d27f8767941eb439f698f2b146eb5962.ppt

- Количество слайдов: 27

Chapter 6 Processes, Technology, and Capacity Operations Management - 5 th Edition Roberta Russell & Bernard W. Taylor, III Copyright 2006 John Wiley & Sons, Inc. Beni Asllani University of Tennessee at Chattanooga

Chapter 6 Processes, Technology, and Capacity Operations Management - 5 th Edition Roberta Russell & Bernard W. Taylor, III Copyright 2006 John Wiley & Sons, Inc. Beni Asllani University of Tennessee at Chattanooga

Lecture Outline w Process Planning w Process Analysis w Process Innovation w Technology Decisions w Capacity Decisions Copyright 2006 John Wiley & Sons, Inc. 2

Lecture Outline w Process Planning w Process Analysis w Process Innovation w Technology Decisions w Capacity Decisions Copyright 2006 John Wiley & Sons, Inc. 2

Process Planning w Process n a group of related tasks with specific inputs and outputs w Process design n tasks need to be done and coordinated among functions, people, and organizations w Process planning n converts designs into workable instructions for manufacture or delivery w Process strategy n an organization’s overall approach for physically producing goods and services Copyright 2006 John Wiley & Sons, Inc. 3

Process Planning w Process n a group of related tasks with specific inputs and outputs w Process design n tasks need to be done and coordinated among functions, people, and organizations w Process planning n converts designs into workable instructions for manufacture or delivery w Process strategy n an organization’s overall approach for physically producing goods and services Copyright 2006 John Wiley & Sons, Inc. 3

Process Strategy w Capital intensity n mix of capital (i. e. , equipment, automation) and labor resources used in production process w Process flexibility n ease with which resources can be adjusted in response to changes in demand, technology, products or services, and resource availability w Vertical integration n extent to which firm will produce inputs and control outputs of each stage of production process w Customer involvement n role of customer in production process Copyright 2006 John Wiley & Sons, Inc. 4

Process Strategy w Capital intensity n mix of capital (i. e. , equipment, automation) and labor resources used in production process w Process flexibility n ease with which resources can be adjusted in response to changes in demand, technology, products or services, and resource availability w Vertical integration n extent to which firm will produce inputs and control outputs of each stage of production process w Customer involvement n role of customer in production process Copyright 2006 John Wiley & Sons, Inc. 4

Make or Buy Decisions w Cost w Capacity w Quality Copyright 2006 John Wiley & Sons, Inc. w Speed w Reliability w Expertise 5

Make or Buy Decisions w Cost w Capacity w Quality Copyright 2006 John Wiley & Sons, Inc. w Speed w Reliability w Expertise 5

Process Selection w Projects n one-of-a-kind production of a product to customer order w Batch production n systems process many different jobs through the system in groups or batches w Mass production n produces large volumes of a standard product for a mass market w Continuous production n used for very-high volume commodity products Copyright 2006 John Wiley & Sons, Inc. 6

Process Selection w Projects n one-of-a-kind production of a product to customer order w Batch production n systems process many different jobs through the system in groups or batches w Mass production n produces large volumes of a standard product for a mass market w Continuous production n used for very-high volume commodity products Copyright 2006 John Wiley & Sons, Inc. 6

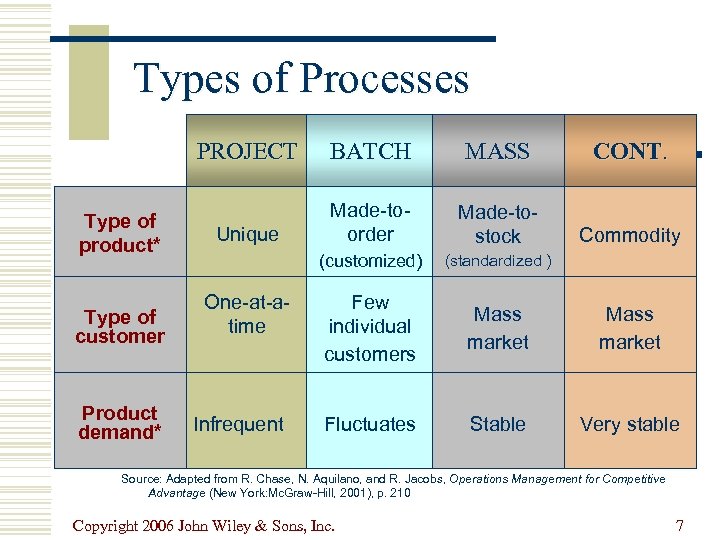

Types of Processes PROJECT Type of product* Type of customer Product demand* BATCH MASS CONT. Unique Made-toorder Made-tostock Commodity (customized) (standardized ) Few individual customers Mass market Fluctuates Stable Very stable One-at-atime Infrequent Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 7

