Gas Pressure Infiltration is a forced infiltration method of liquid phase fabrication of Metal Matrix Composites, using a pressurized gas for applying pressure on the molten metal and forcing it to penetrate into a preformed dispersed phase.

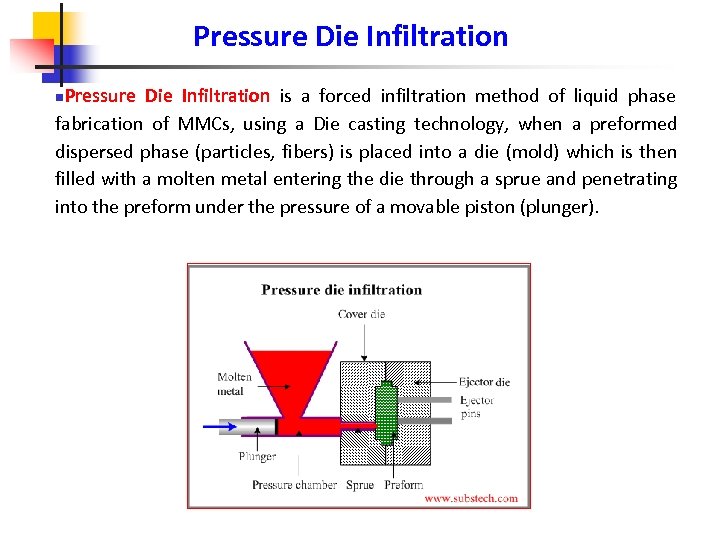

Pressure Die Infiltration is a forced infiltration method of liquid phase fabrication of MMCs, using a Die casting technology, when a preformed dispersed phase (particles, fibers) is placed into a die (mold) which is then filled with a molten metal entering the die through a sprue and penetrating into the preform under the pressure of a movable piston (plunger). n

Pressure Die Infiltration is a forced infiltration method of liquid phase fabrication of MMCs, using a Die casting technology, when a preformed dispersed phase (particles, fibers) is placed into a die (mold) which is then filled with a molten metal entering the die through a sprue and penetrating into the preform under the pressure of a movable piston (plunger). n

Thank you

Thank you