Types of Processes PROJECT Type of product* Type of customer Product demand* BATCH MASS CONT. Unique Made-toorder Made-tostock Commodity (customized) (standardized ) Few individual customers Mass market Fluctuates Stable Very stable One-at-atime Infrequent Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 7

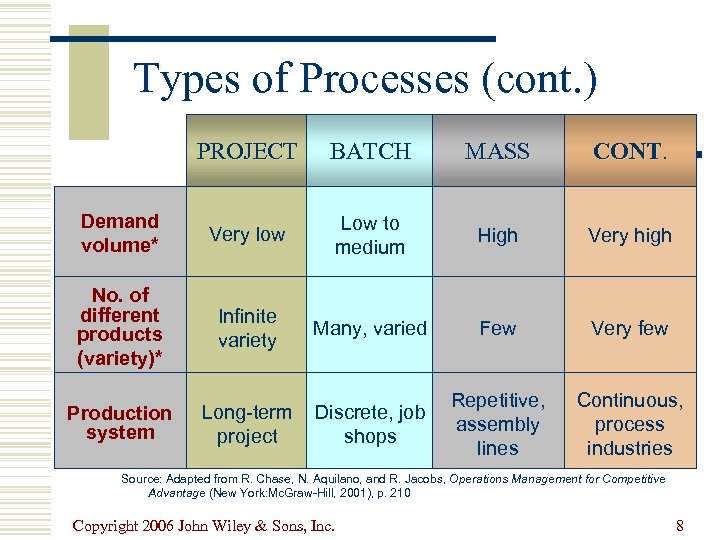

Types of Processes (cont. ) PROJECT BATCH MASS CONT. Demand volume* Very low Low to medium High Very high No. of different products (variety)* Infinite variety Many, varied Few Very few Production system Long-term project Discrete, job shops Repetitive, assembly lines Continuous, process industries Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 8

Types of Processes (cont. ) PROJECT BATCH MASS CONT. Demand volume* Very low Low to medium High Very high No. of different products (variety)* Infinite variety Many, varied Few Very few Production system Long-term project Discrete, job shops Repetitive, assembly lines Continuous, process industries Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 8

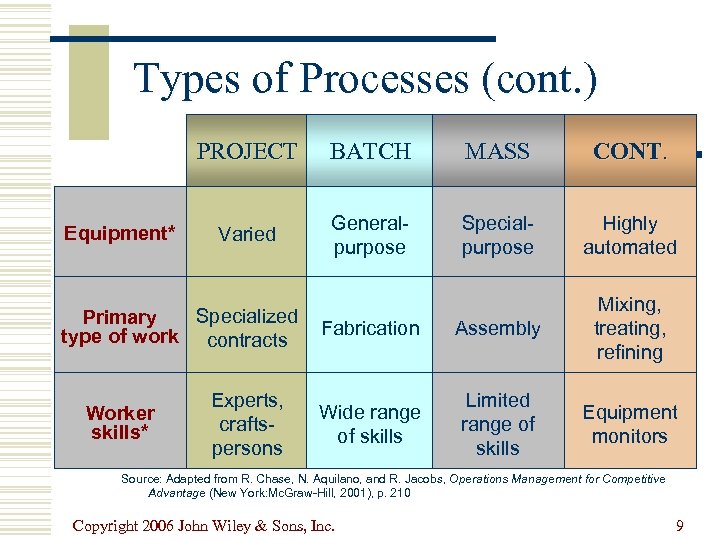

Types of Processes (cont. ) PROJECT Equipment* BATCH MASS CONT. Varied Generalpurpose Specialpurpose Highly automated Fabrication Assembly Mixing, treating, refining Wide range of skills Limited range of skills Equipment monitors Specialized Primary type of work contracts Worker skills* Experts, craftspersons Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 9

Types of Processes (cont. ) PROJECT Equipment* BATCH MASS CONT. Varied Generalpurpose Specialpurpose Highly automated Fabrication Assembly Mixing, treating, refining Wide range of skills Limited range of skills Equipment monitors Specialized Primary type of work contracts Worker skills* Experts, craftspersons Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 9

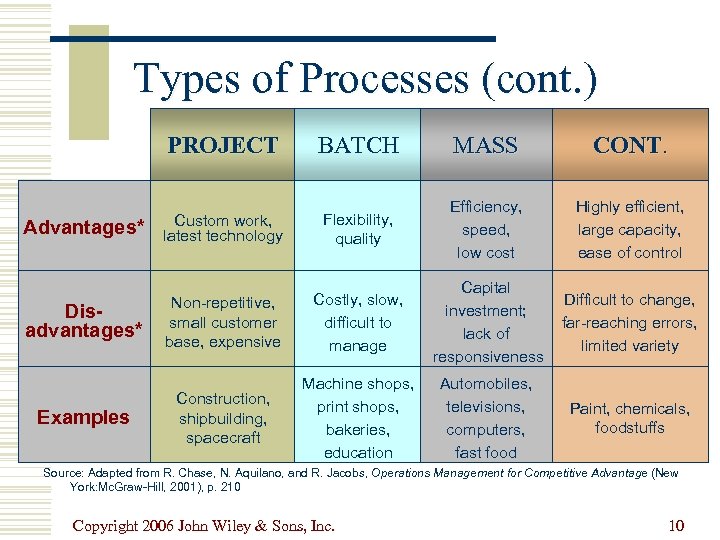

Types of Processes (cont. ) PROJECT Advantages* Disadvantages* Examples BATCH MASS CONT. Custom work, latest technology Flexibility, quality Efficiency, speed, low cost Highly efficient, large capacity, ease of control Non-repetitive, small customer base, expensive Costly, slow, difficult to manage Capital investment; lack of responsiveness Difficult to change, far-reaching errors, limited variety Construction, shipbuilding, spacecraft Machine shops, print shops, bakeries, education Automobiles, televisions, computers, fast food Paint, chemicals, foodstuffs Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 10

Types of Processes (cont. ) PROJECT Advantages* Disadvantages* Examples BATCH MASS CONT. Custom work, latest technology Flexibility, quality Efficiency, speed, low cost Highly efficient, large capacity, ease of control Non-repetitive, small customer base, expensive Costly, slow, difficult to manage Capital investment; lack of responsiveness Difficult to change, far-reaching errors, limited variety Construction, shipbuilding, spacecraft Machine shops, print shops, bakeries, education Automobiles, televisions, computers, fast food Paint, chemicals, foodstuffs Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 10

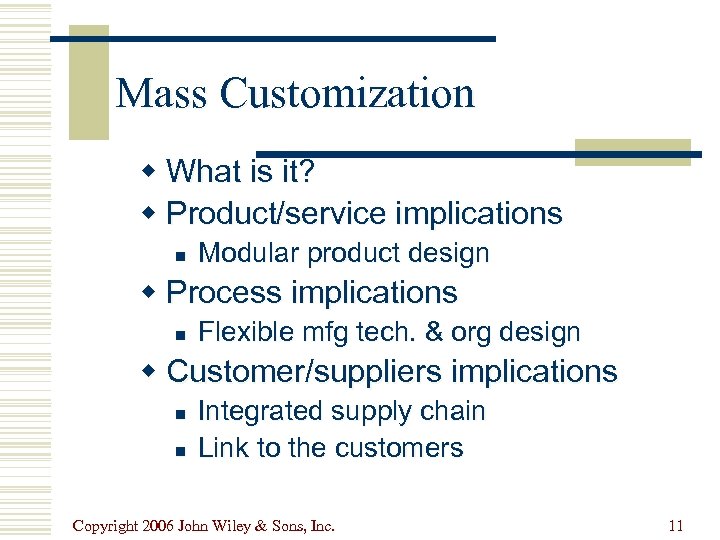

Mass Customization w What is it? w Product/service implications n Modular product design w Process implications n Flexible mfg tech. & org design w Customer/suppliers implications n n Integrated supply chain Link to the customers Copyright 2006 John Wiley & Sons, Inc. 11

Mass Customization w What is it? w Product/service implications n Modular product design w Process implications n Flexible mfg tech. & org design w Customer/suppliers implications n n Integrated supply chain Link to the customers Copyright 2006 John Wiley & Sons, Inc. 11

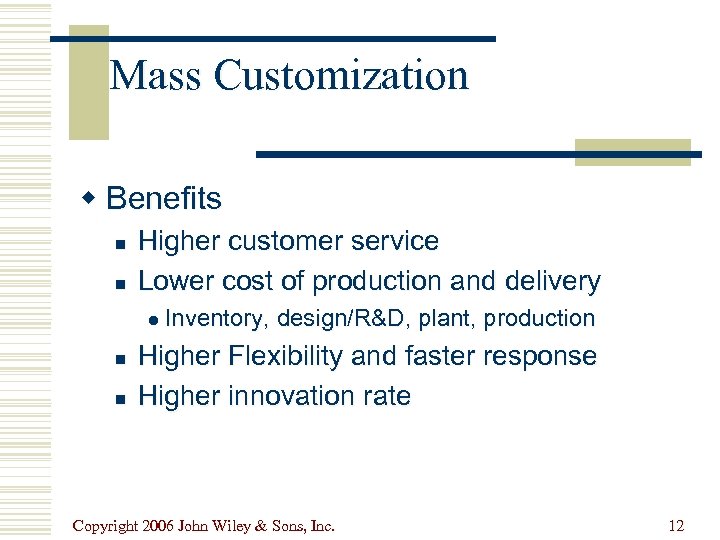

Mass Customization w Benefits n n Higher customer service Lower cost of production and delivery l n n Inventory, design/R&D, plant, production Higher Flexibility and faster response Higher innovation rate Copyright 2006 John Wiley & Sons, Inc. 12

Mass Customization w Benefits n n Higher customer service Lower cost of production and delivery l n n Inventory, design/R&D, plant, production Higher Flexibility and faster response Higher innovation rate Copyright 2006 John Wiley & Sons, Inc. 12

Focusing on Mass Customization w Dell w Mattel w Levi Straus w Morpheus Tech. Copyright 2006 John Wiley & Sons, Inc. w Cductive. com w Artuframe. com w Acumines. com w New. Edge. com 13

Focusing on Mass Customization w Dell w Mattel w Levi Straus w Morpheus Tech. Copyright 2006 John Wiley & Sons, Inc. w Cductive. com w Artuframe. com w Acumines. com w New. Edge. com 13

Process Selection with Break-Even Analysis w Cost n Fixed costs l n constant regardless of the number of units produced Variable costs l vary with the volume of units produced w Revenue n price at which an item is sold w Total revenue n is price times volume sold w Profit n difference between total revenue and total cost Copyright 2006 John Wiley & Sons, Inc. 14

Process Selection with Break-Even Analysis w Cost n Fixed costs l n constant regardless of the number of units produced Variable costs l vary with the volume of units produced w Revenue n price at which an item is sold w Total revenue n is price times volume sold w Profit n difference between total revenue and total cost Copyright 2006 John Wiley & Sons, Inc. 14

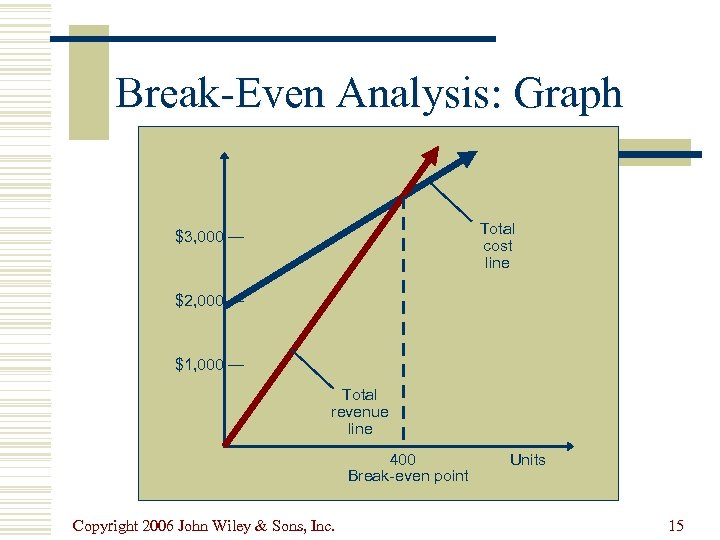

Break-Even Analysis: Graph Total cost line $3, 000 — $2, 000 — $1, 000 — Total revenue line 400 Break-even point Copyright 2006 John Wiley & Sons, Inc. Units 15

Break-Even Analysis: Graph Total cost line $3, 000 — $2, 000 — $1, 000 — Total revenue line 400 Break-even point Copyright 2006 John Wiley & Sons, Inc. Units 15

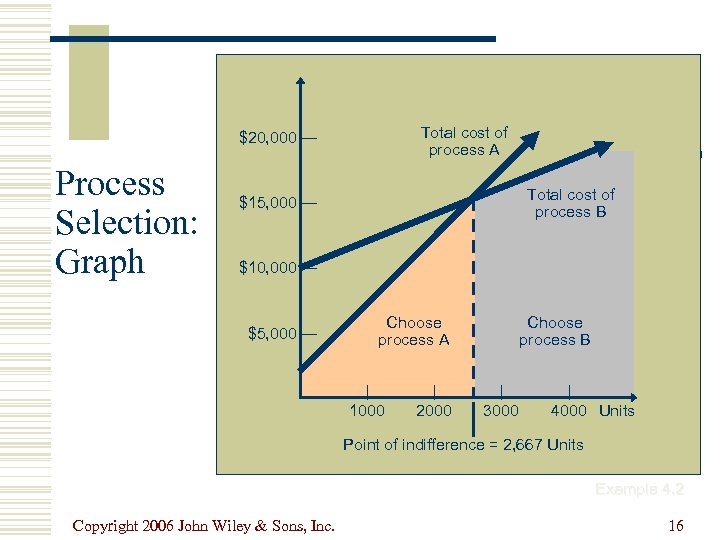

Total cost of process A $20, 000 — Process Selection: Graph Total cost of process B $15, 000 — $10, 000 — $5, 000 — Choose process A | 1000 | 2000 Choose process B | 3000 | 4000 Units Point of indifference = 2, 667 Units Example 4. 2 Copyright 2006 John Wiley & Sons, Inc. 16

Total cost of process A $20, 000 — Process Selection: Graph Total cost of process B $15, 000 — $10, 000 — $5, 000 — Choose process A | 1000 | 2000 Choose process B | 3000 | 4000 Units Point of indifference = 2, 667 Units Example 4. 2 Copyright 2006 John Wiley & Sons, Inc. 16

Process Analysis w Process flowcharts n n Symbolic representation of processes Incorporate nonproductive activities (inspection, transportation, delay, storage) l productive activities (operations) l Copyright 2006 John Wiley & Sons, Inc. 17

Process Analysis w Process flowcharts n n Symbolic representation of processes Incorporate nonproductive activities (inspection, transportation, delay, storage) l productive activities (operations) l Copyright 2006 John Wiley & Sons, Inc. 17

Technology Decisions w Financial justification of technology n n n n Purchase cost Operating Costs Annual Savings Revenue Enhancement Replacement Analysis Risk and Uncertainty Piecemeal Analysis Copyright 2006 John Wiley & Sons, Inc. 18

Technology Decisions w Financial justification of technology n n n n Purchase cost Operating Costs Annual Savings Revenue Enhancement Replacement Analysis Risk and Uncertainty Piecemeal Analysis Copyright 2006 John Wiley & Sons, Inc. 18

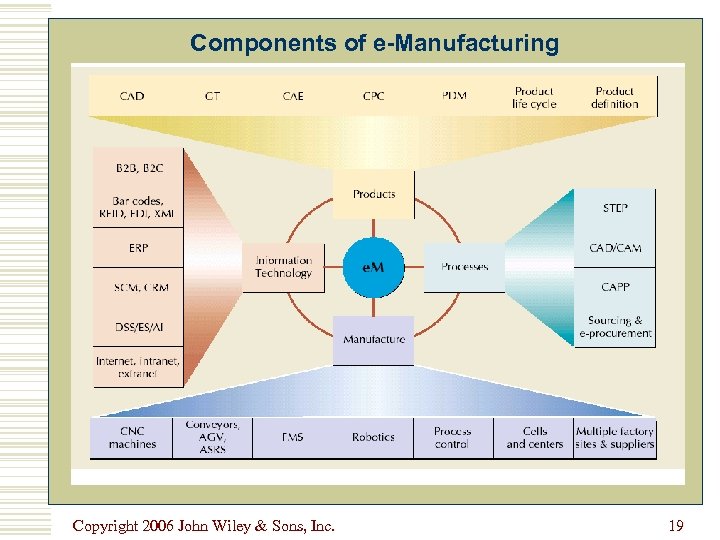

Components of e-Manufacturing Copyright 2006 John Wiley & Sons, Inc. 19

Components of e-Manufacturing Copyright 2006 John Wiley & Sons, Inc. 19

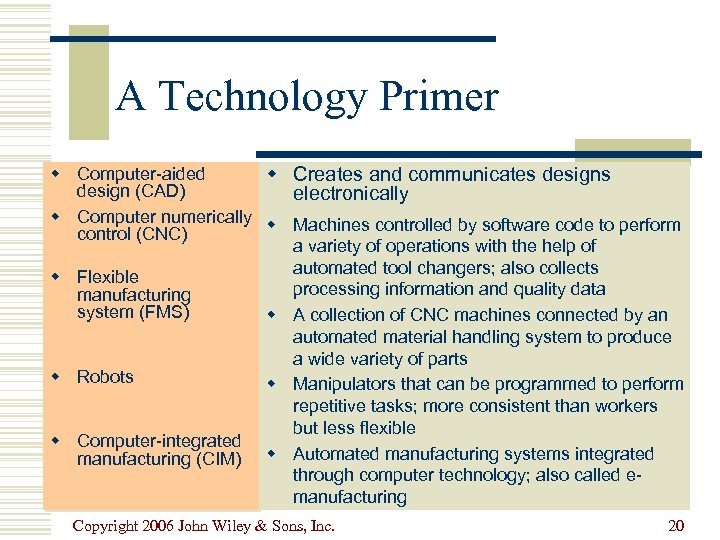

A Technology Primer w Computer-aided w Creates and communicates design (CAD) electronically w Computer numerically w Machines controlled by software code to perform control (CNC) a variety of operations with the help of automated tool changers; also collects w Flexible processing information and quality data manufacturing system (FMS) w A collection of CNC machines connected by an automated material handling system to produce a wide variety of parts w Robots w Manipulators that can be programmed to perform repetitive tasks; more consistent than workers but less flexible w Computer-integrated manufacturing (CIM) w Automated manufacturing systems integrated through computer technology; also called emanufacturing Copyright 2006 John Wiley & Sons, Inc. 20

A Technology Primer w Computer-aided w Creates and communicates design (CAD) electronically w Computer numerically w Machines controlled by software code to perform control (CNC) a variety of operations with the help of automated tool changers; also collects w Flexible processing information and quality data manufacturing system (FMS) w A collection of CNC machines connected by an automated material handling system to produce a wide variety of parts w Robots w Manipulators that can be programmed to perform repetitive tasks; more consistent than workers but less flexible w Computer-integrated manufacturing (CIM) w Automated manufacturing systems integrated through computer technology; also called emanufacturing Copyright 2006 John Wiley & Sons, Inc. 20

Capacity w Importance of capacity decision w Capacity unit of measurement n n n Output Input State of the system Copyright 2006 John Wiley & Sons, Inc. 21

Capacity w Importance of capacity decision w Capacity unit of measurement n n n Output Input State of the system Copyright 2006 John Wiley & Sons, Inc. 21

Capacity Decisions w Capacity n maximum capability to produce l l rated capacity is theoretical effective capacity includes efficiency and utilization w Capacity utilization n percent of available time spend working w Capacity efficiency n how well a machine or worker performs compared to a standard output level w Capacity load n standard hours of work assigned to a facility w Capacity load percent n Copyright 2006 John Wiley & Sons, Inc. ratio of load to capacity 22

Capacity Decisions w Capacity n maximum capability to produce l l rated capacity is theoretical effective capacity includes efficiency and utilization w Capacity utilization n percent of available time spend working w Capacity efficiency n how well a machine or worker performs compared to a standard output level w Capacity load n standard hours of work assigned to a facility w Capacity load percent n Copyright 2006 John Wiley & Sons, Inc. ratio of load to capacity 22

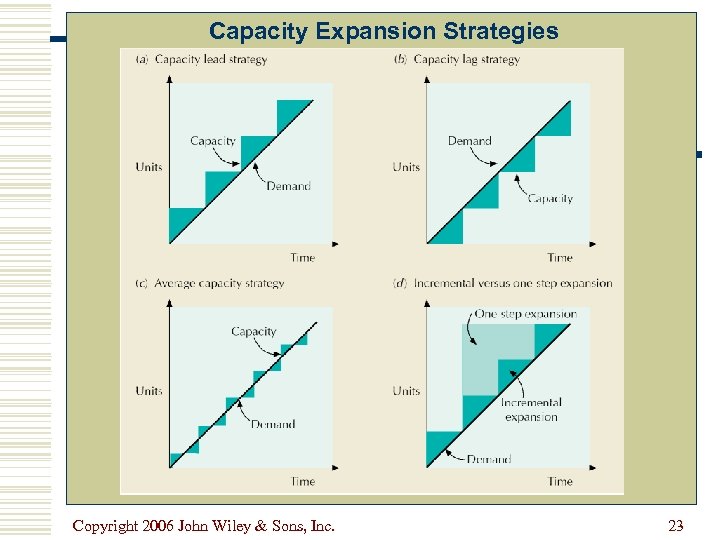

Capacity Expansion Strategies Copyright 2006 John Wiley & Sons, Inc. 23

Capacity Expansion Strategies Copyright 2006 John Wiley & Sons, Inc. 23

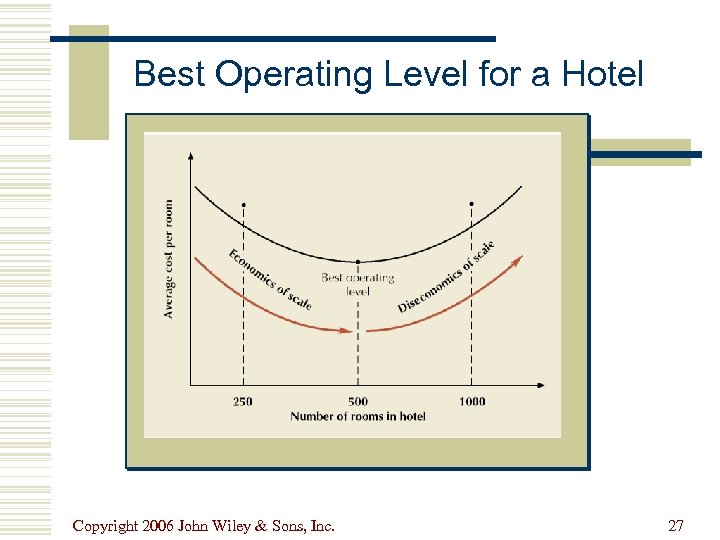

Capacity Decisions (cont. ) w Capacity increase depends on n volume and certainty of anticipated demand strategic objectives costs of expansion and operation w Best operating level n % of capacity utilization that minimizes unit costs w Capacity cushion n % of capacity held in reserve for unexpected occurrences Copyright 2006 John Wiley & Sons, Inc. 24

Capacity Decisions (cont. ) w Capacity increase depends on n volume and certainty of anticipated demand strategic objectives costs of expansion and operation w Best operating level n % of capacity utilization that minimizes unit costs w Capacity cushion n % of capacity held in reserve for unexpected occurrences Copyright 2006 John Wiley & Sons, Inc. 24

Economies of Scale w it costs less per unit to produce high levels of output n n fixed costs can be spread over a larger number of units production or operating costs do not increase linearly with output levels quantity discounts are available for material purchases operating efficiency increases as workers gain experience Copyright 2006 John Wiley & Sons, Inc. 25

Economies of Scale w it costs less per unit to produce high levels of output n n fixed costs can be spread over a larger number of units production or operating costs do not increase linearly with output levels quantity discounts are available for material purchases operating efficiency increases as workers gain experience Copyright 2006 John Wiley & Sons, Inc. 25

Diseconomies of Scale w Occur above a certain level of output n n Diseconomies of Distribution Diseconomies of Bureaucracy Diseconomies of Confusion Diseconomies of Vulnerability Copyright 2006 John Wiley & Sons, Inc. 26

Diseconomies of Scale w Occur above a certain level of output n n Diseconomies of Distribution Diseconomies of Bureaucracy Diseconomies of Confusion Diseconomies of Vulnerability Copyright 2006 John Wiley & Sons, Inc. 26

Best Operating Level for a Hotel Copyright 2006 John Wiley & Sons, Inc. 27

Best Operating Level for a Hotel Copyright 2006 John Wiley & Sons, Inc. 27